Boron-containing calcium sulfonate complex lubricating grease composition and preparation method thereof

A technology of lubricating grease composition and complex calcium sulfonate, applied in lubricating composition, petroleum industry, thickener, etc., can solve the problems of poor extreme pressure anti-wear performance and low dropping point of lubricating grease, and achieve good extreme pressure performance , high dropping point, excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

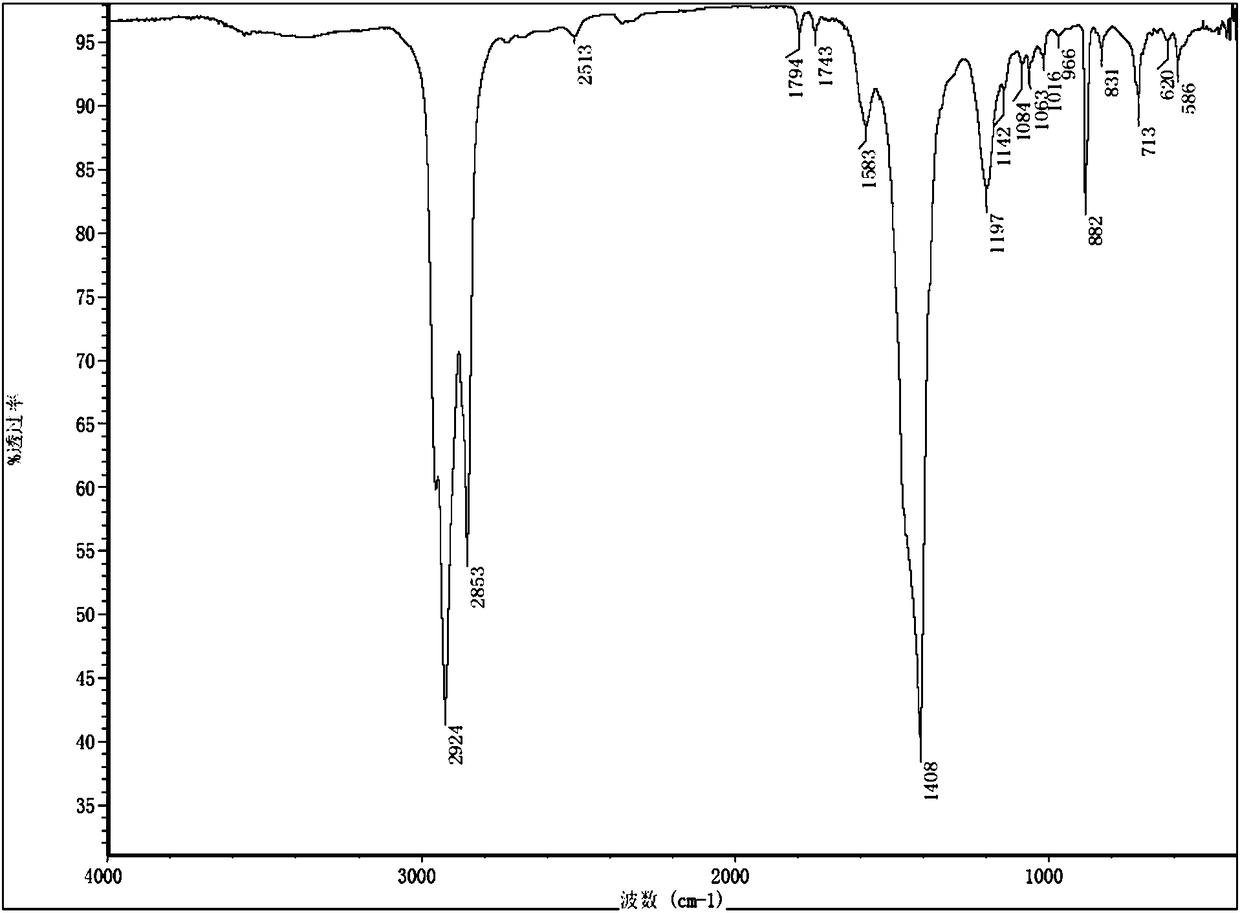

[0037] A method for preparing a boron-containing composite calcium sulfonate grease, the composite calcium sulfonate grease is: comprising the following components: based on the weight of the grease, 20-60 wt% of ultra-high alkali value synthetic calcium sulfonate, monohydrocarbyl 0.1-20% of substituted boric acid, 0.5-5wt% of extreme pressure anti-wear agent, 0.5-2wt% of antioxidant, 2-10wt% of adhesive, 0.5-20wt% of base oil and conversion agent.

[0038] The technical scheme that the present invention solves its technical problem also can be:

[0039]A method for preparing boron-containing complex calcium sulfonate lubricating grease, the base oil is one of paraffin base, intermediate base or naphthenic mineral oil, ester oil, polyalphaolefin synthetic oil or polyether synthetic oil One or their mixture, the ultra-high base value synthetic calcium sulfonate, its ultra-high base value is 350 ~ 420mgKOH / g, the extreme pressure antiwear agent can be thiodibutyldithiocarbamic a...

Embodiment 1

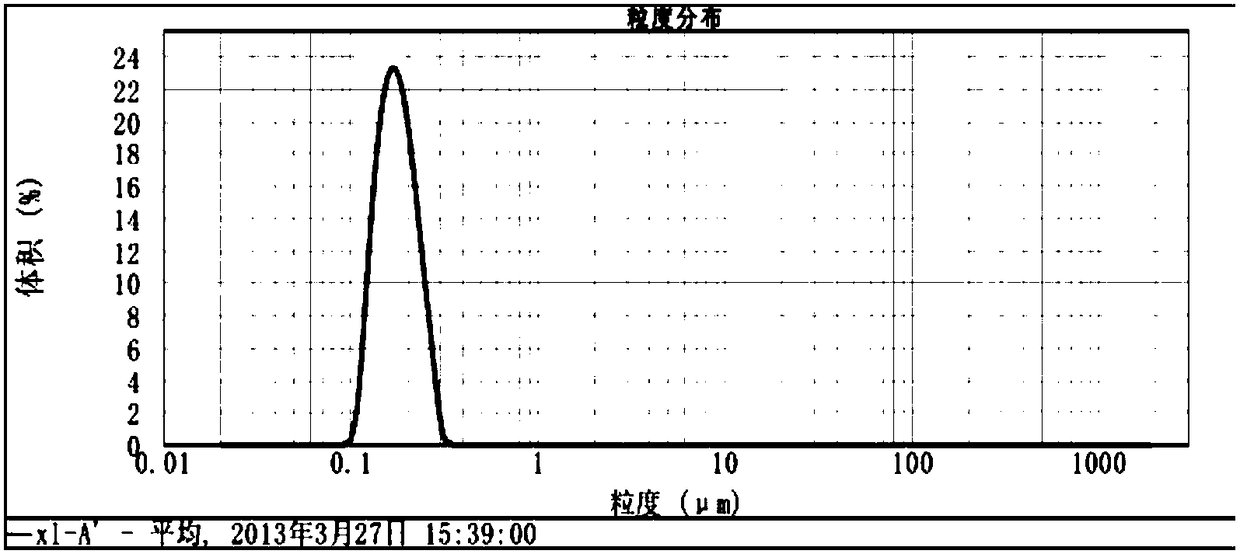

[0045] Put 1.8 kg of high alkali value calcium sulfonate with a total base value of 420mgKOH / g in a 5L atmospheric pressure reactor with heating and stirring, and the kinematic viscosity at 40°C is 560mm 2 2 kg of HVI 150BS base oil per s, mix at 50°C for 0.5 hours, add 100g of 12-hydroxystearic acid, 120g of water and stir, raise the temperature to 80°C, keep it for 1 hour, add 60g of methanol and a certain amount of dodecylbenzene The sulfonic acid is converted, and the material gradually becomes fat; the temperature is raised to 100°C, and calcium hydroxide and 45g of phenylboronic acid are added, and the stirring is continued for 1 hour; After stirring for 1 hour, cool down to 100°C and add 0.12 kg of antimony dibutyldithiocarbamate, 0.02 kg of phenyl α-naphthylamine and dialkyl diphenylamine, 0.2 kg of polyisobutylene (molecular weight 1000), stir for 30 minutes, and finally Homogenize and degas. The specific test results of the product are shown in Table 1, and the lase...

Embodiment 2

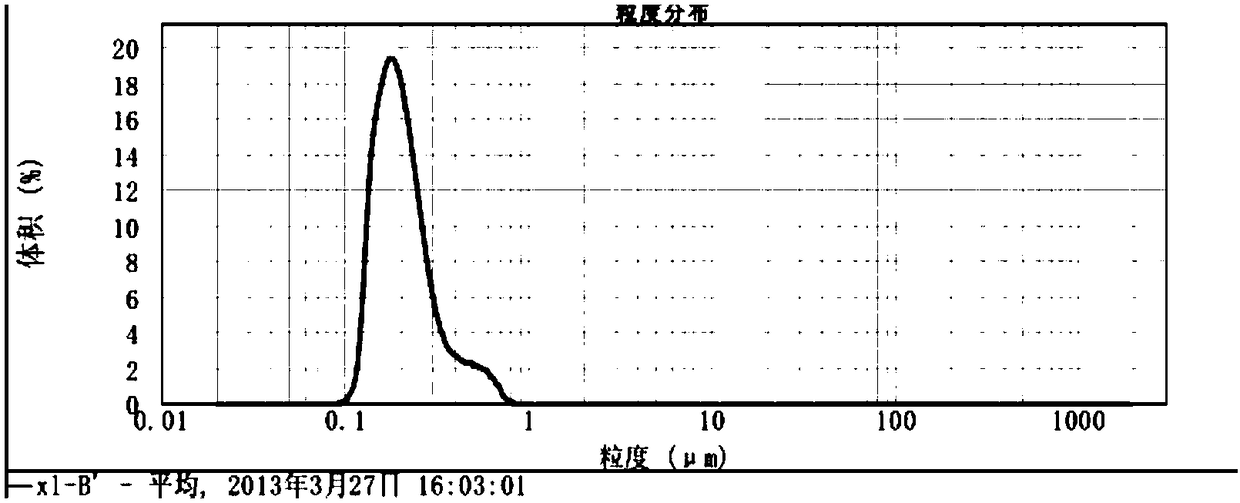

[0047] Put 1.8 kg of high alkali value calcium sulfonate with a total base value of 400 mgKOH / g and 1 kg of KN4010 naphthenic base oil in a 5 L atmospheric pressure reactor with heating and stirring, and mix at 50 ° C for 0.5 hours , add 120g of 12-hydroxystearic acid and 120g of water and stir, heat up to 80°C, keep for 1 hour, add 50g of n-butanol and a certain amount of dodecylbenzenesulfonic acid and stir, the material gradually becomes fat; heat up to 100°C Add 52g of phenylboronic acid and a certain amount of calcium hydroxide, stir, and keep for 1 hour; heat up to 160°C for dehydration, keep for 2 hours, add 2 kg of KN4010 naphthenic base oil in three times, stir for 1 hour, then cool down to 100°C and add 0.06 kg of di-n-butyl phosphite, 0.02 kg of phenyl α-naphthylamine and dialkyl diphenylamine, 0.2 kg of polymethacrylate (molecular weight 3000), stirred for 30 minutes, and finally, cooled to 40 ° C and ground with three rolls Machine grinding three times to become a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com