Anticorrosion waterproof coating special for light steel and preparation method thereof

A waterproof coating and light steel technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of light steel becoming garbage, large market capacity, environmental pollution, etc., and achieve the effect of cost reduction, low cost and environmental pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

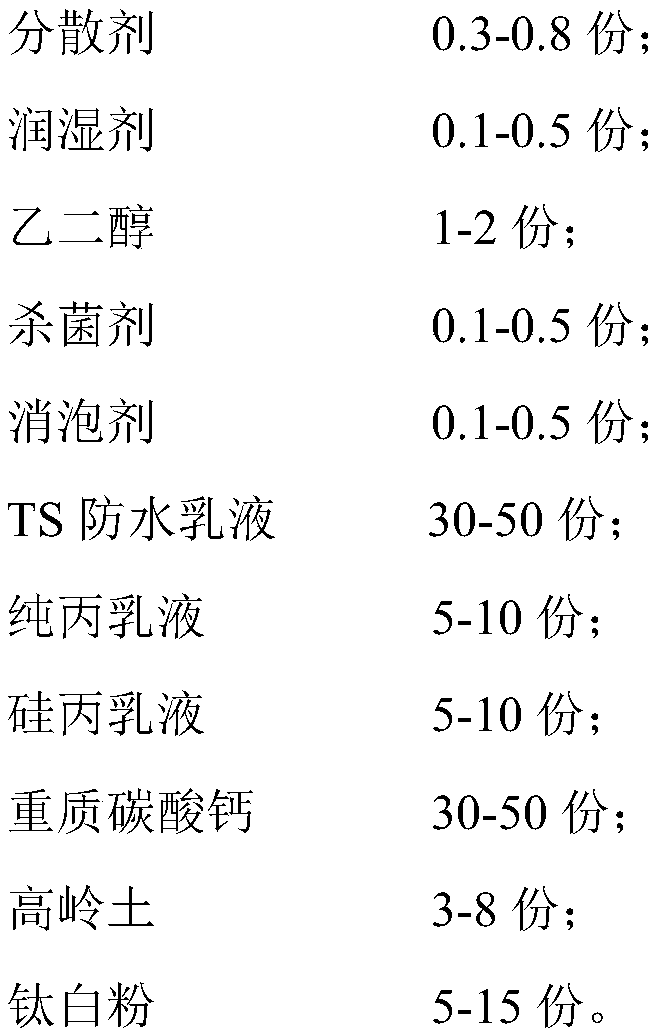

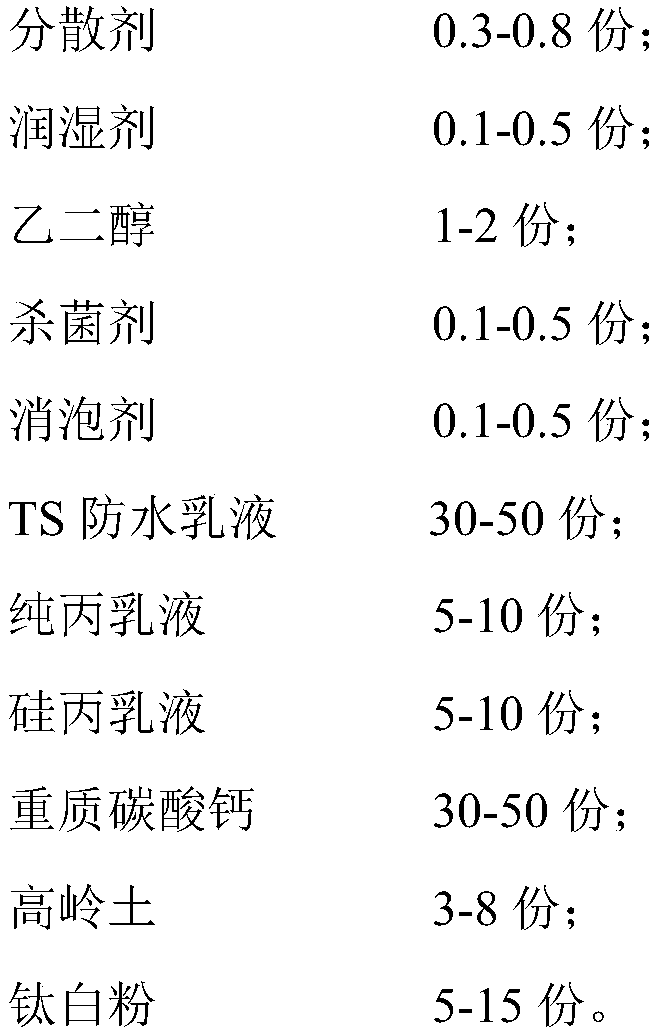

Method used

Image

Examples

Embodiment 1

[0024] 0.3 parts of dispersant; 0.1 part of wetting agent; 1 part of ethylene glycol; 0.1 part of bactericide; 0.3 part of defoamer; 40 parts of TS waterproof emulsion; 8 parts of pure acrylic emulsion; 5 parts of silicon-acrylic emulsion; heavy calcium carbonate 35.2 parts; 5 parts of kaolin; 5 parts of titanium dioxide.

[0025] The wetting agent is nonylphenol polyvinyl ether; the dispersing agent is polyacrylate ammonium salt; the bactericide is isothiazolinone.

[0026] Follow the steps below to prepare:

[0027] 1) Sequentially add pure acrylic emulsion, silicone acrylic emulsion, TS waterproof emulsion, fungicide, defoamer, dispersant and wetting agent in mass ratio, stirring speed 200rpm, stirring time 10min;

[0028] 2) Slowly add kaolin, titanium dioxide and heavy calcium carbonate in mass proportions to the mixture in step 1, the stirring speed is 800-1200 rpm, and the stirring time is 20-30 min; after stirring, it can be filled into barrels.

[0029] The particle size of ka...

Embodiment 2

[0031] 0.5 part of dispersant; 0.2 part of wetting agent; 1.1 part of ethylene glycol; 0.2 part of bactericide; 0.2 part of defoamer; 42 parts of TS waterproof emulsion; 5 parts of pure acrylic emulsion; 6 parts of silicon-acrylic emulsion; heavy calcium carbonate 33 parts; 6 parts of kaolin; 6 parts of titanium dioxide.

[0032] The wetting agent is nonylphenol polyvinyl ether; the dispersing agent is polyacrylate sodium salt; the bactericide is a mixture of benzimidazolyl carbamate and dichlorophthalamide.

[0033] Follow the steps below to prepare:

[0034] 1) Add the pure acrylic emulsion, silicone acrylic emulsion, TS waterproof emulsion, bactericide, defoamer, dispersant and wetting agent in the mass ratio in sequence, stirring speed 300rpm, stirring time 20min;

[0035] 2) Slowly add kaolin, titanium dioxide and heavy calcium carbonate in mass proportions to the mixture in step 1, the stirring speed is 800-1200 rpm, and the stirring time is 20-30 min; after stirring, it can be ...

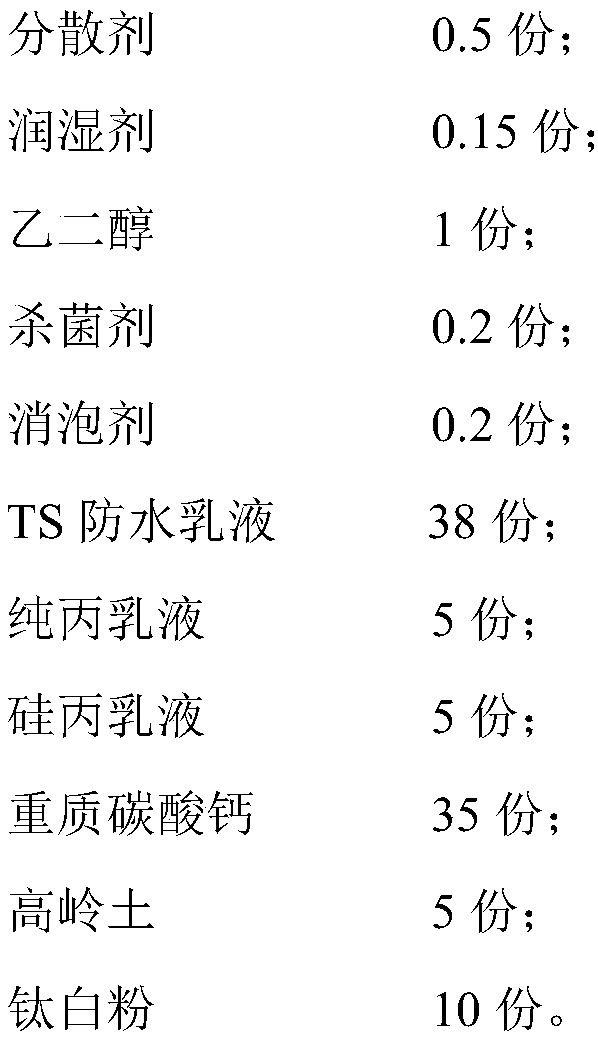

Embodiment 3

[0038] 0.5 part of dispersant; 0.15 part of wetting agent; 1 part of ethylene glycol; 0.2 part of bactericide; 0.2 part of defoamer; 38 parts of TS waterproof emulsion; 5 parts of pure acrylic emulsion; 5 parts of silicon-acrylic emulsion; heavy calcium carbonate 35 parts; 5 parts of kaolin; 10 parts of titanium dioxide.

[0039] The wetting agent is nonylphenol polyvinyl ether, the dispersing agent is Guer gum; the bactericide is 1,2 phenylpropisothiazolin-3-one.

[0040] Follow the steps below to prepare:

[0041] 1) Add the pure acrylic emulsion, silicone acrylic emulsion, TS waterproof emulsion, bactericide, defoamer, dispersant and wetting agent in the mass ratio in sequence, stirring speed 250rpm, stirring time 15min;

[0042] 2) Slowly add kaolin, titanium dioxide and heavy calcium carbonate in mass proportions to the mixture in step 1, the stirring speed is 800-1200 rpm, and the stirring time is 20-30 min; after stirring, it can be filled into barrels.

[0043] The particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com