Method for preparing high-purity silicon by energy-saving and environmental protection technology

An energy-saving, environmentally-friendly, high-tech technology, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve the problems of complex production process, high production cost, and many reaction steps, and achieve simple production process , Low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

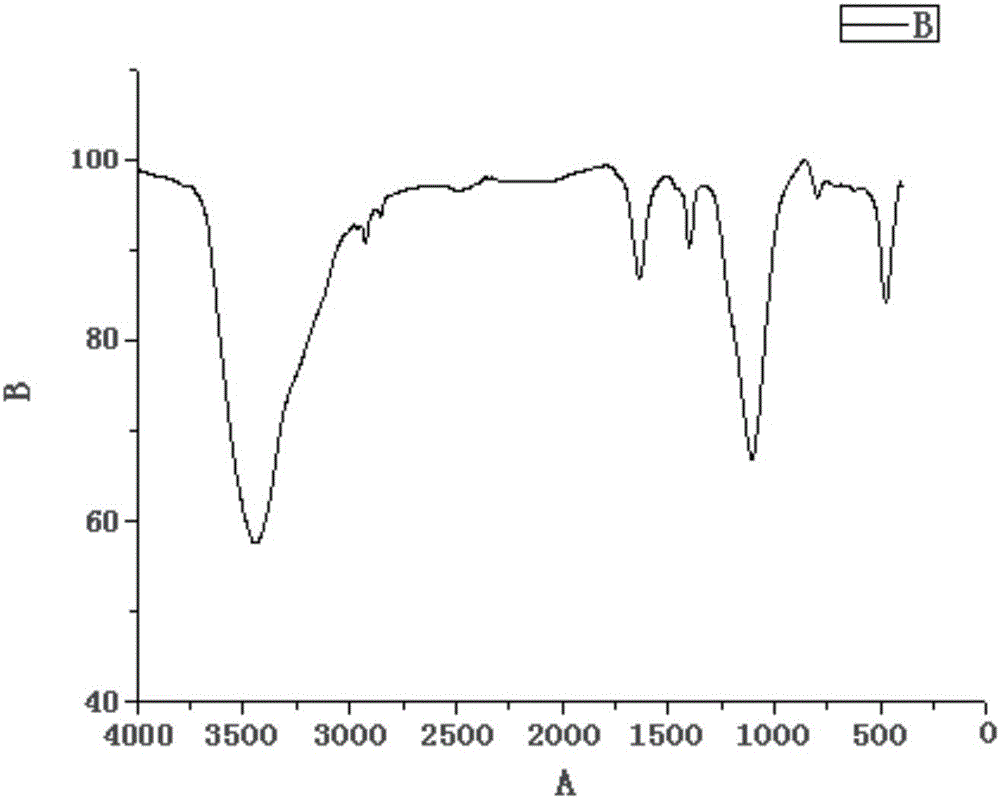

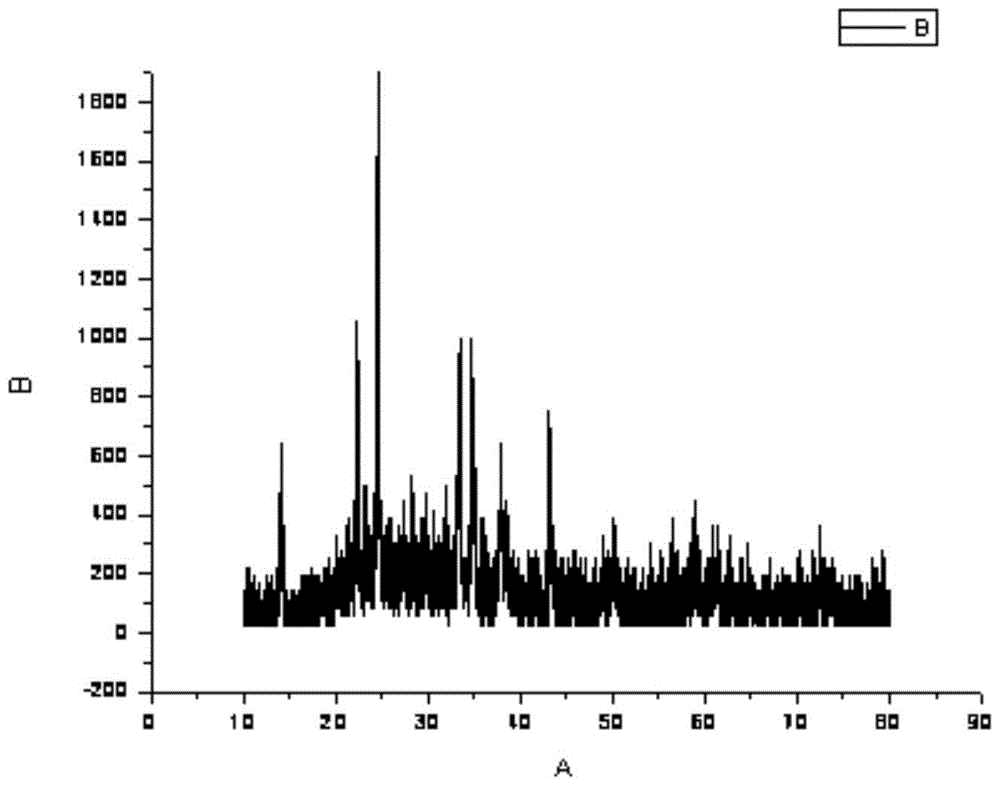

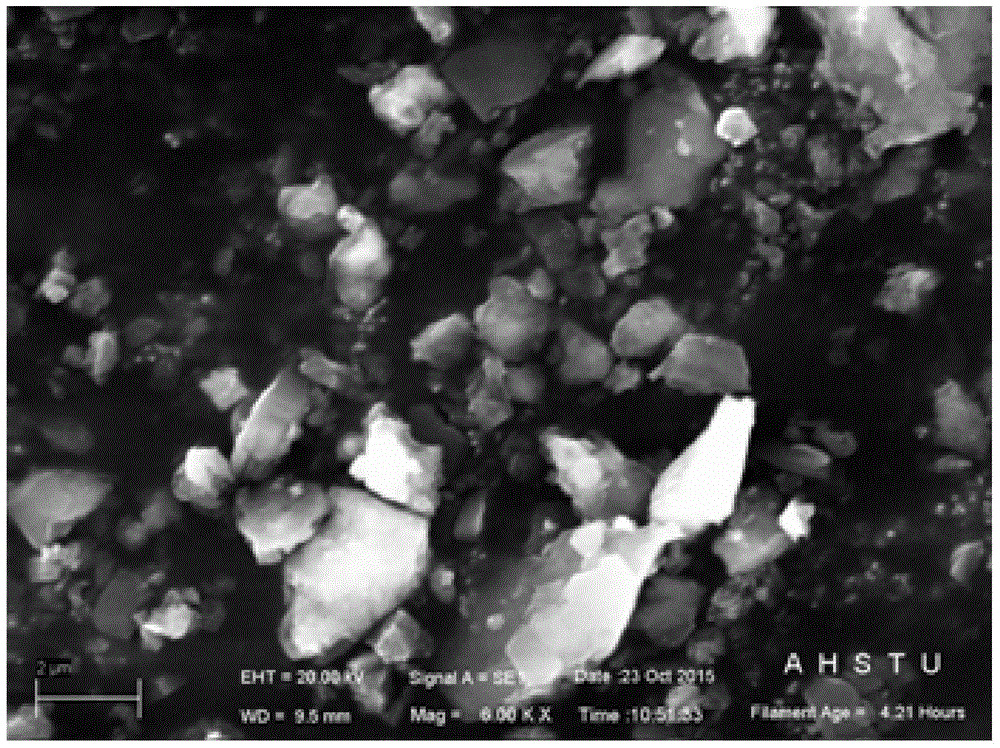

Examples

Embodiment 1

[0030] A method for producing high-purity silicon by utilizing energy-saving and environment-friendly technologies, comprising the following steps in sequence:

[0031] (1) Mix white carbon black and LiH uniformly in a ratio of 1.0094:1.4517 parts by weight to obtain a mixture, and place the mixture in a heating furnace with a chamber volume of 20 liters;

[0032] (2) Evenly spread 200-mesh carbon powder on the surface of the mixture, and the ratio of carbon powder to the mixture is 0.2161:2.4611 by weight;

[0033] (3) The temperature of the furnace cavity of the heating furnace is raised to 240°C through 0.8h, and the temperature is kept for 1.4h;

[0034] (4) The temperature of the furnace cavity of the heating furnace is raised to 360°C through 0.8h, and the temperature is kept for 4.2h to obtain the reaction product;

[0035] (5) cooling the reaction product to room temperature, washing it three times with normal temperature distilled water, each time using 20 parts by w...

Embodiment 2

[0039] A method for producing high-purity silicon by utilizing energy-saving and environment-friendly technologies, comprising the following steps in sequence:

[0040] (1) Quartz sand, LiAlH 4 Mix evenly according to the ratio of 0.8909:1.3501 parts by weight to obtain a mixture, and place the mixture in a heating furnace with a chamber volume of 10 liters;

[0041] (2) Evenly spread 140-mesh carbon powder on the surface of the mixture, and the ratio of carbon powder to the mixture is 0.1859:2.241 by weight;

[0042] (3) The temperature of the furnace cavity of the heating furnace is raised to 200° C. over 0.5 h, and the temperature is kept for 2 h;

[0043] (4) The temperature of the furnace chamber of the heating furnace is raised to 300° C. over 0.5 h, and the temperature is kept for 6 h to obtain the reaction product;

[0044] (5) cooling the reaction product to room temperature, washing it three times with normal temperature distilled water, each time using 15 parts by...

Embodiment 3

[0048] A method for producing high-purity silicon by utilizing energy-saving and environment-friendly technologies, comprising the following steps in sequence:

[0049] (1) White carbon black, NaBH 4 Mix evenly in the ratio of 0.9092:1.4078 parts by weight to obtain a mixture, and place the mixture in a heating furnace with a chamber volume of 15 liters;

[0050] (2) Evenly spread 170 mesh carbon powder on the surface of the mixture, the ratio of carbon powder to the mixture is 0.2103:2.317 by weight;

[0051] (3) The temperature of the furnace cavity of the heating furnace is raised to 220° C. over 0.65 hours, and kept for 1.7 hours;

[0052] (4) The temperature of the furnace chamber of the heating furnace is raised to 330°C through 0.65h, and the temperature is kept for 5h to obtain the reaction product;

[0053] (5) cooling the reaction product to room temperature, washing it three times with normal temperature distilled water, each time using 18 parts by weight of norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com