Flame-retardant leather brick and embroidery method thereof

A leather and leather layer technology, applied in the field of leather bricks, can solve the problems of heavy gypsum weight, injury, safety hazards, etc., and achieve the effects of long service life, reasonable price and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

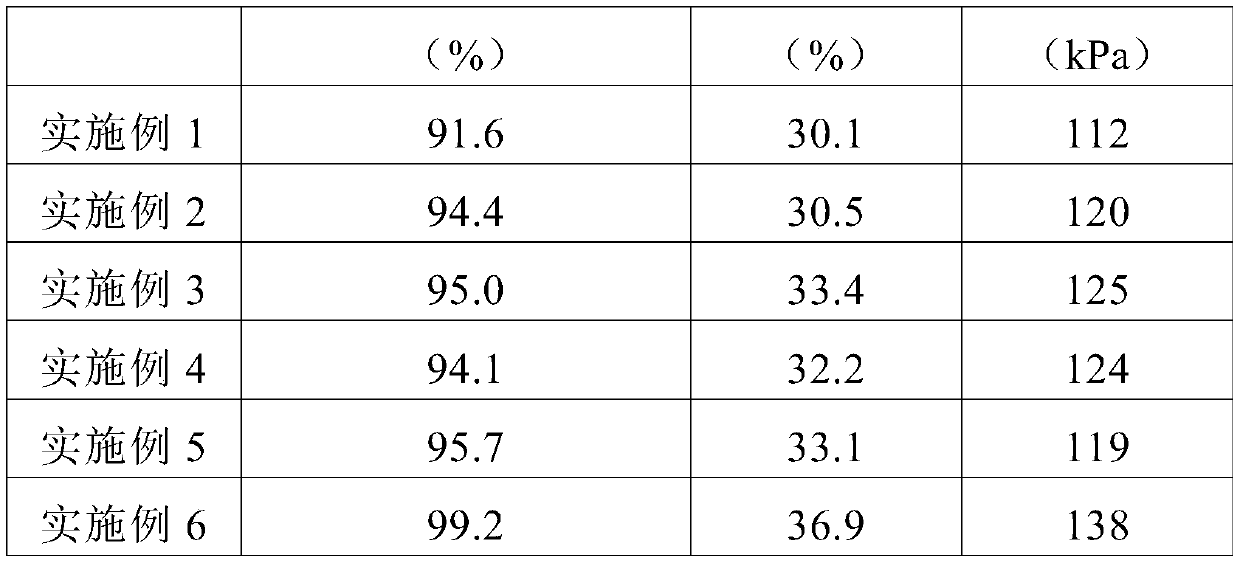

Embodiment 1

[0025] Flame retardant leather tiles, including leather layer and flame retardant PU layer.

[0026] The leather layer is artificial leather.

[0027] The flame-retardant PU layer is prepared from the following raw materials in parts by weight: 85 parts of polyether polyol, 3 parts of spodumene powder, 15 parts of bentonite, 1.5 parts of simethicone, and 3 parts of 1,4-butanediol , 0.05 parts of triethanolamine, 0.6 parts of triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 4 parts of water, 8 parts of magnesium carbonate, triacetin 3 parts, 1 part of potassium isozincate, 5 parts of flame retardant additive, 2 parts of vinyltrimethoxysilane, 35 parts of 1,4-cyclohexane diisocyanate.

[0028] The flame retardant additive is manganese hypophosphite.

[0029] The preparation method of the above-mentioned leather brick is: the raw materials of the above-mentioned flame-retardant PU layer are mixed with polyether polyol, spodumene powder, bentonite,...

Embodiment 2

[0032] Flame retardant leather tiles, including leather layer and flame retardant PU layer.

[0033] The leather layer is artificial leather.

[0034] The flame-retardant PU layer is prepared from the following raw materials in parts by weight: 85 parts of polyether polyol, 15 parts of bentonite, 1.5 parts of simethicone, 3 parts of 1,4-butanediol, 0.05 parts of triethanolamine, 0.6 parts of triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate, 4 parts of water, 8 parts of magnesium carbonate, 3 parts of glycerol triacetate, isozincic acid 1 part of potassium, 5 parts of flame retardant additive, 2 parts of vinyltrimethoxysilane, 35 parts of 1,4-cyclohexane diisocyanate.

[0035] The flame retardant additive is modified manganese hypophosphite.

[0036]The preparation method of the modified manganese hypophosphite is as follows: in a 50L four-necked flask with a stirring paddle and a reflux device, add 40L of water and 6kg of manganese hypophosphite,...

Embodiment 3

[0040] Flame retardant leather tiles, including leather layer and flame retardant PU layer.

[0041] The leather layer is artificial leather.

[0042] The flame-retardant PU layer is prepared from the following raw materials in parts by weight: 85 parts of polyether polyol, 3 parts of spodumene powder, 15 parts of bentonite, 1.5 parts of simethicone, and 3 parts of 1,4-butanediol , 0.05 parts of triethanolamine, 0.6 parts of triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 4 parts of water, 8 parts of magnesium carbonate, triacetin 3 parts, 1 part of potassium isozincate, 5 parts of flame retardant additive, 2 parts of vinyltrimethoxysilane, 35 parts of 1,4-cyclohexane diisocyanate.

[0043] The flame retardant additive is modified manganese hypophosphite.

[0044] The preparation method of the modified manganese hypophosphite is as follows: in a 50L four-necked flask with a stirring paddle and a reflux device, add 40L of water and 6kg of manga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com