Patents

Literature

136results about "Fuse connectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

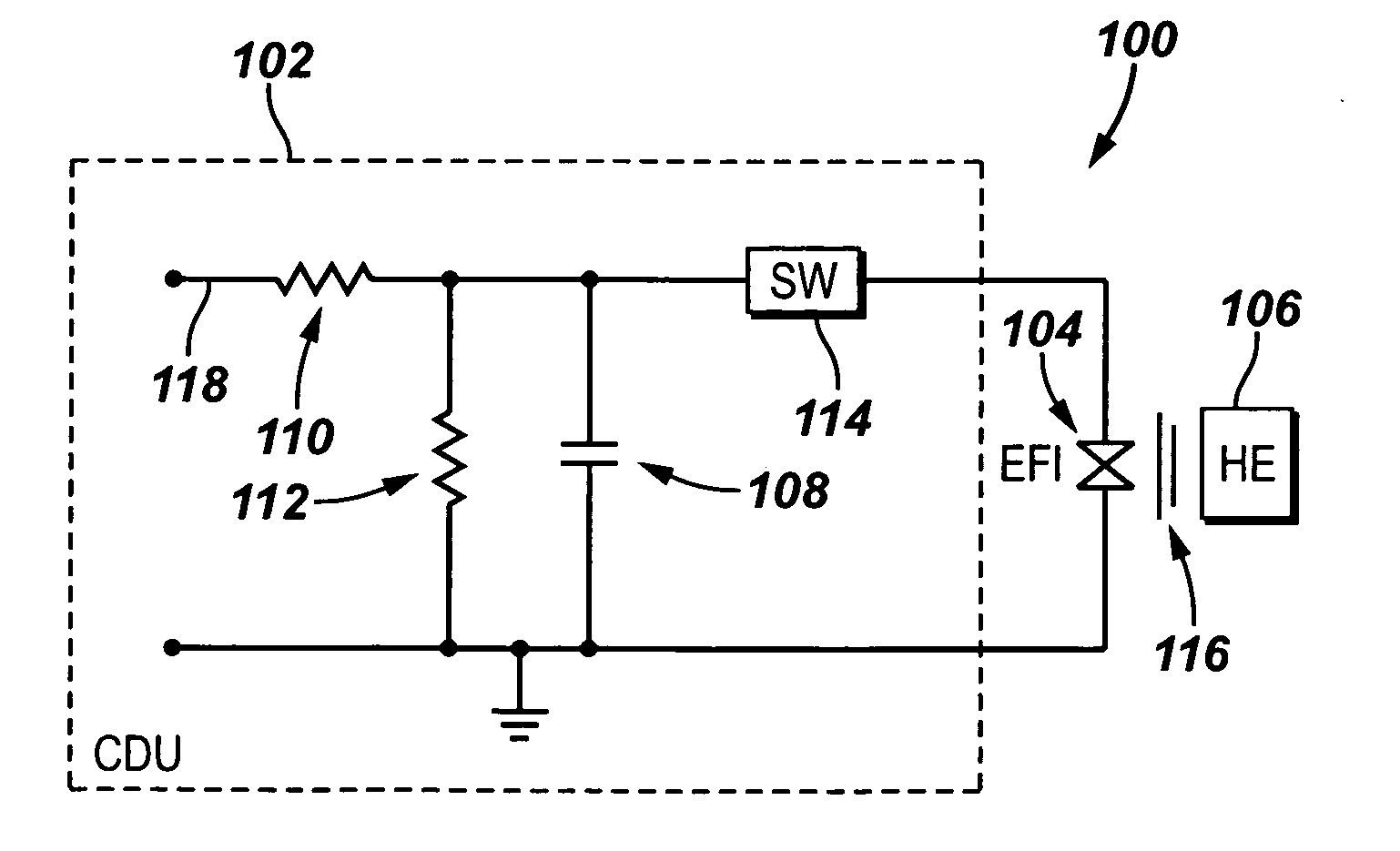

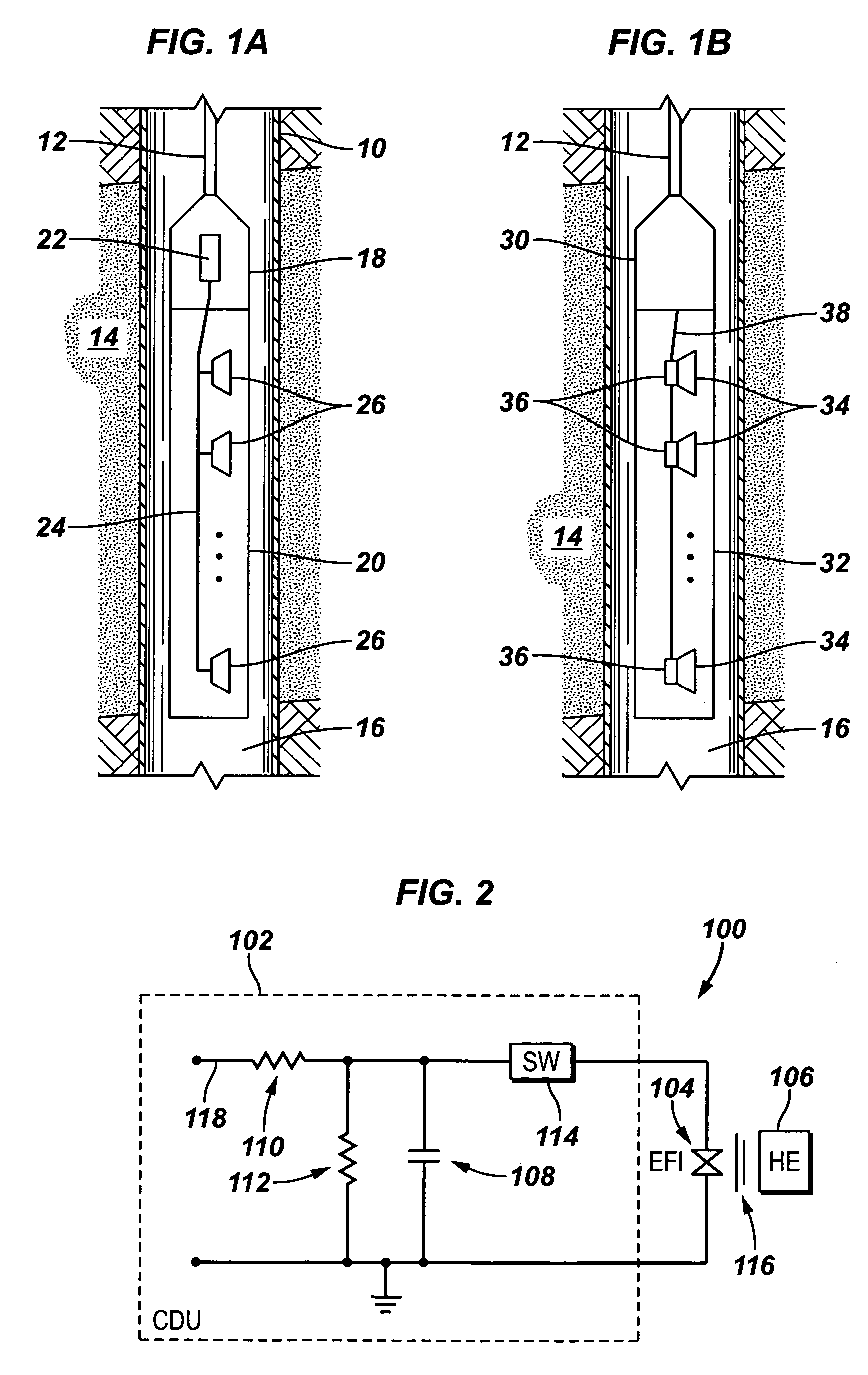

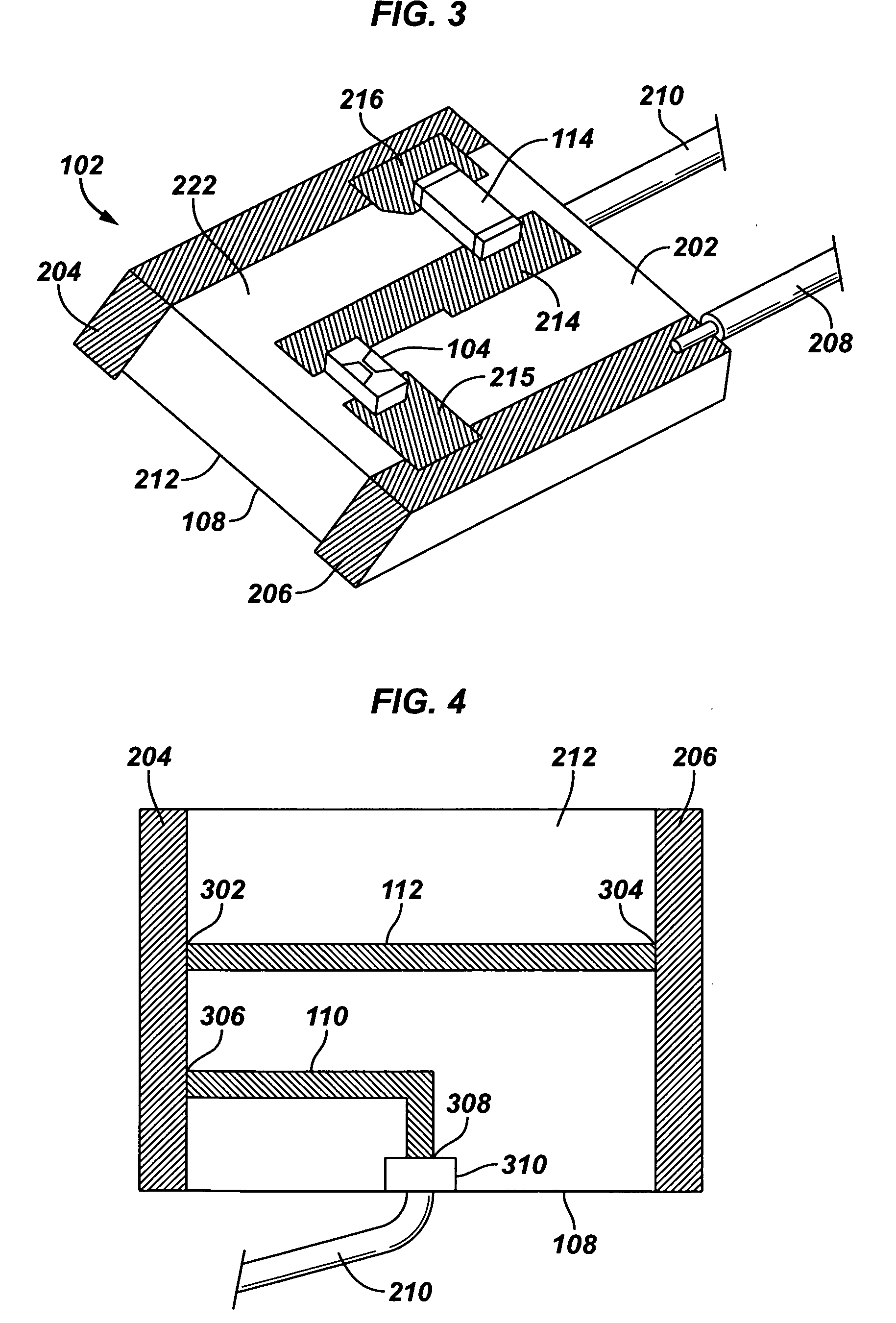

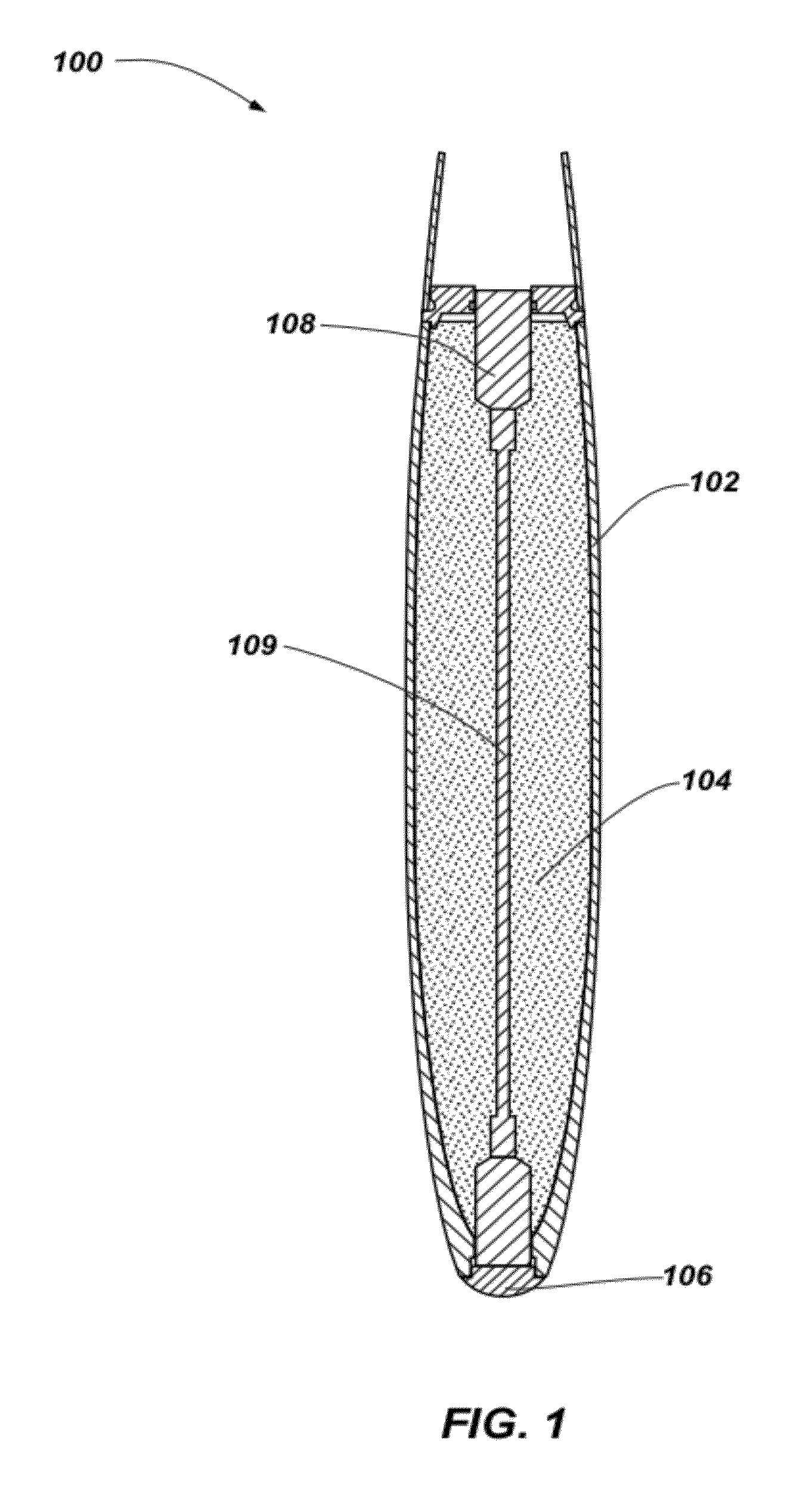

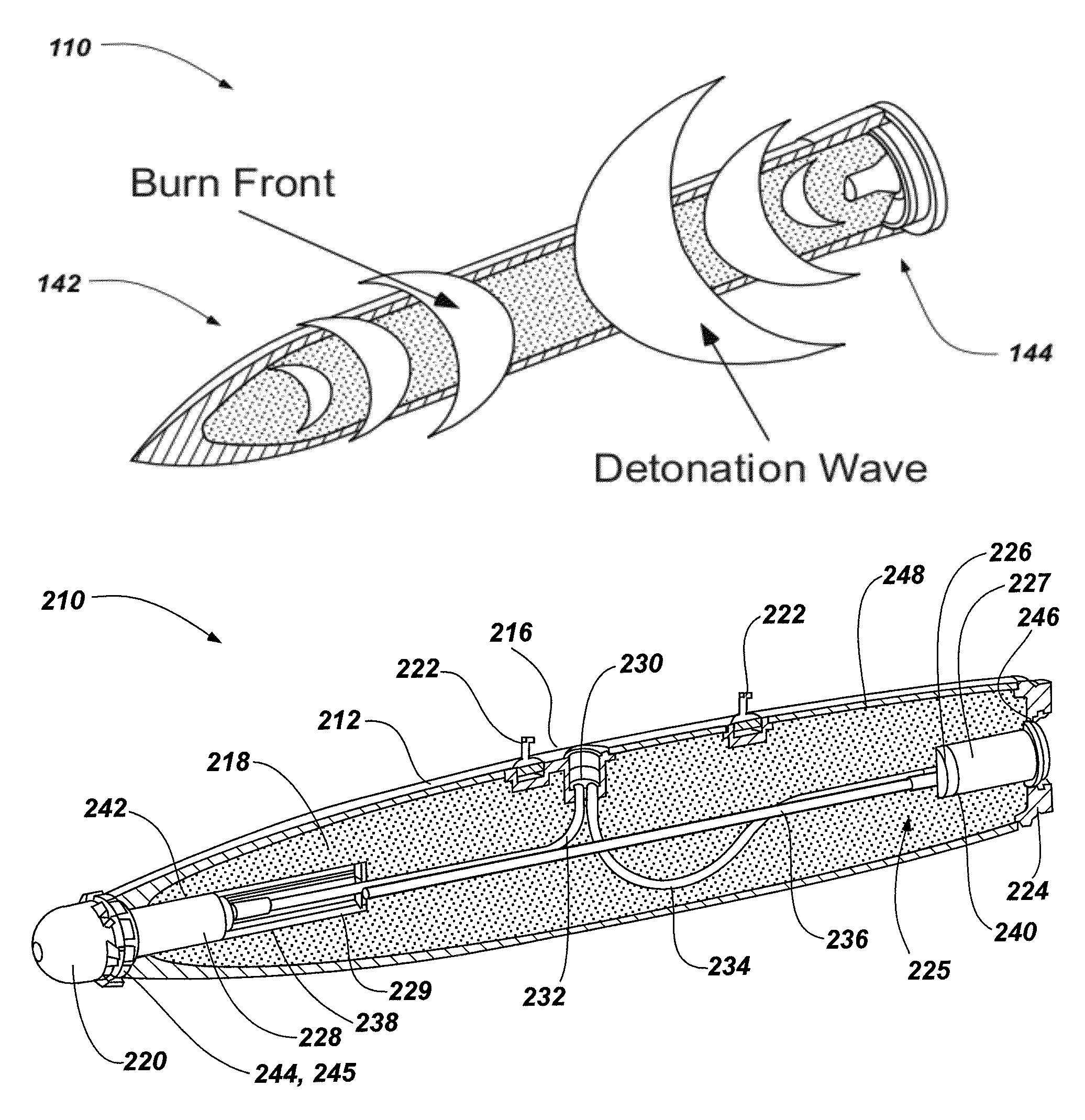

Integrated detonators for use with explosive devices

A detonator assembly is provided for use in oilfield operations to detonate an explosive downhole including a capacitor discharge unit and initiator electrically connected together to form a single unit. It is emphasized that this abstract is provided to comply with the rules requiring an abstract, which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

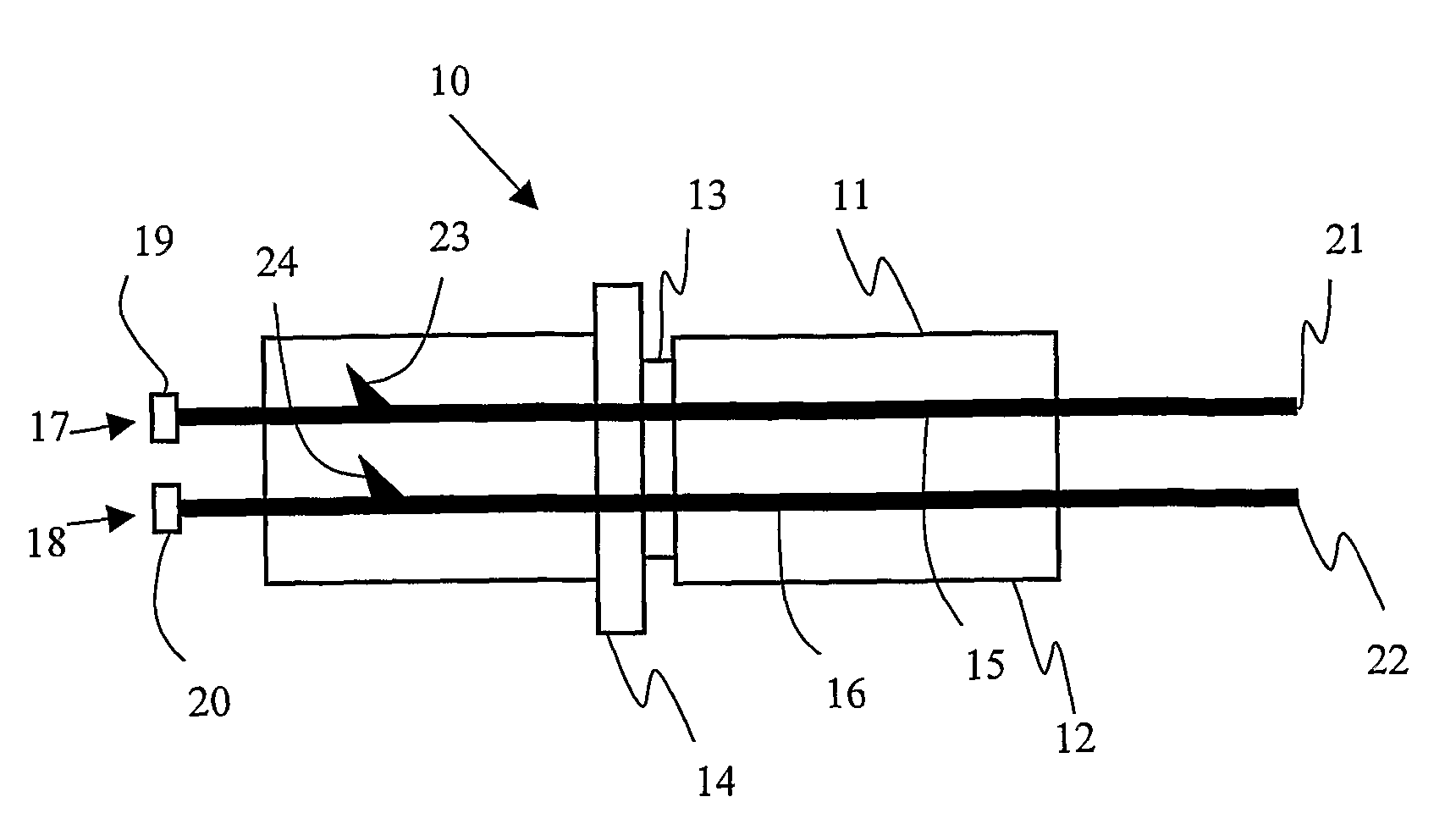

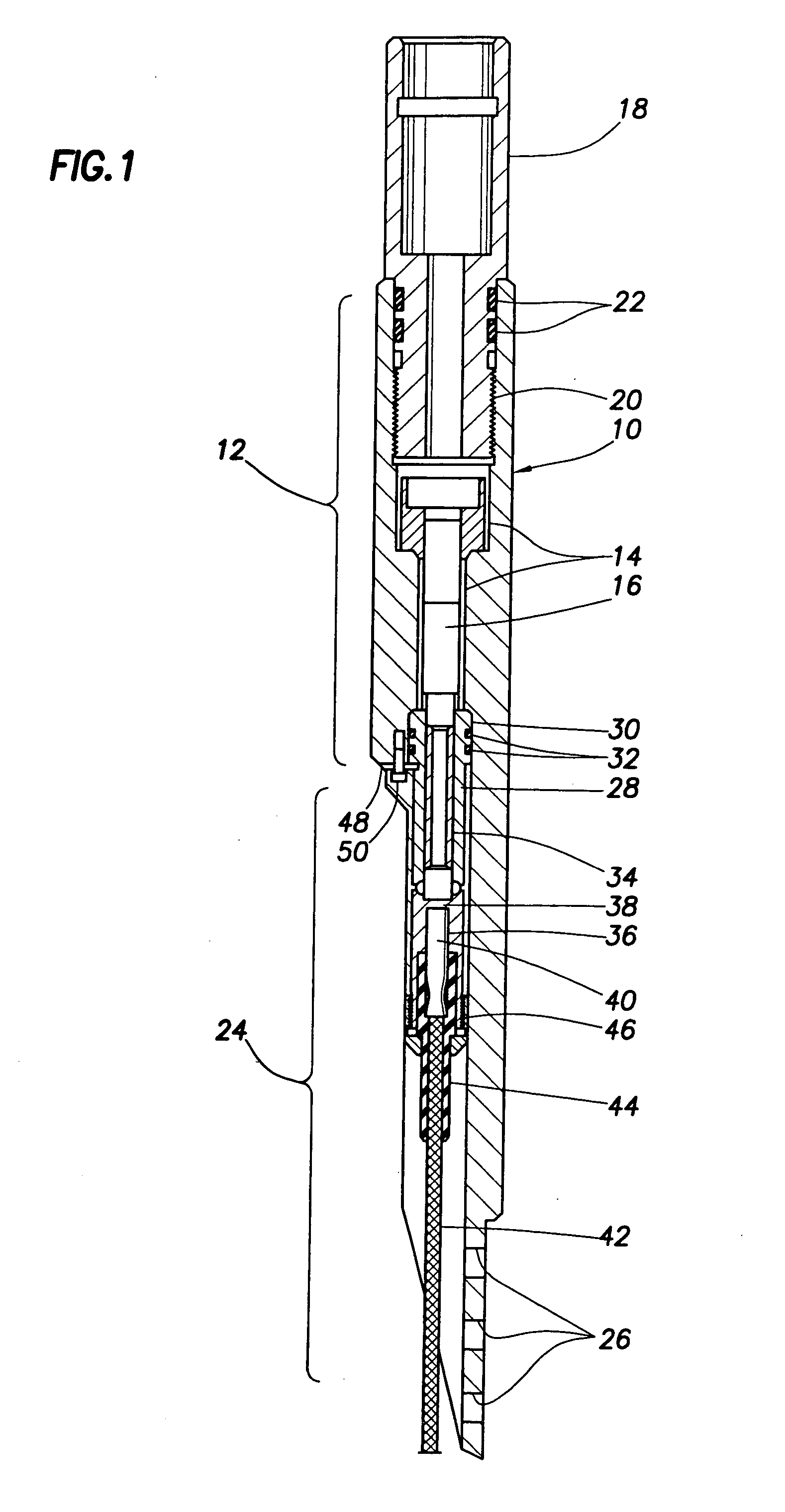

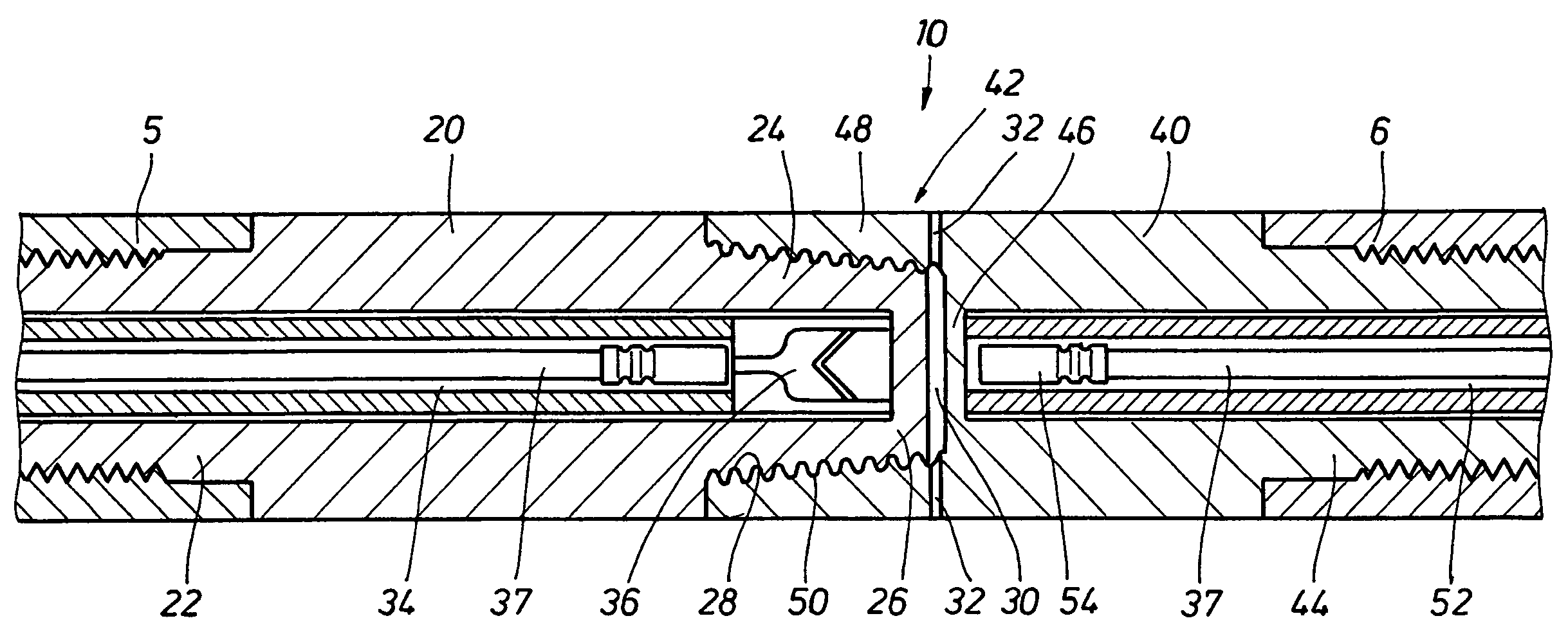

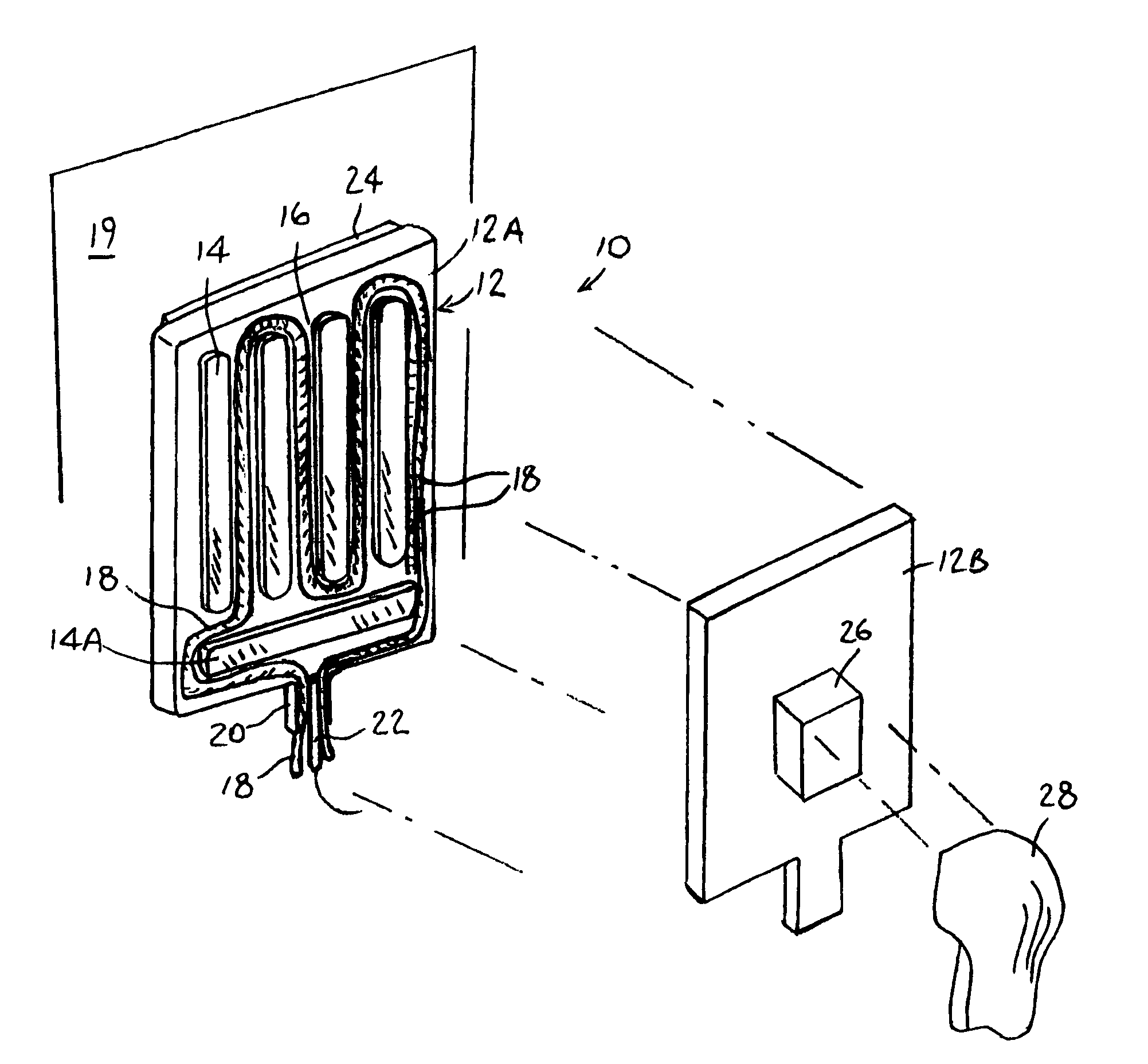

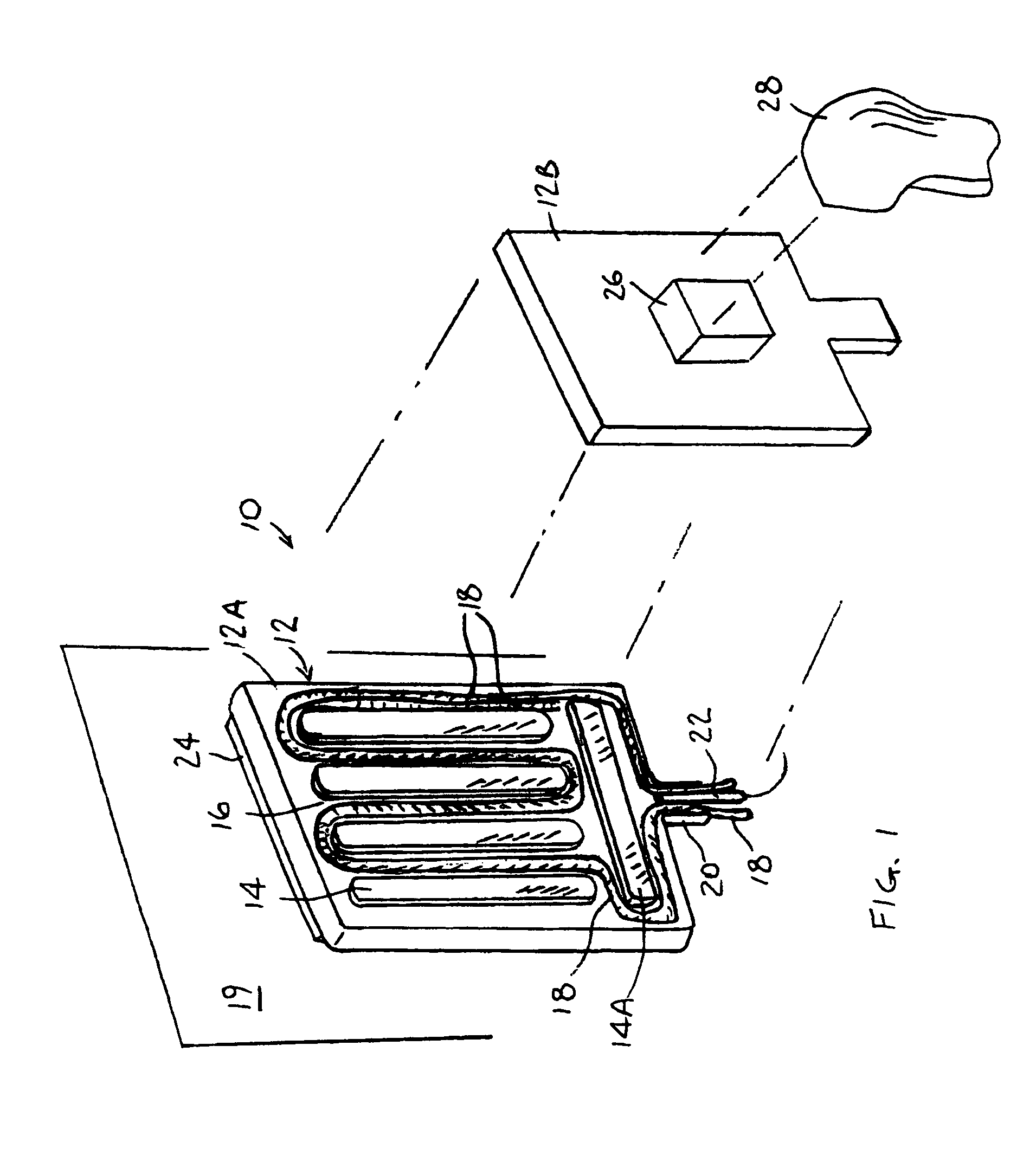

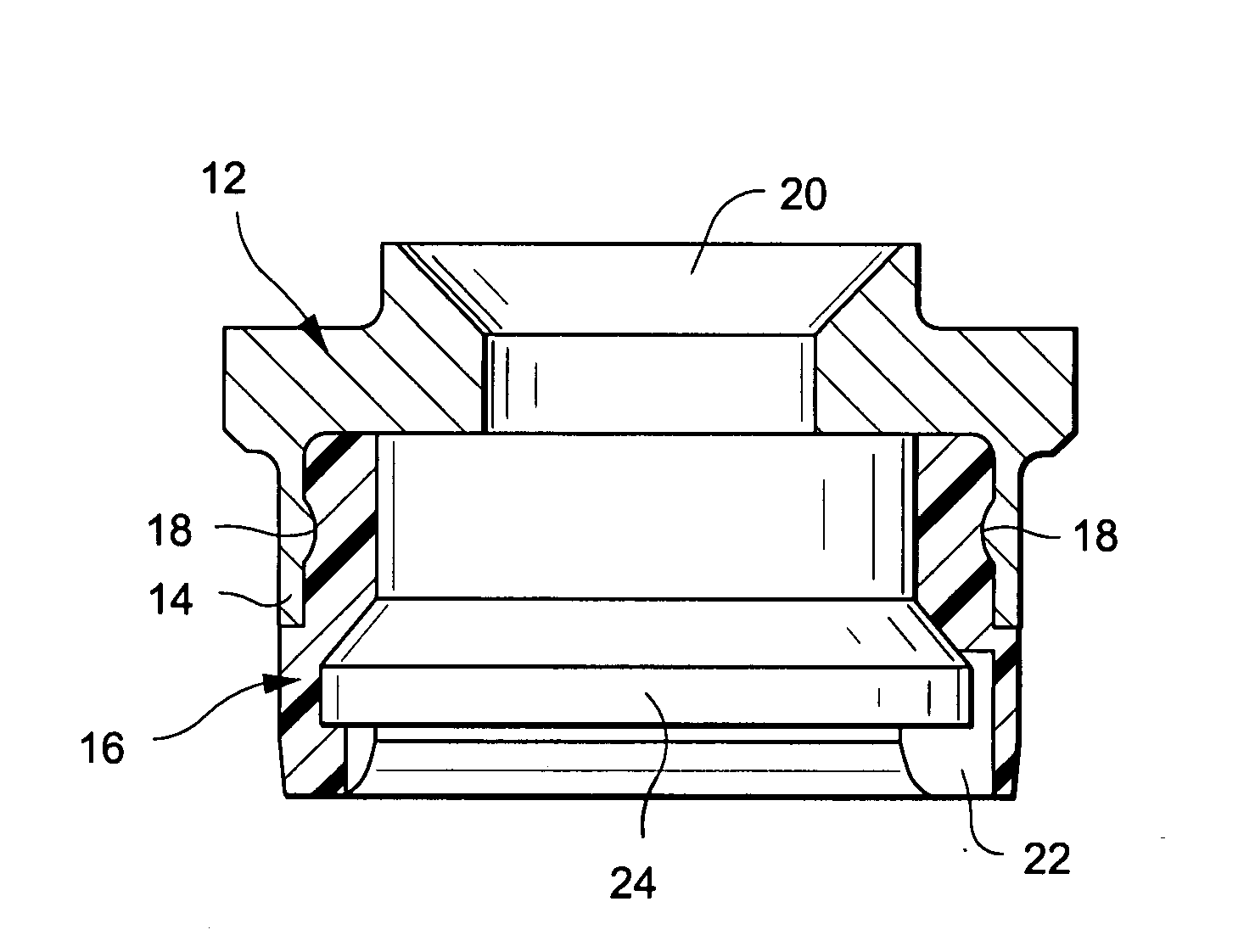

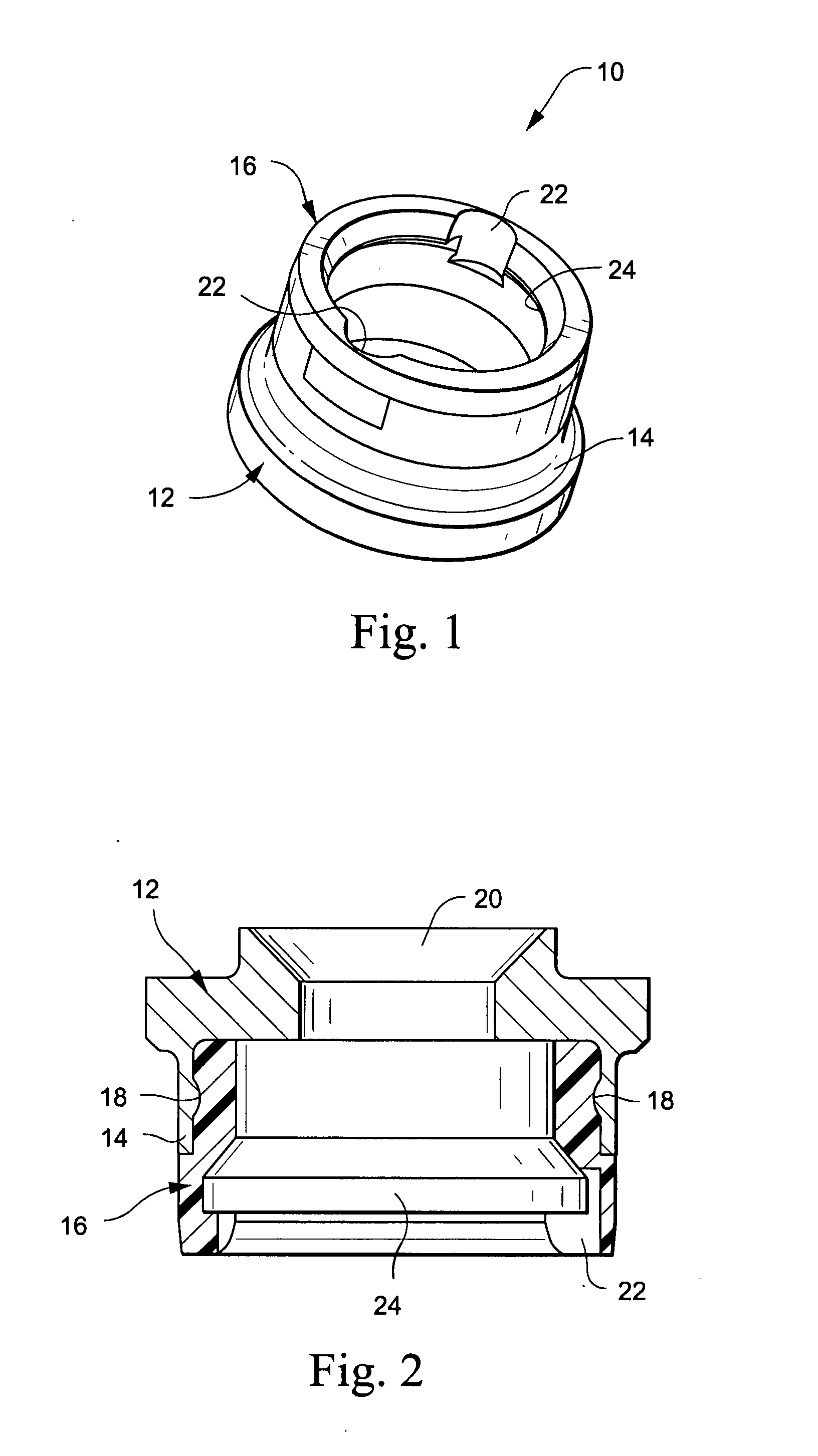

Connector for electronic detonators

ActiveUS8069789B2Avoid unnecessary distractionsImprove connection securityRelieving strain on wire connectionBlasting cartridgesDetonatorElectricity

Fire, arm, and disarm signals are typically transmitted to electronic detonators via signal transmission lines. Traditionally, such signal transmission lines include wires wherein one end of each wire is soldered directly to printed circuit boards and / or other signal processing components retained within the shell of a detonator. Other ‘modular’ blasting apparatuses of the prior art provide means to connect signal transmission lines to detonators in the field. Signal transmission line / detonator contacts are susceptible to disruption, particularly when the signal transmission lines are subject to inadvertent tugging or tensile forces at the blast site. The present application discloses an electrical connector that enables secure connection between a signal transmission line and any detonator adapted to receive and optionally process electrical signals from the signal transmission line. Specifically, the electrical connector can be affixed to the signal input end of a detonator, and includes at least one bridge element to provide electrical contact between a signal transmission line, and internal electrical component(s) of the detonator.

Owner:ORICA EXPLOSIVES TECH PTY LTD

Non-explosive two component initiator

Owner:WEATHERFORD TECH HLDG LLC

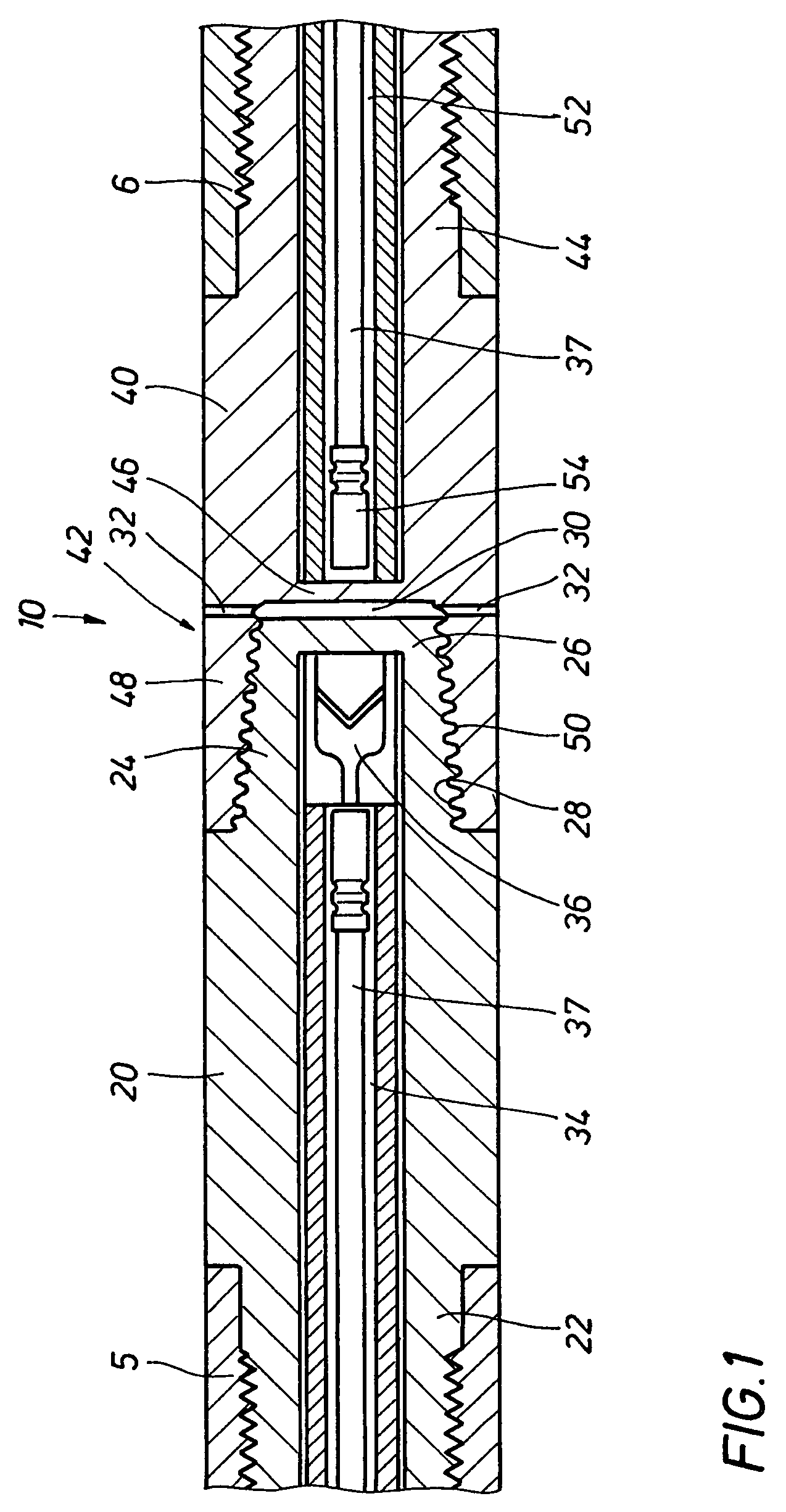

High pressure exposed detonating cord detonator system

A detonator system for borehole systems which include detonating cord exposed to borehole fluids, pressures and temperatures. A firing head has a sealed chamber for an electrically fired detonator and has a booster charge holder forming part of the seal. The chamber is sealed by a wire line firing sub and by the booster holder. The charge holder includes a bulkhead separating the detonator chamber from a booster charge chamber and providing part of the detonator chamber seal. The detonator explosive and the booster charge are positioned on opposite sides of the bulkhead so that upon detonation of the detonator, the bulkhead is ruptured and the explosion transfers to the booster charge and from it to the detonating cord. The firing head includes holes for attachment of borehole tools such as perforating guns or back off tools to be fired by the detonating cord.

Owner:HALLIBURTON ENERGY SERVICES INC

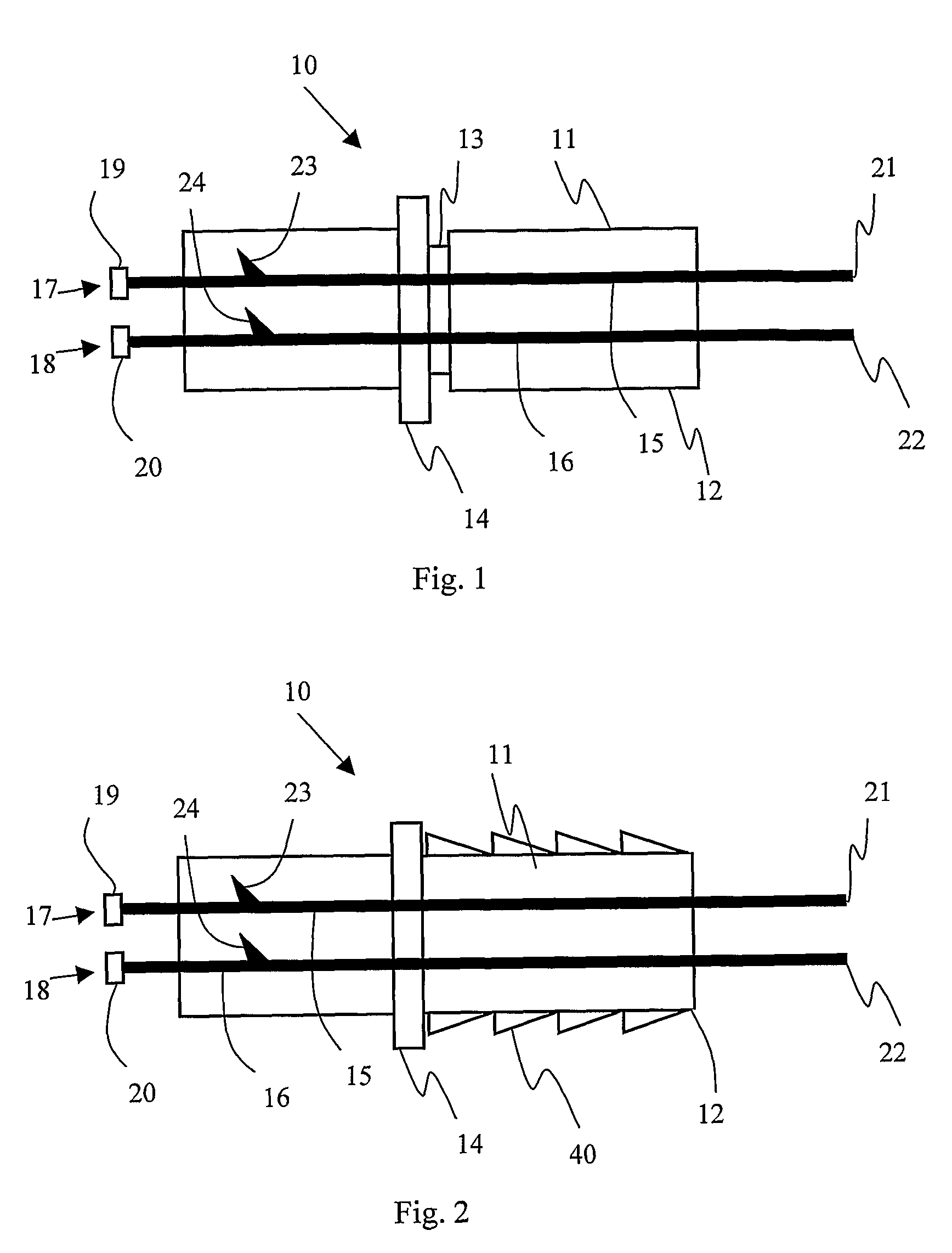

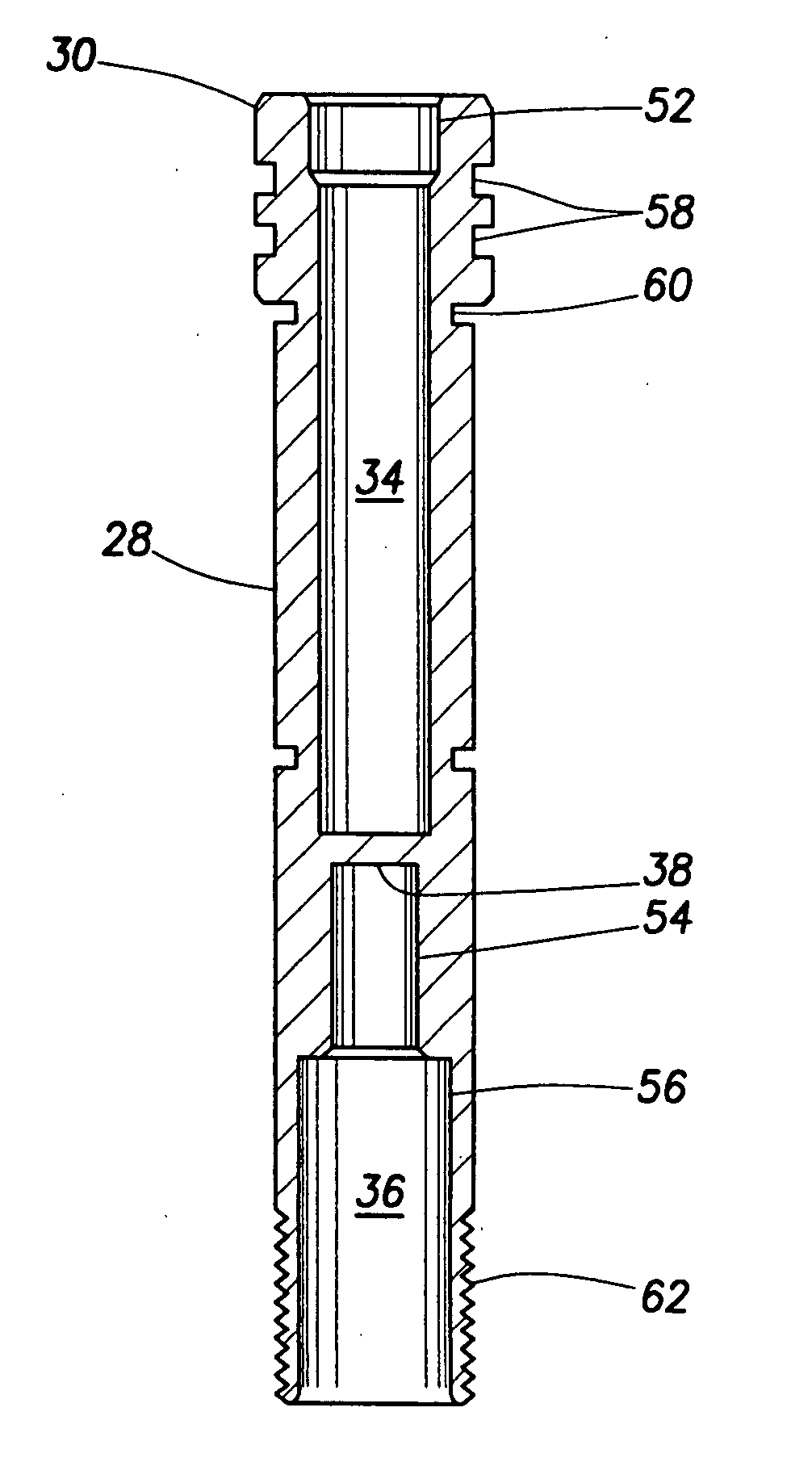

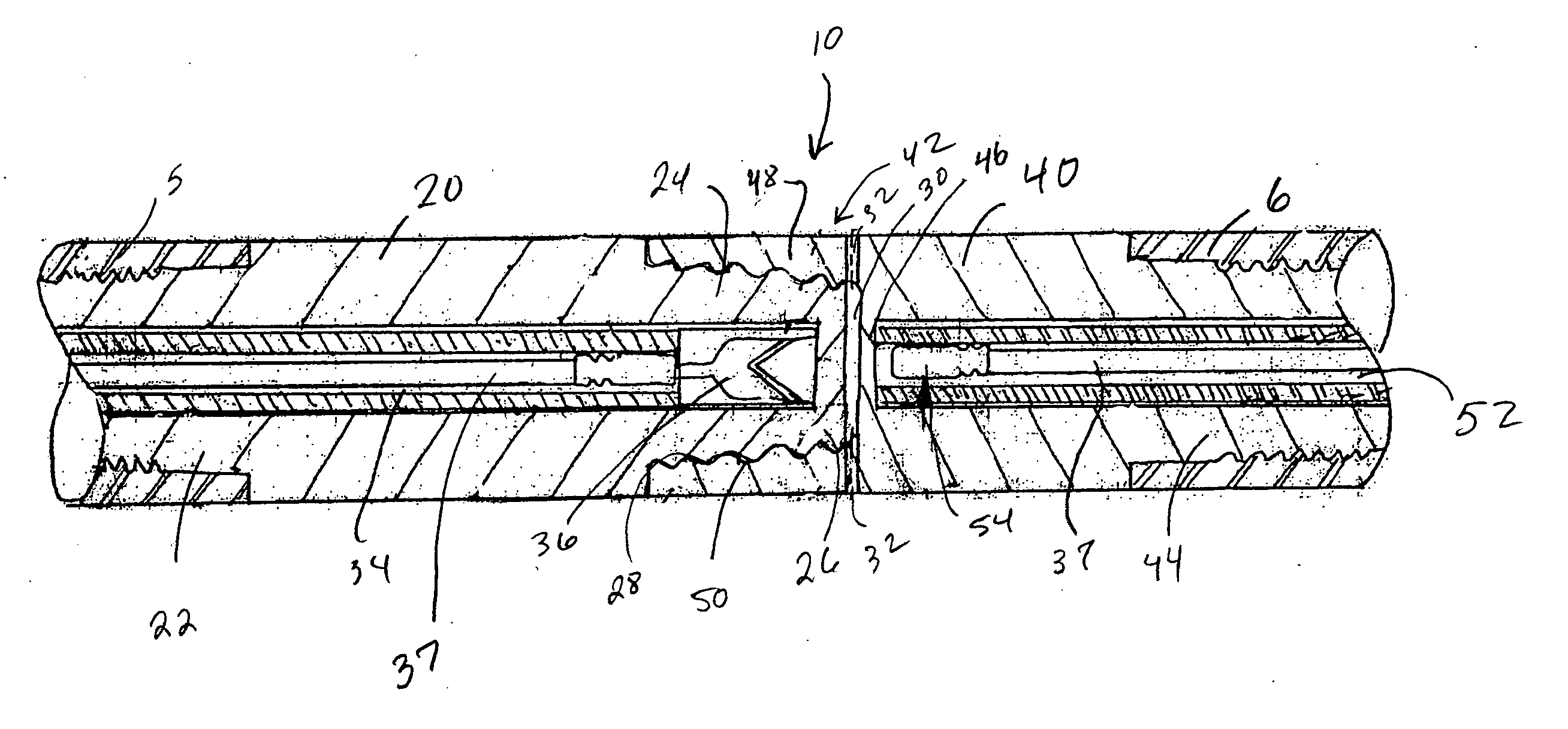

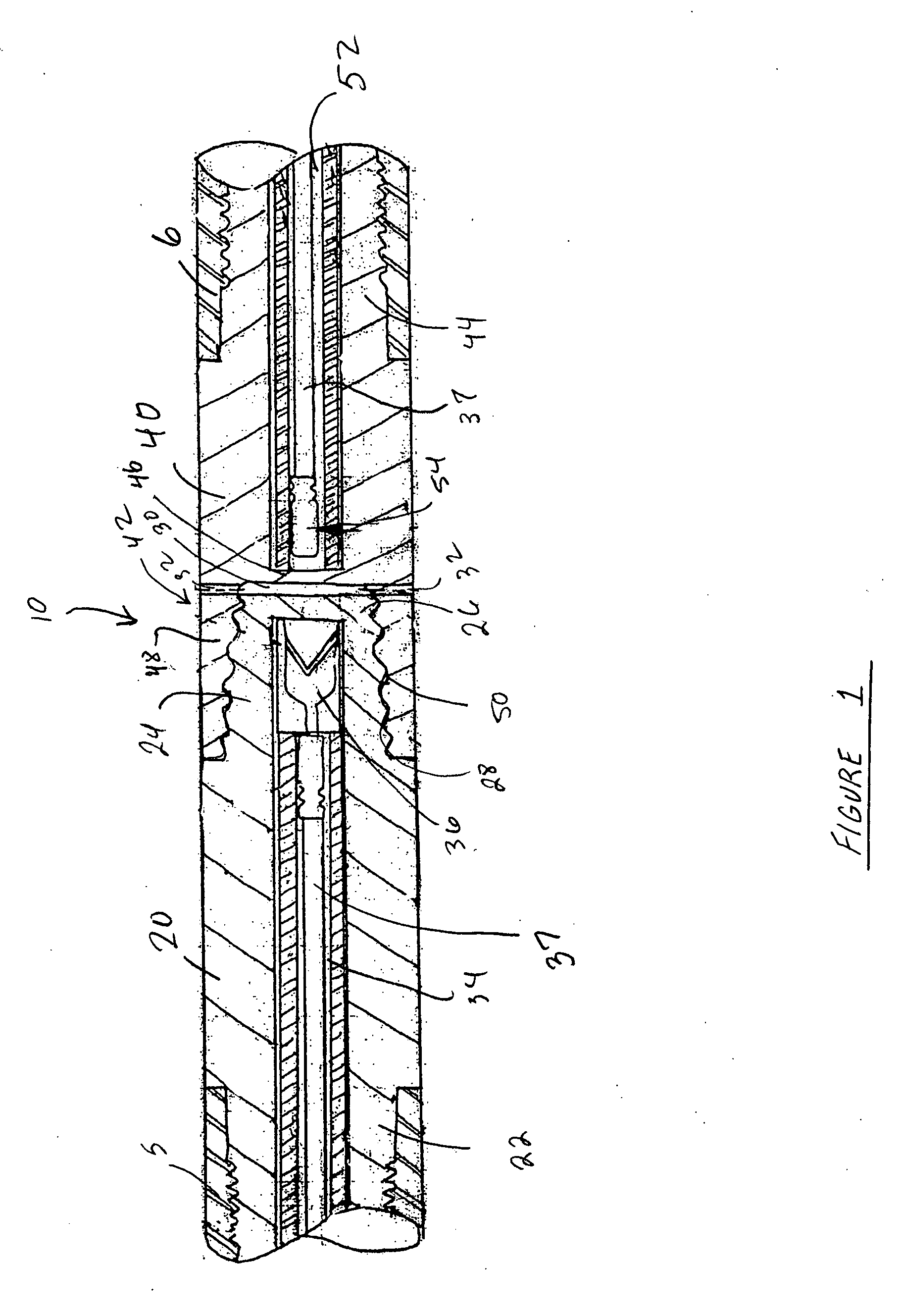

Connector for perforating gun tandem

ActiveUS20050229805A1Easy to participateDrilling rodsImpact fuzesShaped chargeMechanical engineering

Owner:BAKER HUGHES INC

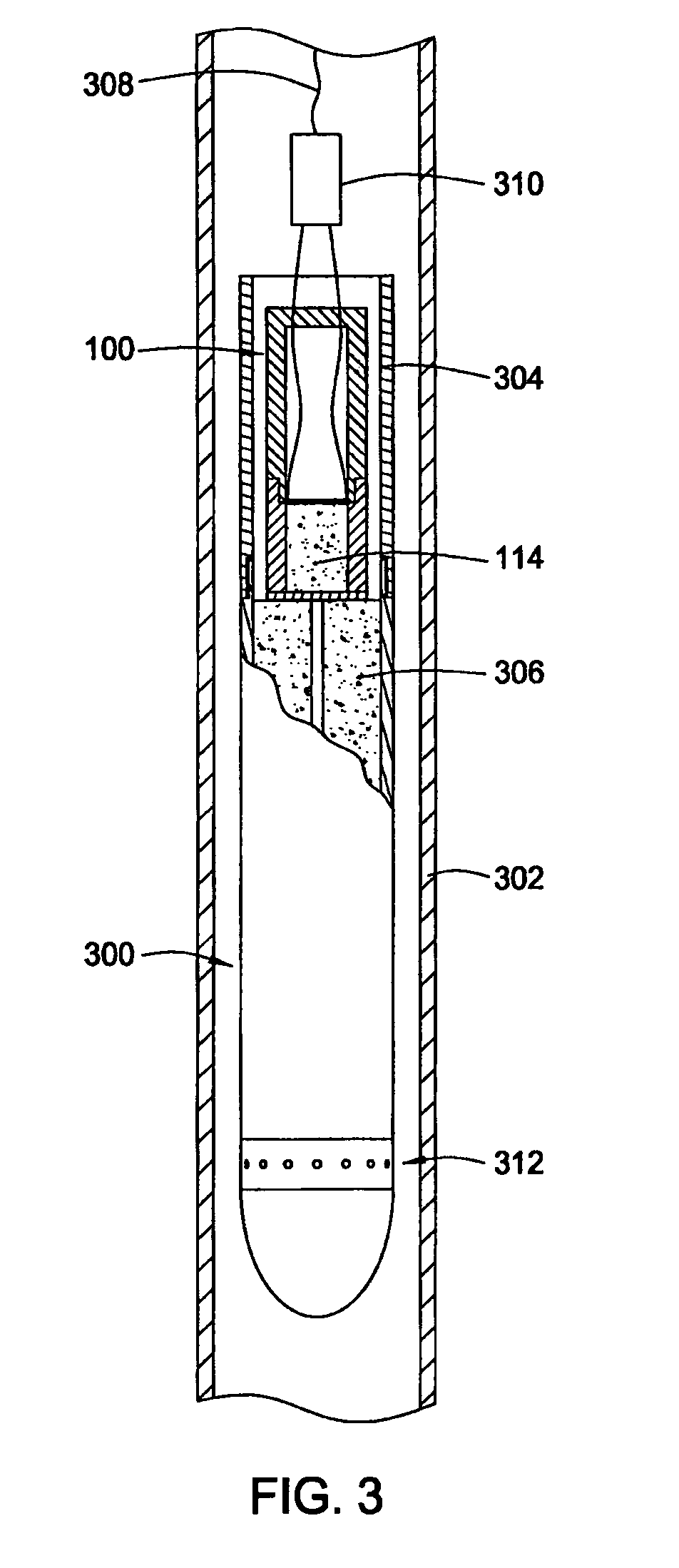

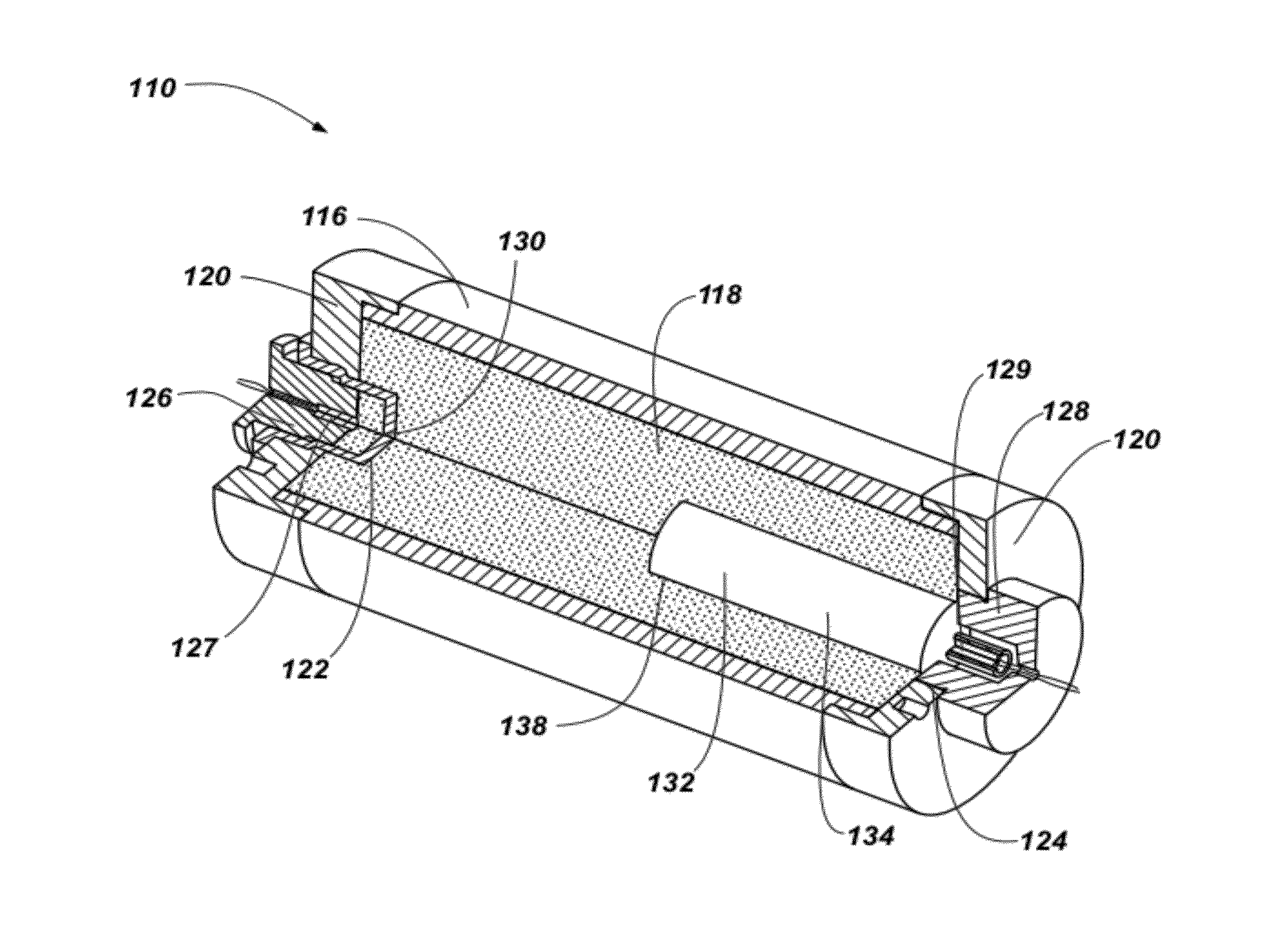

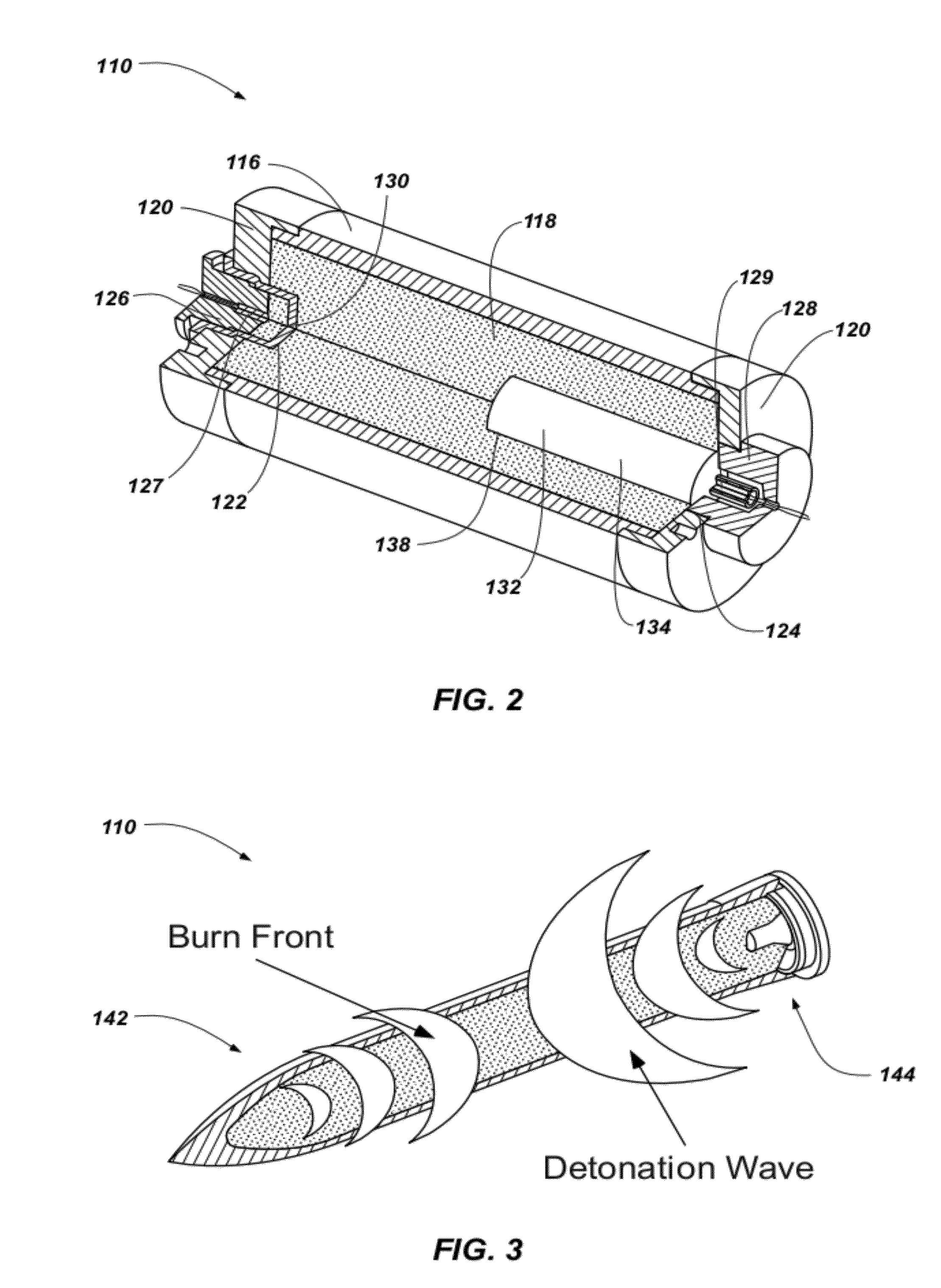

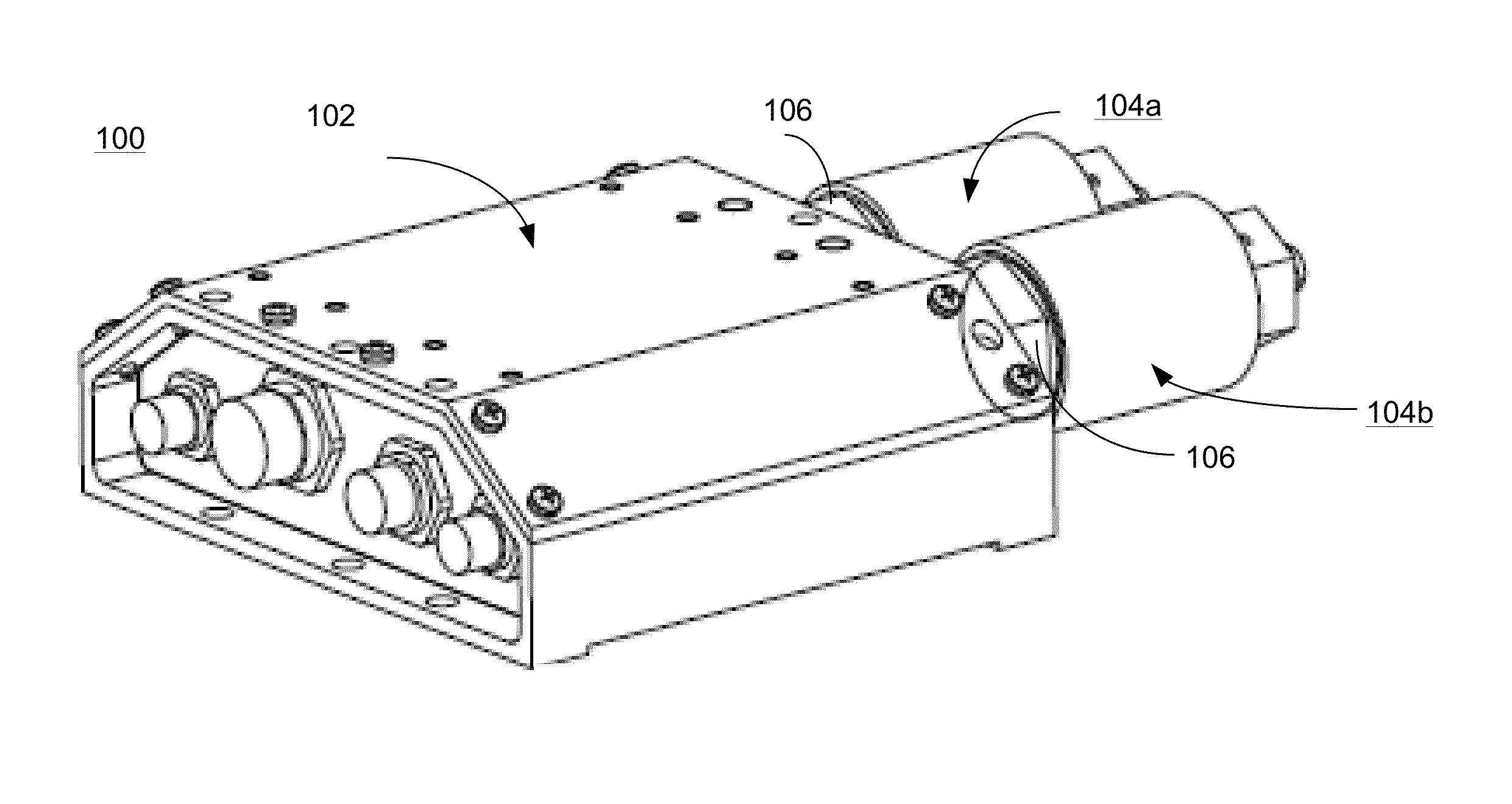

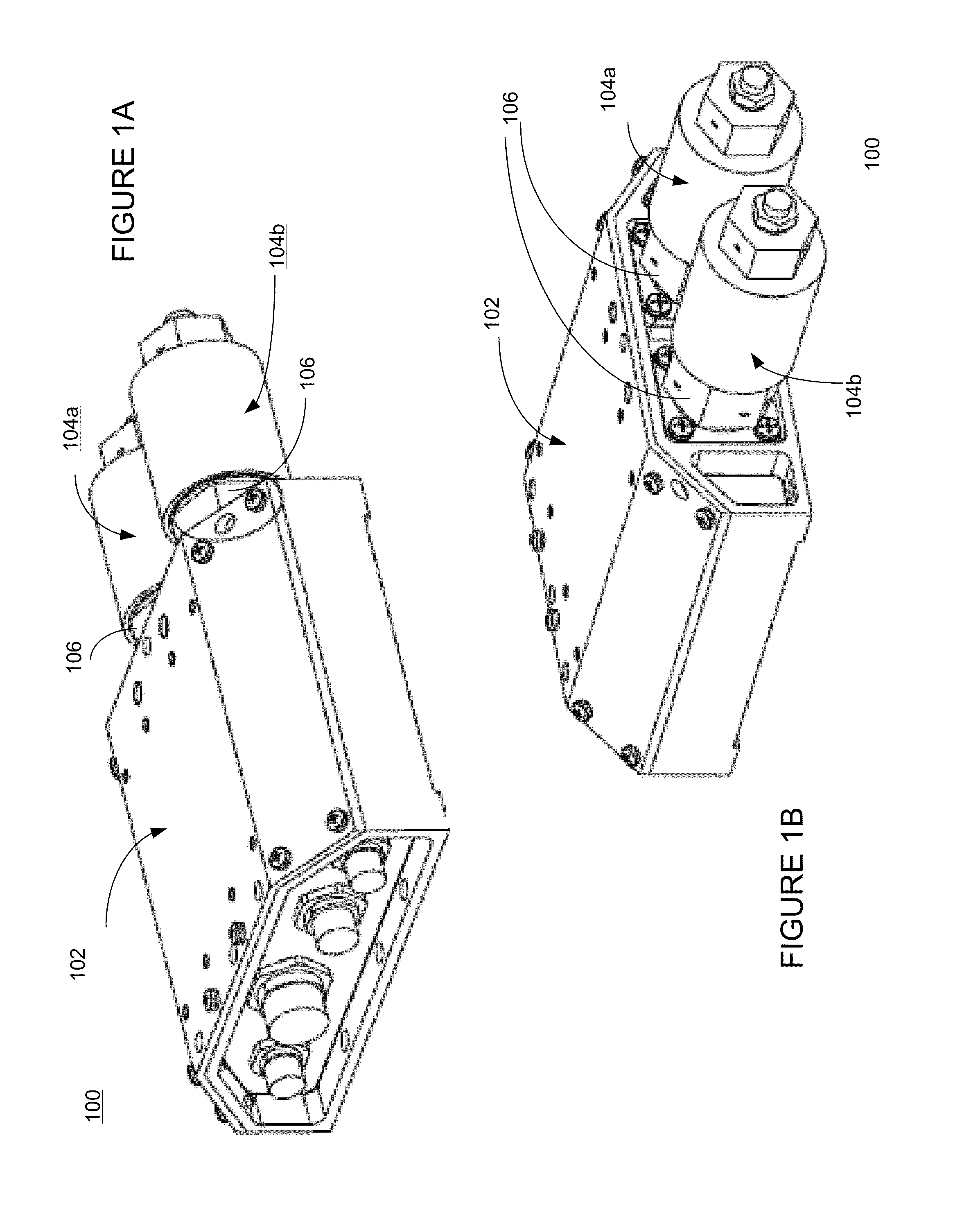

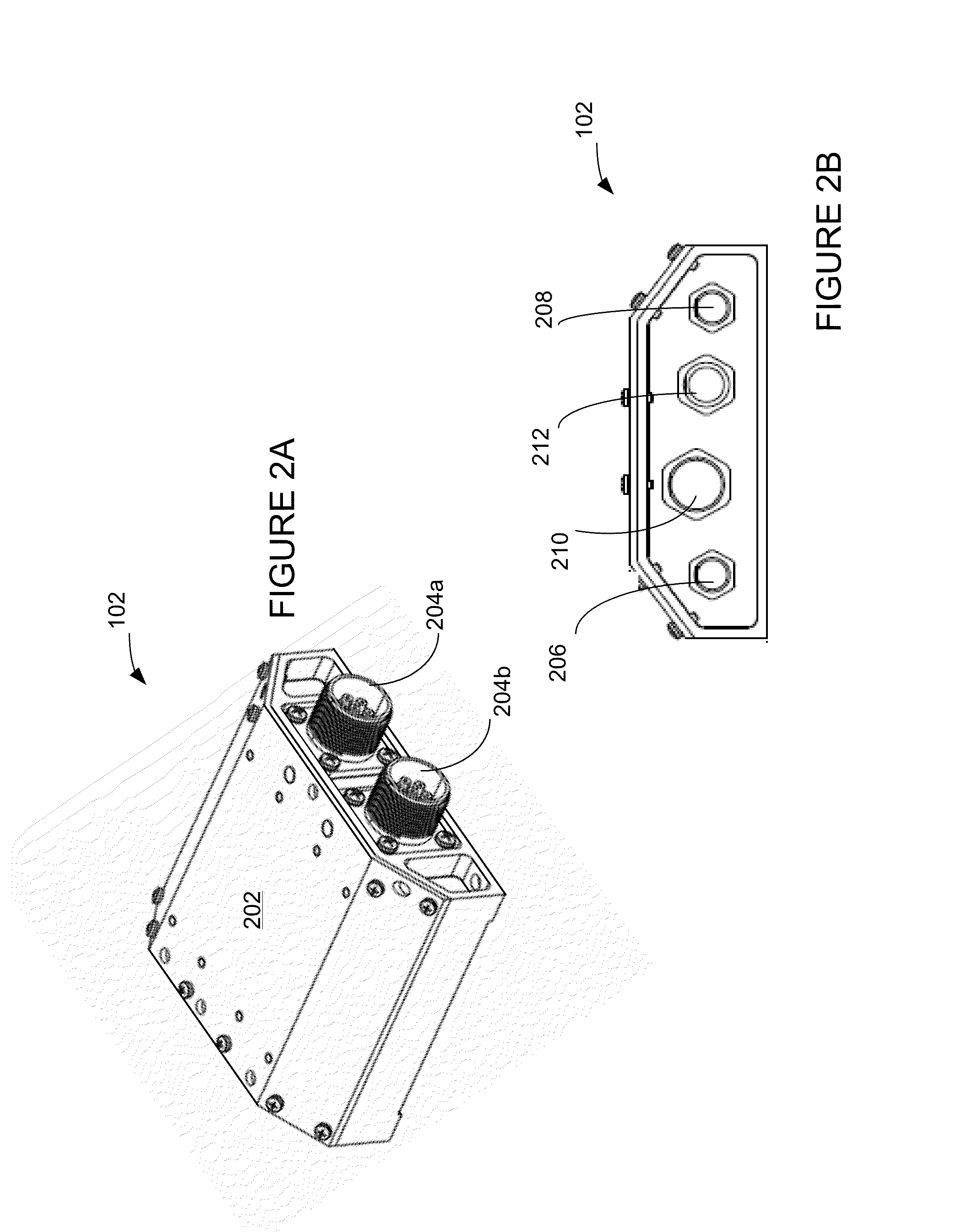

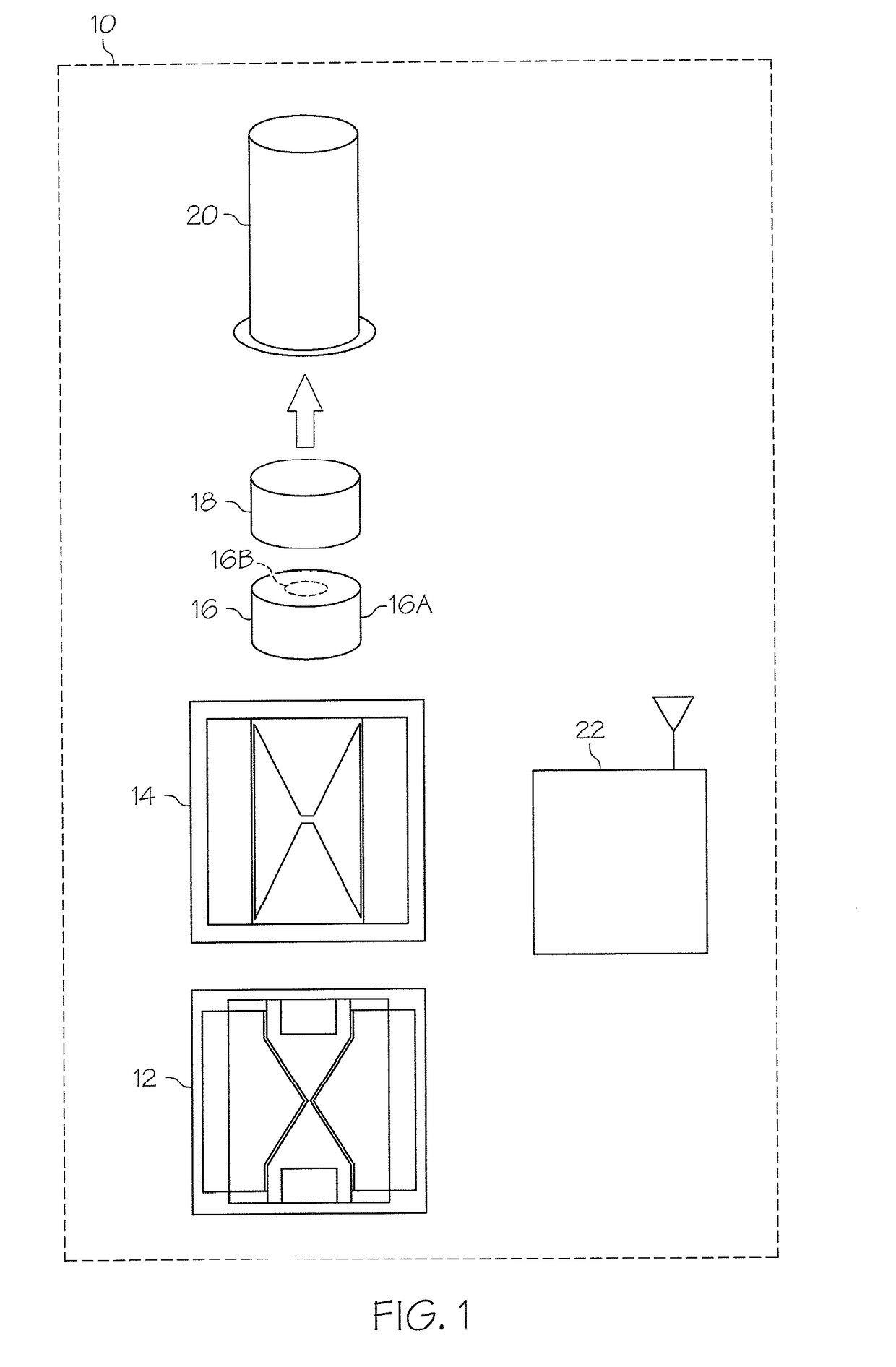

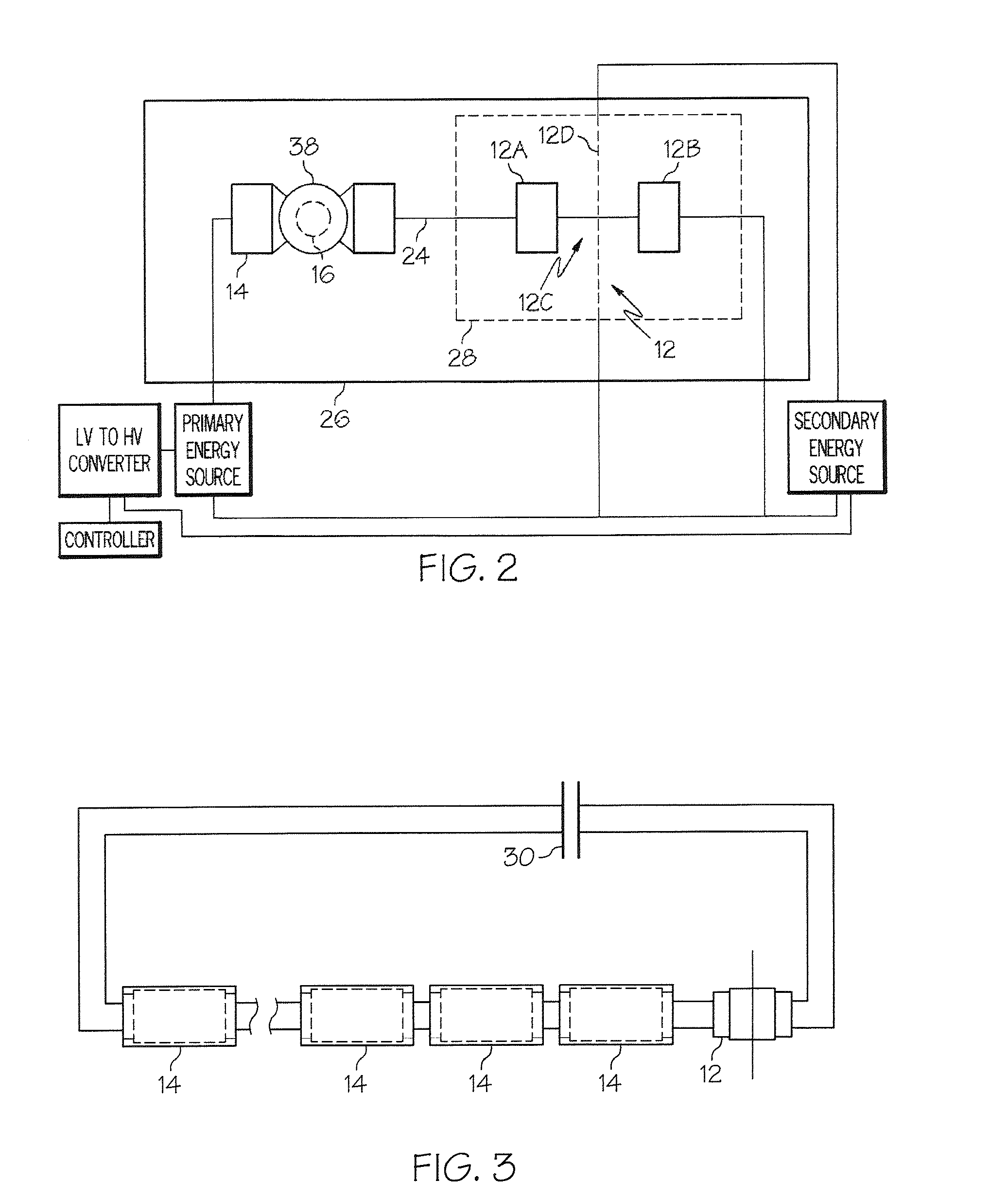

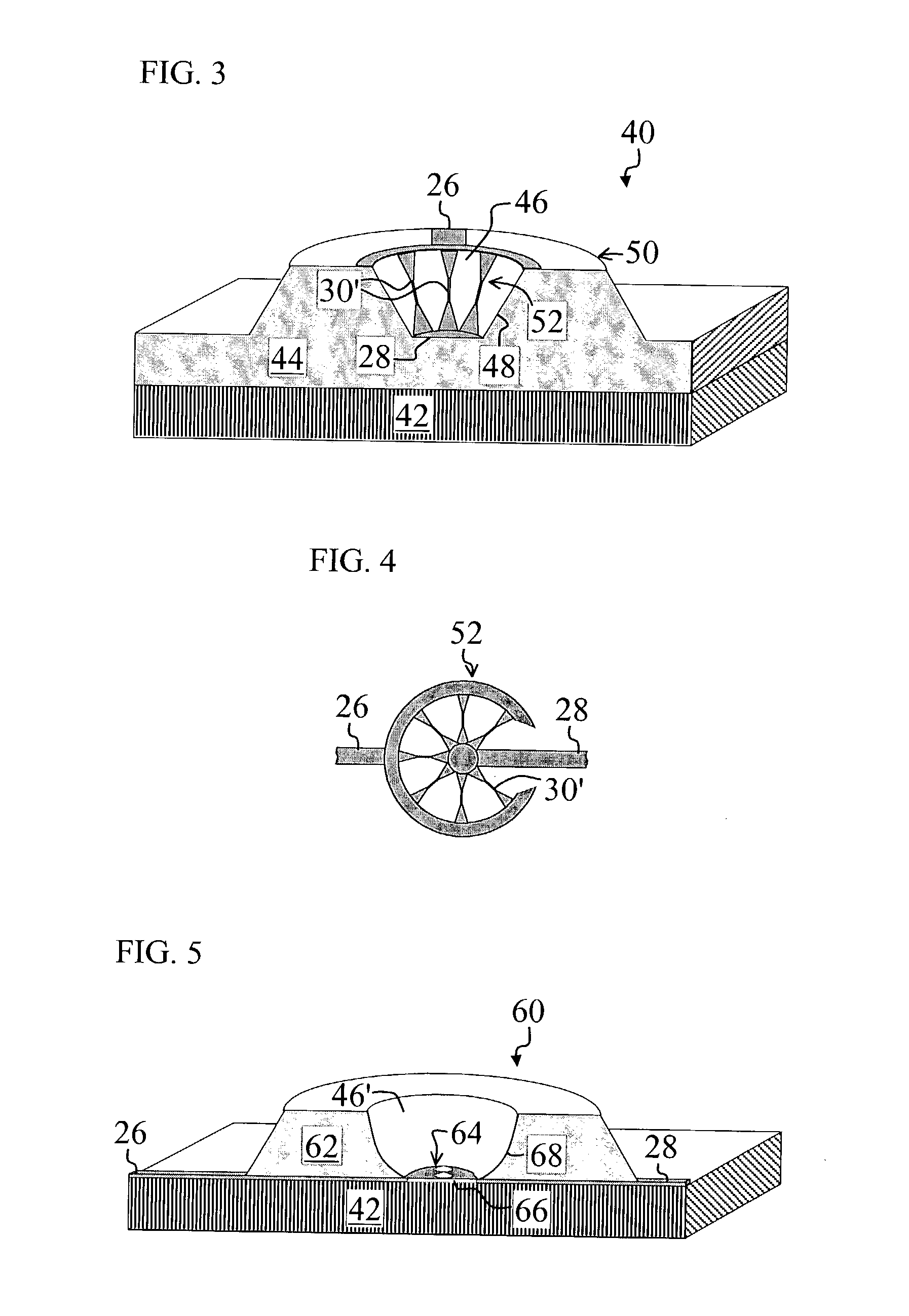

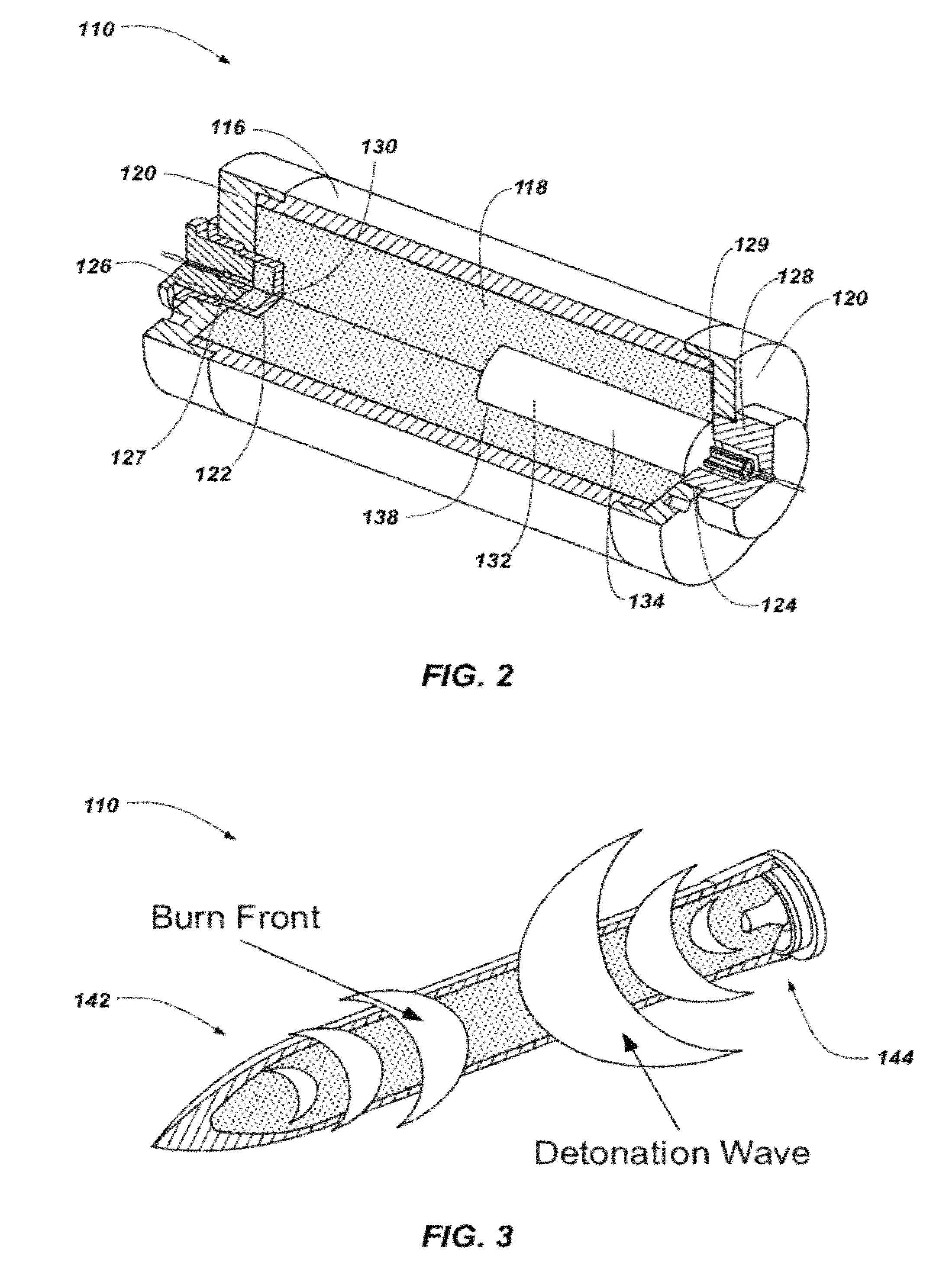

Initiation systems for explosive devices, scalable output explosive devices including initiation systems, and related methods

Initiator systems for warheads include a first initiation device configured to detonate at least a portion of an explosive material contained in an explosive device and a second initiation device configured to deflagrate at least a portion of an explosive material of a warhead. Scalable output explosive devices include an explosive material at least partially disposed within a housing and an initiator system including a first initiation device configured to detonate at least a portion of the explosive material and a second initiation device configured to deflagrate at least another portion of the explosive material. Methods of igniting warheads include deflagrating a portion of an explosive material disposed within the warhead and detonating at least another portion of the explosive material disposed within the warhead.

Owner:NORTHROP GRUMMAN SYST CORP

Electronic safe/arm system and methods of use thereof

ActiveUS8573124B2Good adhesionLow impedance connectionCosmonautic vehiclesIncandescent ignitionDetonatorElectricity

Owner:NORTHROP GRUMMAN SYST CORP

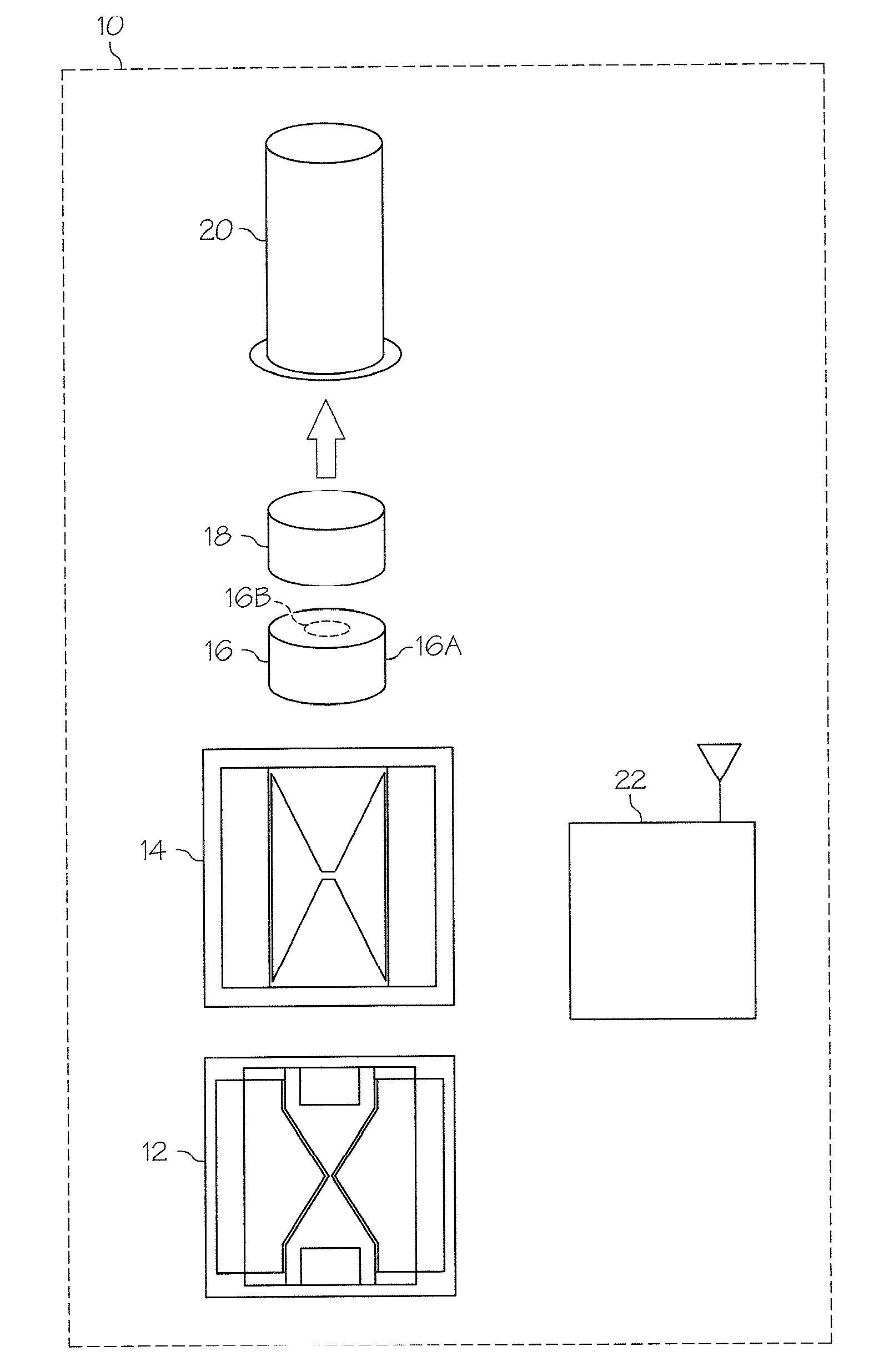

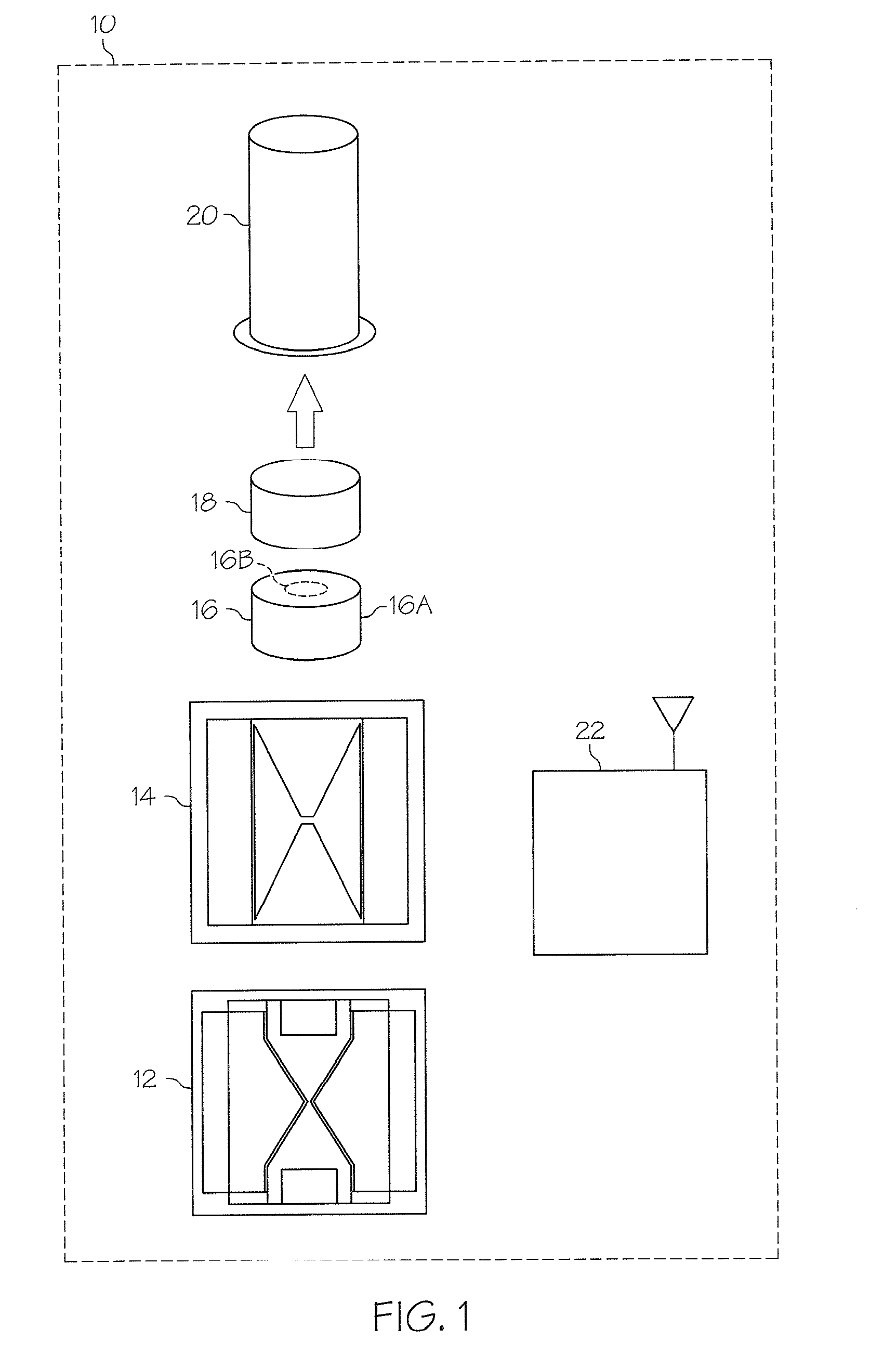

Electronic detonator system

A detonator includes a high voltage switch, an initiator and an initiating pellet. The detonator also includes a low voltage to high voltage firing set coupled to the switch and initiator such that the detonator includes a high voltage power source and initiator in an integrated package. The detonator may also include inductive powering and communications, a microprocessor, tracking and / or locating technologies, such as RFID, GPS, etc., and either a single or combination explosive output pellet. The combination explosive pellet has a first explosive having a first shock energy and a high brisance secondary explosive in the output pellet having a second shock energy greater than the shock energy of the first explosive. Systems are also provided for facilitating fast and easy deployment of one or more detonators in the field.

Owner:BATTELLE MEMORIAL INST

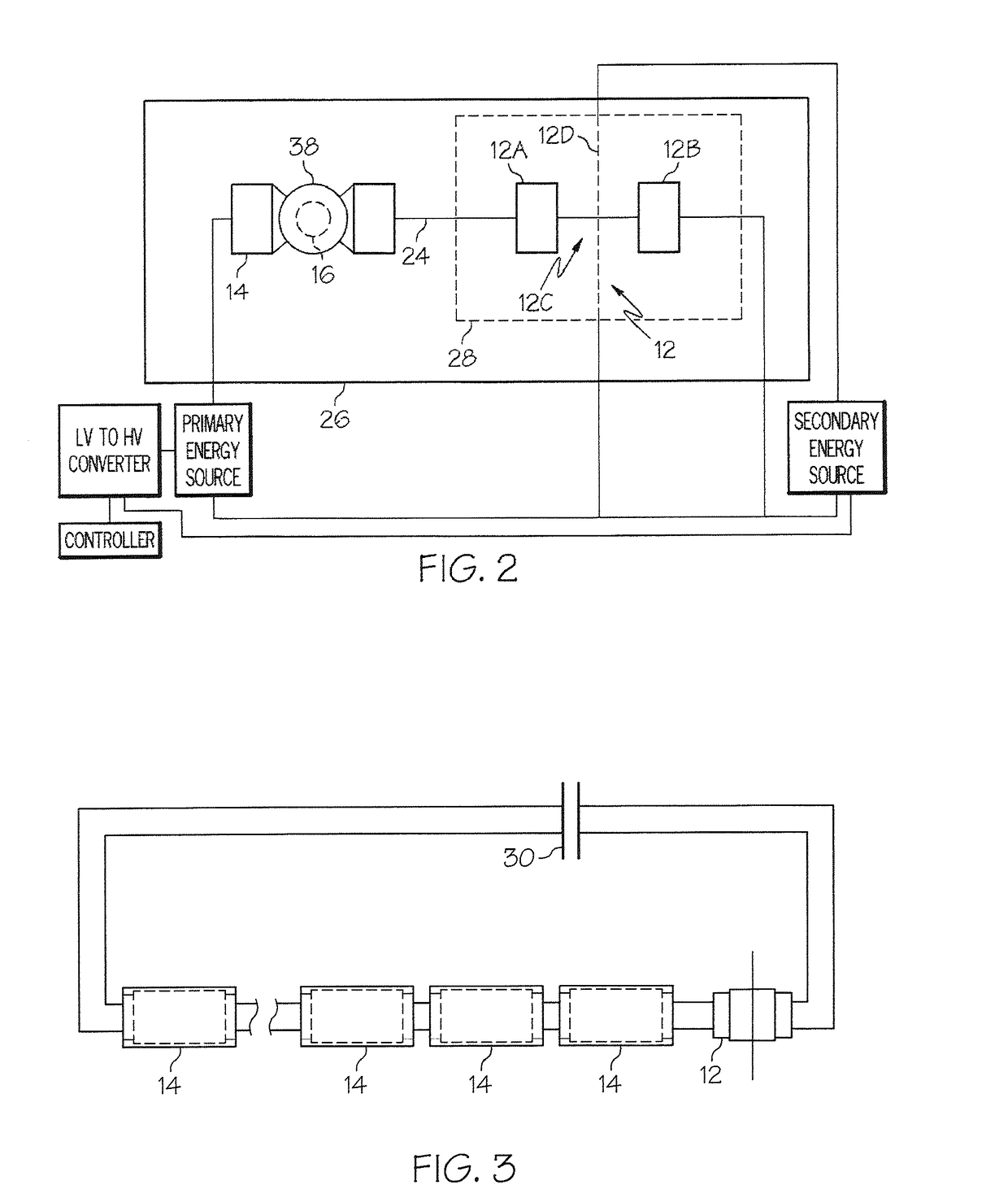

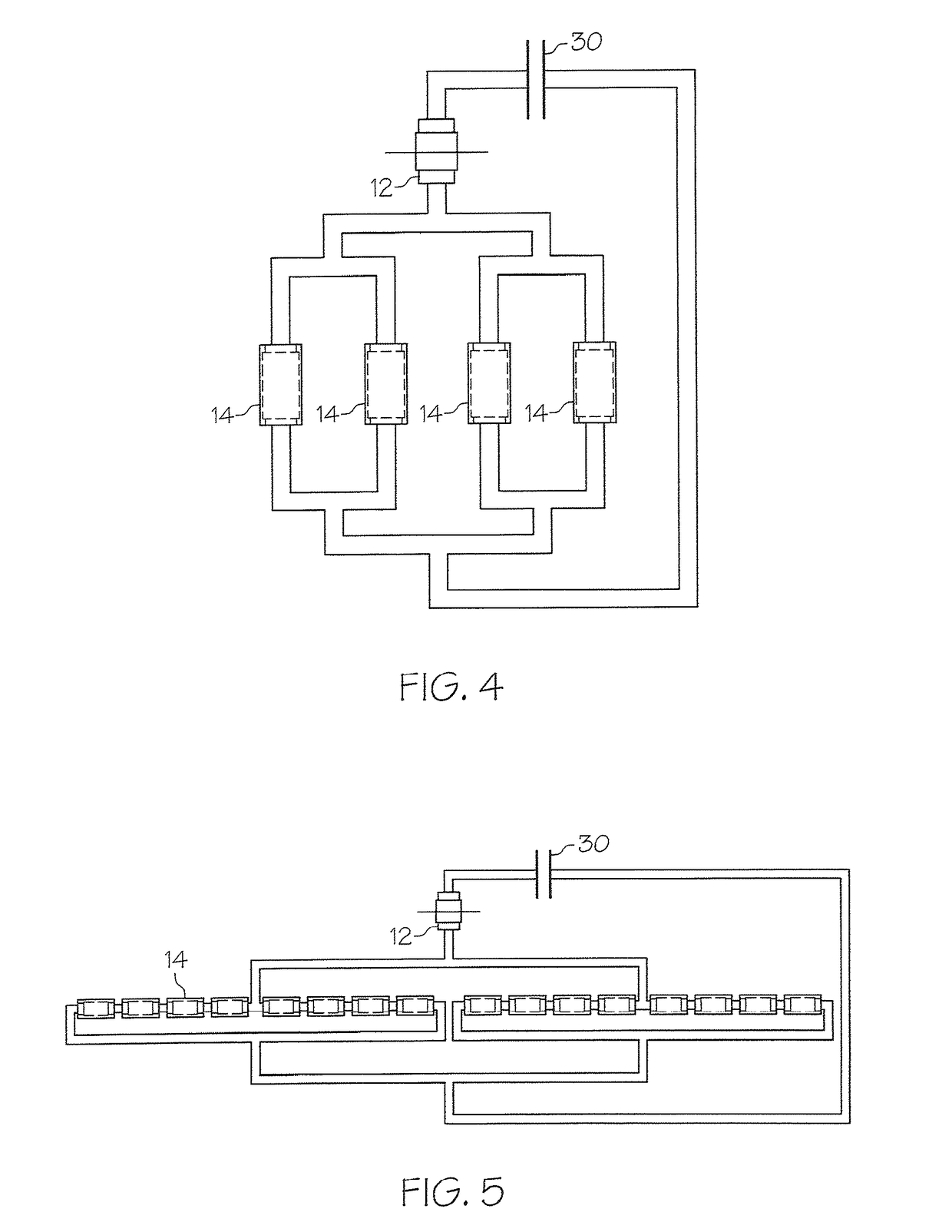

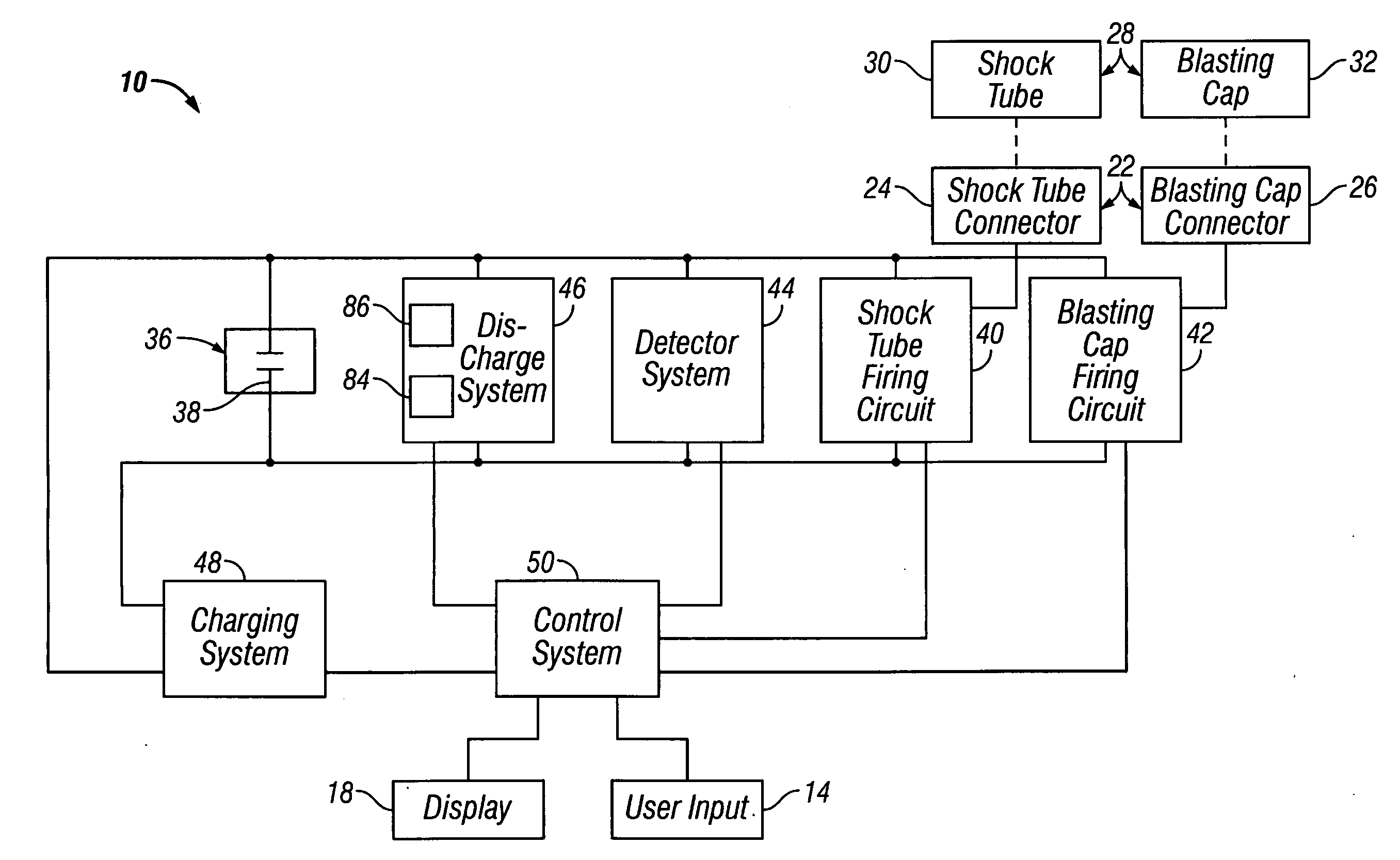

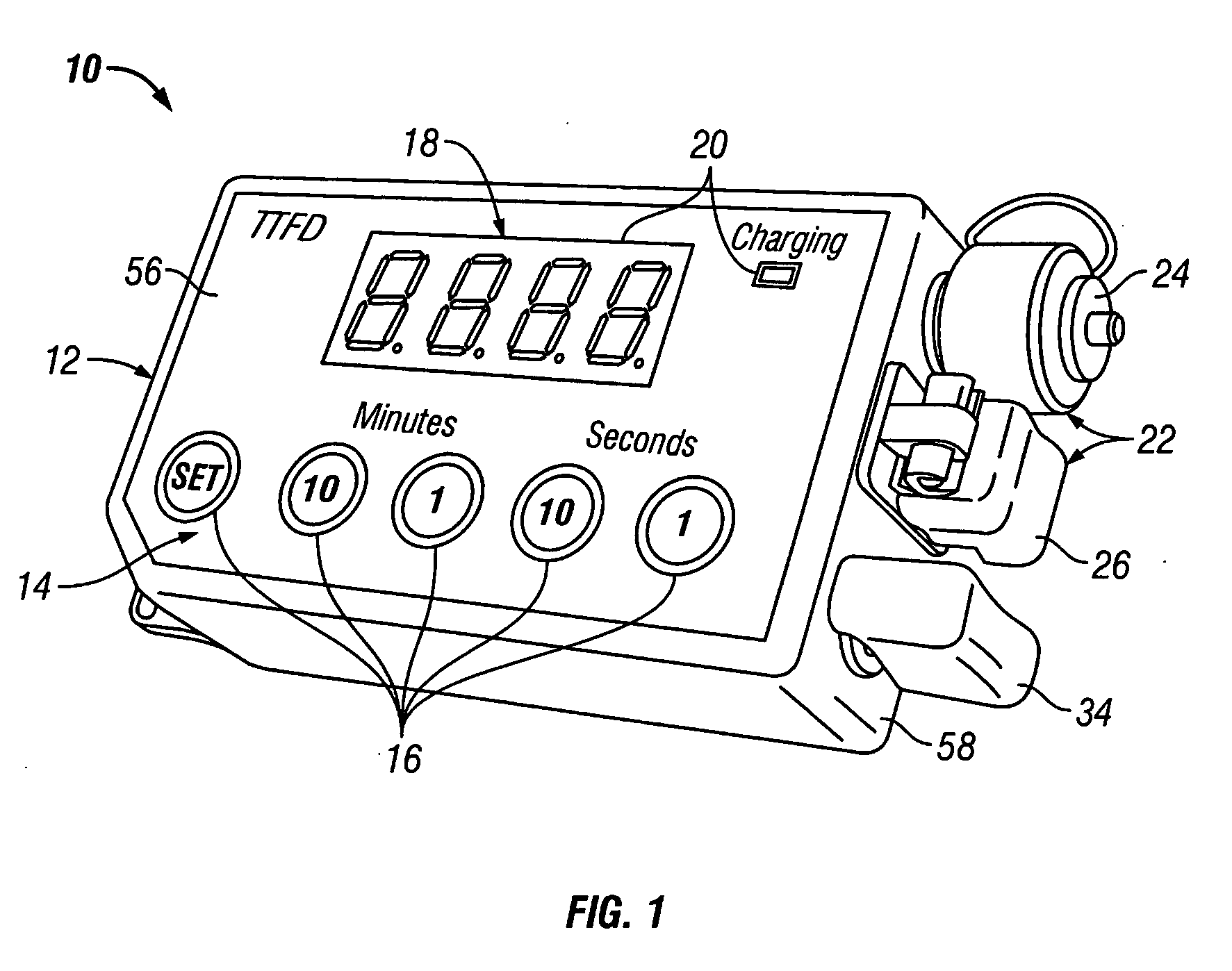

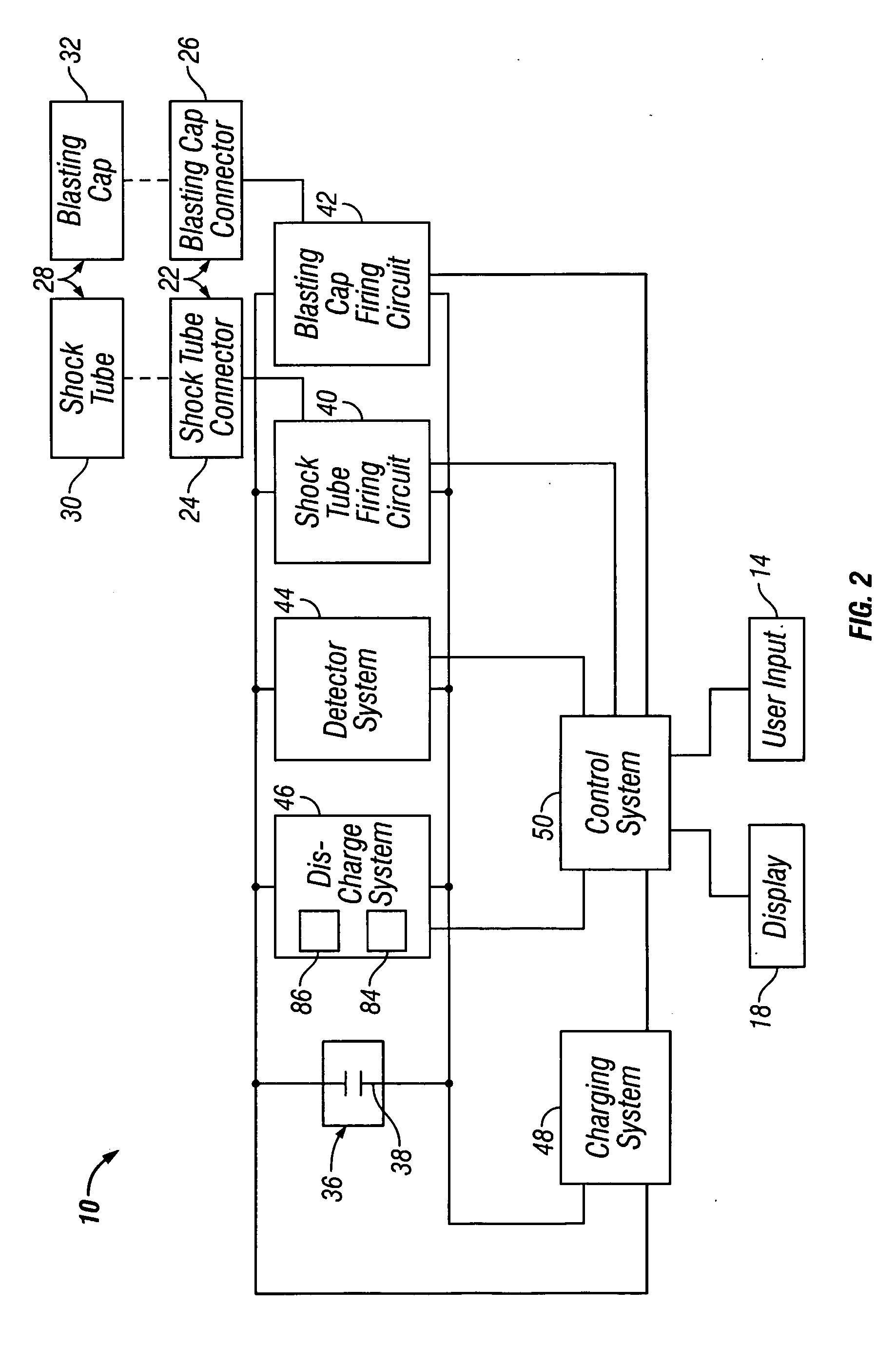

Electronic firing systems and methods for firing a device

InactiveUS20070125256A1Fuse ignition meansFuse connectorsEngineeringElectrical and Electronics engineering

An electronic firing system may include a first firing circuit and a second firing circuit. A detection system operatively associated with the first and second firing circuits detects whether a device to be fired is connected one of the first and second firing circuits. The electronic firing system actuates either of said first and second firing circuits to which is connected the device to be fired.

Owner:BATTELLE ENERGY ALLIANCE LLC

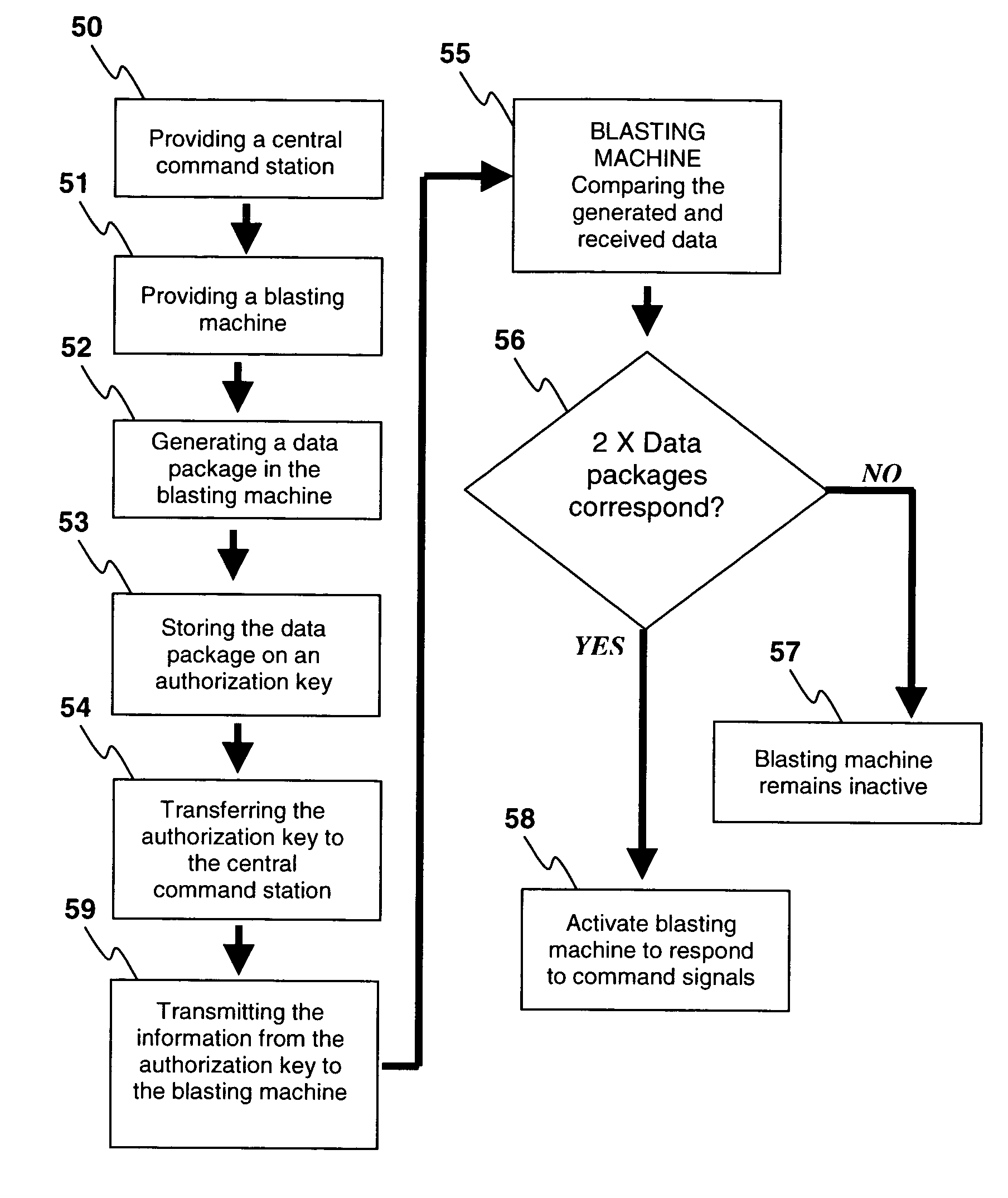

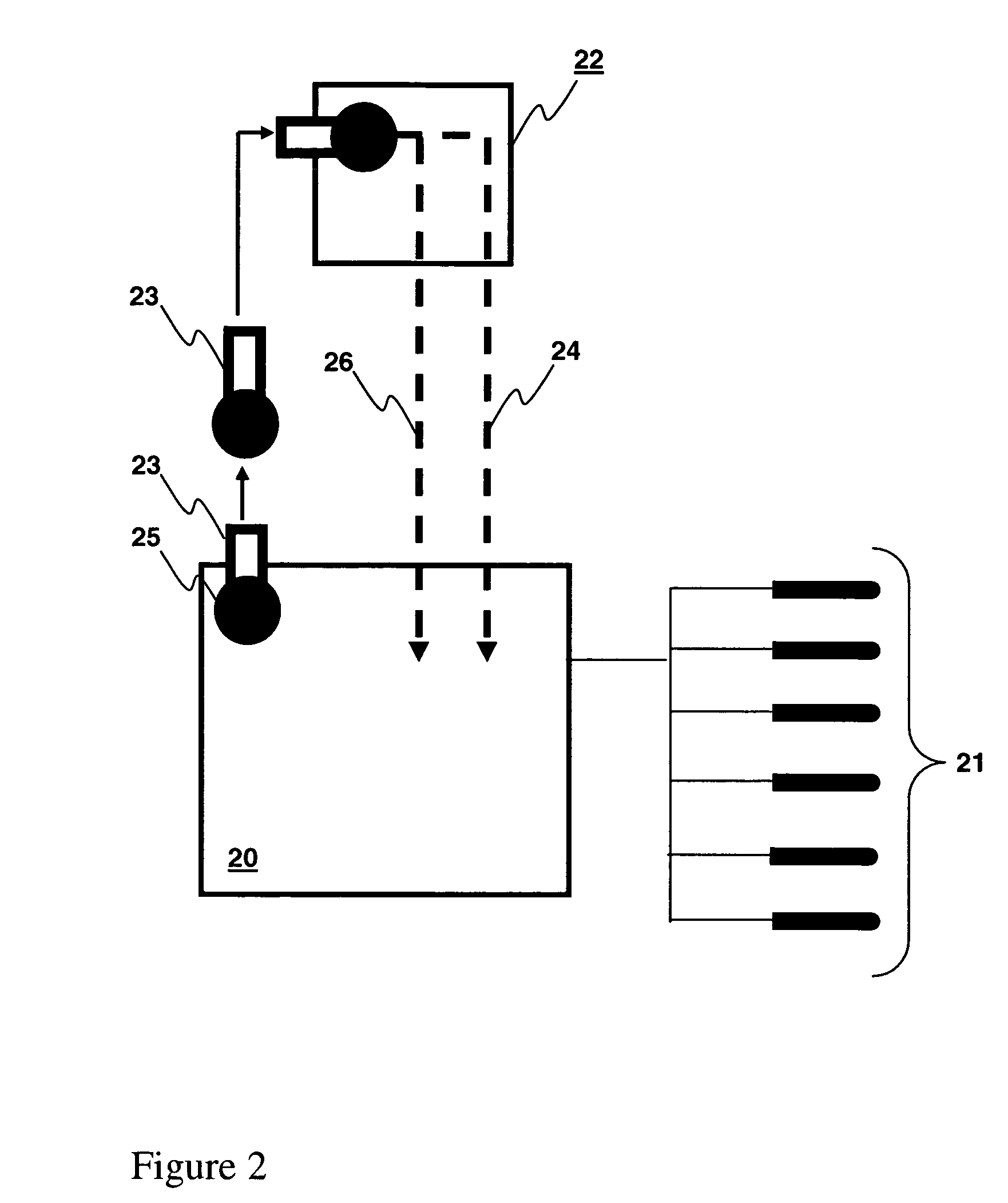

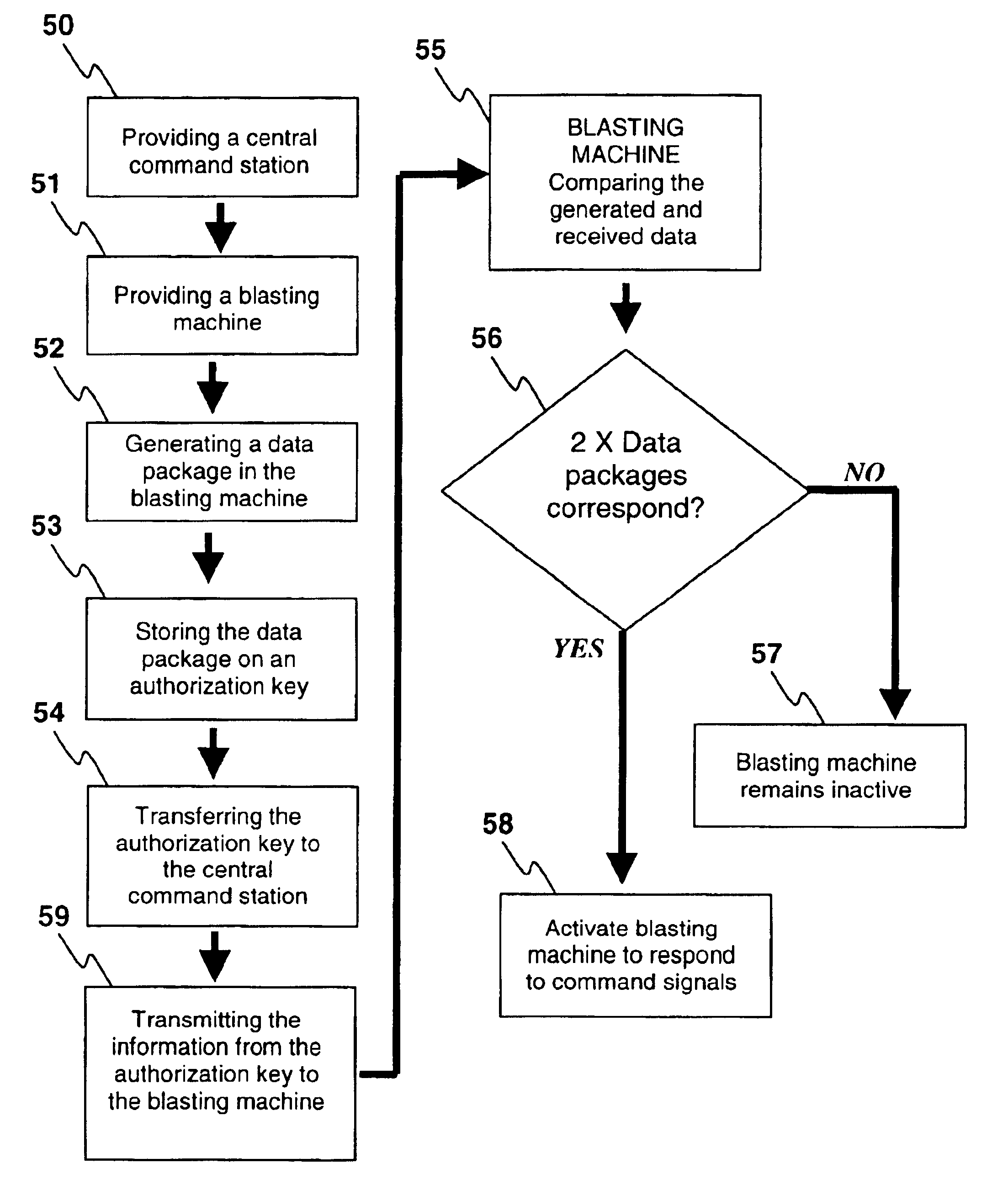

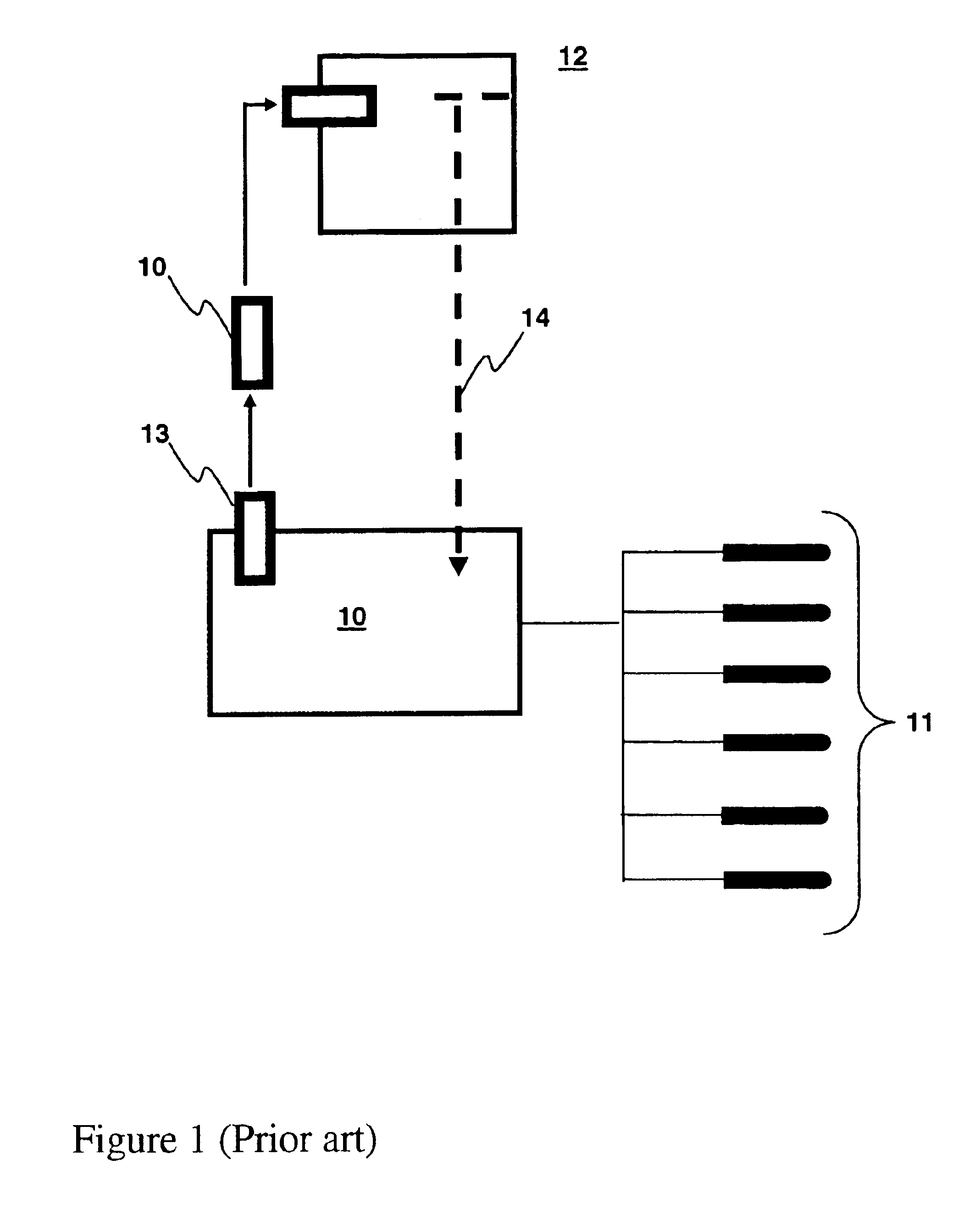

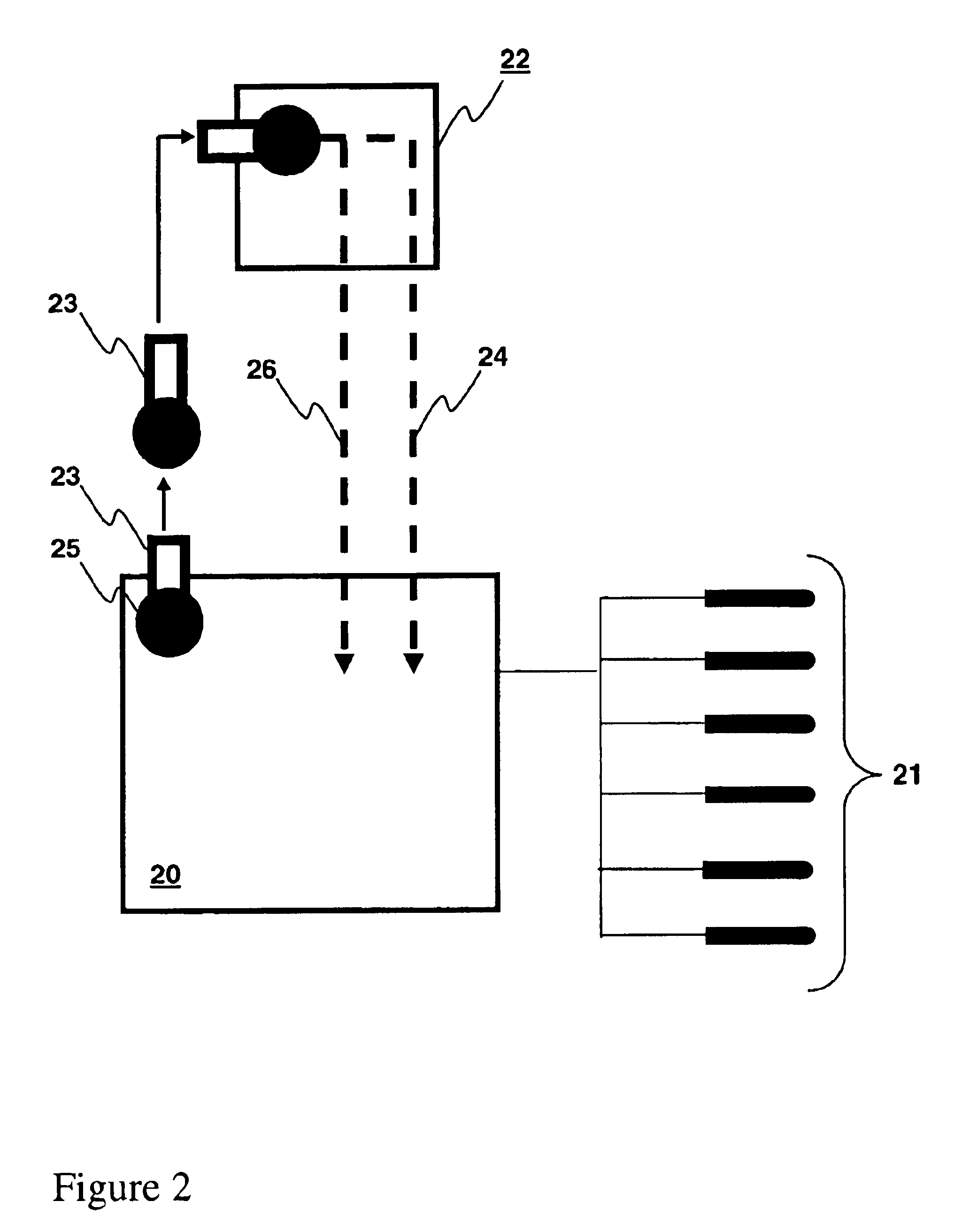

Access control for electronic blasting machines

Blasting apparatuses and methods control actuation of a plurality of detonators, and involve the use of one or more authorization keys each associated with a blasting machine. The authorization key(s) are transferable from the blasting machine(s) to a central command station, each authorization key storing a data package comprising a randomly generated access code generated by its corresponding blasting machine. Transfer of the one or more authorization keys to a central command station allows the data packages (and associated randomly generated access codes) to be transmitted by the central command station for receipt by the blasting machine(s).

Owner:ORICA EXPLOSIVES TECH PTY LTD

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

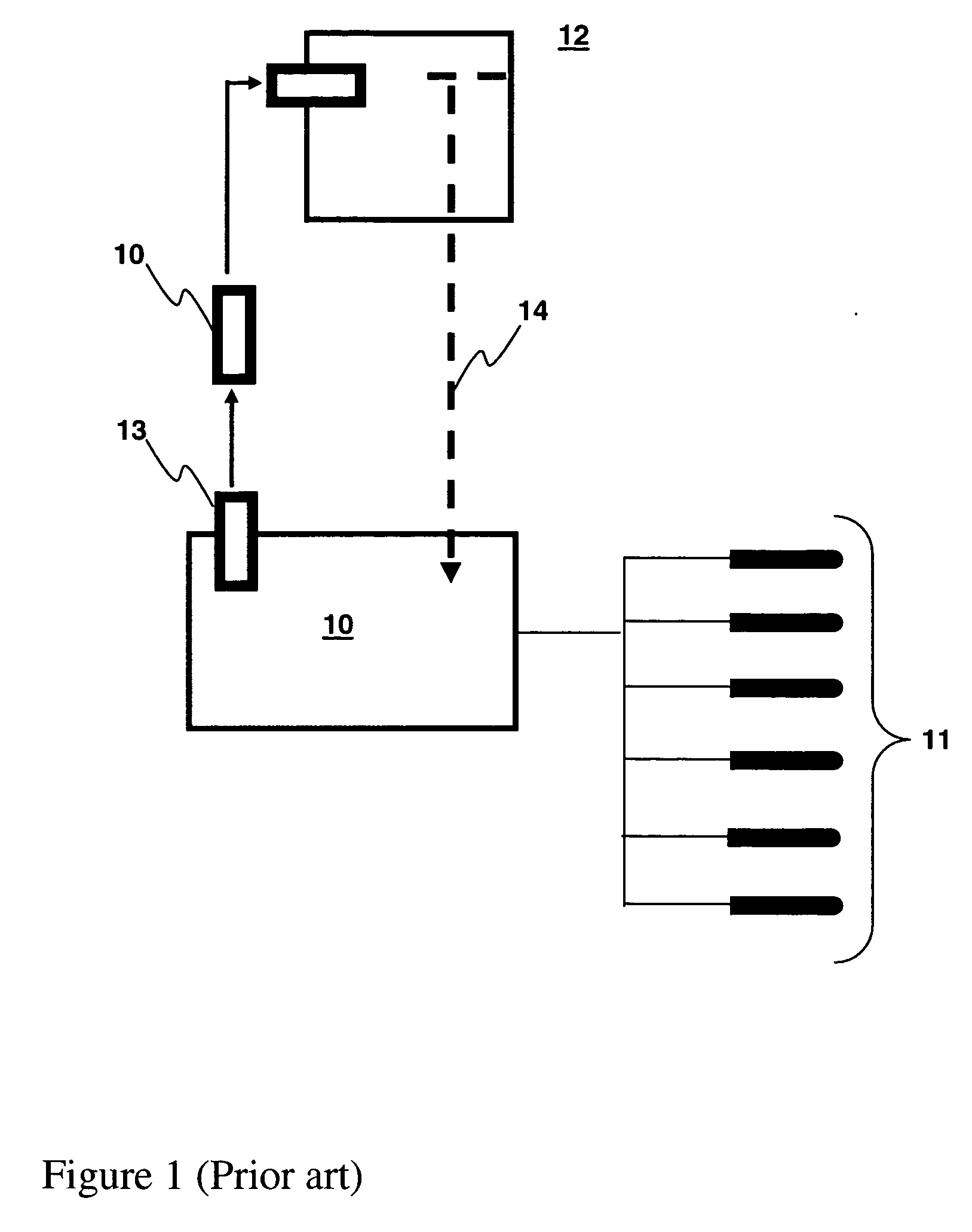

Access control for electronic blasting machines

InactiveUS6851369B2Improve securityIncandescent ignitionBlasting cartridgesDetonatorComputer hardware

Blasting apparatuses and methods control actuation of a plurality of detonators, and involve the use of one or more authorization keys each associated with a blasting machine. The authorization key(s) are transferable from the blasting machine(s) to a central command station, each authorization key storing a data package comprising a randomly generated access code generated by its corresponding blasting machine. Transfer of the one or more authorization keys to a central command station allows the data packages (and associated randomly generated access codes) to be transmitted by the central command station for receipt by the blasting machine(s).

Owner:ORICA EXPLOSIVES TECH PTY LTD

Connector for perforating gun tandem

Owner:BAKER HUGHES INC

Electronic detonator system

A detonator includes a high voltage switch, an initiator and an initiating pellet. The detonator also includes a low voltage to high voltage firing set coupled to the switch and initiator such that the detonator includes a high voltage power source and initiator in an integrated package. The detonator may also include inductive powering and communications, a microprocessor, tracking and / or locating technologies, such as RFID, GPS, etc., and either a single or combination explosive output pellet. The combination explosive pellet has a first explosive having a first shock energy and a high brisance secondary explosive in the output pellet having a second shock energy greater than the shock energy of the first explosive. Systems are also provided for facilitating fast and easy deployment of one or more detonators in the field.

Owner:BATTELLE MEMORIAL INST

Multifunctional breaching apparatus

InactiveUS7000545B2Improve explosive powerEfficient detonationExplosive chargesBlasting cartridgesEngineeringExplosive force

Breaching apparatus including a housing constructed of a material that disintegrates upon explosion without significant amounts of fragments being given off, and an explosive element disposed in the housing capable of producing an explosive force sufficient for breaching a structure.

Owner:SANSOLO ARIE

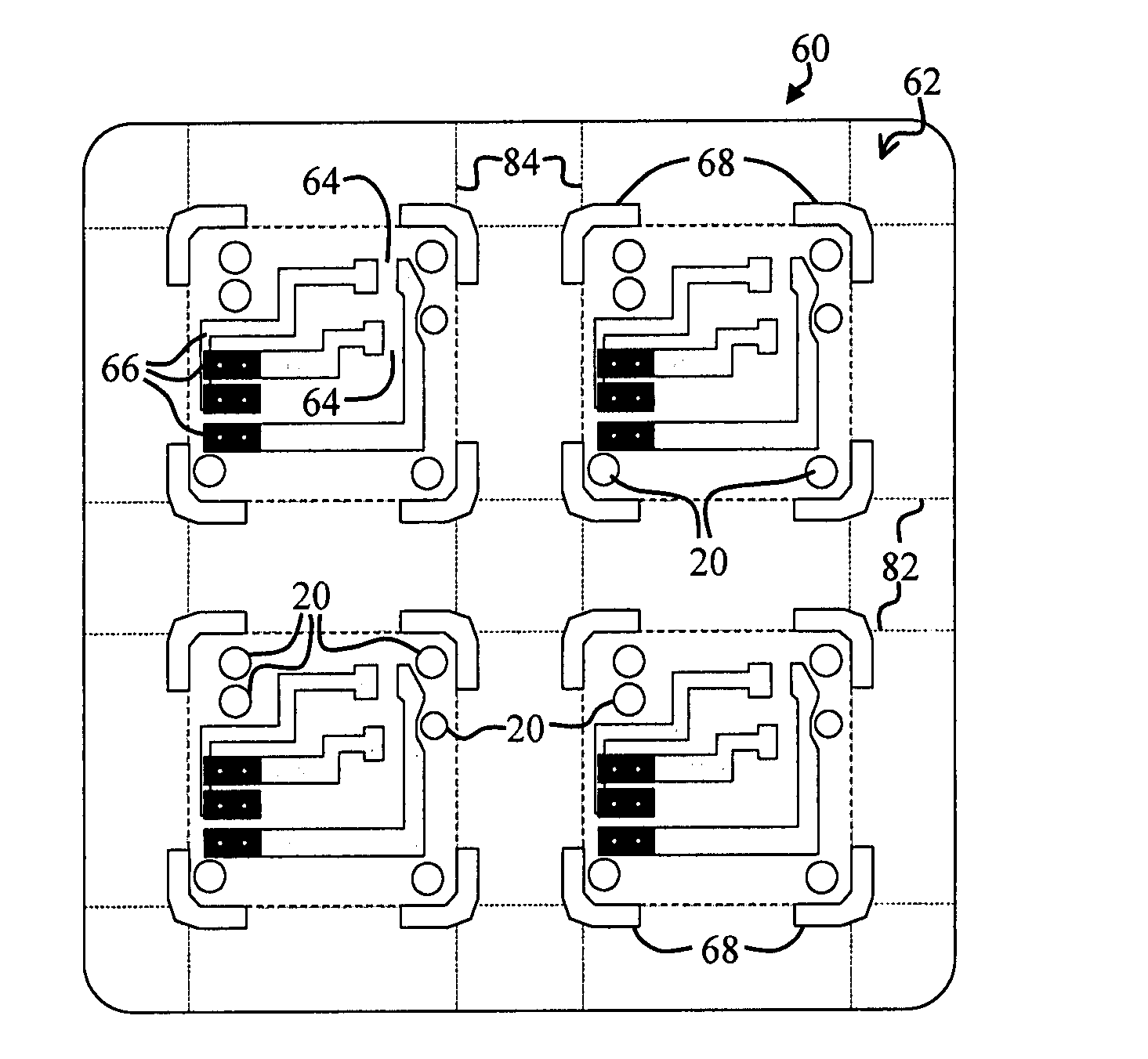

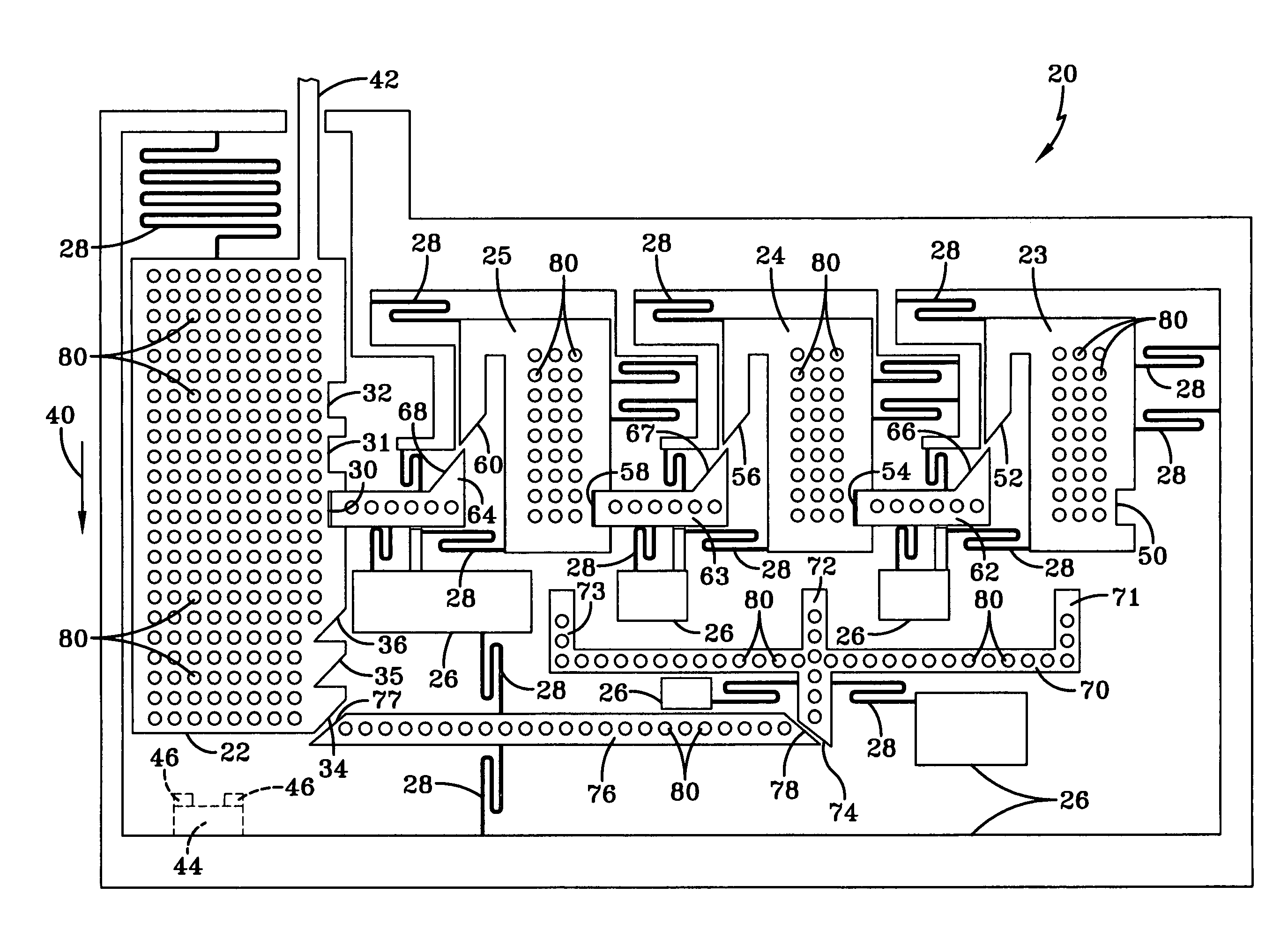

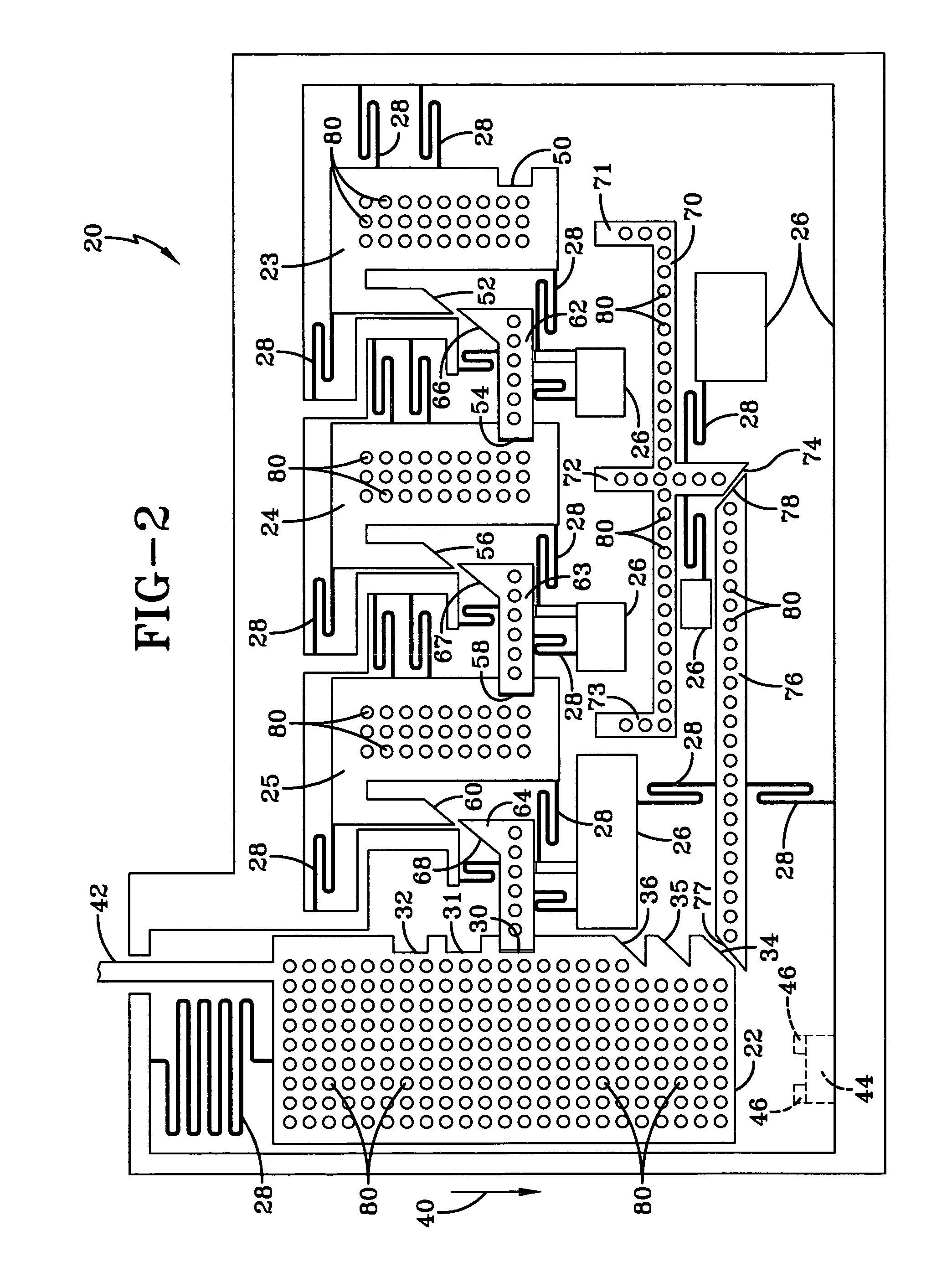

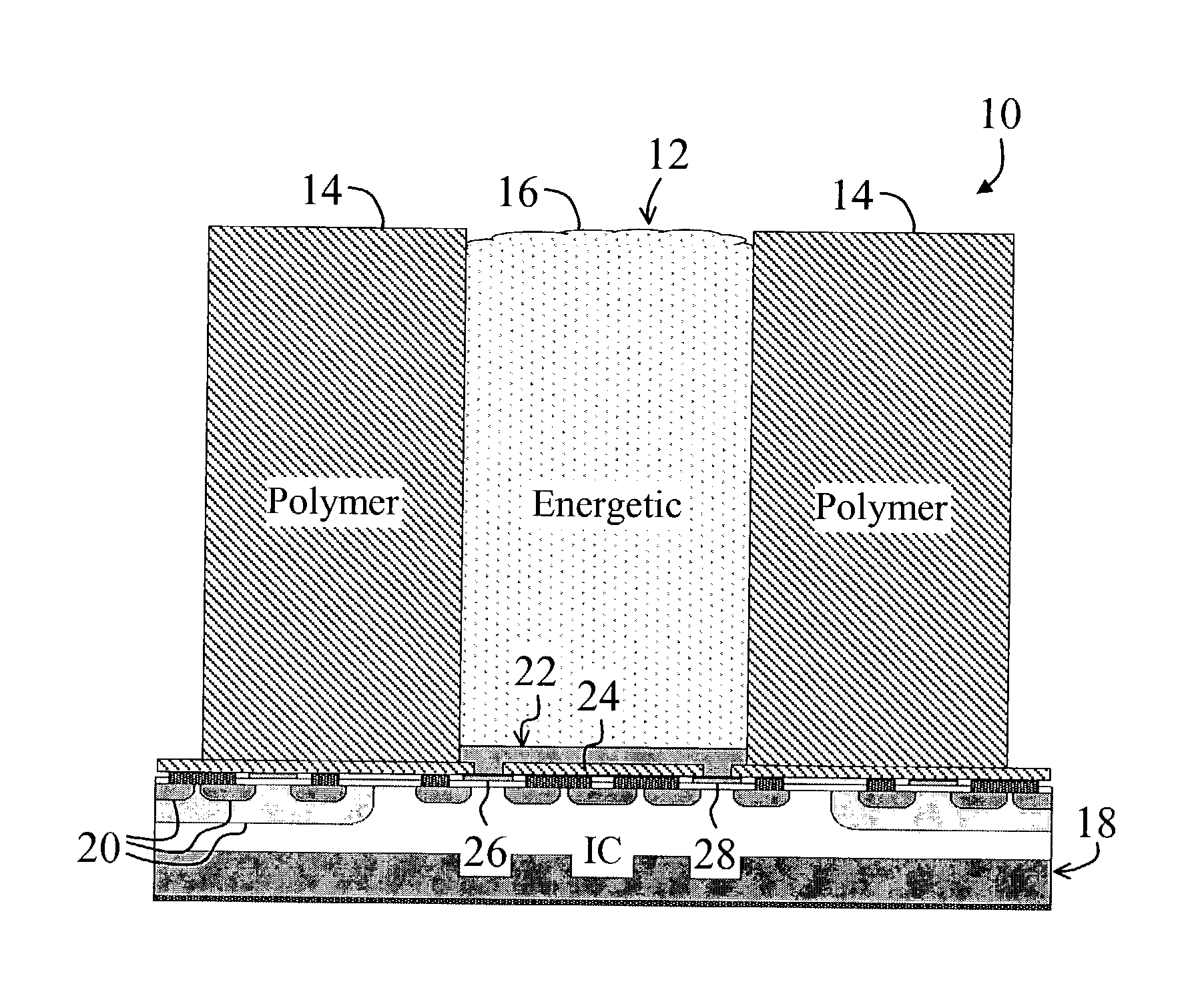

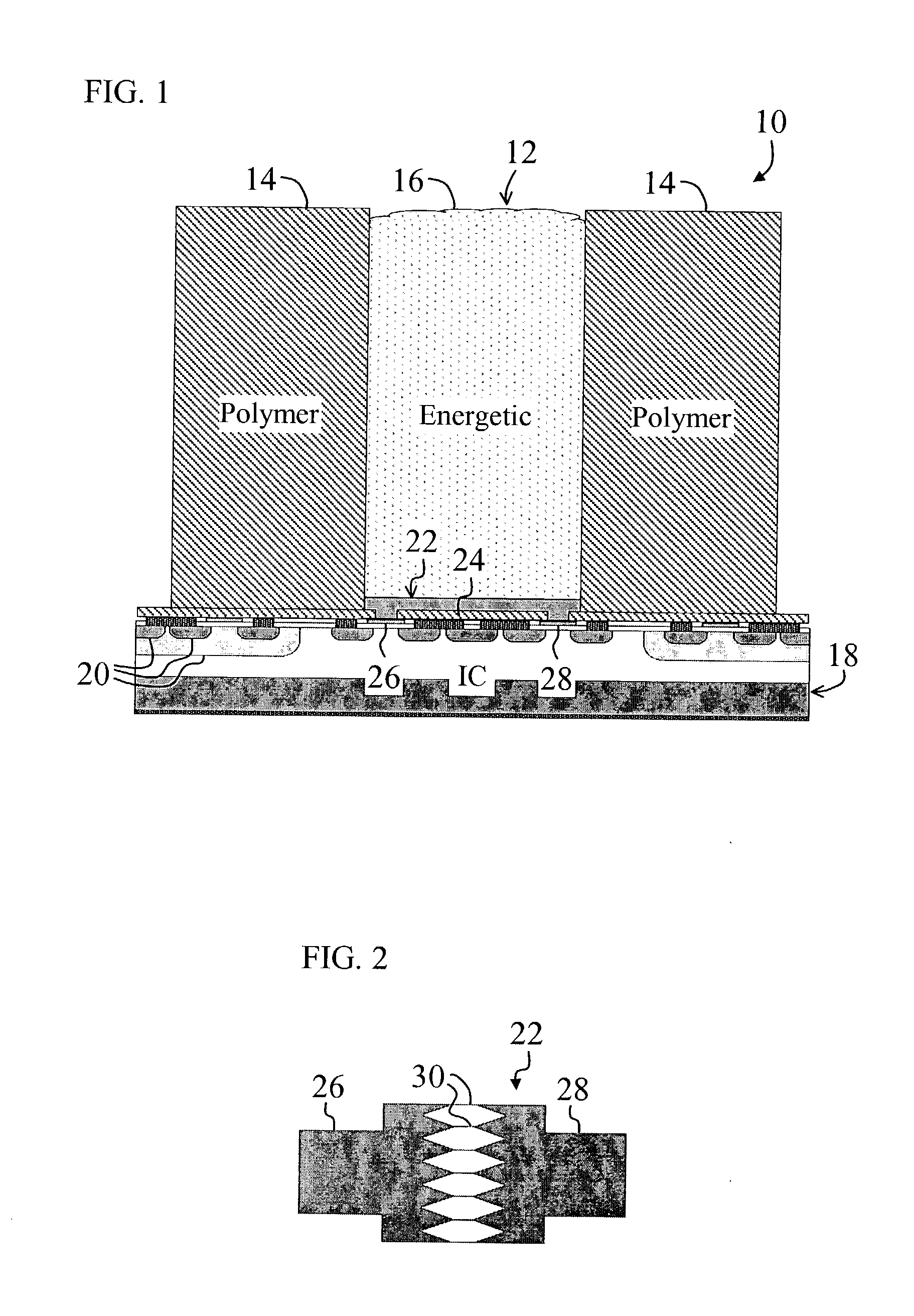

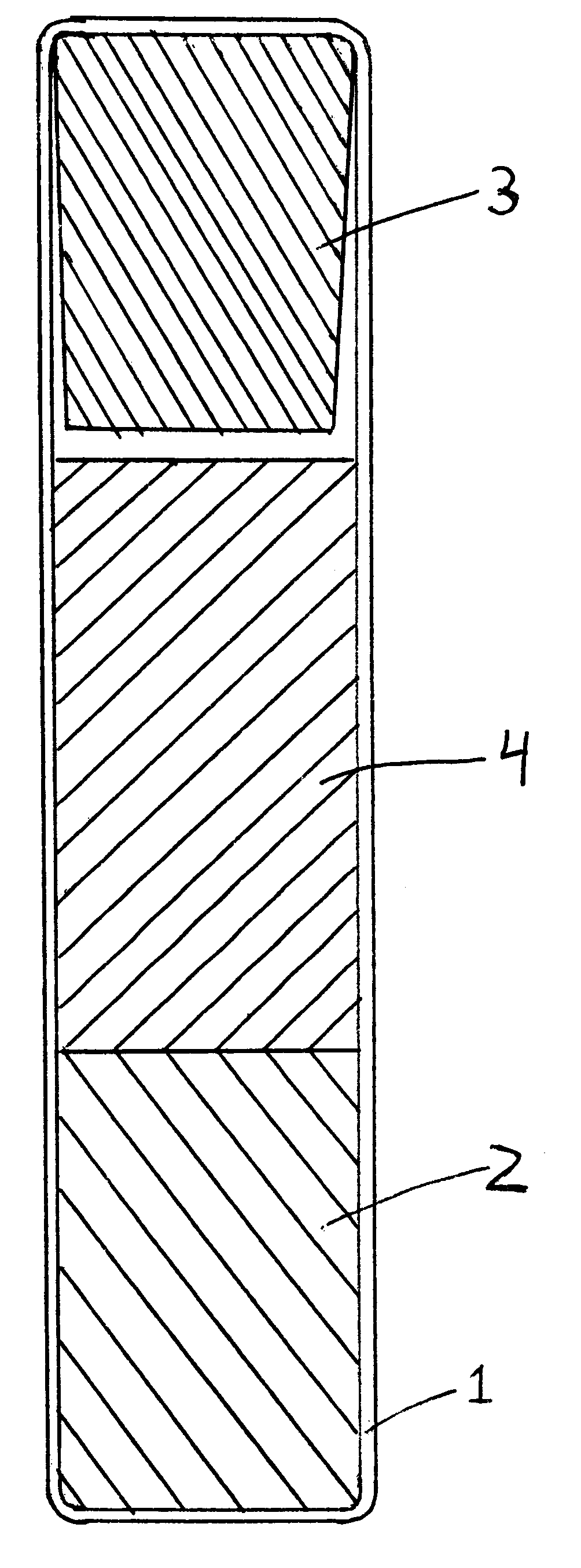

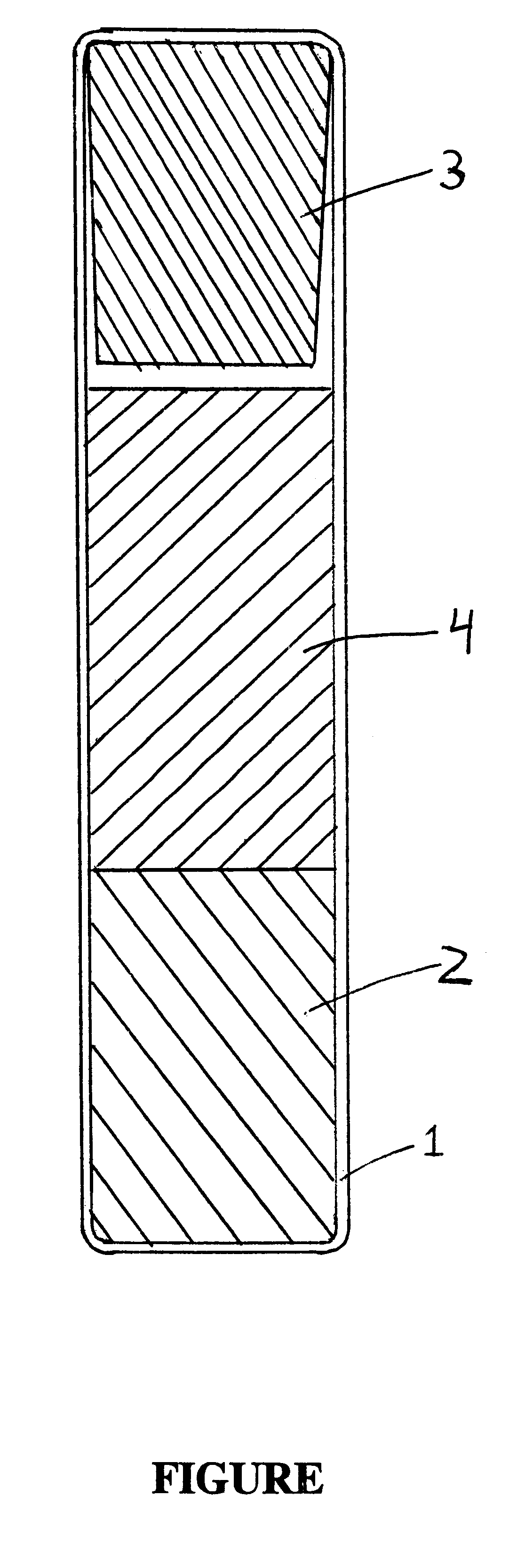

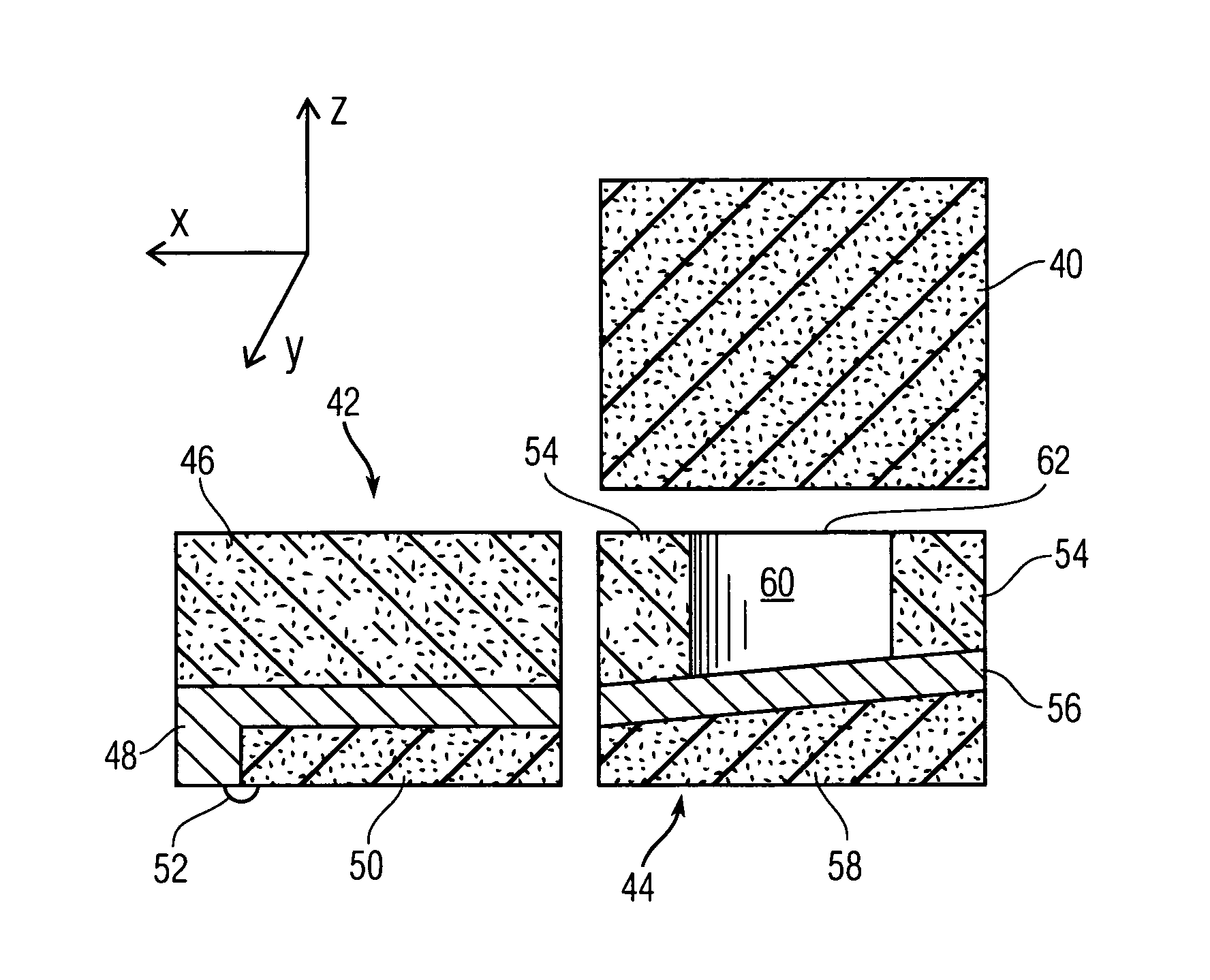

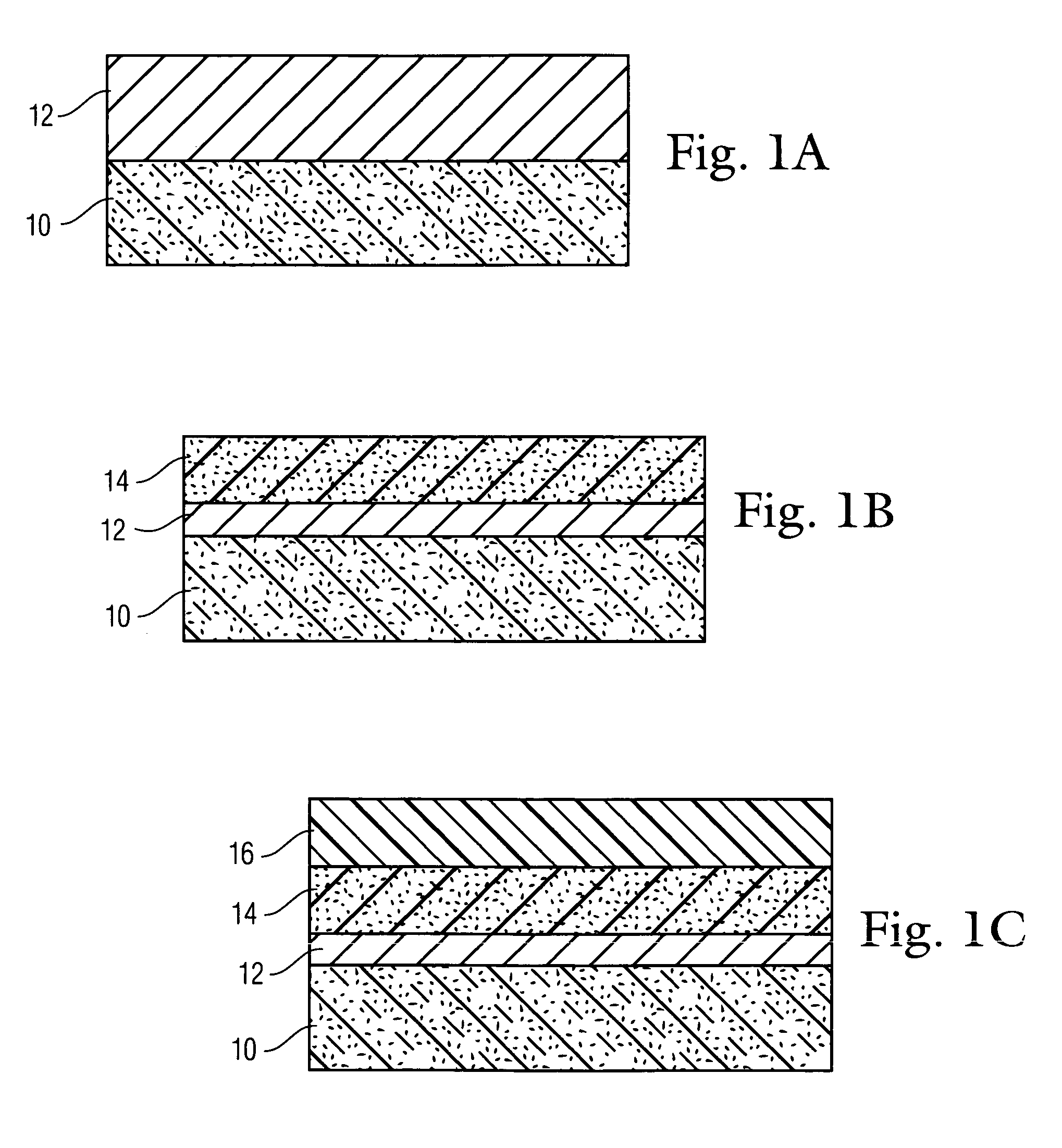

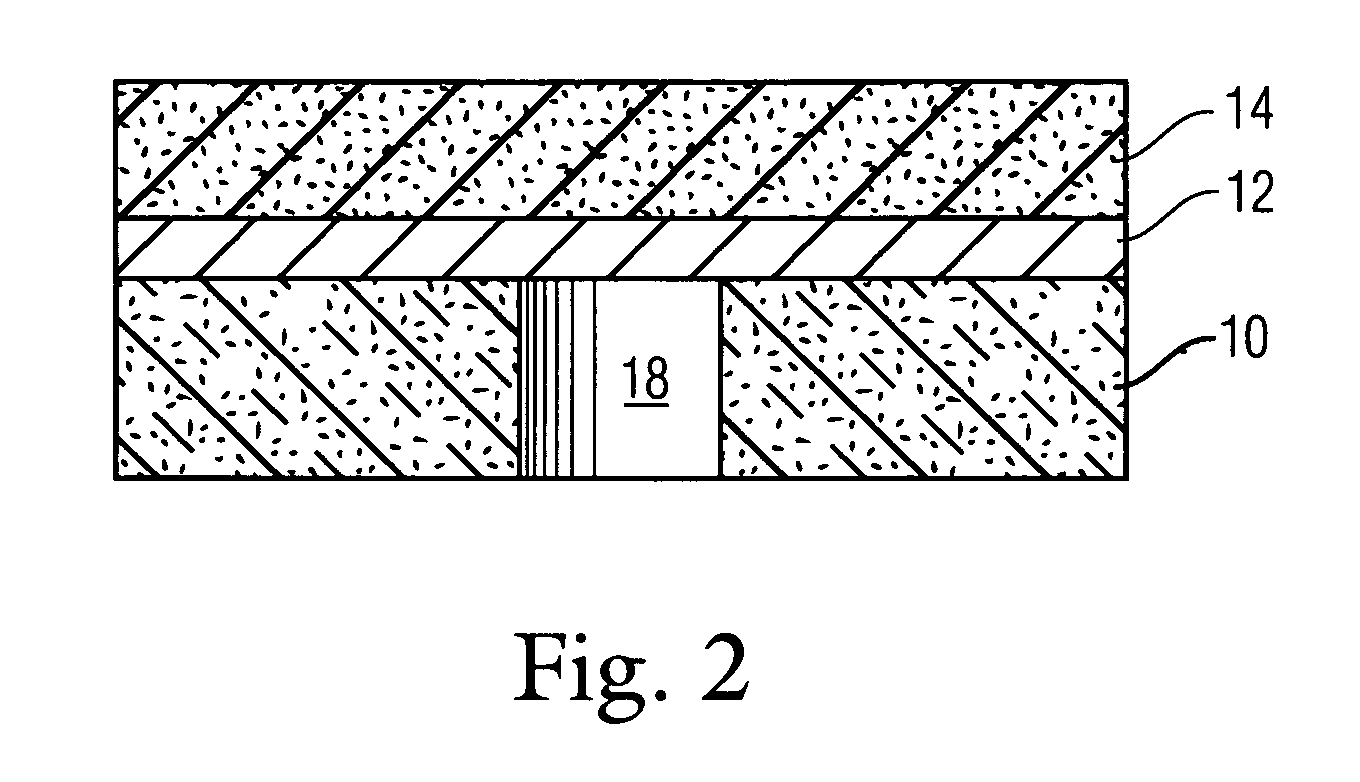

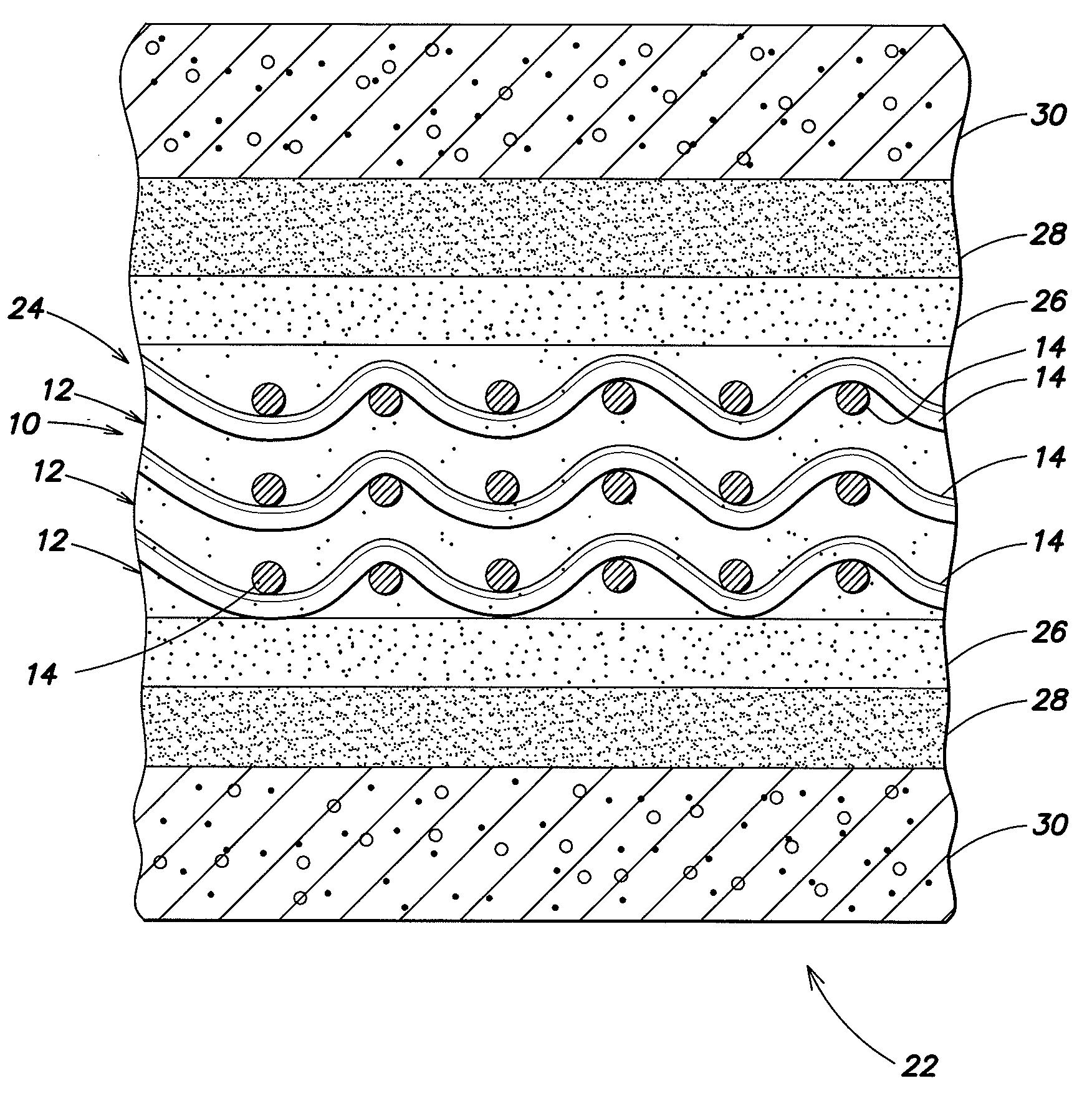

Multilayered microcavities and actuators incorporating same

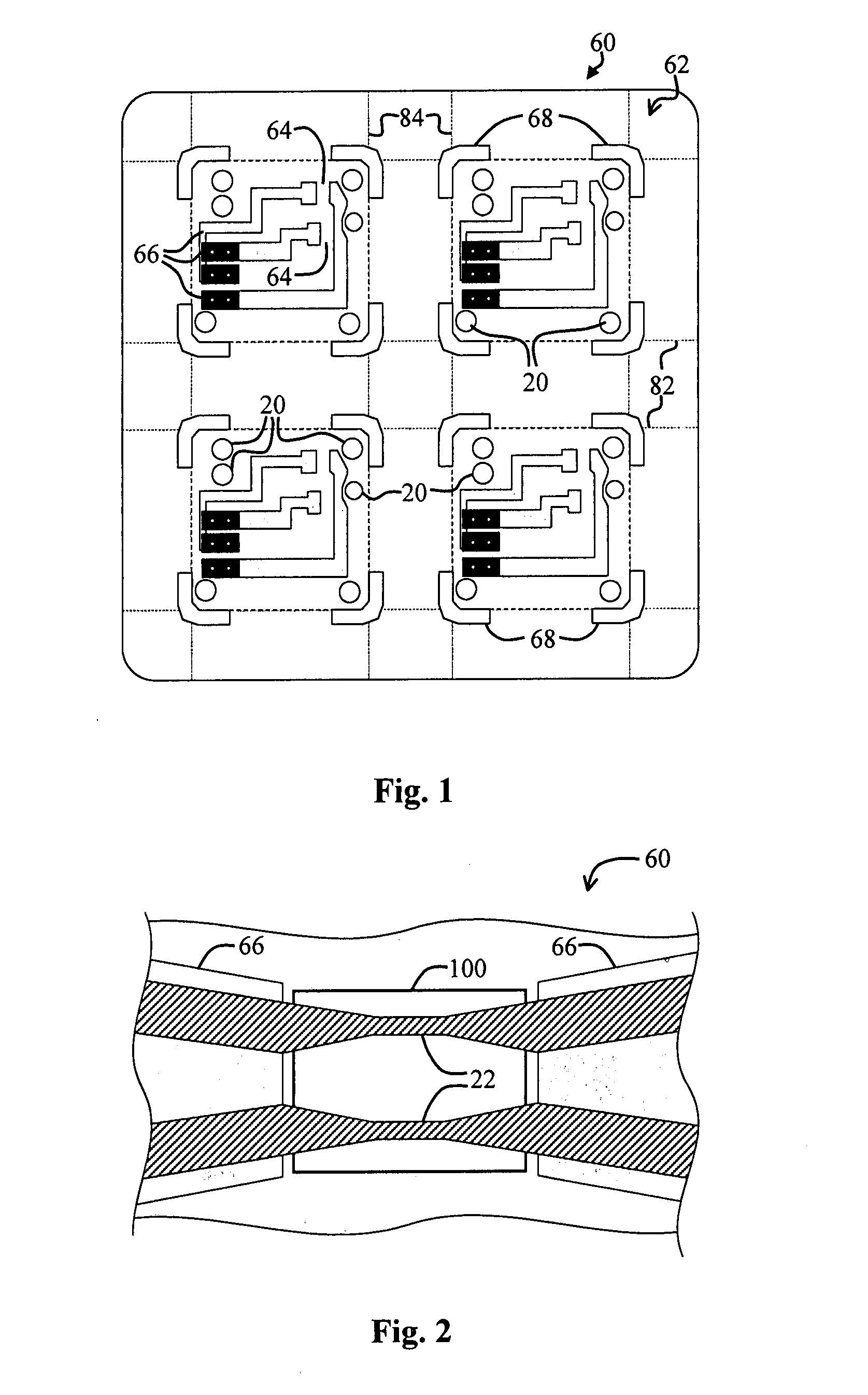

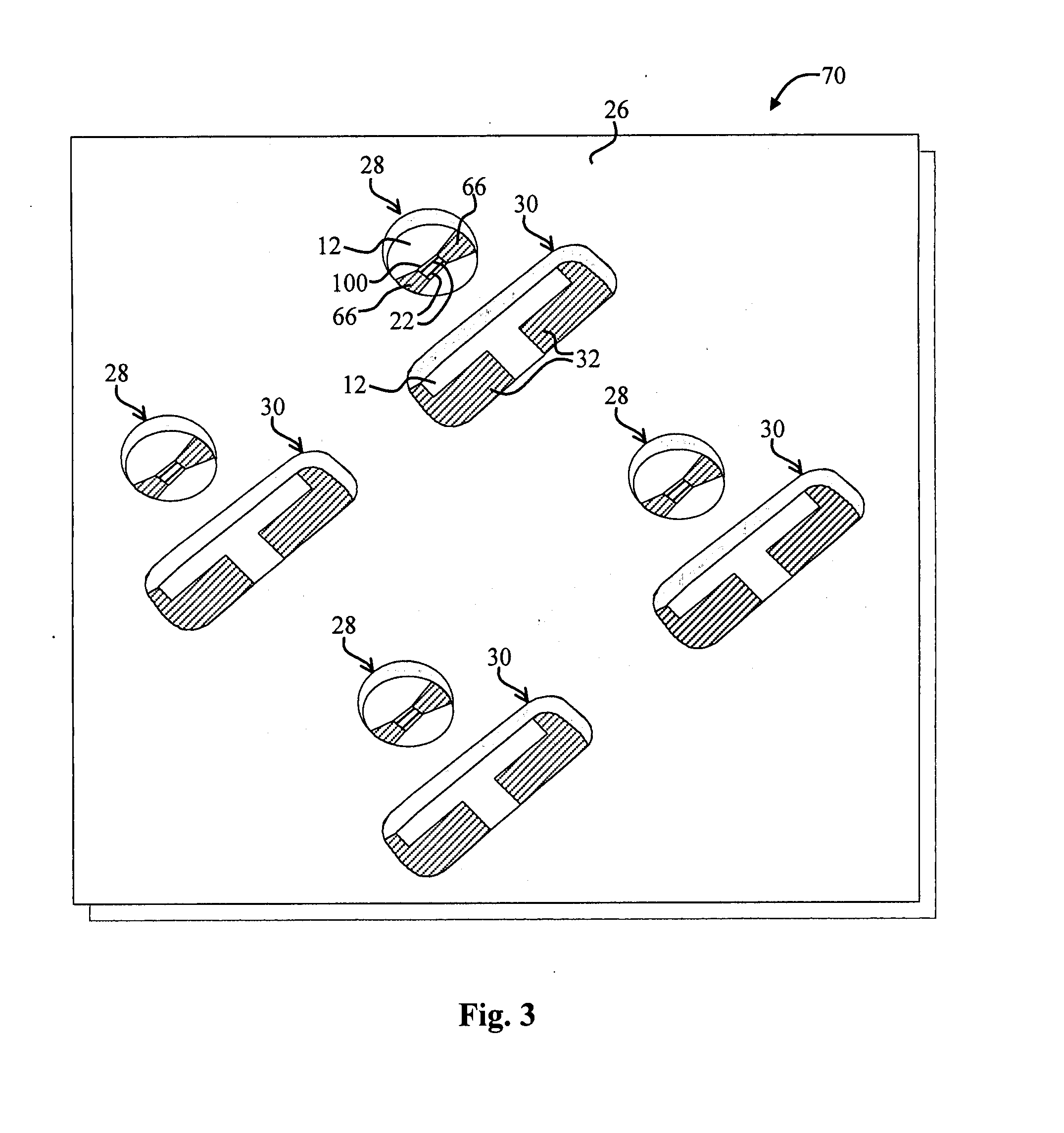

ActiveUS20080276819A1Innovative designCost-effective manufacturingPrinted electric component incorporationBlasting cartridgesActuatorBridgewire

A microcavity structure. In an illustrative embodiment, the microcavity structure includes a first substrate, which has a region of interest. A second substrate with a perforation therein is bonded to the first substrate. The perforation coincides with the region of interest. In a specific embodiment, the first substrate is implemented via a Printed Circuit Board (PCB). The region of interest includes one or more circuit components, including an actuator, such as a bridgewire, thereon or therein. A smoothing layer is included between the PCB and the actuator. A bonding gasket adheres the first substrate to the second substrate. The perforation accommodates energetic material that is selectively ignited via the actuator.

Owner:DESAI AMISH +4

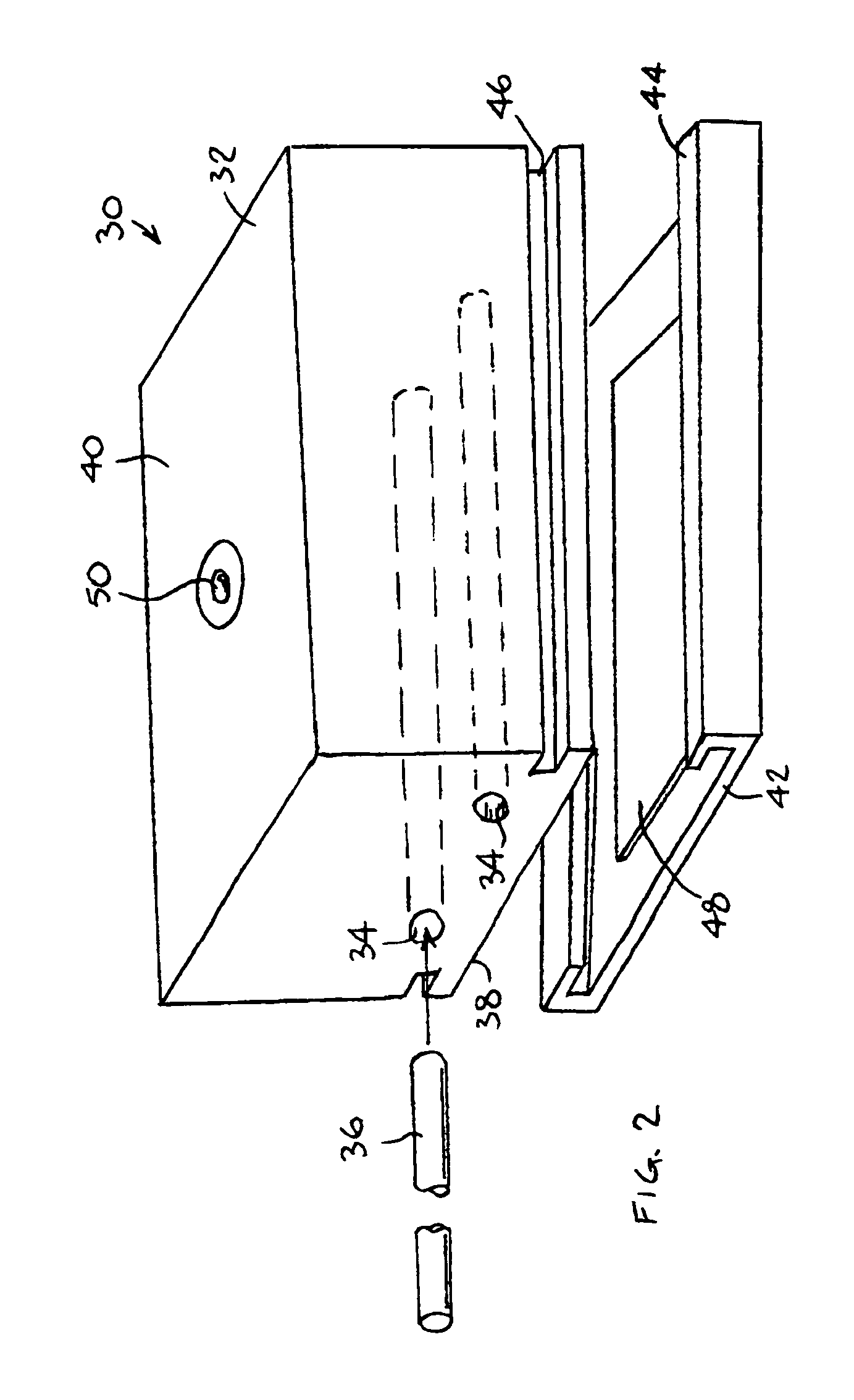

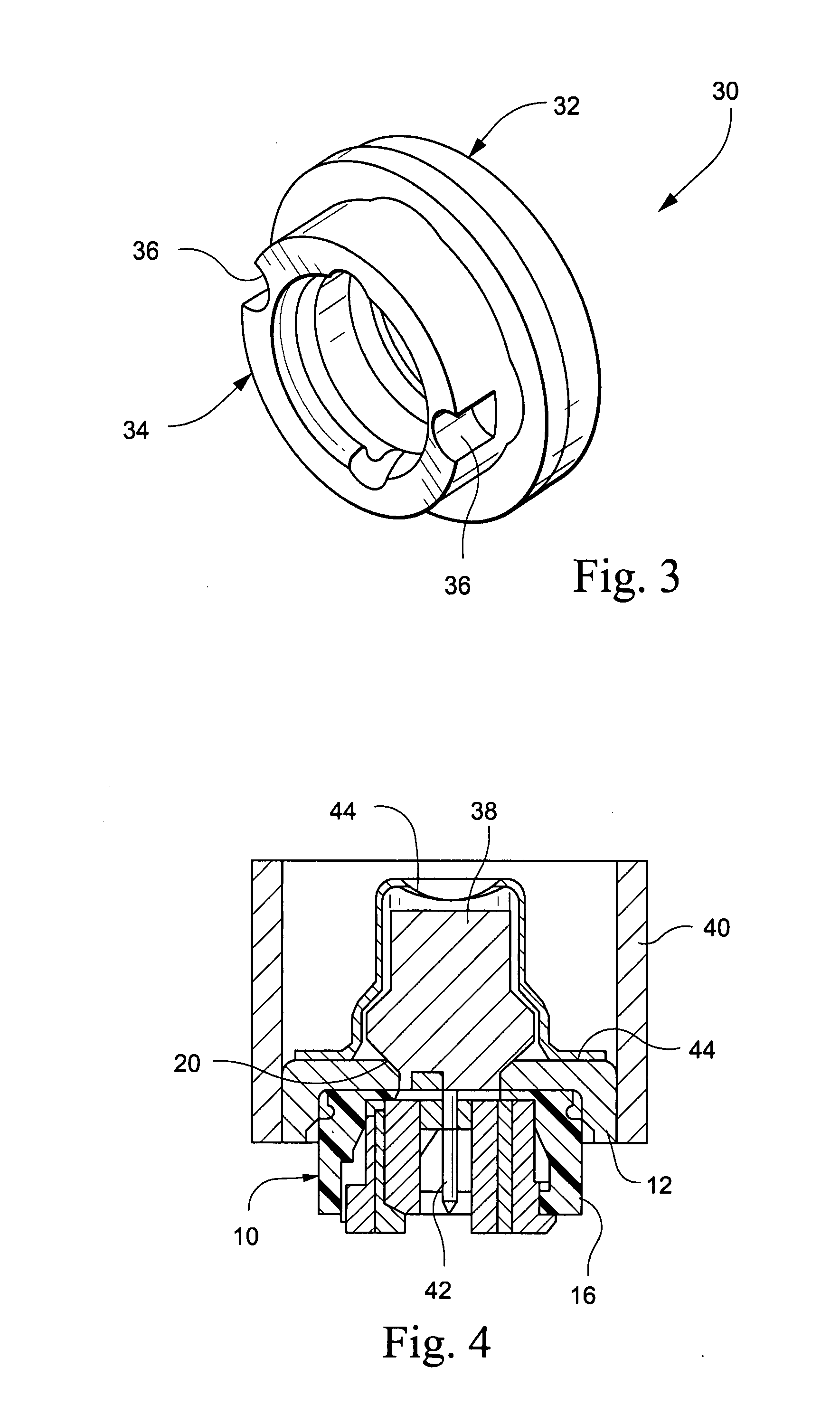

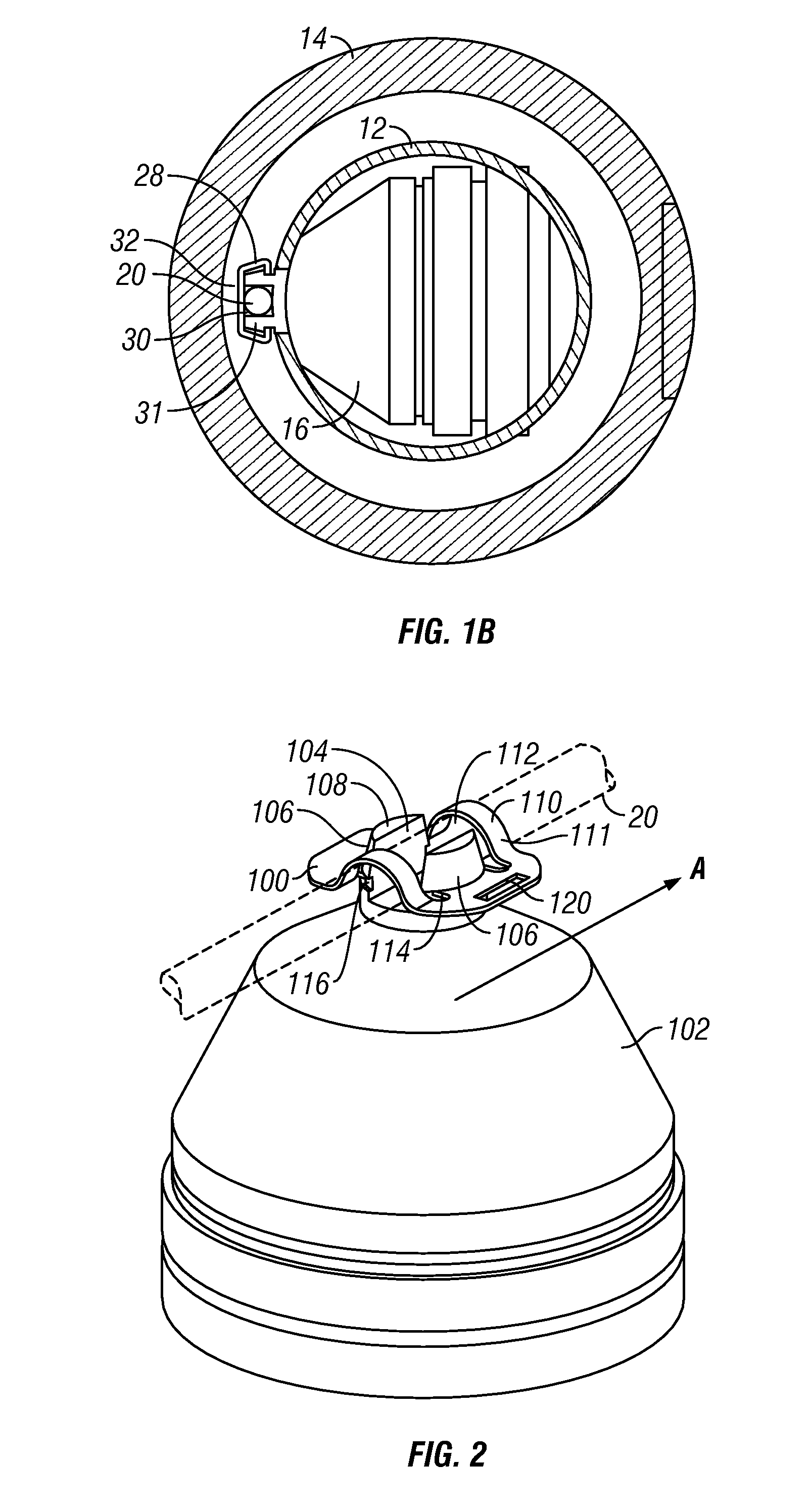

Connector for detonator, corresponding booster assembly, and method of use

InactiveUS7823508B2Increase contactAvoid problemsIncandescent ignitionBlasting cartridgesElectricityDetonator

Mining operations frequently involve the use of electric or electronic delay detonators in operative association with an explosive charge contained in a booster. Disclosed herein are connectors for connecting a signal transmission line to a detonator associated with a booster. In this way, the connectors, at least in preferred embodiments, allow the production of a substantially sealed booster assembly having a secure electrical connection to a signal transmission line. Also disclosed are methods of producing substantially sealed booster assemblies, and methods for their use in mining operations.

Owner:ORICA EXPLOSIVES TECH PTY LTD

MEMS resettable timer

A MEMS resettable timer including a primary inertial element and at least one secondary inertial element, which includes a camming surface. When the secondary inertial element moves, its camming surface engages the camming surface of a locking element to remove it from the notch of a subsequent inertial element. When the primary inertial element is released for movement it activates a resetting arrangement to place the secondary inertial element back to the initial position and prevent further movement of the primary inertial element. The cycle is repeatable to commence some predetermined action.

Owner:NAVY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE THE

Stamped and molded igniter body for airbag inflators

InactiveUS20090114109A1Reduce and eliminate gas leakEliminate needBlasting cartridgesPedestrian/occupant safety arrangementAirbagElectrical and Electronics engineering

An igniter body for an airbag inflator comprising a stamped metal body portion having a generally annular flange and a central opening. A generally cylindrical plastic connector portion is disposed within the annular flange and is connected to the body portion. The connector portion may be integrally molded within the body portion. The central opening in the body portion is constructed to receive an initiator therein, and the connector portion is constructed to receive a power module therein for connection to an initiator disposed in the central opening and surrounded by a sleeve that is secured to the body portion to retain the initiator thereon.

Owner:ARC AUTOMOTIVE

Versatile cavity actuator and systems incorporating same

A versatile cavity actuator. The versatile cavity actuator includes a cavity having one or more polymer-based sidewalls. An energetic material is disposed therein. A heater is disposed on or within the cavity. In a specific embodiment, the cavity includes a thermally insulating base positioned beneath the heater, which is positioned near the bottom of the cavity. The polymer-based sidewalls are constructed from a photo-curable epoxy, which is disposed on a substrate via microelectromechanical processes. The sidewalls are angled or parabolic and are constructed via a low-temperature lithographic spin process compatible with post integrated circuit processing.

Owner:TANNER RES

Initiation systems for explosive devices, scalable output explosive devices including initiation systems, and related methods

Initiator systems for warheads include a first initiation device configured to detonate at least a portion of an explosive material contained in an explosive device and a second initiation device configured to deflagrate at least a portion of an explosive material of a warhead. Scalable output explosive devices include an explosive material at least partially disposed within a housing and an initiator system including a first initiation device configured to detonate at least a portion of the explosive material and a second initiation device configured to deflagrate at least another portion of the explosive material. Methods of igniting warheads include deflagrating a portion of an explosive material disposed within the warhead and detonating at least another portion of the explosive material disposed within the warhead.

Owner:NORTHROP GRUMMAN SYST CORP

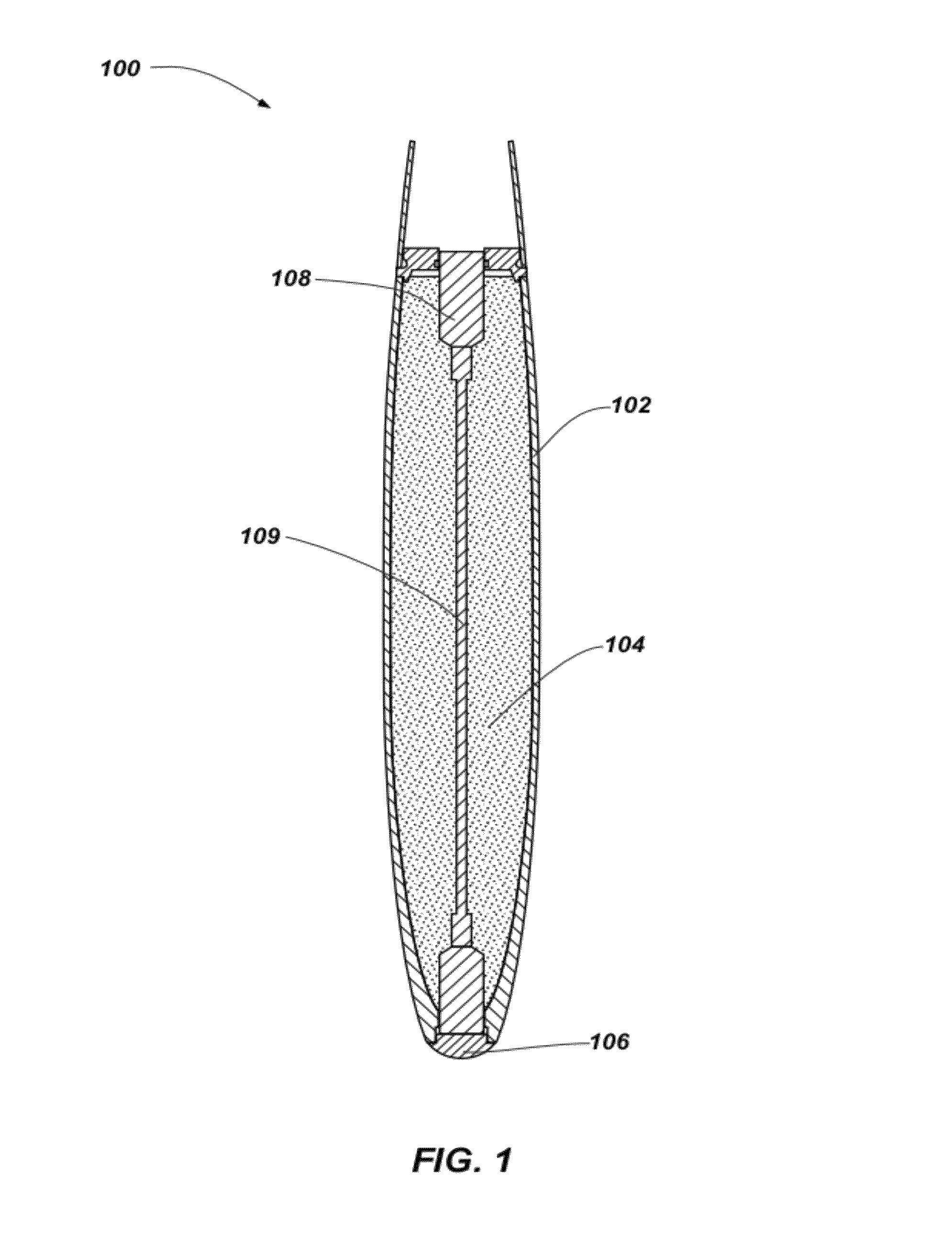

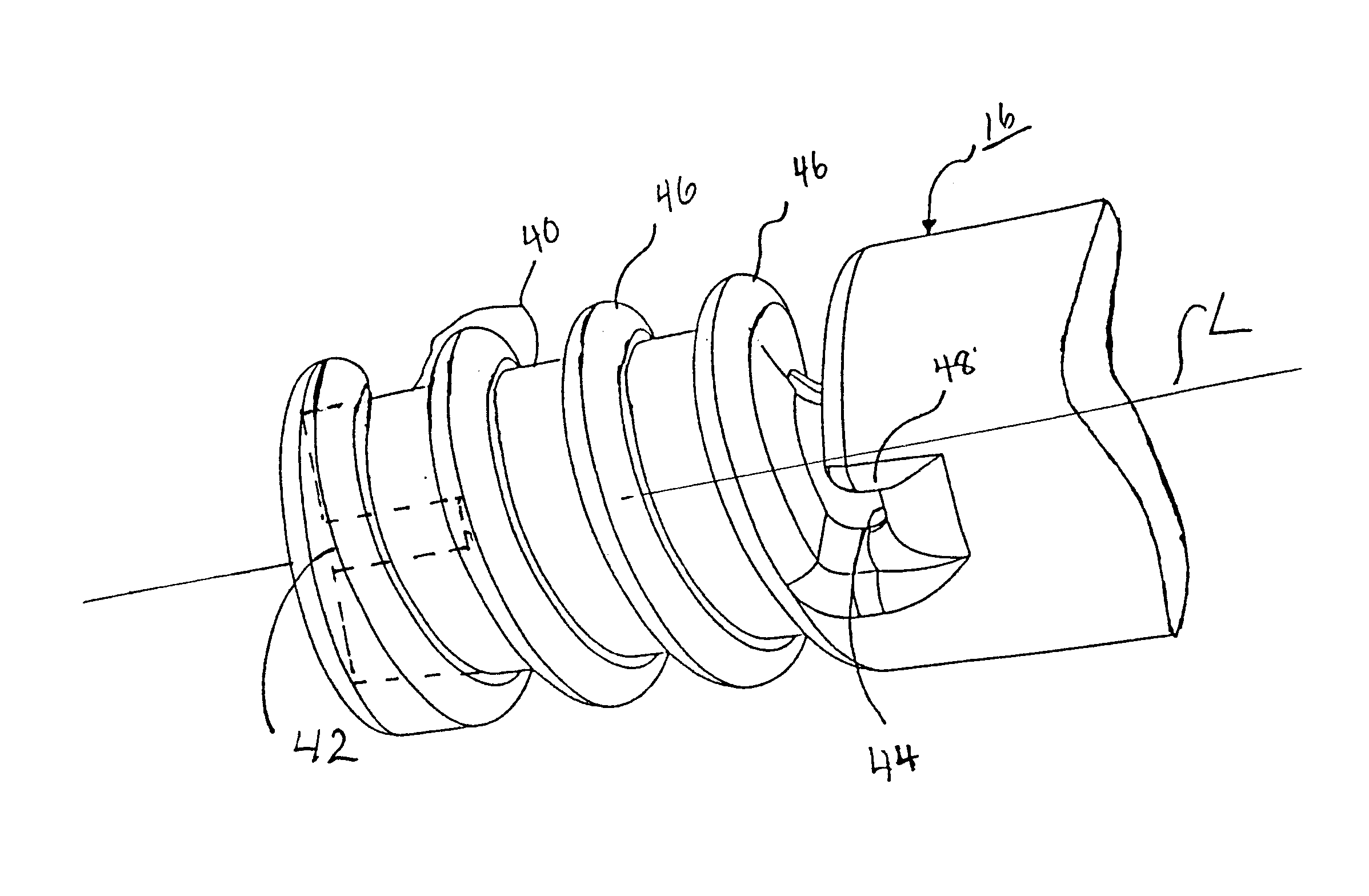

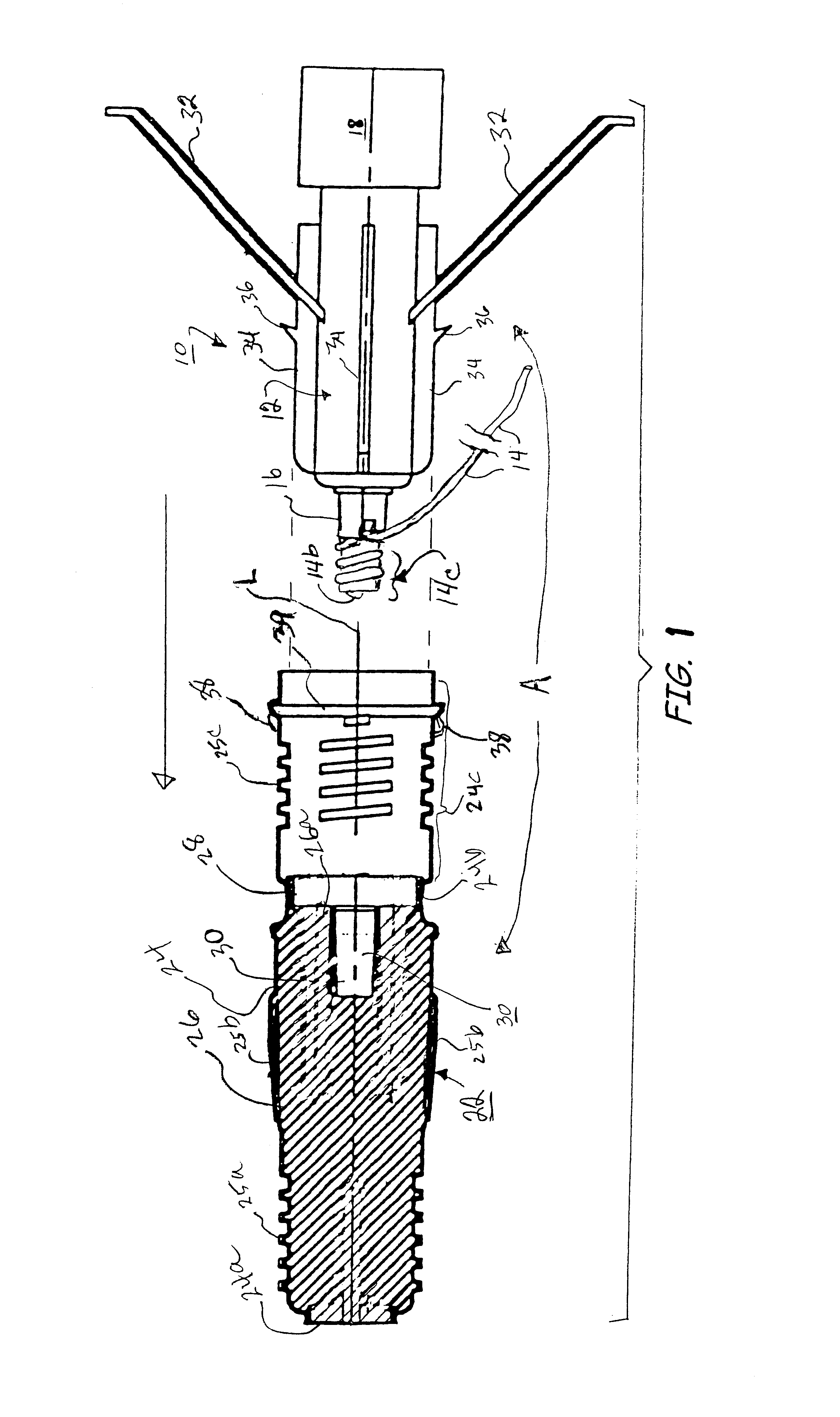

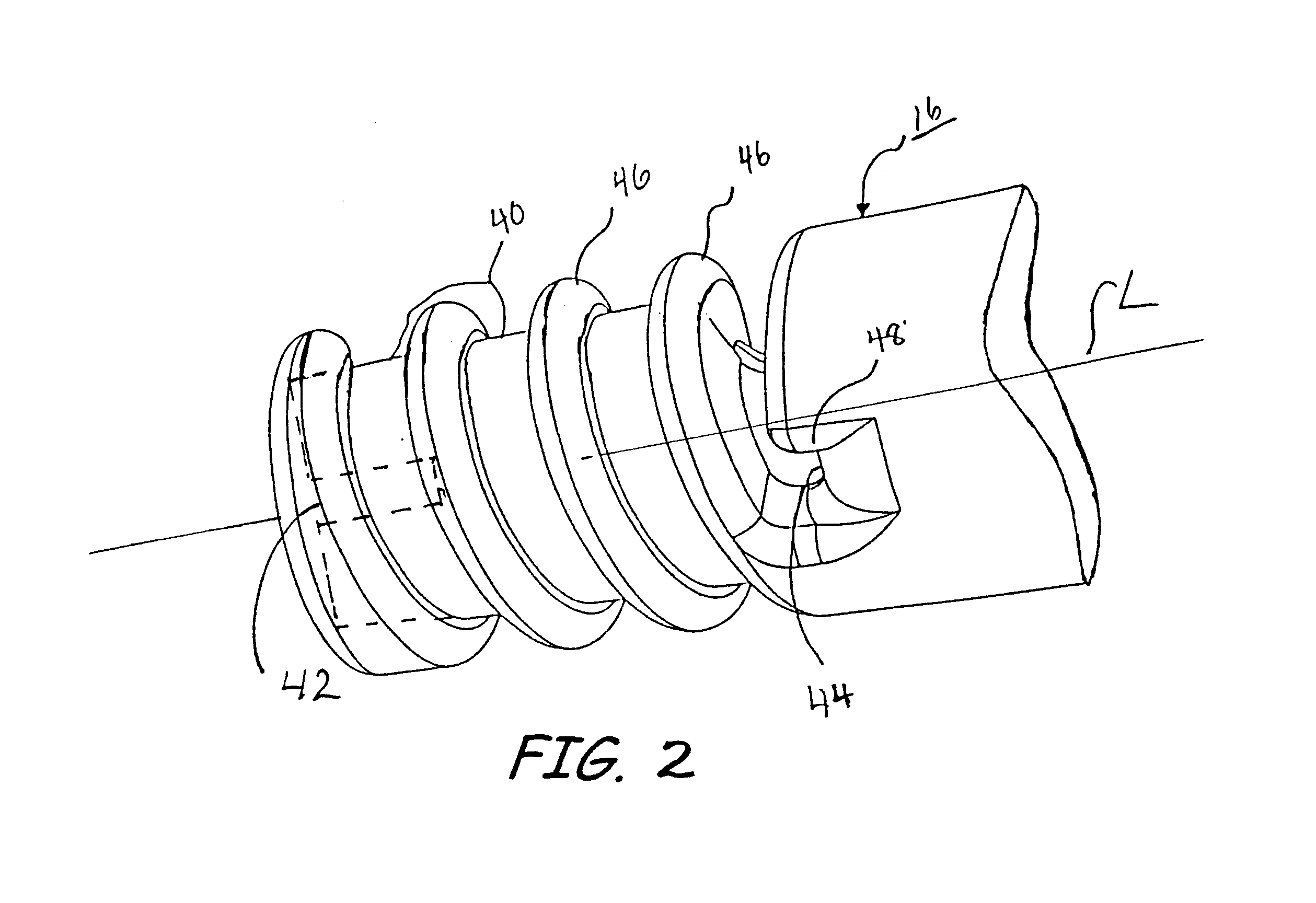

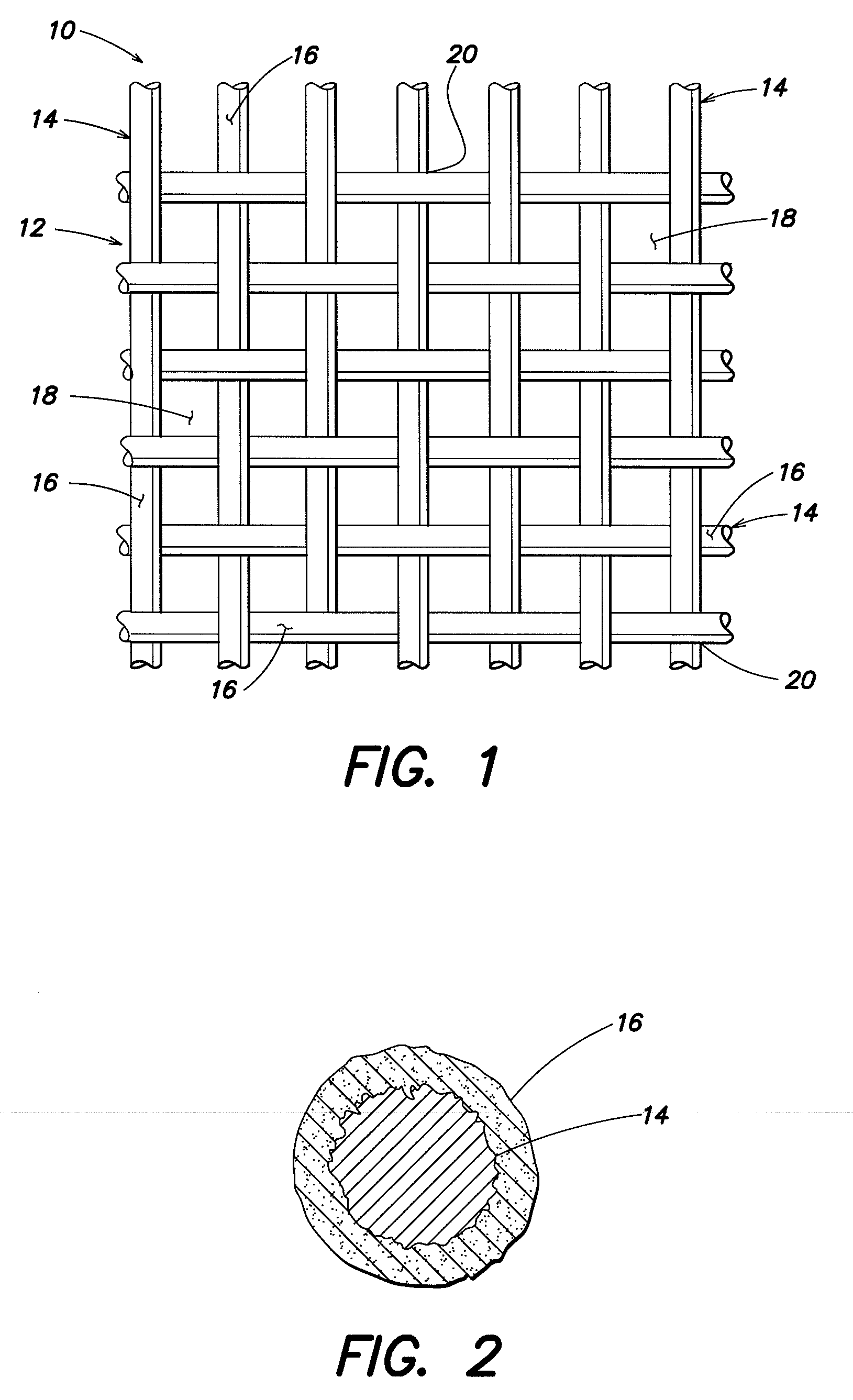

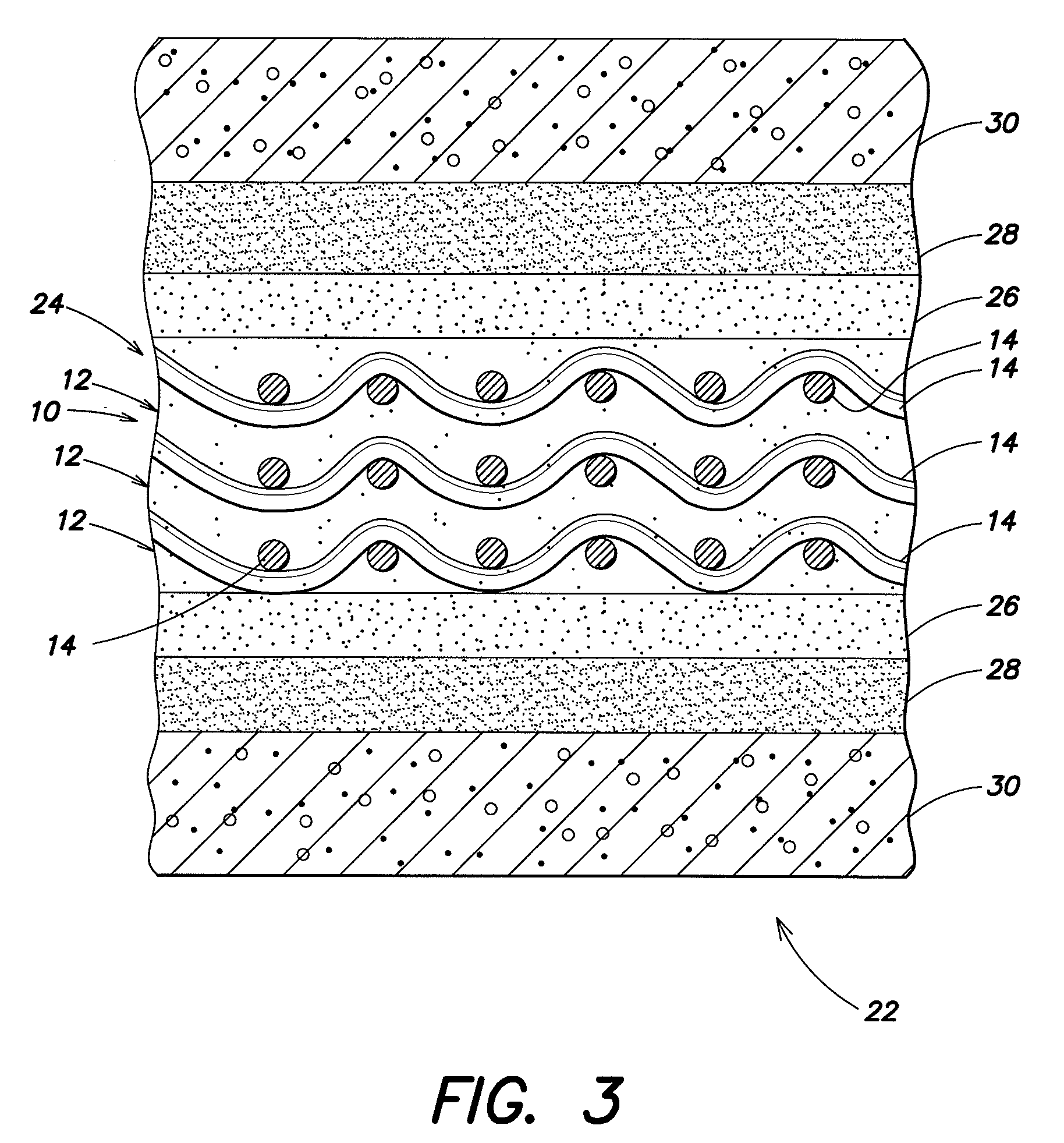

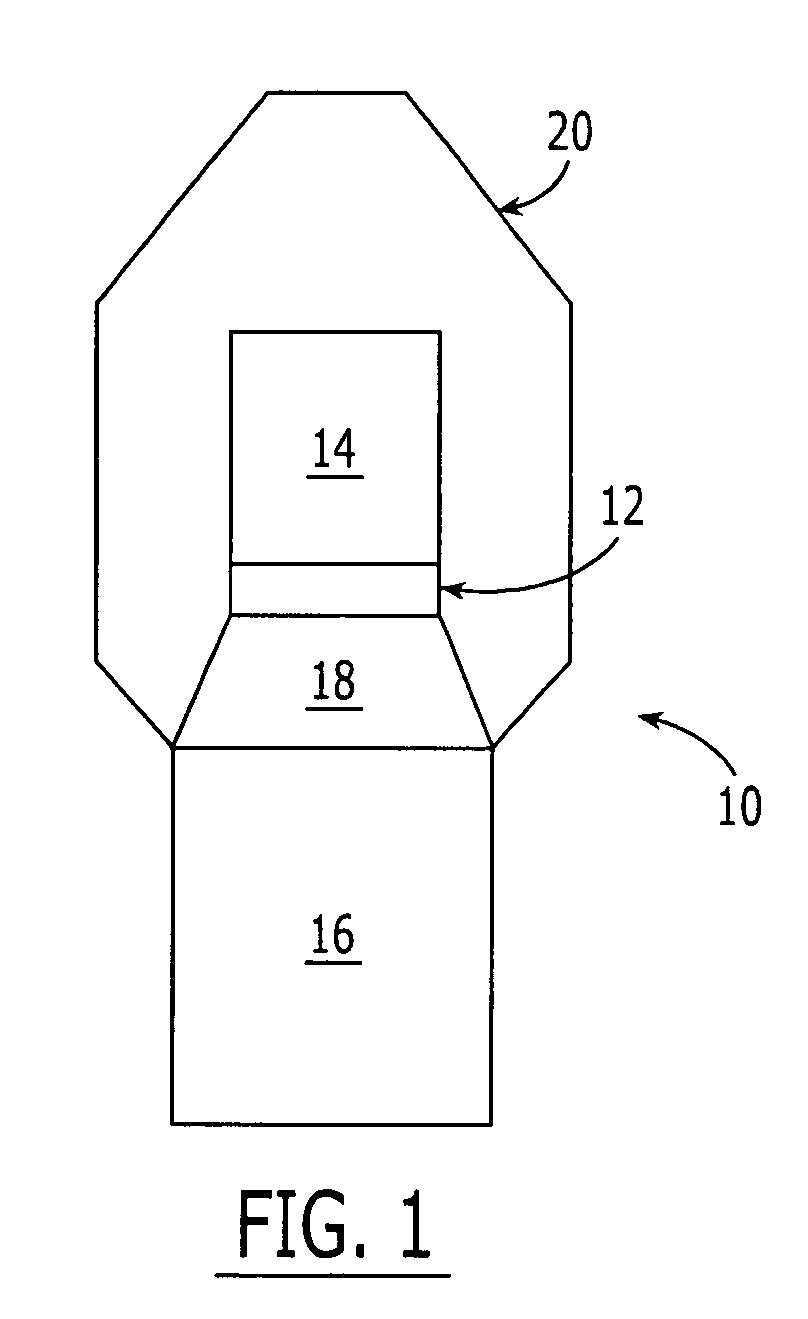

Accumulated detonating cord explosive charge and method of making and of use of the same

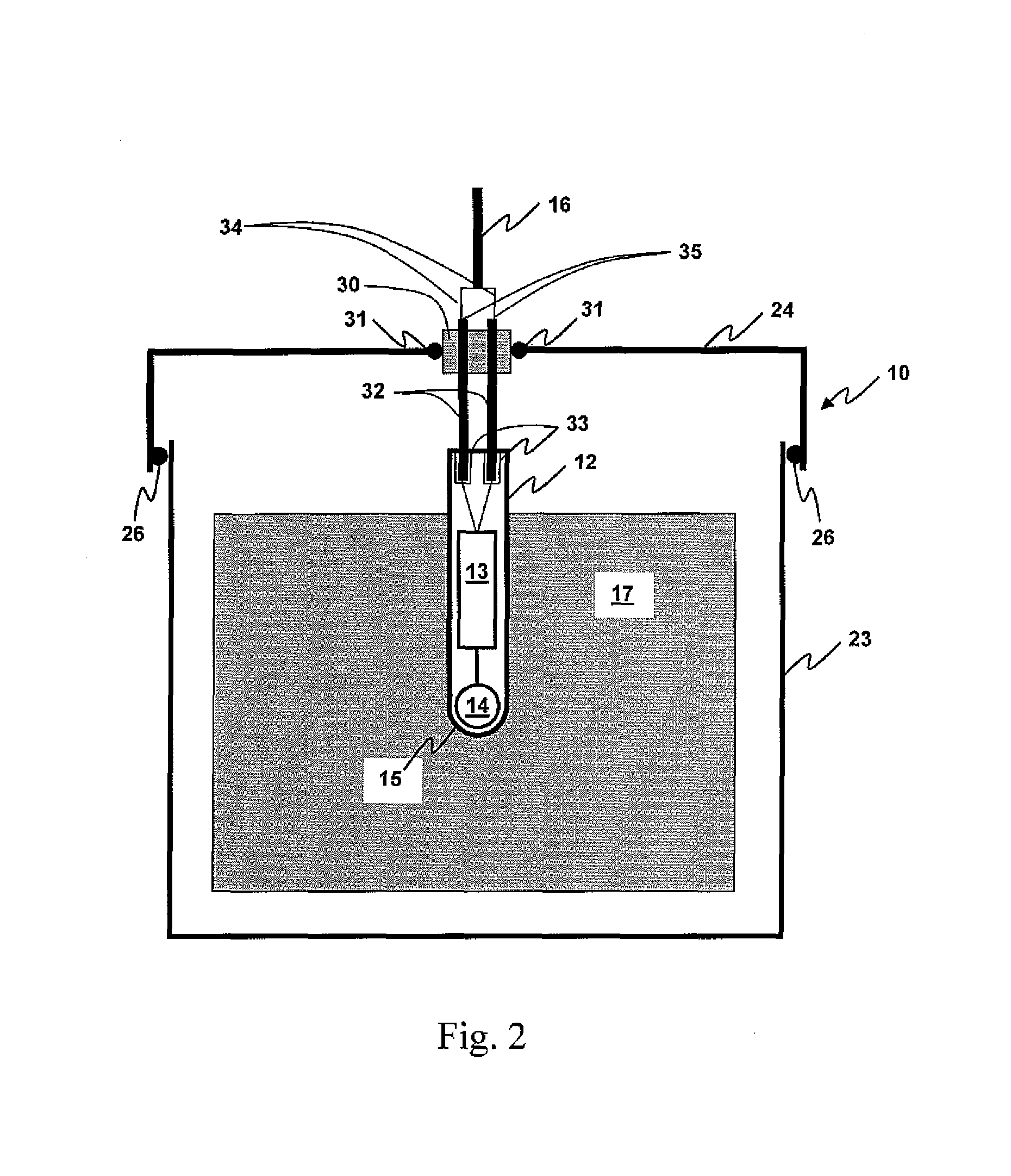

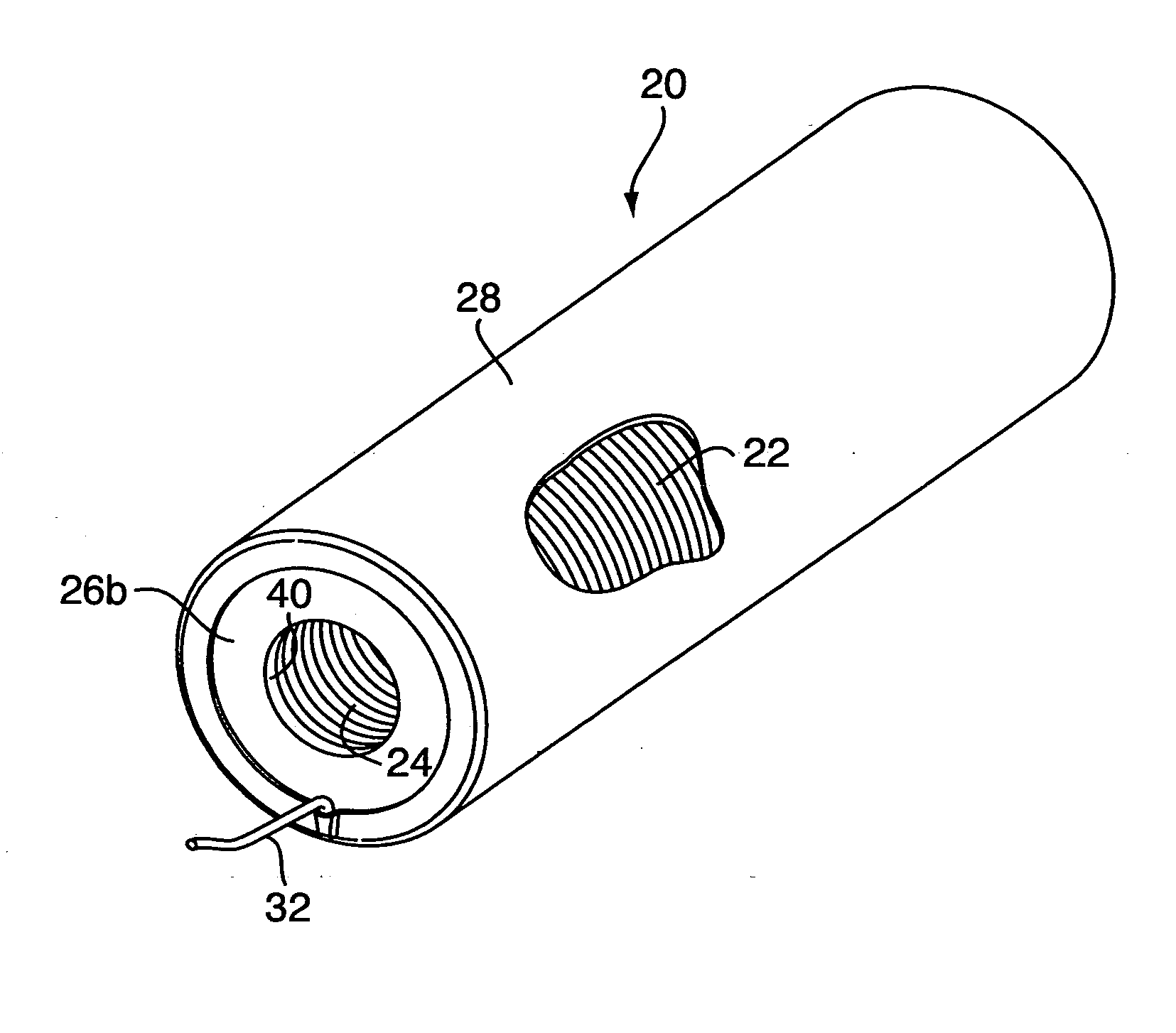

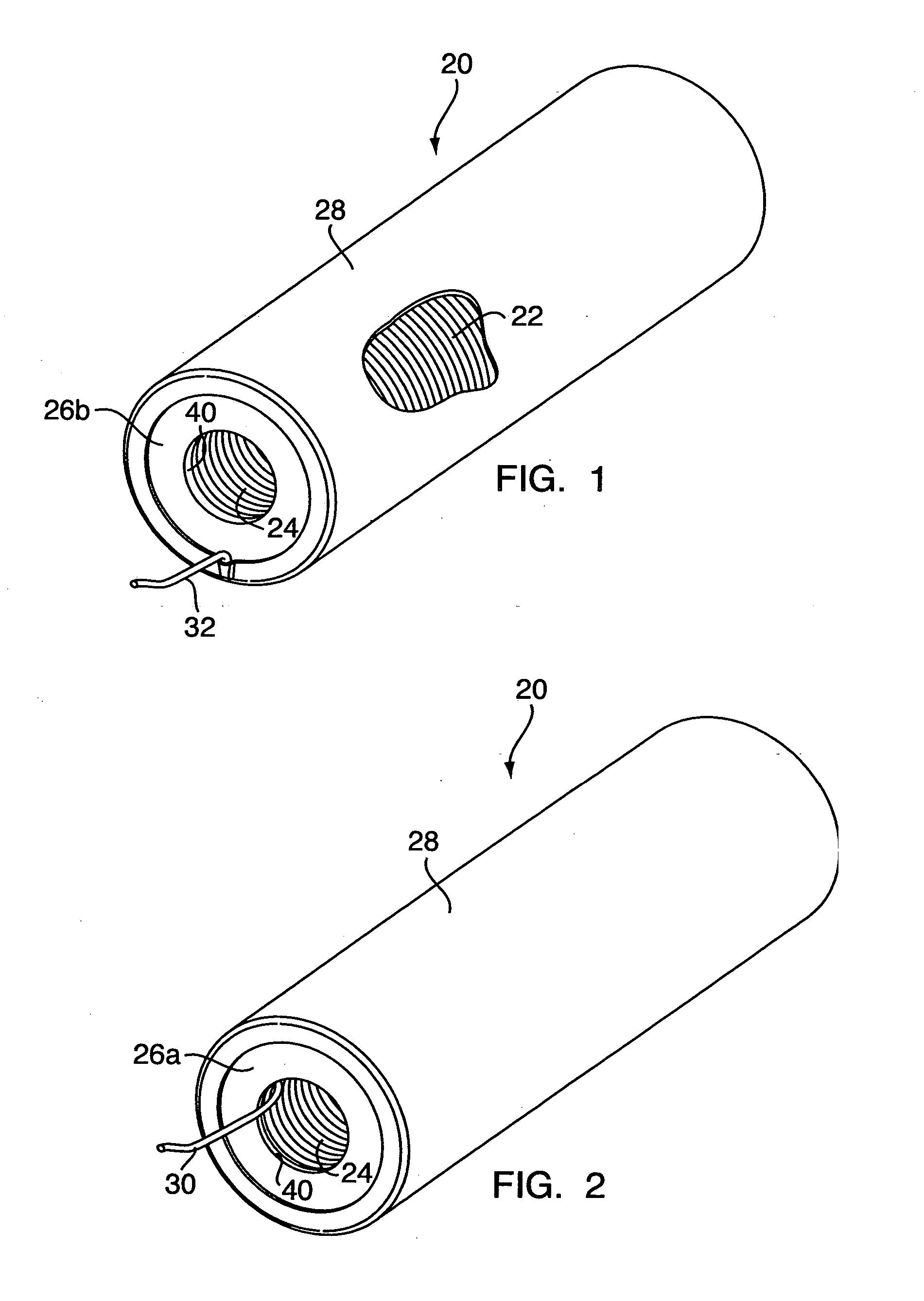

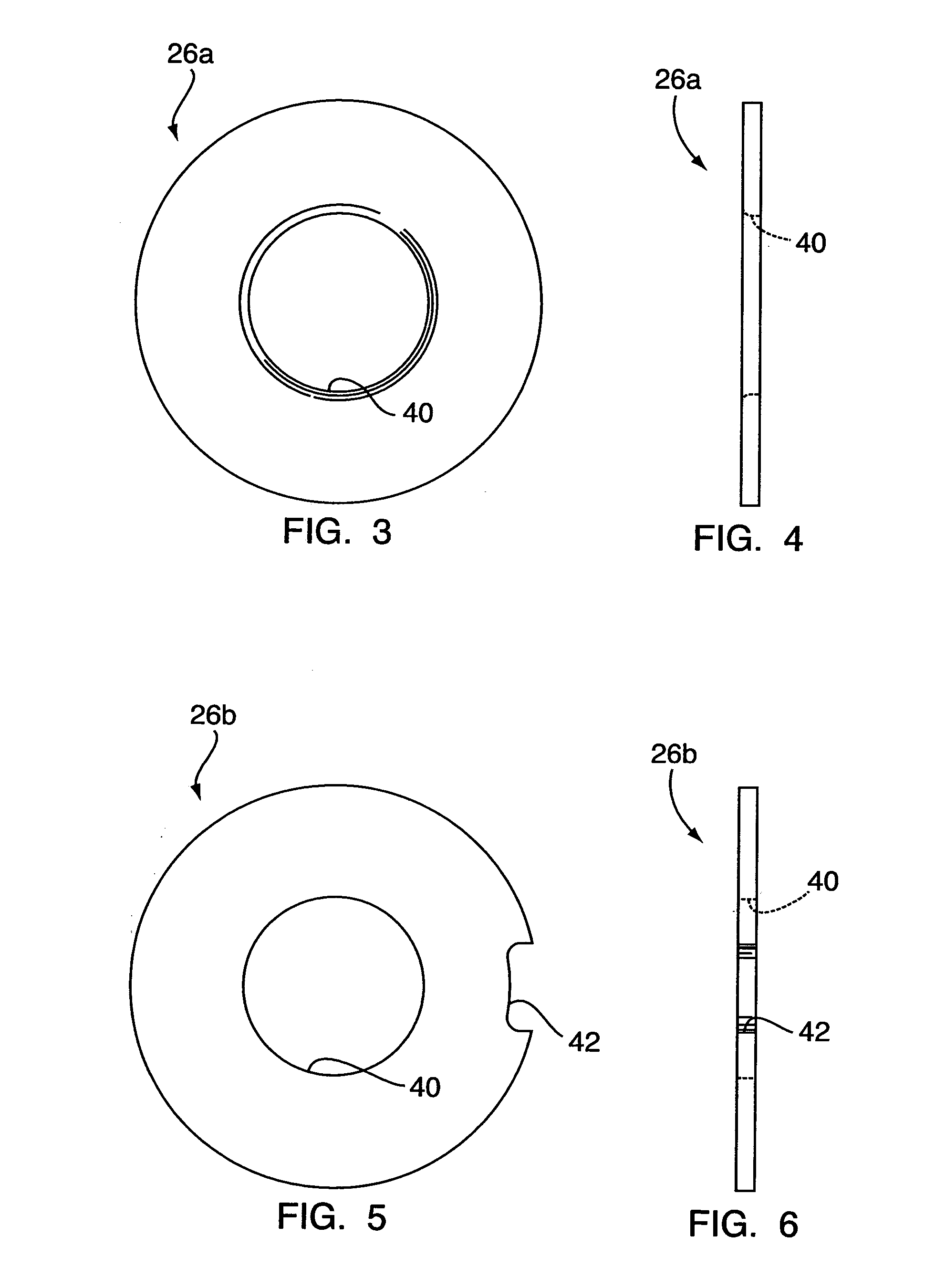

An initiator (14c) for a secondary explosive receptor charge is provided by forming a length of detonating cord (14) into a helical coil containing a plurality of windings with a cutoff barrier provided by, e.g., a separating rib (46) between adjacent windings. The adjacent windings may be not more than about 0.5 inch (12.7 mm) apart. The detonating cord (14) may be wound about a spindle (16) which may optionally provide the separating rib (46). The coil may be a tapered coil which may define a taper angle of e.g., from about 2 to 4 degrees. Alternatively, the coil may be a cylindrical coil, or the cord may be configured in a planar spiral. Optionally, the detonating cord in the helical coil may have a core of explosive material with a loading of less than 15 grains per foot of the cord, e.g., less than 12 grains per foot of the cord, or a loading in the range of from 8 to 12 grains per foot of the cord. The coil may consume about six inches of the cord. Conversely, the detonating cord in the spiral may have a core of explosive material with a loading of at least 2.5 grains per foot, optionally at least 15 grains per foot of the cord.

Owner:DYNO NOBEL INC

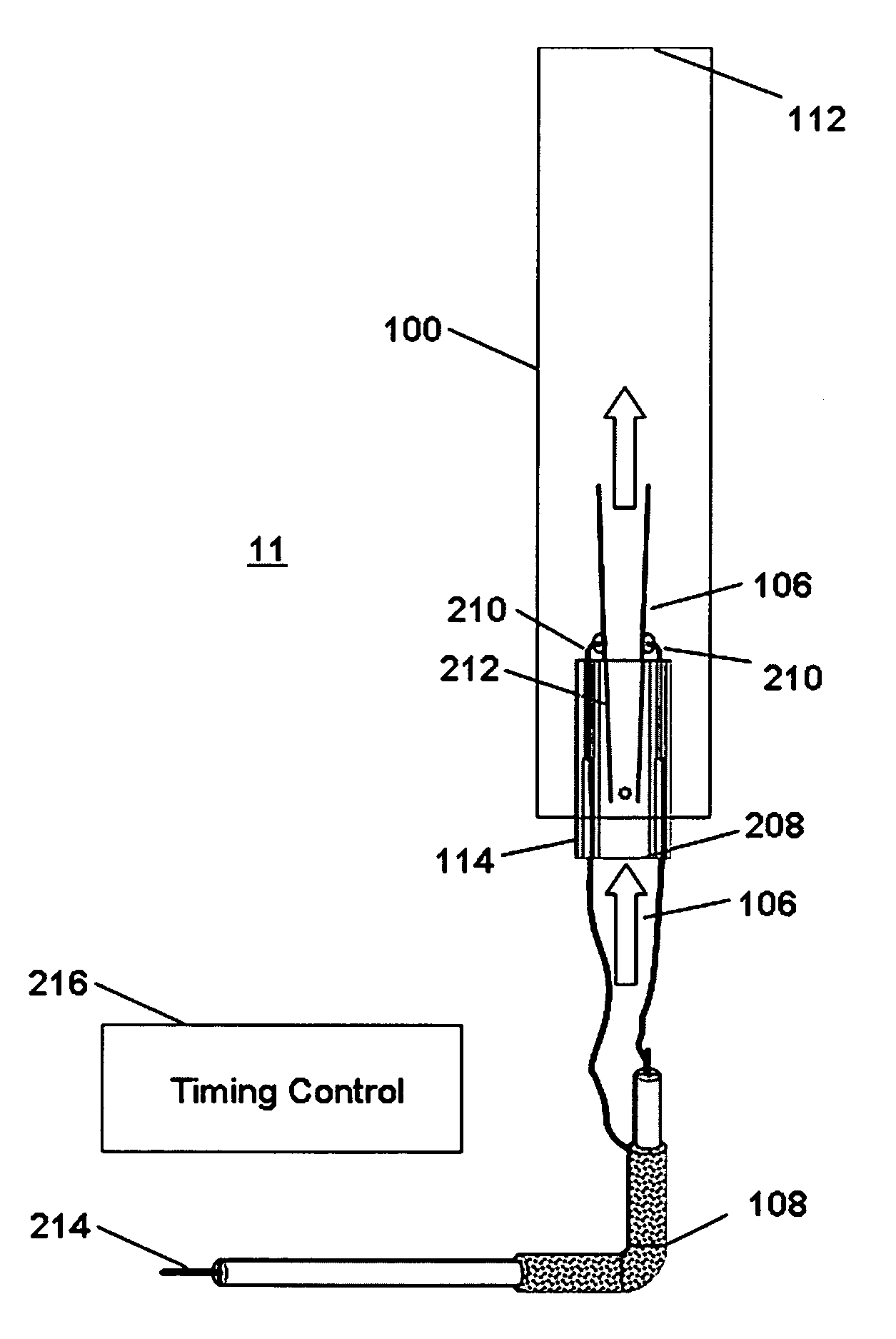

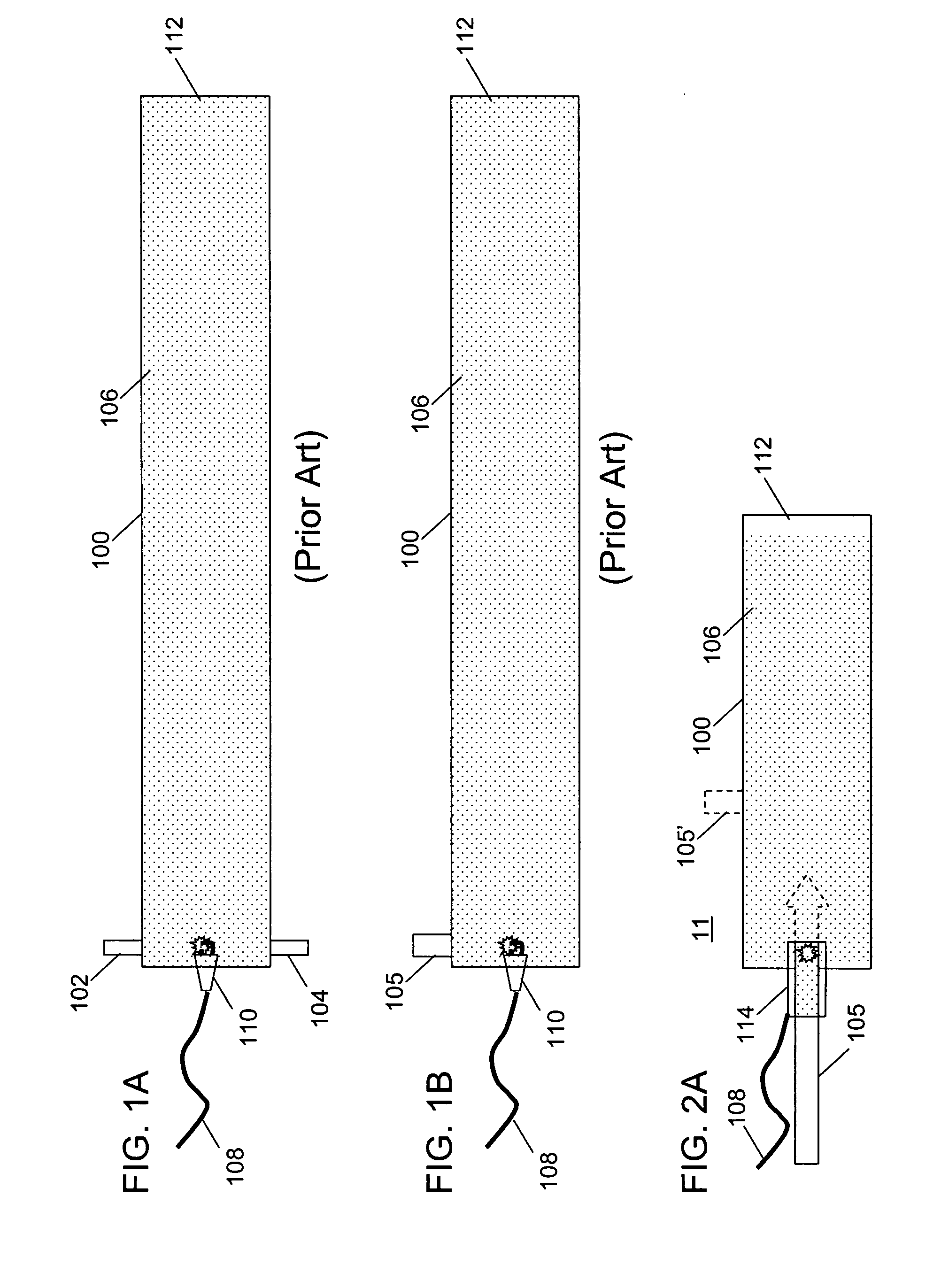

Coreless-coil shock tube package system

ActiveUS20060144279A1Easy to storeEasy to transportFuse ignition meansFilament handlingDetonatorEngineering

A coreless-coil shock tube package system includes a “coreless” bundle of shock tubing, meaning that the tubing is not wrapped around a spool. The bundle may be a generally cylindrical coil of shock tubing. Optionally, two washer-like end plates abut the ends of the tubing coil for axial support. A layer of shrink-wrap or other polymer film partially covers the coil and end plates. A detonator is attached to one end of the tubing and lies tucked into the coil, through an end plate, for storage and transport. An igniter is attached to the tubing's other end. In use, the detonator is removed from the coil and attached to an explosive device. Then, the package is pulled away from the detonator and explosive, thereby uncoiling the tubing through the end plate for deployment. The igniter is actuated for igniting the shock tubing and activating the detonator and explosive.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

Pyrotechnical charge for detonators

InactiveUS6227116B1Improve performanceImprove propertiesLoomsBlasting cartridgesDetonatorOxidation-Reduction Agent

A detonator comprising a shell with a secondary explosive base charge, igniting means and an intermediate pyrotechnical train, said train comprising a novel ignition composition with a specific redox-pair of a metal fuel and a metal oxide oxidant, said fuel being present in excess to the amount of stoichiometrically being required to reduce the metal oxide, the ignition composition being able to ignite said secondary explosive into a convective deflagrating state to reliably detonate the same. Use of said novel ignition composition for the ignition of secondary explosives in general.

Owner:EDWARDS STUART D +1

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

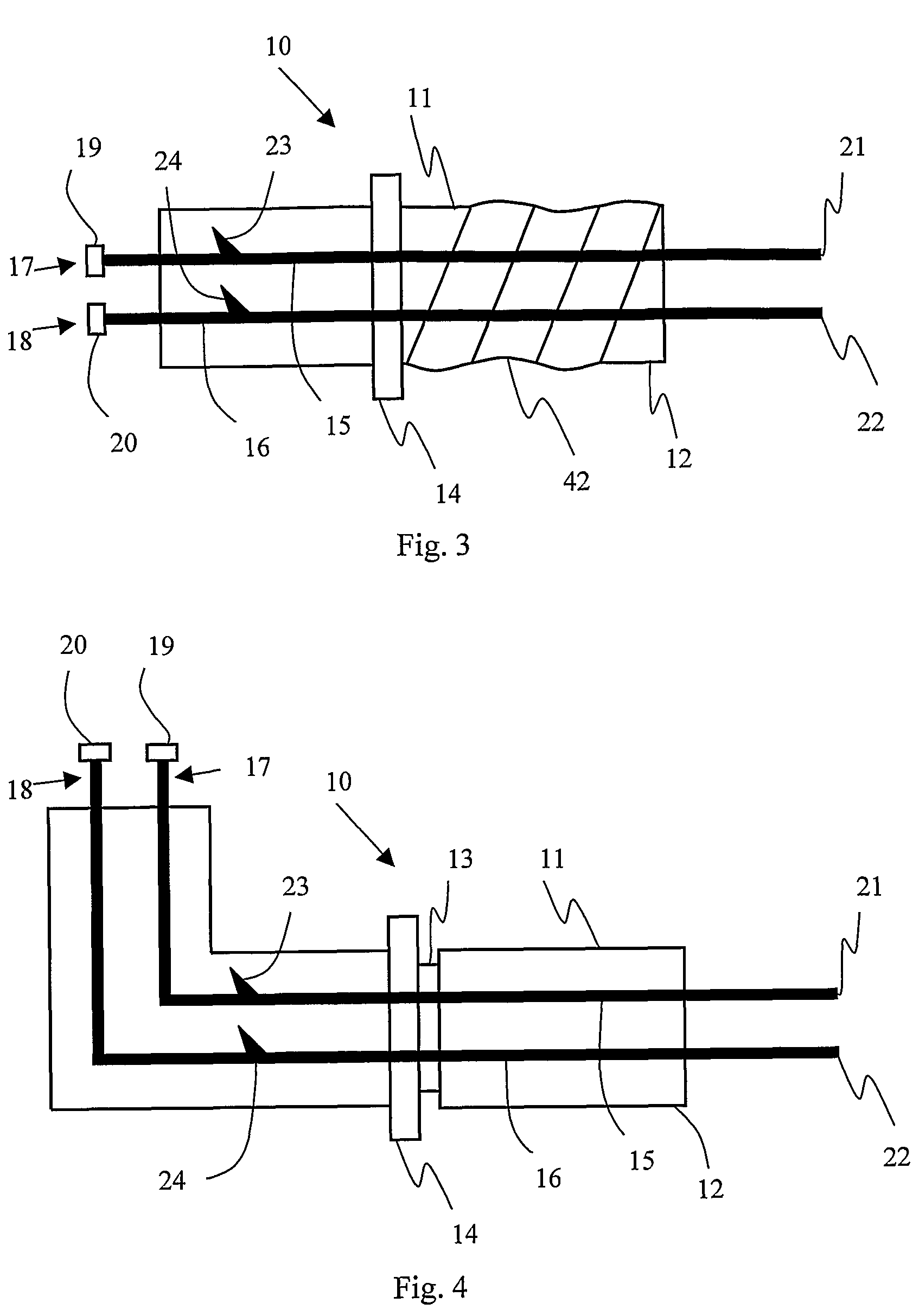

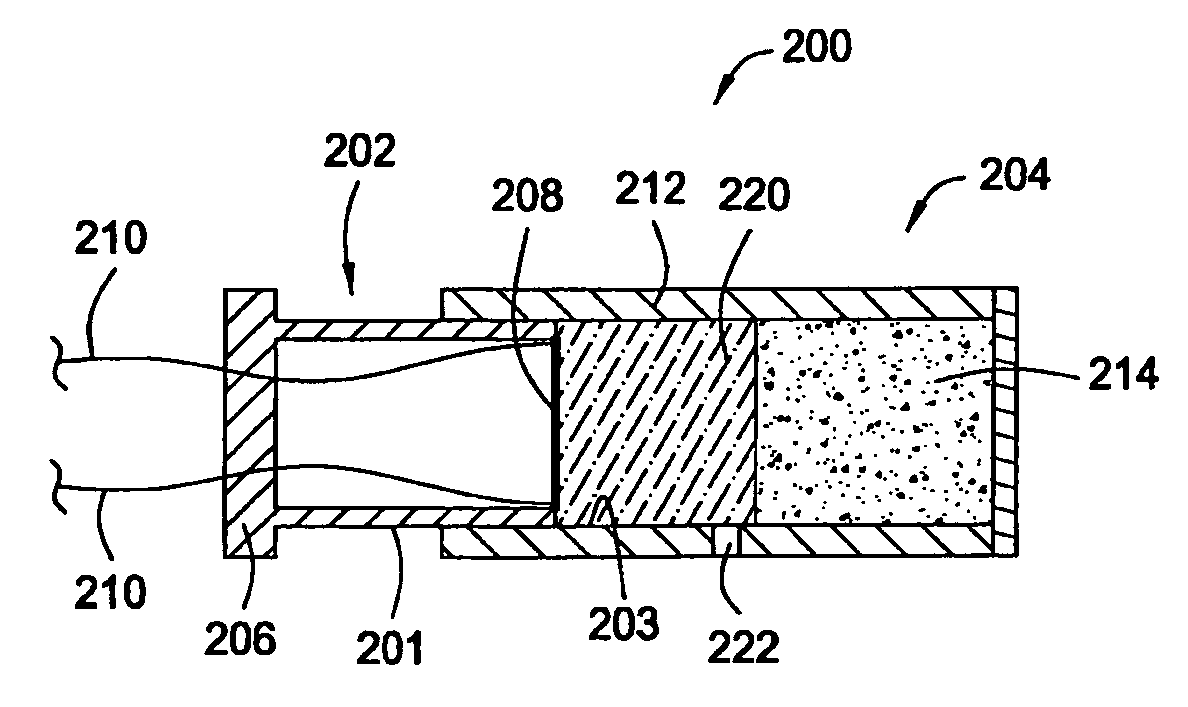

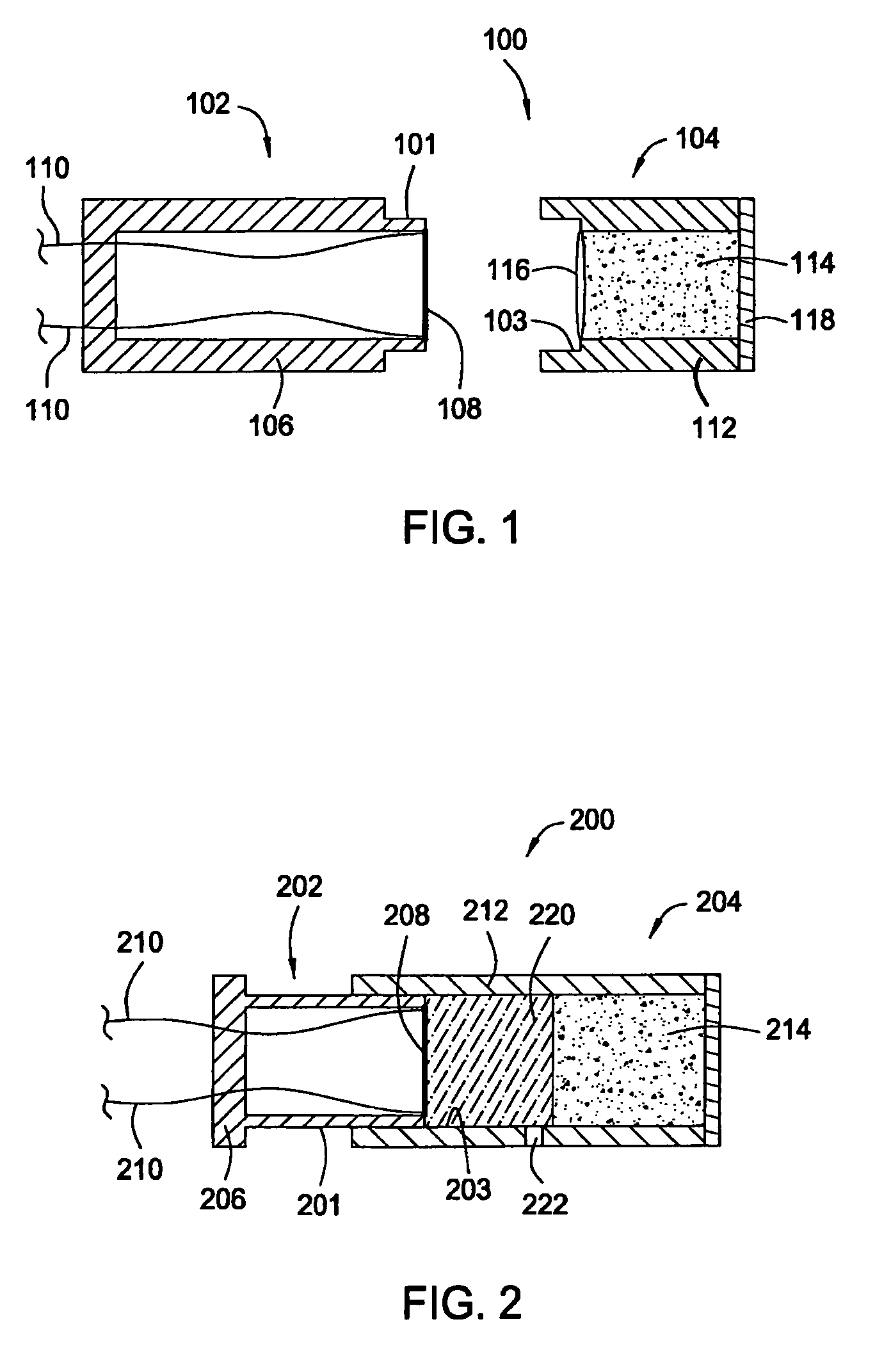

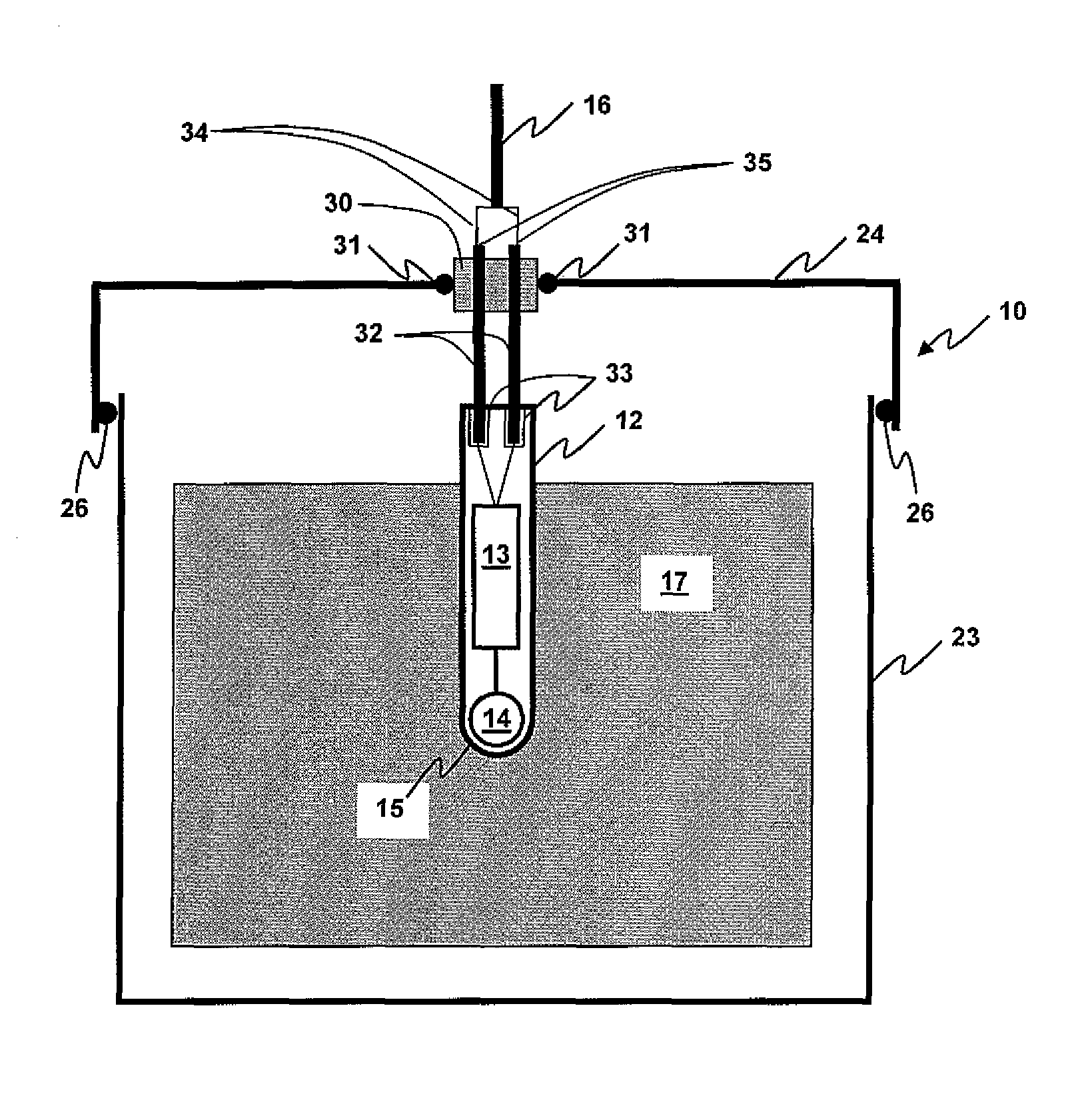

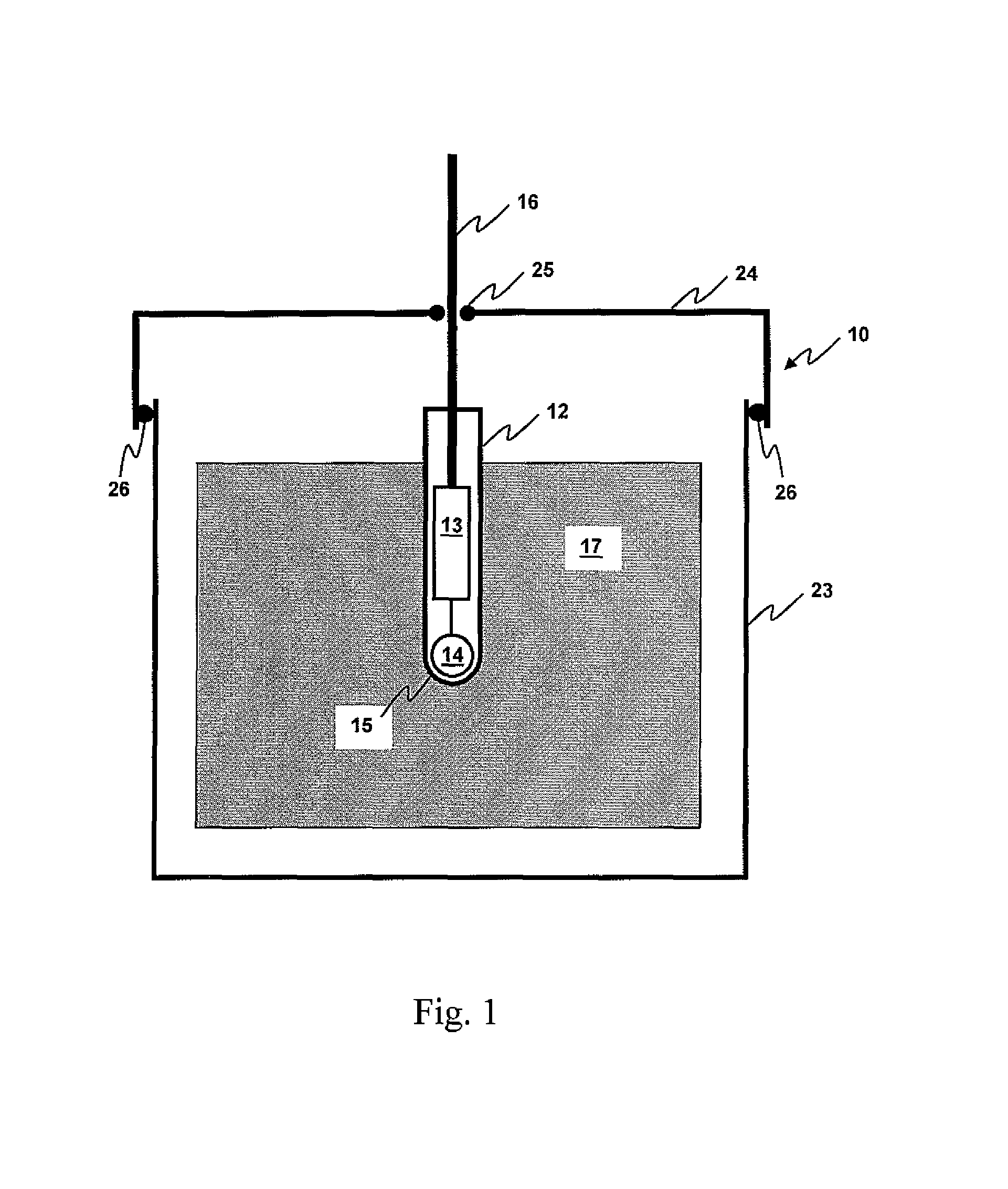

Non-explosive two component initiator

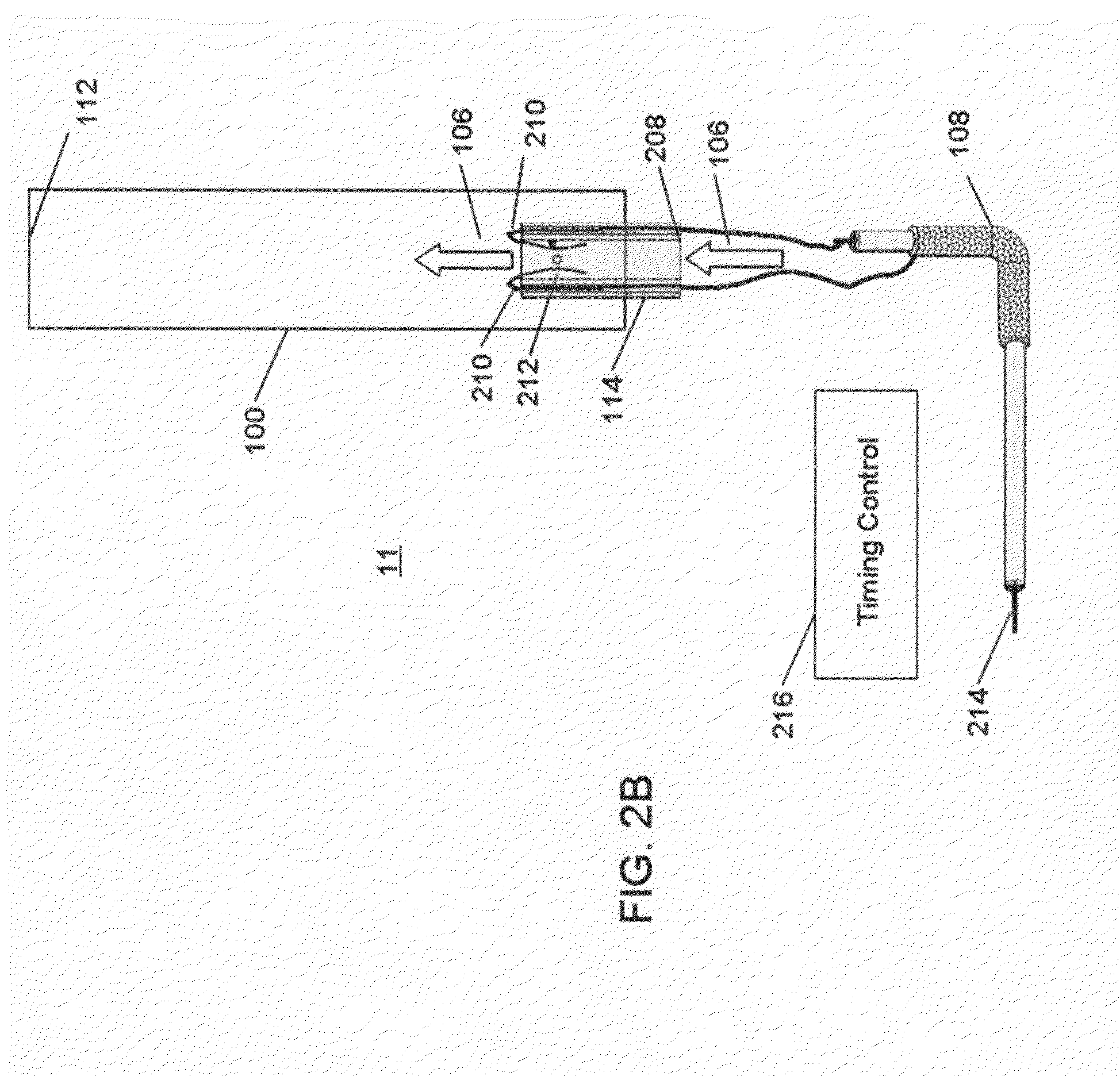

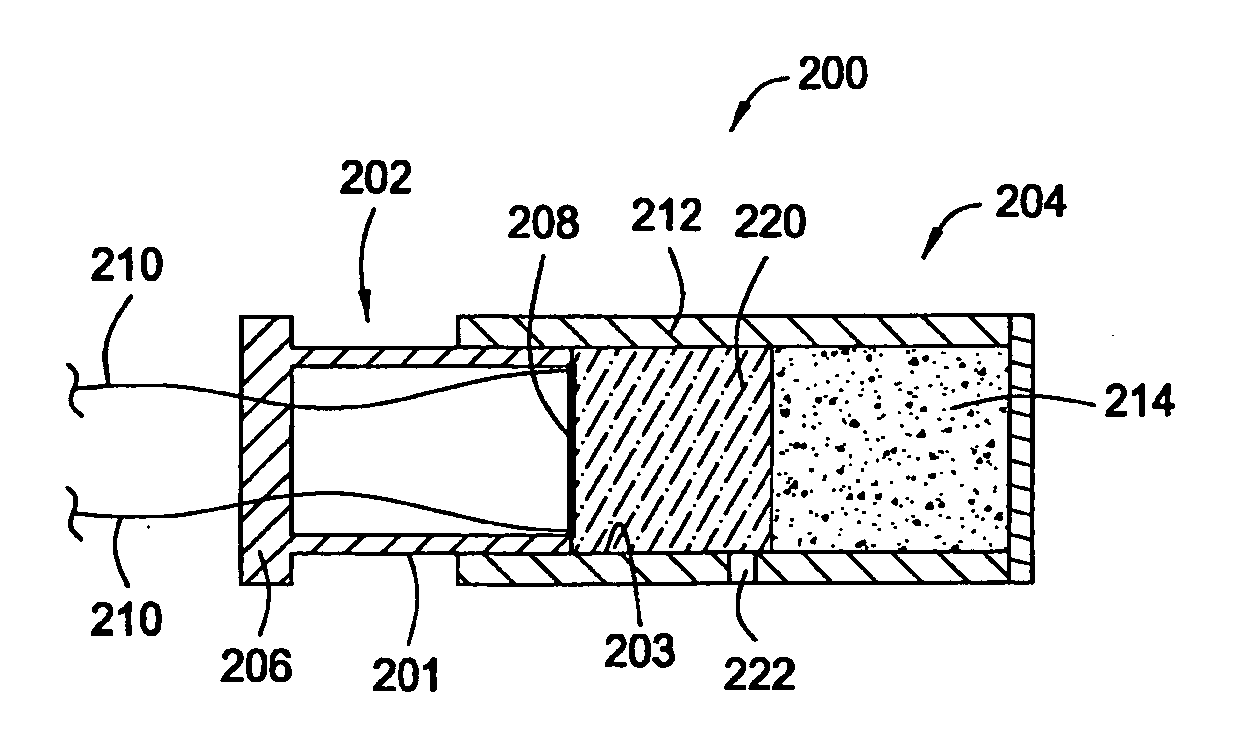

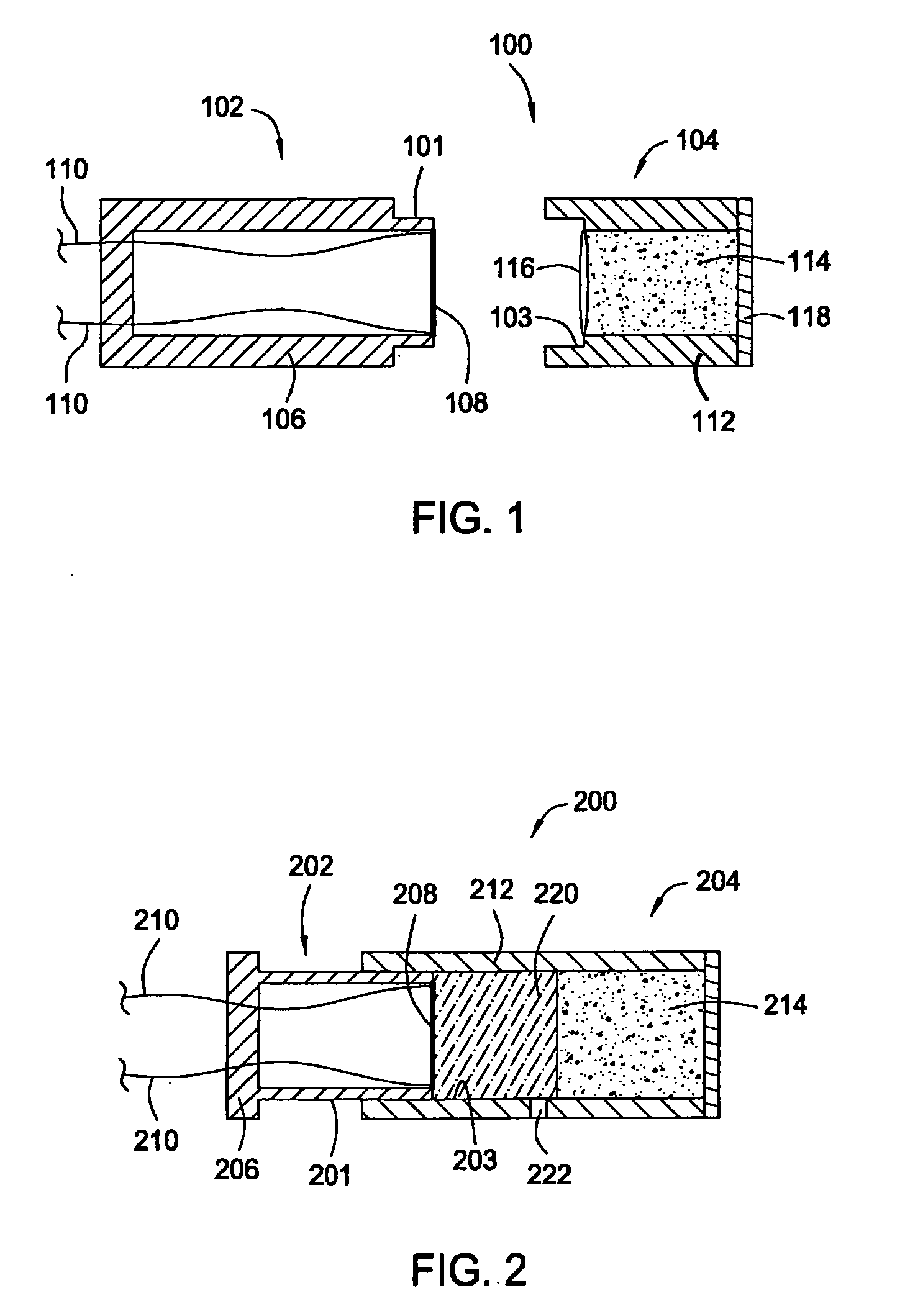

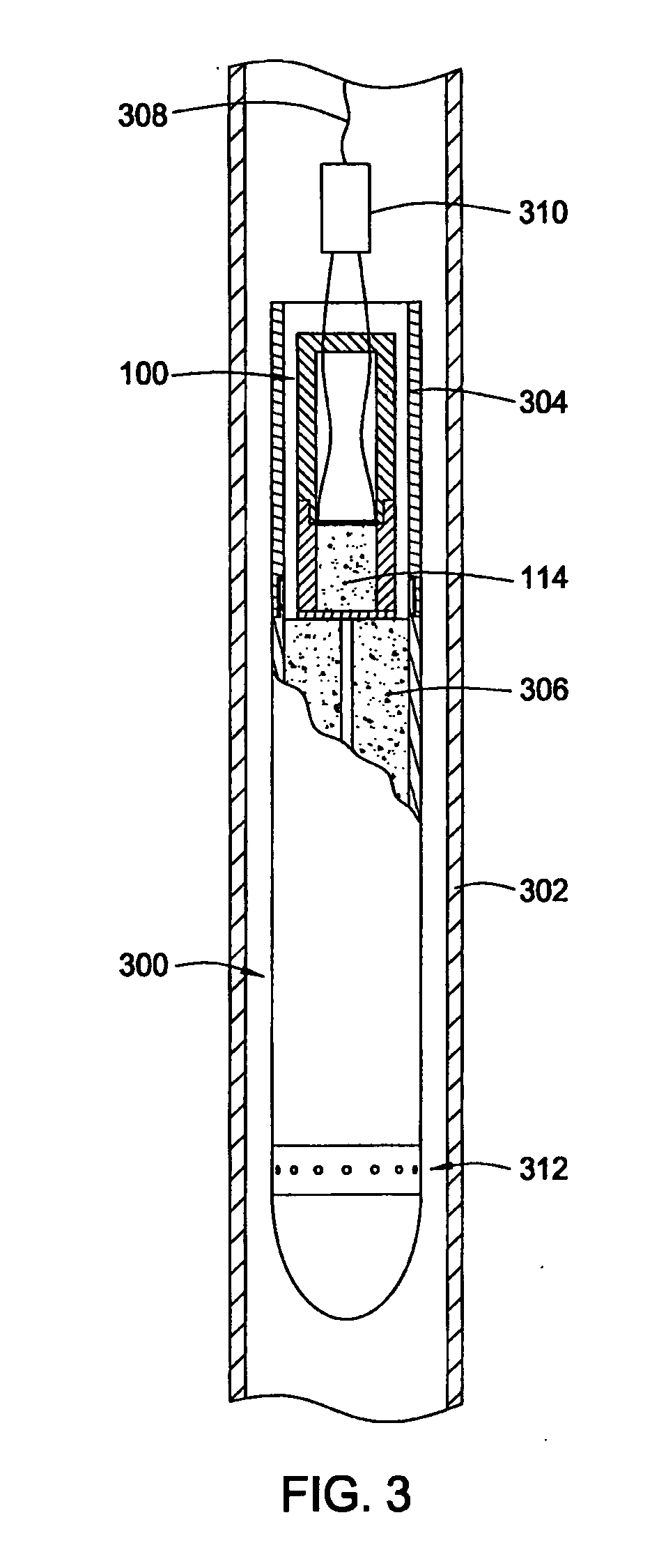

Methods and apparatus for detonating explosives or igniting flammables are disclosed. According to some embodiments of the invention, initiators include an initiating component holding an exploding bridgewire (EBW) or an exploding foil initiator (EFI) and a flammable component housing thermite. An end of the flammable component mates with a corresponding end of the initiating component. A method of initiating the explosives or flammables includes connecting the two components to assemble the initiator, disposing the initiator proximate the explosives or flammables, and activating the initiator to cause ignition of the thermite that then initiates the explosives or flammables. Additionally, a non-explosive kit for the initiator includes the two components with the EBW or EFI initially spaced from the thermite within the flammable component to make the initiator disarmed until final assembly thereof. Cutting torches and perforating guns provide examples of downhole tools that benefit from aspects of the invention.

Owner:WEATHERFORD TECH HLDG LLC

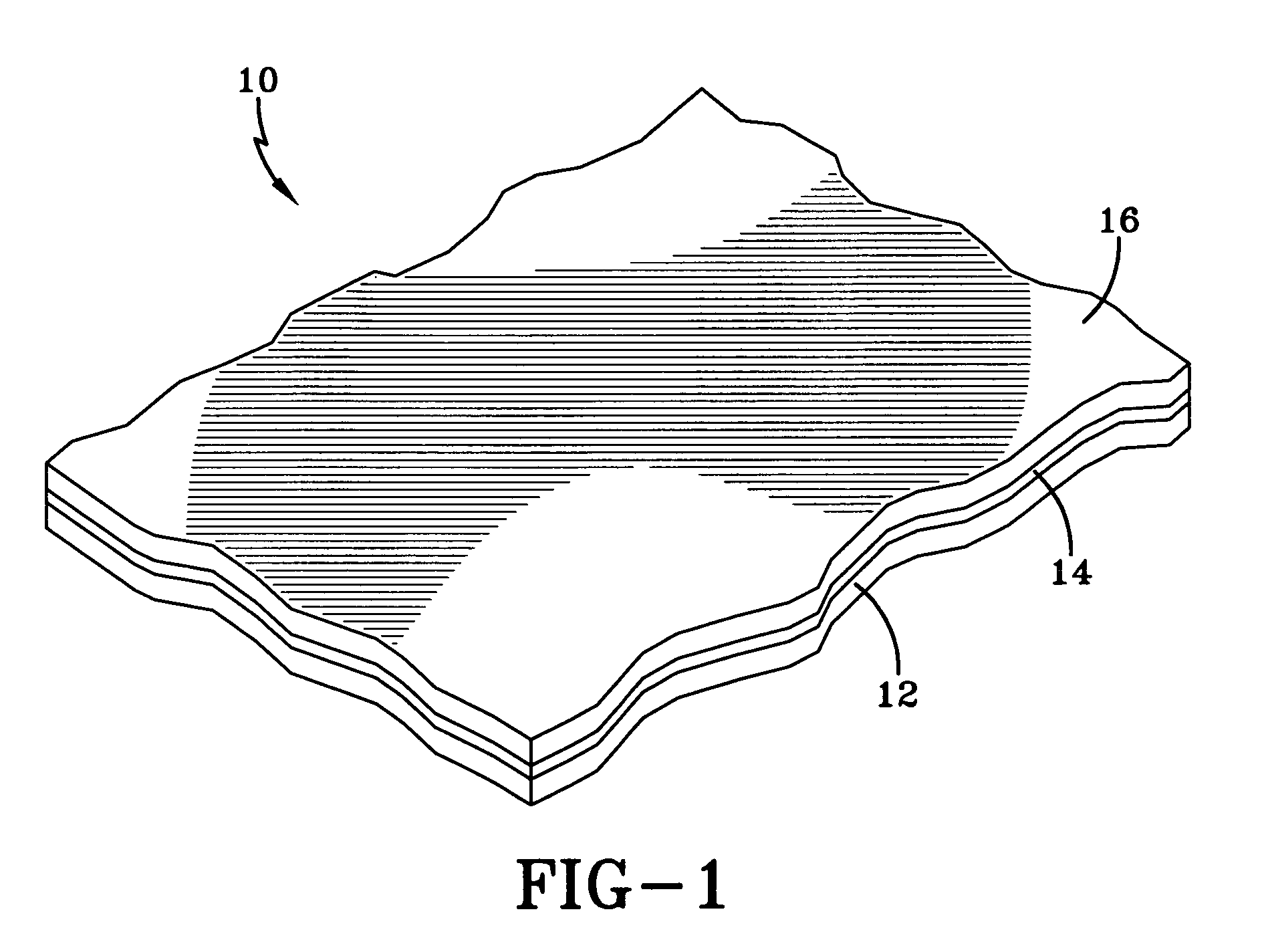

Integrated thin film explosive micro-detonator

A method of making a thin film explosive detonator includes forming a substrate layer; depositing a metal layer in situ on the substrate layer; and reacting the metal layer to form a primary explosive layer. The method and apparatus formed thereby integrates fabrication of a micro-detonator in a monolithic MEMS structure using “in-situ” production of the explosive material within the apparatus, in sizes with linear dimensions below about 1 mm. The method is applicable to high-volume low-cost manufacturing of MEMS safety-and-arming devices. The apparatus can be initiated either electrically or mechanically at either a single point or multiple points, using energies of less than about 1 mJ.

Owner:NAVY THE US SEC

Heat generating structures

A heat generating structure includes a substrate of a first material and a second material coating at least a portion and preferably all of the first material, where the second material is different from the first material. The structure also includes an additional material or compound such as ammonia borane that is impregnated or located within the structure. When the structure is thermally energized, the first and second materials react with each other in an exothermic and self-sustaining reaction that pyrolyzes the impregnated ammonia borane compound to create a target gas, for example, hydrogen from the ammonia borane. An additional material, for example, a thermite, may be interposed between the structure and the ammonia borane to facilitate the ignition of the ammonia borane.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

Apparatus and method for releaseably joining elements

InactiveUS7367738B2Gentle releaseLess risk of damageYielding couplingCosmonautic vehiclesEngineeringMechanical engineering

The apparatus and method for releasably joining first and second elements according to the present invention include a retaining member mounted to one of the elements and a reshapeable tube near the retaining member. The reshapeable tube has at least two states, an at least partially collapsed state and an at least partially expanded state. As such, the retaining member joins the elements while the reshapeable tube is in the at least partially collapsed state. Furthermore, the retaining member releases the other element while the reshapeable tube is in the at least partially expanded state, which deflects the retaining member. Thus, because components of the apparatus are not broken during the release of the elements, the amount of constrained or potential energy that is released when the retaining member releases the elements is substantially reduced or eliminated, which protects the elements from being damaged during the release.

Owner:THE BOEING CO

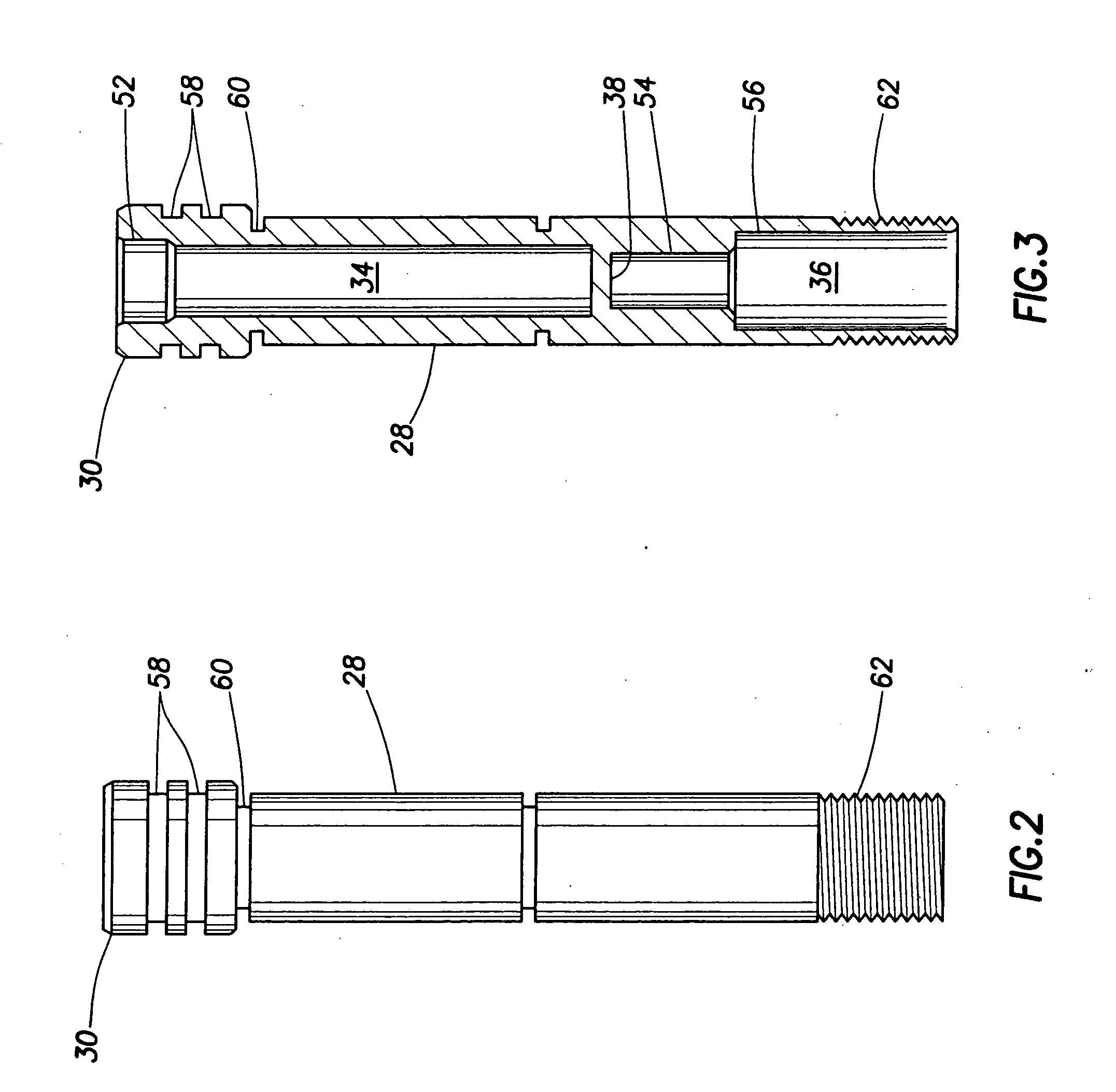

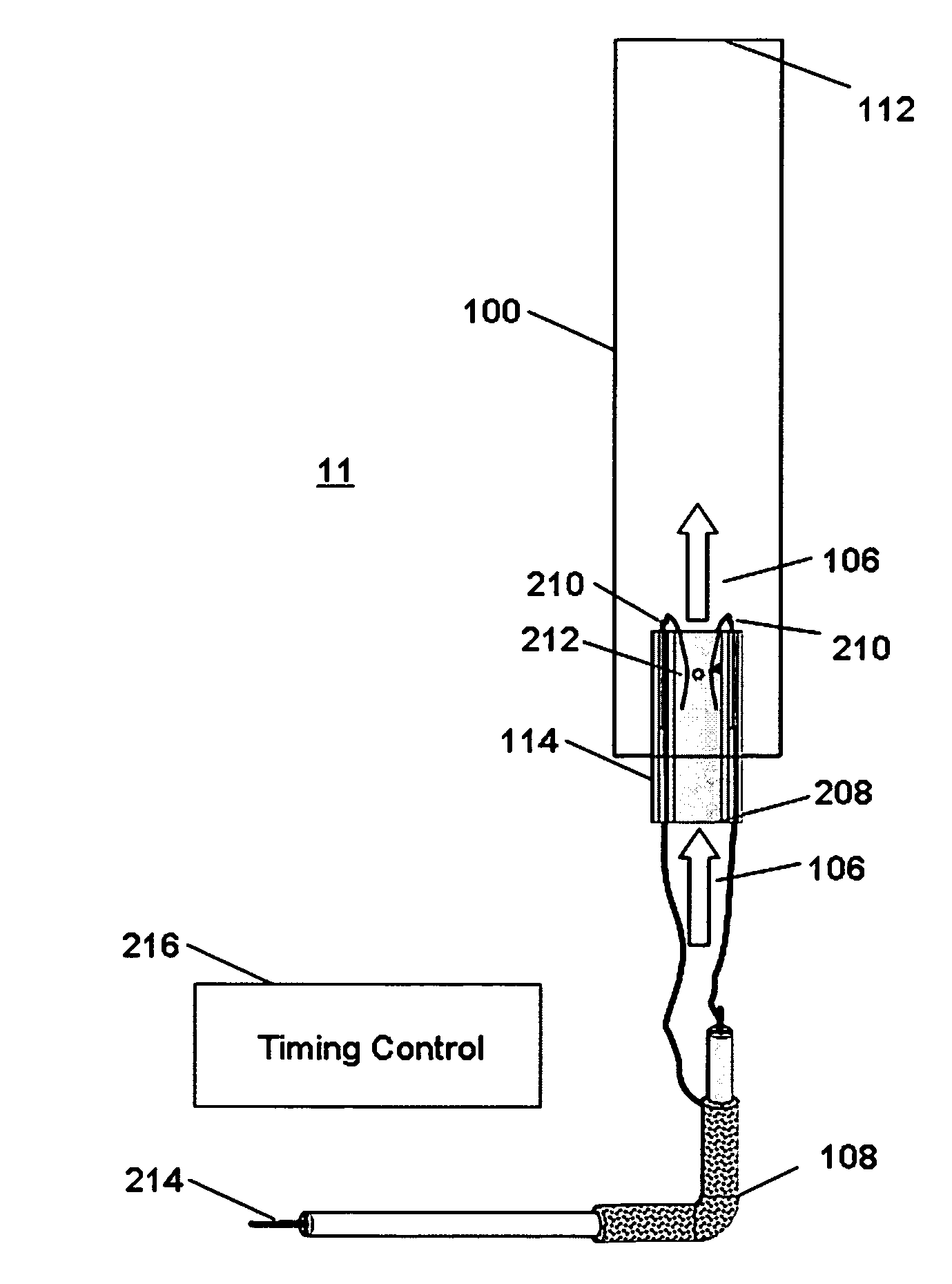

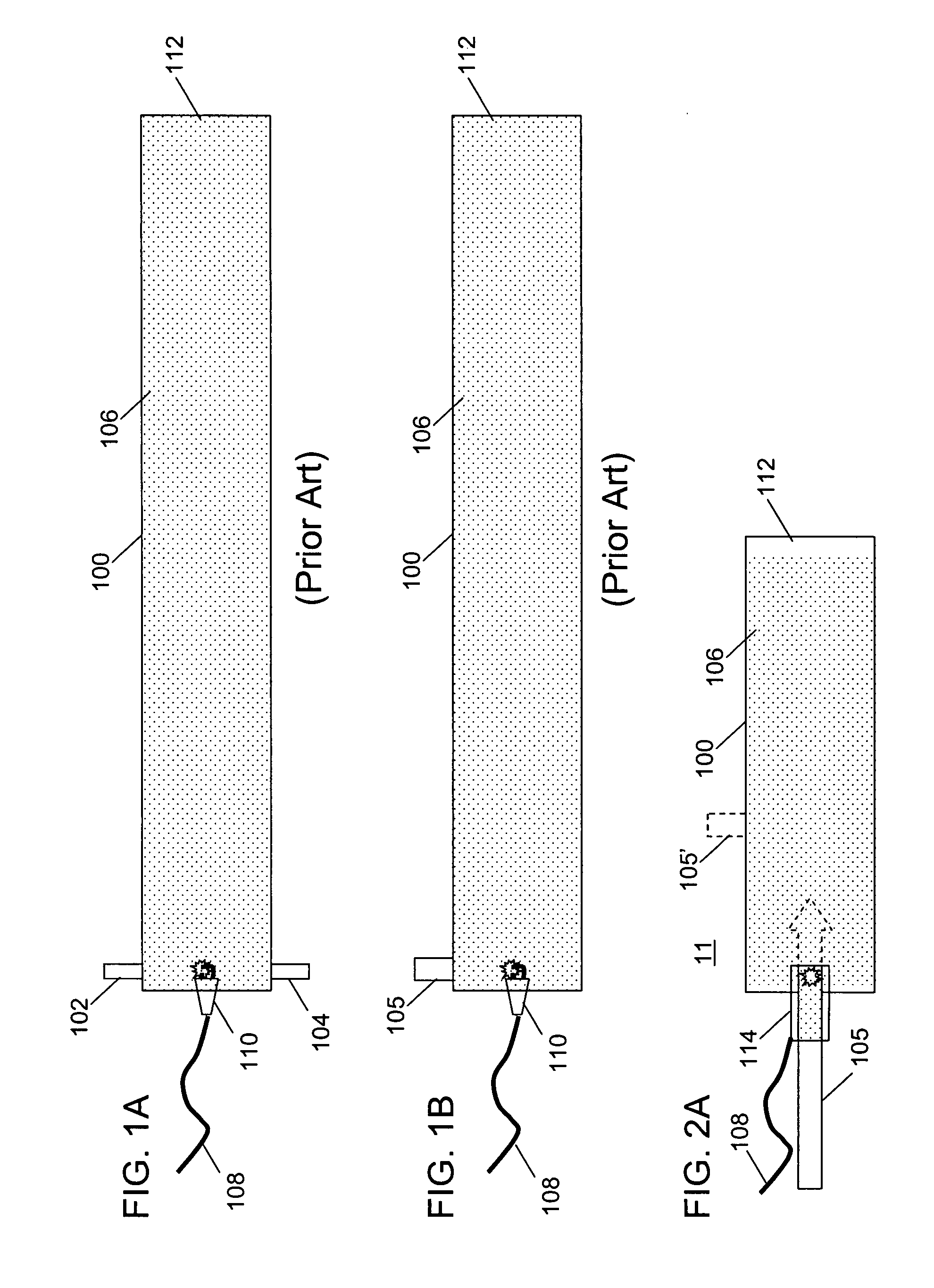

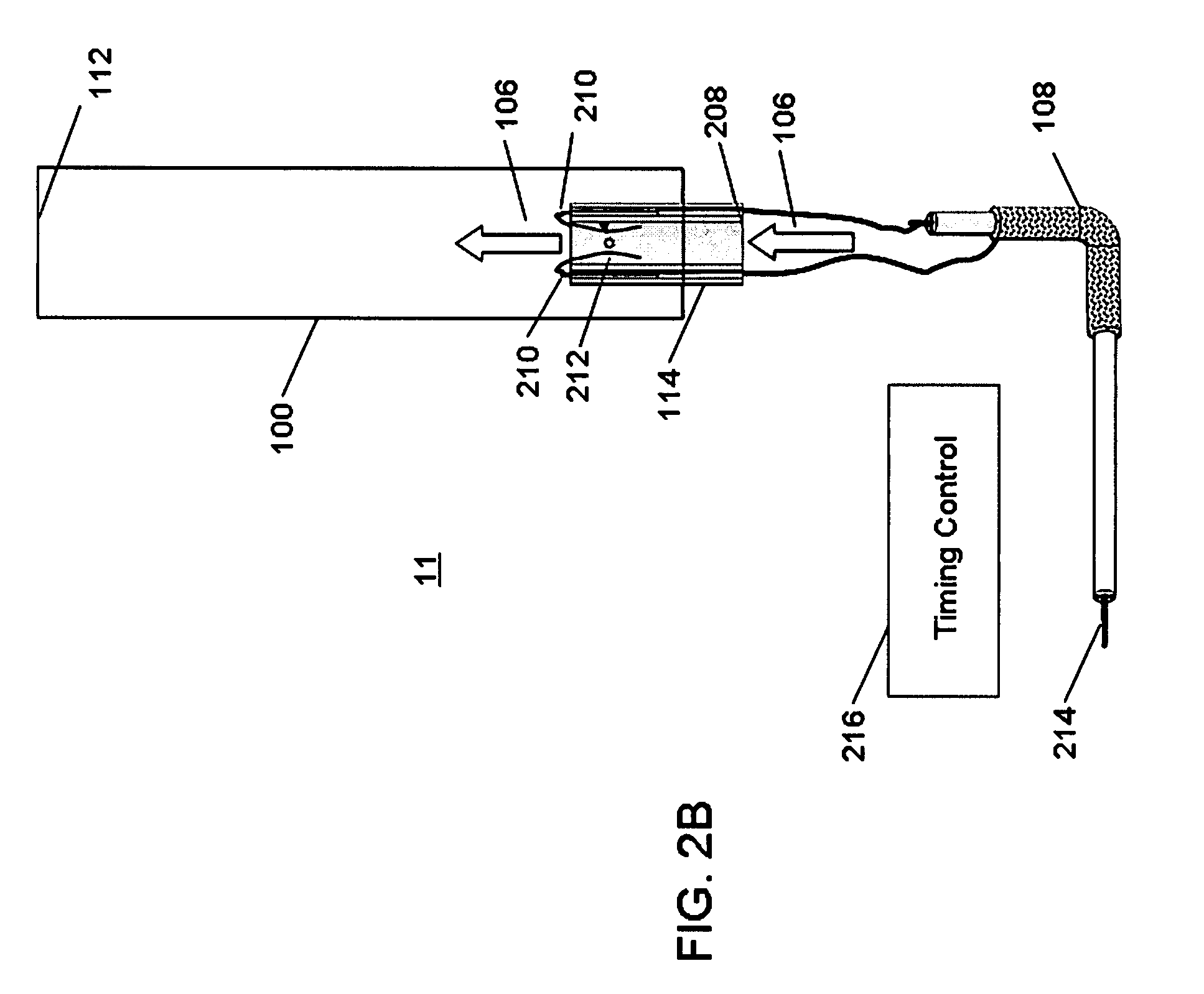

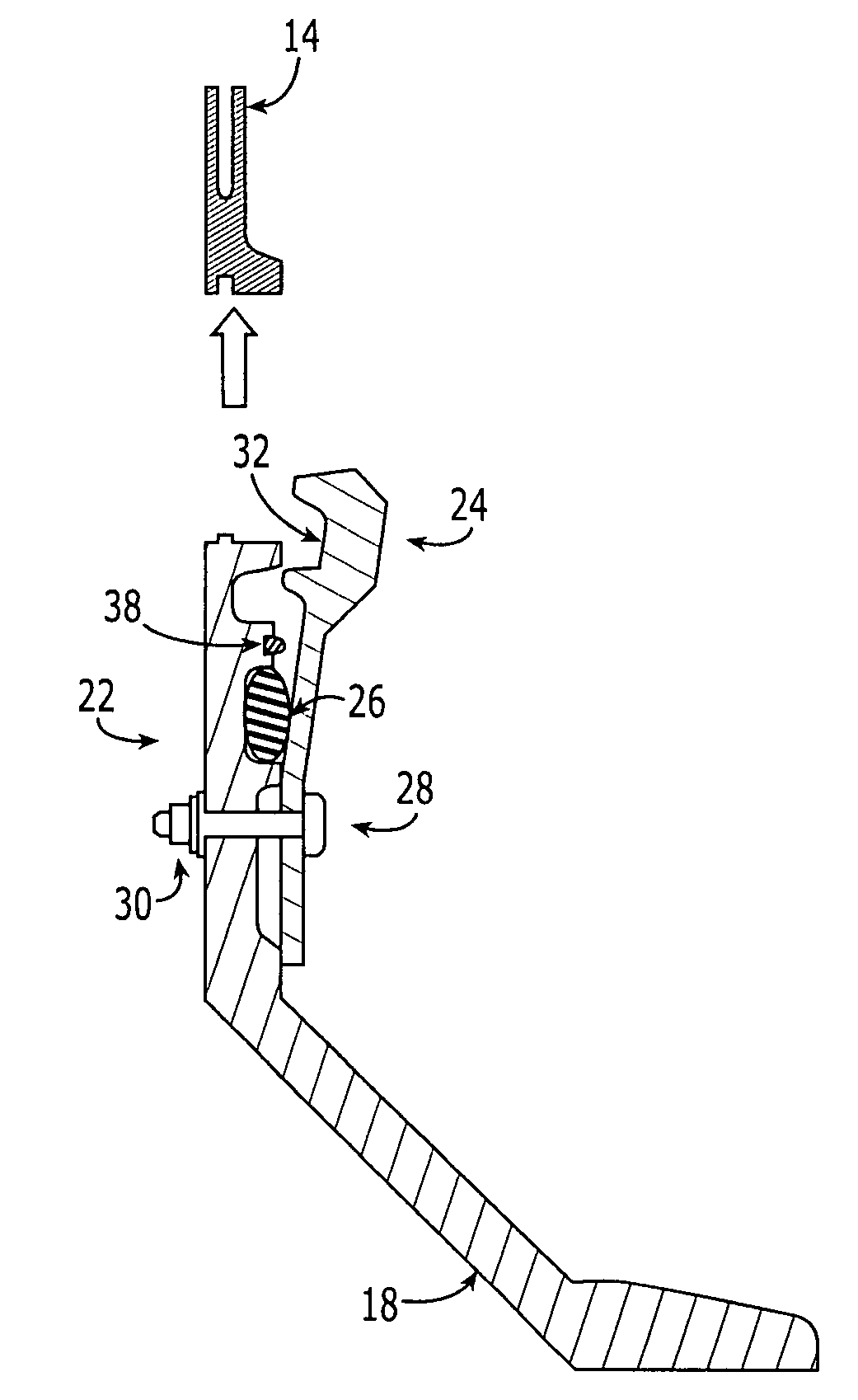

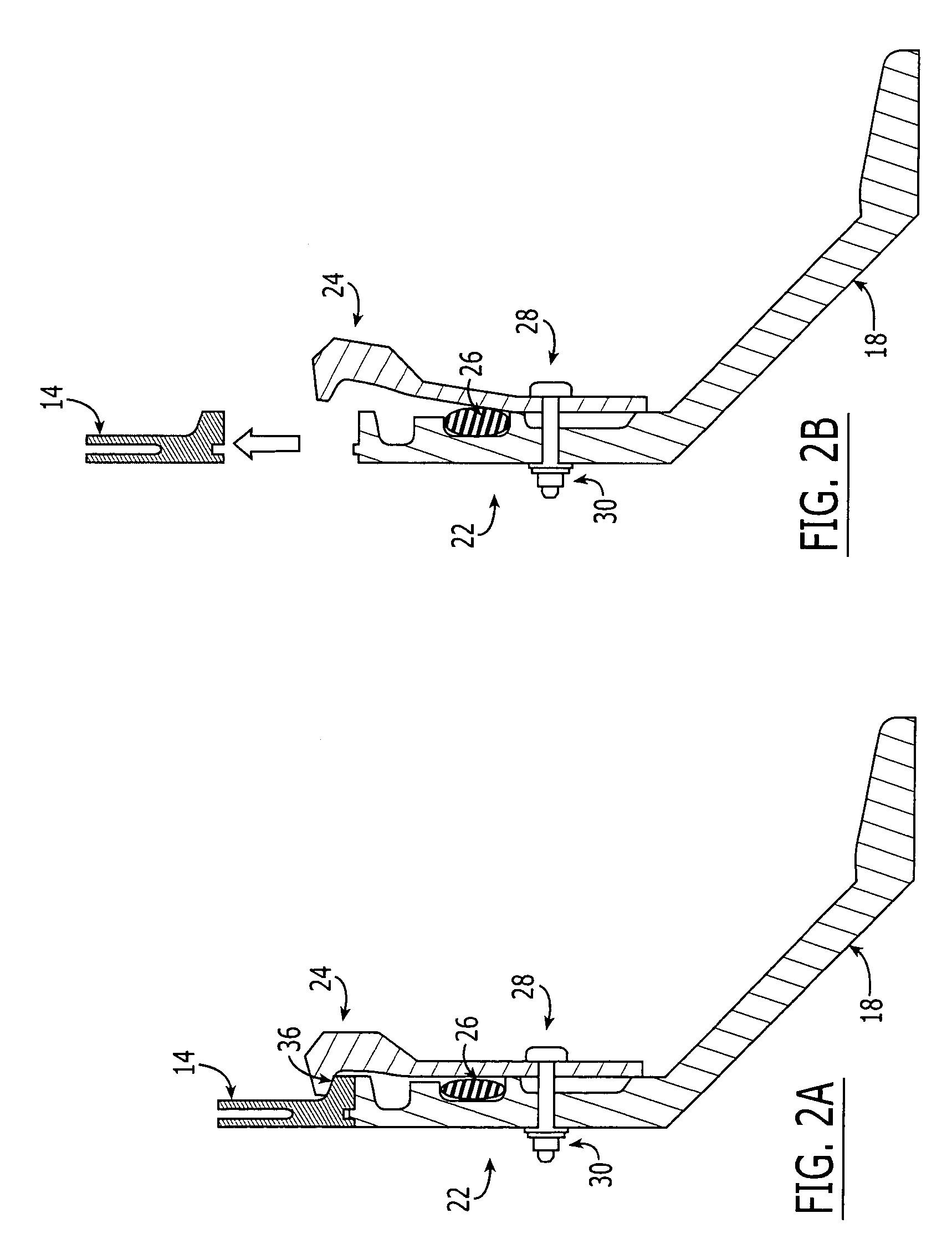

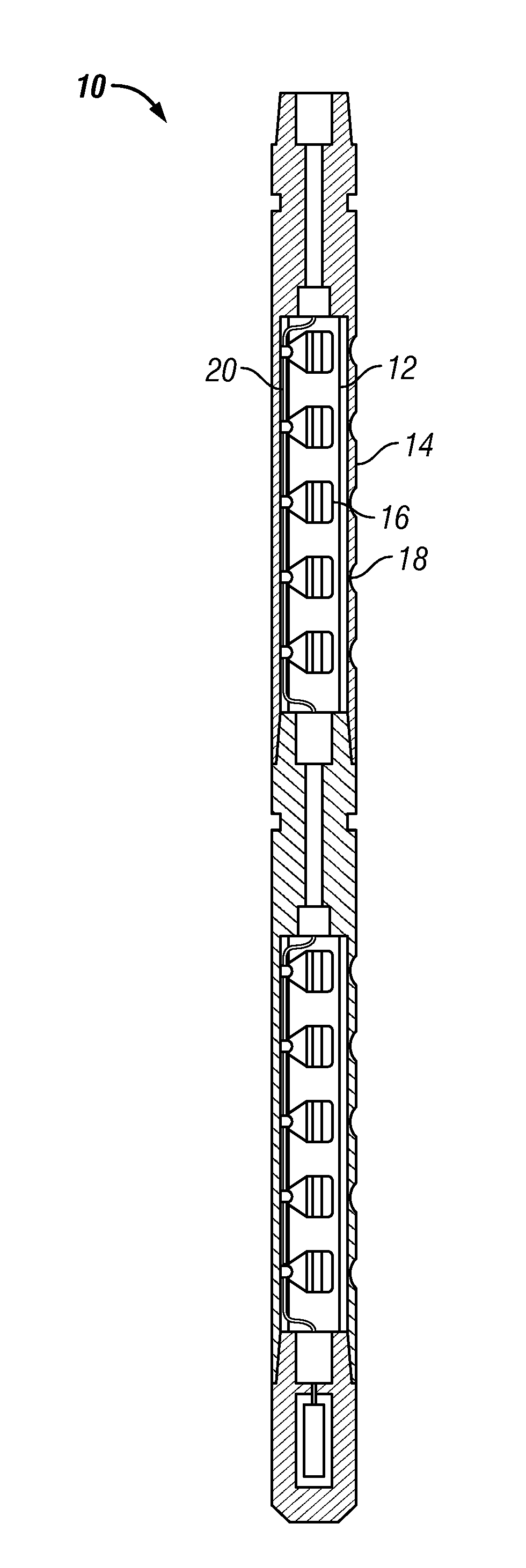

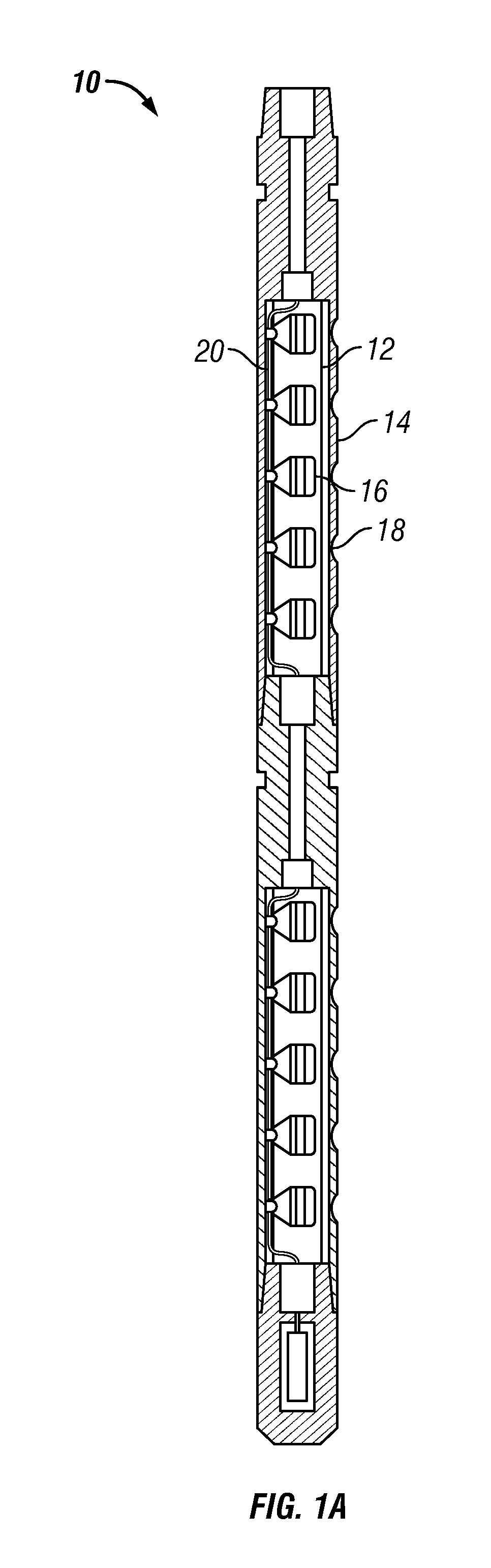

Retention member for perforating guns

ActiveUS20100263523A1Enhanced energetic couplingRemained chargedFuse ignition meansFuse connectorsDetonatorShaped charge

A perforating gun includes a charge tube having shaped charges affixed thereto. Each shaped charge includes a radially outward pointing post adapted to receive a detonator cord. A retention member installed on the post provides a compressive force that energetically couples the detonator cord to the post. The radially outermost portion of the retention member is radially flush with or radially recessed relative to the radially outermost portion of each post. In one embodiment, the retention member has a rounded medial portion, a central opening and a pair of locking tabs that point radially inward to the central opening. Each post may include a slot for receiving the detonator cord and a circumferential groove that is adapted to receive the locking tabs.

Owner:OWEN OIL TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com