Softening agent capable of improving sublimation fastness of disperse dye and wet friction fastness of reactive dye

A technology of wet rubbing fastness and sublimation fastness, applied in the field of textile printing and dyeing, can solve the problems of reducing wet rubbing fastness, poor wet rubbing fastness of reactive dyes, poor sublimation fastness, etc., and achieves excellent anti-fouling and delicate hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

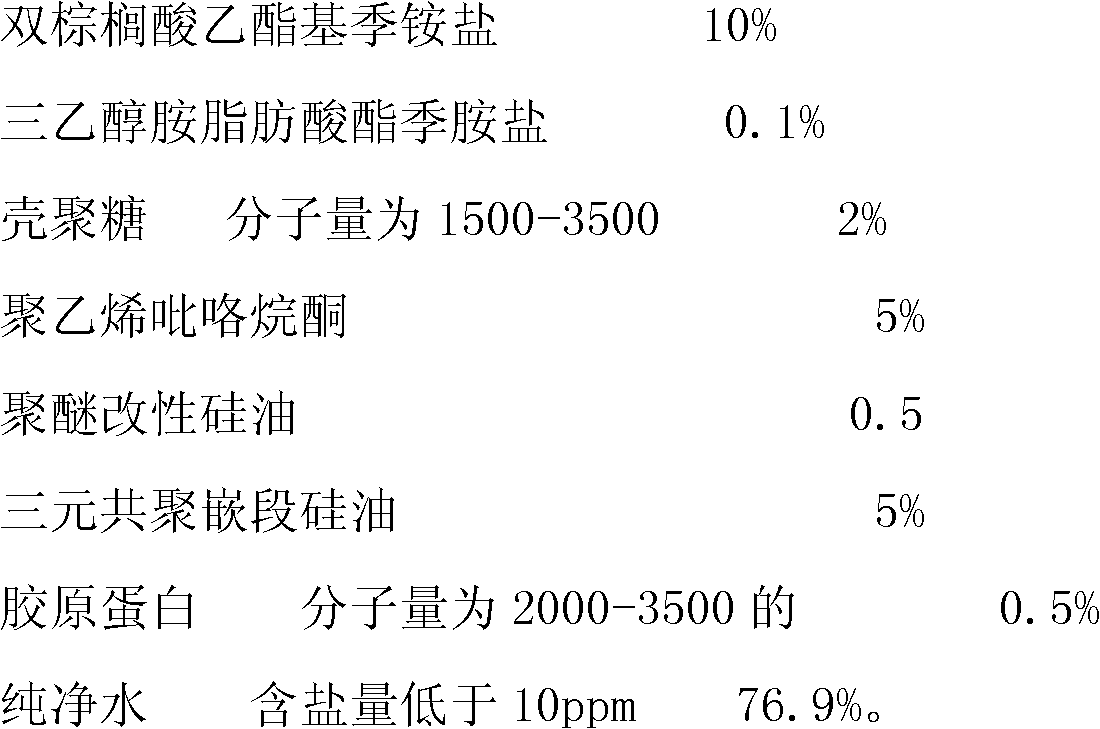

[0019] The softening agent for improving the sublimation fastness of disperse dyes and the wet rubbing fastness of reactive dyes of the present invention is mainly composed of the following raw material components by weight percentage:

[0020]

[0021] The preparation method of the softener for improving the sublimation fastness of disperse dyes and the wet rubbing fastness of reactive dyes of the present invention is: first add pure water of the whole formula amount to the emulsification disperser with stainless steel stirrer, and then press other components into double palm Ethyl acid ester quaternary ammonium salt, triethanolamine fatty acid ester quaternary ammonium salt, chitosan, polyvinylpyrrolidone, polyether modified silicone oil, ternary copolymerized block silicone oil, and collagen are added in sequence, and after all the materials are added Continue to emulsify and disperse for 0.5-2 hours, stop stirring after the solution presents a uniform milky white color, ...

Embodiment 2

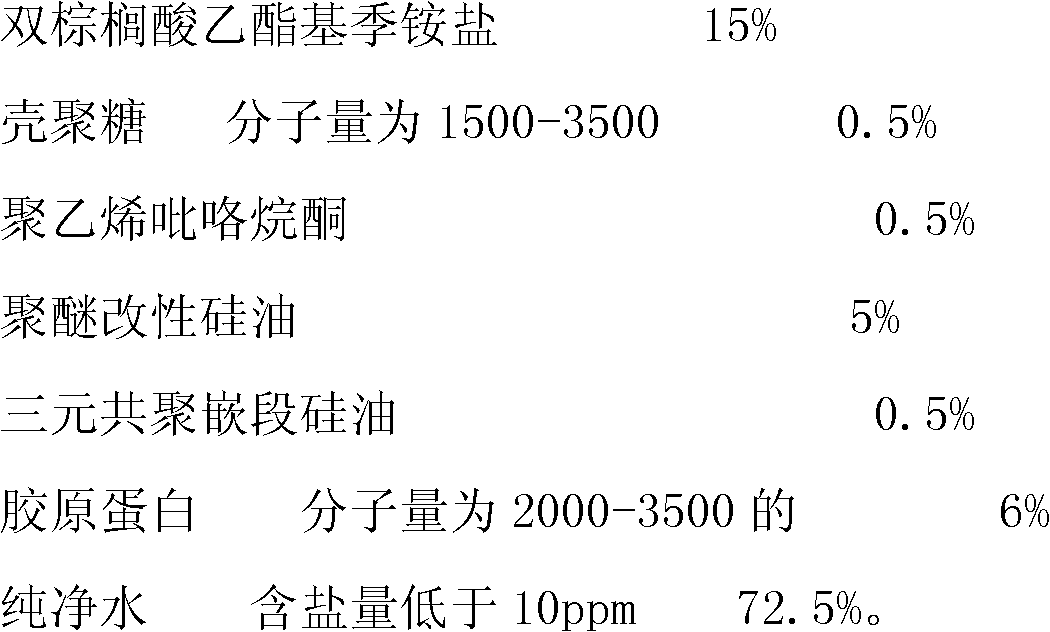

[0024] The softening agent for improving the sublimation fastness of disperse dyes and the wet rubbing fastness of reactive dyes of the present invention is mainly composed of the following raw material components by weight percentage:

[0025]

[0026] The preparation method of the softener for improving the sublimation fastness of disperse dyes and the wet rubbing fastness of reactive dyes of the present invention is: first add pure water of the whole formula amount to the emulsification disperser with stainless steel stirrer, and then press other components into double palm Ethyl ester quaternary ammonium salt, chitosan, polyvinylpyrrolidone, polyether modified silicone oil, ternary copolymerized block silicone oil, and collagen are added in sequence, and after all the materials are added, continue emulsification and dispersion for 0.5-2 hours. After the solution showed a uniform milky white color, the stirring was stopped, and the processing was completed.

[0027] Taki...

Embodiment 3

[0029] The softening agent for improving the sublimation fastness of disperse dyes and the wet rubbing fastness of reactive dyes of the present invention is mainly composed of the following raw material components by weight percentage:

[0030] Ethyl Dipalmitate Quaternary Ammonium Salt 1%,

[0031] Triethanolamine fatty acid ester quaternary ammonium salt 5%,

[0032] Chitosan molecular weight 1500-3500 1.5%,

[0033] Polyvinylpyrrolidone 5%,

[0034] Polyether modified silicone oil 4%,

[0035] Ternary copolymer block silicone oil 3%,

[0036] Collagen molecular weight 2000-3500 2.5%,

[0037] Purified water Salt content less than 10ppm 78%.

[0038] Its preparation method is with embodiment 1.

[0039] Taking the dark pure cotton knitted fabric as an example, the treatment method is: after soaping the dyed dark pure cotton knitted fabric, add 2-9g / l softener of the present invention, and treat it at a temperature of about 50°C for 15 -25 minutes, out of the tank, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com