High pressure exposed detonating cord detonator system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following description of embodiments, various terms such as “above” and “below” and “up hole” and “down hole” are used to indicate relative position of elements. These terms are used with reference to the normal position of the apparatus when used in a vertical borehole and are not intended to be limiting. In wells which include slanted or horizontal portions, the term up hole or above refers to the direction toward the surface location of the well and down hole or below refers to the direction toward the end of the well farthest from the surface location. It is to be understood that the a system according to the present invention may be inverted in some applications, for example bottom fired systems, and the relative positions of the various elements may therefore be reversed or inverted.

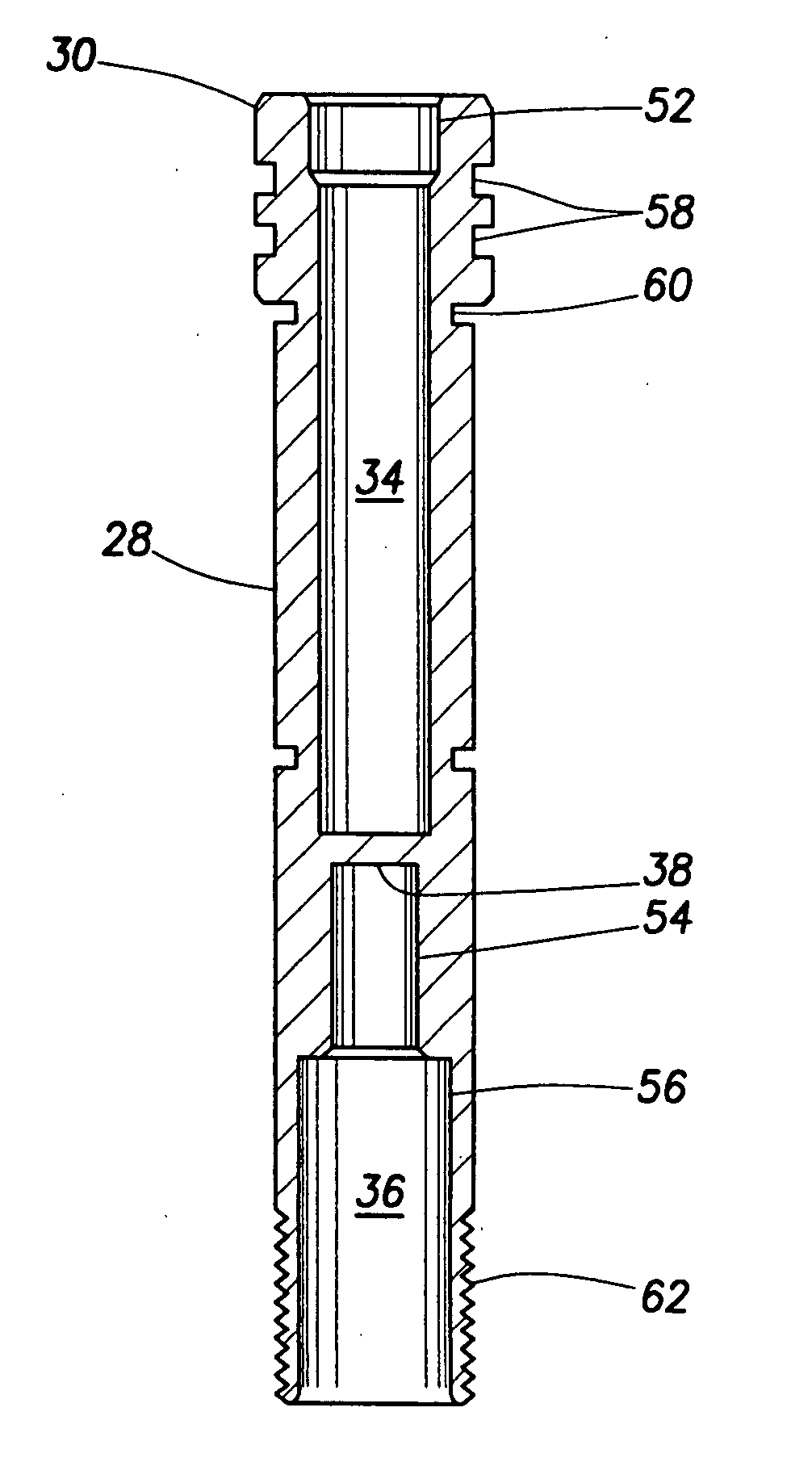

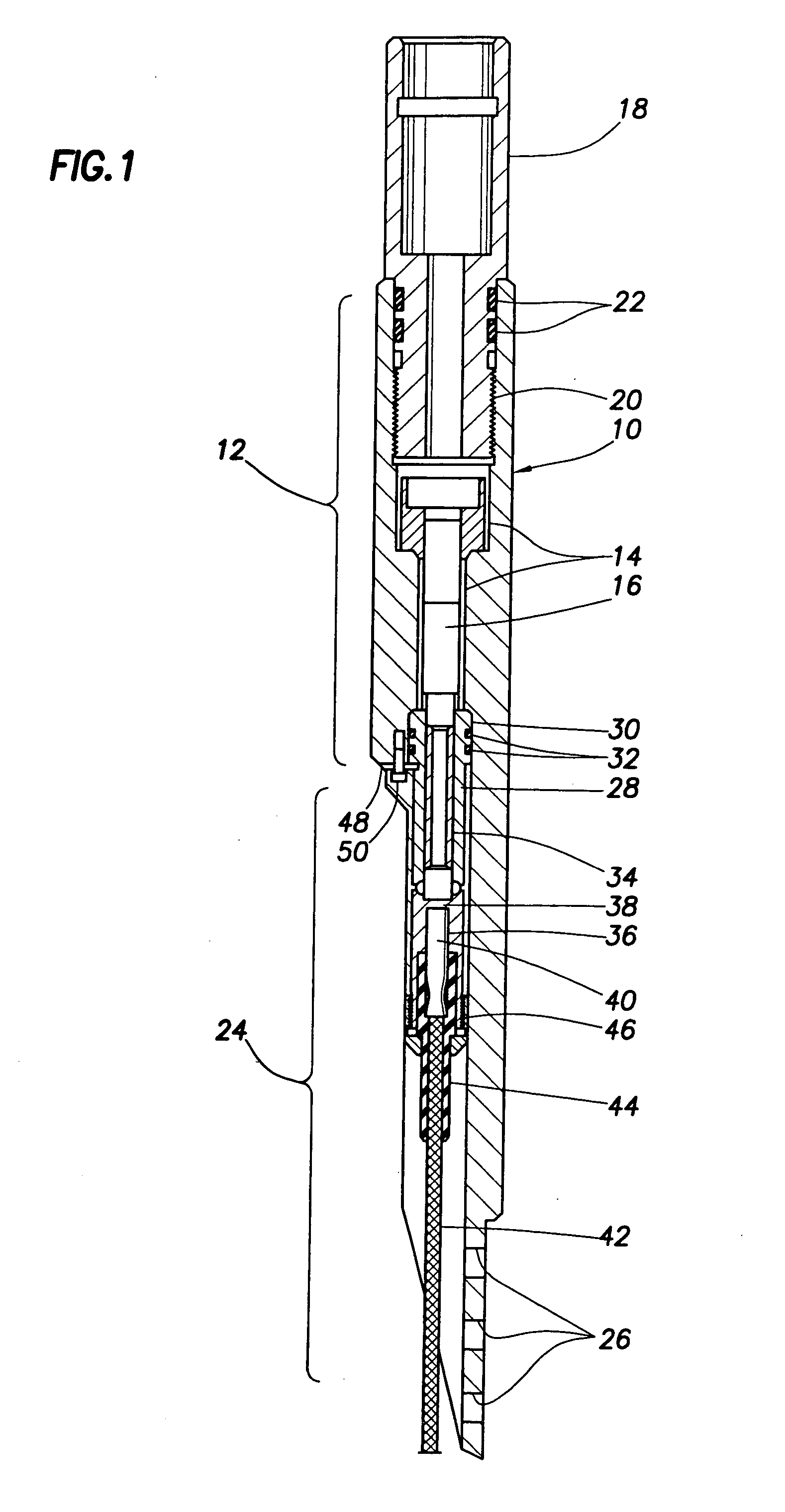

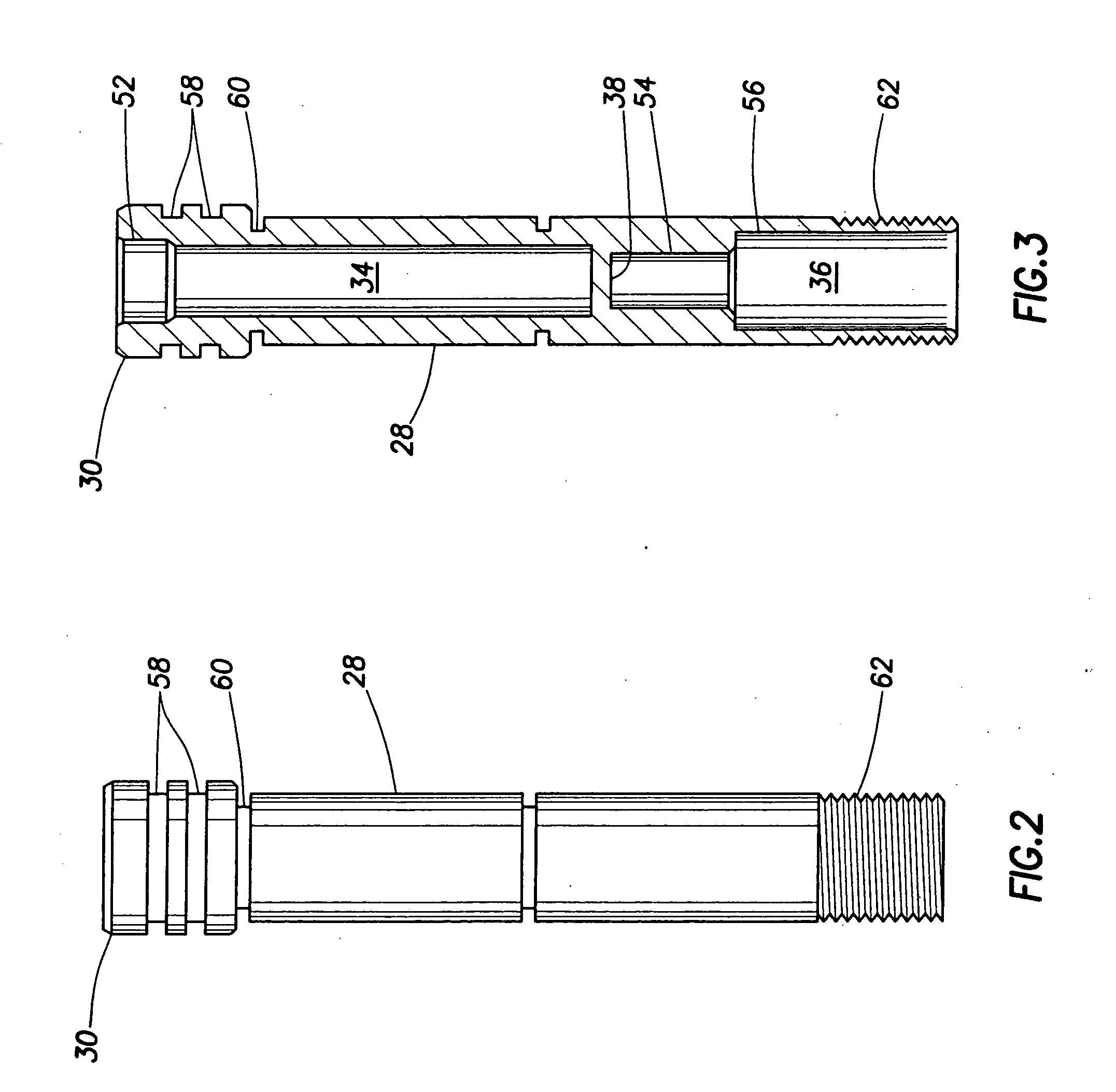

[0023]FIG. 1 provides a cross sectional view of an assembled detonator system according to one embodiment. The primary mechanical component of this embodiment is a firing head 10. Ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com