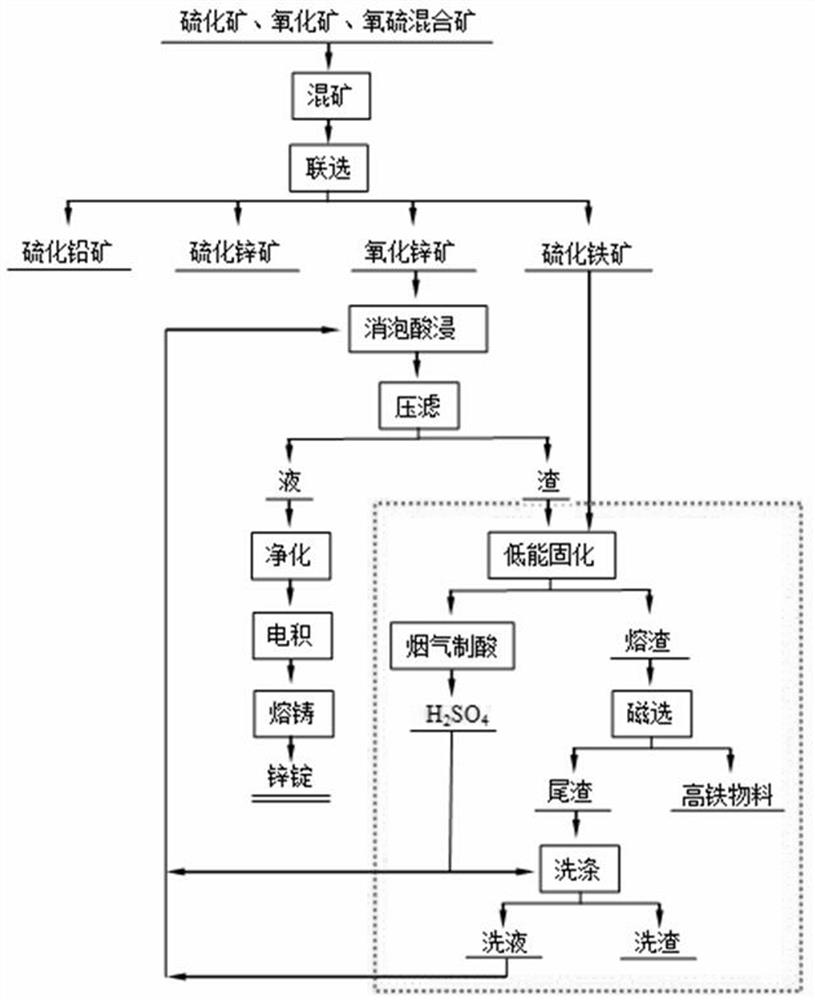

Process for comprehensively utilizing oxygen-sulfur mixed lead-zinc ore

A technology of lead-zinc ore and mixed ore, applied in the field of metallurgy, can solve the problems of low grade of zinc ore, high production cost, low metal recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Sulphide ore (grade 8%) and oxygen-sulfur mixed ore (grade 7%, oxidation rate 80%) are blended to obtain mixed ore, and the mass percentage of zinc sulfide in the mixed ore is controlled to 50%, and the mass percentage of zinc oxide is 50% , CaO+MgO2 <25%.

[0051] 2. Crushing and finely grinding the mixed ore to ensure that the mixed ore is ground to -200, accounting for 70%.

[0052] 3. Flotation in the order of galena → sphalerite → pyrite → zinc oxide ore, after flotation, the grade of lead sulfide concentrate is 48%, the recovery rate is 80%, the grade of zinc sulfide concentrate is 52%, the recovery rate is 92% %, iron sulfide concentrate grade 25%, recovery rate 50%; zinc oxide concentrate grade 22%, recovery rate 65%.

[0053] 4. Sizing and acid leaching the zinc oxide concentrate with a grade of 22%: the acid concentration of the sizing liquid is 10g / L, and the liquid-solid ratio is 4:1; acid leaching P 压缩气 / P 调浆液 =2 (gas is compressed air), the stirring ...

Embodiment 2

[0059] 1. Sulfide ore (grade 23%), oxide ore (grade 14%), oxygen-sulfur mixed ore (grade 4%, oxidation rate 68%) are mixed to obtain mixed ore, and the mass percentage of zinc sulfide in the mixed ore is controlled to 60% , the mass percentage of zinc oxide is 40%, CaO+MgO2 <25%.

[0060] 2. Crushing and finely grinding the mixed ore to ensure that the mixed ore is ground to -200, accounting for 80%.

[0061] 3. Flotation in the order of galena → sphalerite → pyrite → zinc oxide ore, after flotation, the grade of lead sulfide concentrate is 49%, the recovery rate is 83%, the grade of zinc sulfide concentrate is 52%, the recovery rate is 93% %, the grade of iron sulfide concentrate is 28%, and the recovery rate is 48%; the grade of zinc oxide concentrate is 21%, and the recovery rate is 67%.

[0062] 4. Sizing and acid leaching the zinc oxide concentrate with a grade of 21%: the acid concentration of the sizing liquid is 10g / L, and the liquid-solid ratio is 4:1; the acid leach...

Embodiment 3

[0068] 1. Sulphide ore (grade 8%) and oxygen-sulfur mixed ore (grade 7%, oxidation rate 80%) are blended to obtain mixed ore, and the mass percentage of zinc sulfide in the mixed ore is controlled to 50%, and the mass percentage of zinc oxide is 50% , CaO+MgO2 <25%.

[0069] 2. Crushing and finely grinding the mixed ore to ensure that the mixed ore is ground to -200, accounting for 85%.

[0070] 3. Flotation in the order of galena → sphalerite → pyrite → zinc oxide ore, the grade of lead sulfide concentrate after flotation is 49%, the recovery rate is 84%, the grade of zinc sulfide concentrate is 52%, the recovery rate is 93% %, the grade of iron sulfide concentrate is 32%, and the recovery rate is 56%; the grade of zinc oxide concentrate is 25%, and the recovery rate is 67%.

[0071] 4. Sizing and acid leaching the zinc oxide concentrate with a grade of 25%: the acid concentration of the sizing liquid is 10g / L, and the liquid-solid ratio is 4:1; acid leaching P 压缩气 / P 调浆液 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com