Feeding device for producing cigarettes from tobacco

A technology of feeding device and cigarette, which is applied in the directions of tobacco, cigarette manufacturing, and application, etc., can solve the problems of skin surface influence, tobacco product falling, insufficient heat dissipation of skin surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

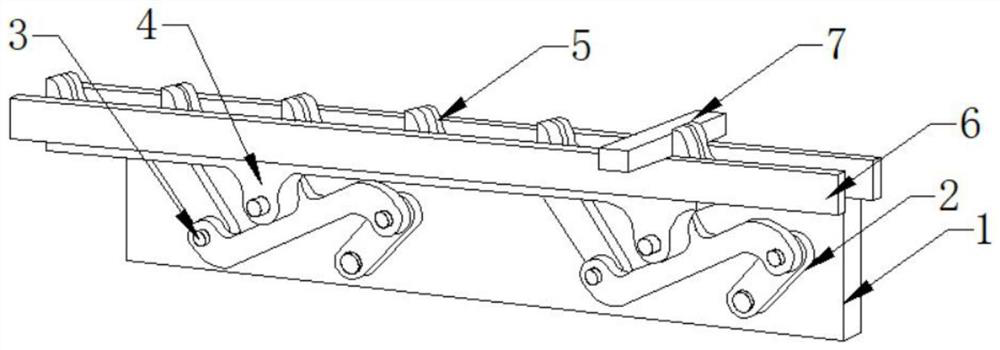

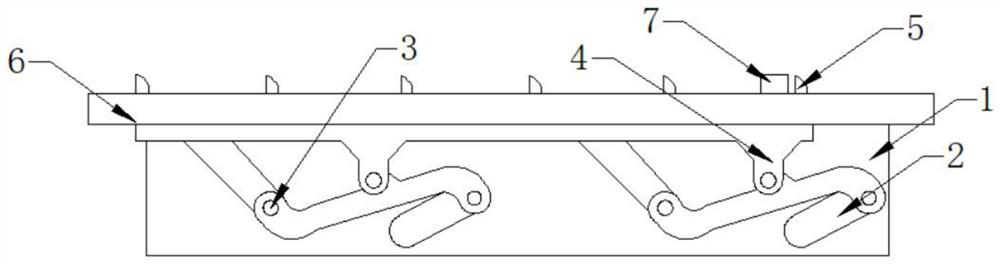

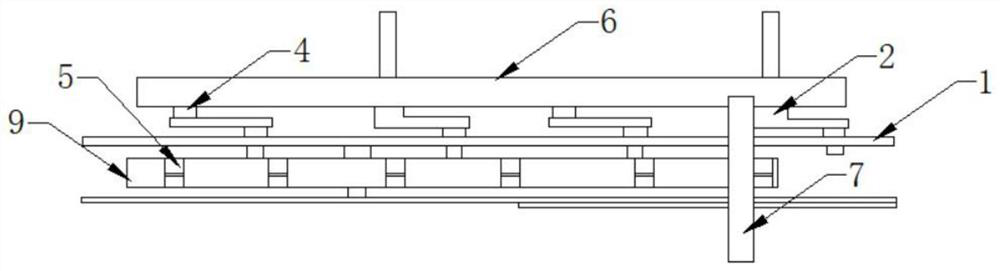

[0025] like Figure 1-5 As shown, the present invention provides a tobacco production cigarette feeding device, including a device main body 1, a clamping structure 5, an air-cooling structure 8 and a push assembly 2, a push assembly 2 is installed on one side of the device main body 1, and a push assembly 2 is installed on one side. The side is provided with a movable screw 3, one side of the movable screw 3 is provided with a stabilizer plate 4, one side of the stabilizer plate 4 is provided with a fixed plate 6, one side of the fixed plate 6 is provided with a fixed rod 7, and one side of the stabilizer plate 4 is provided with There is a clamping structure 5, an elastic pad 501 is installed on one side of the clamping structure 5, a clamping arm 502 is installed on one side of the clamping structure 5, a telescopic column 503 is arranged on one side of the clamping arm 502, and the A transmission bearing 504 is installed on one side, an adjustment rod 505 is installed at o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com