Permafrost region road tunnel peripheral hole blasting construction method

A technology for road tunnels and construction methods, which is applied in blasting and other directions, can solve problems such as permafrost thermal thawing and landslides, and achieve the effects of reducing blasting temperature, cost, and blasting heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one ( full face excavation )

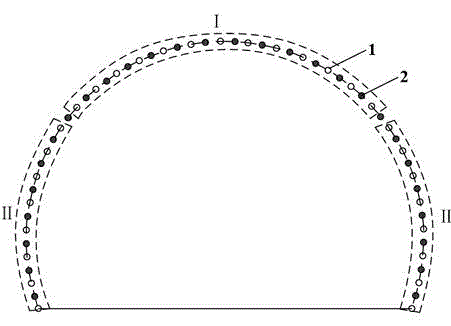

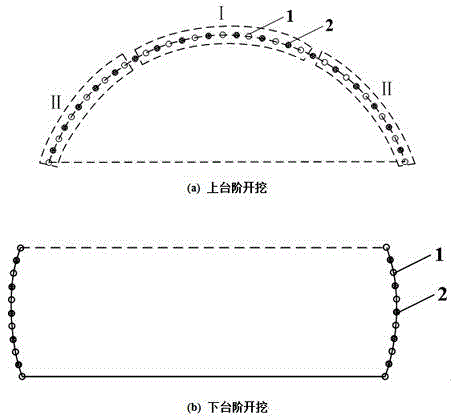

[0030] Step 1: Determine the excavation method and the depth of single-cycle footage according to the grade of the surrounding rock of the tunnel: for the surrounding rock of grade IV and above, the full-section method is adopted for excavation; the charge volume of the surrounding holes is designed to be 3 volumes; the footage is drilled in each blasting cycle The depth is not greater than 1.5m, and the distance between adjacent blastholes is not greater than 60cm. Such as figure 1 shown.

[0031] Step 2: Drill peripheral holes according to the specified spacing according to the excavation outline position of the tunnel design.

[0032] Step 3: After drilling into the hole, use a high-pressure air gun to clean the hole.

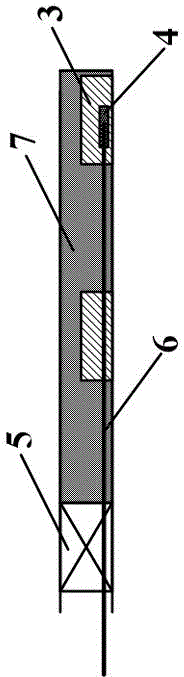

[0033] Step 4: Carry out the explosive loading of each blasthole 1 and the connection of the detonator 4 and the detonating cord 6 . Such as image 3 shown , the non-millisecond detonator 4 and the ...

Embodiment 2

[0036] Embodiment two ( step excavation )

[0037] Step 1: Determine the excavation method and single-cycle footage depth according to the grade of the surrounding rock of the tunnel: for grade VI and grade V surrounding rock, the step method is adopted for excavation; the charge volume of the surrounding holes is designed to be 2 rolls; each blasting cycle The footage depth is not more than 1m, and the distance between adjacent blastholes is 50cm. Such as figure 2 shown.

[0038] Step 2: Drill peripheral holes according to the specified spacing according to the excavation outline position of the tunnel design.

[0039] Step 3: After drilling into the hole, use a high-pressure air gun to clean the hole.

[0040] Step 4: Carry out the explosive loading of each blasthole 1 and the connection of the detonator 4 and the detonating cord 6 . Such as image 3 shown , the non-millisecond detonator 4 and the non-electric detonating cord 6 are used to connect the detonation n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com