Heat generating structures

a technology of generating structures and heat, applied in the direction of oxygen/ozone/oxide/hydroxide, chemistry apparatus and processes, explosives, etc., can solve the problems of low hydrogen generation amount and irrespective of propagation problems, and achieve the effect of facilitating the ignition of ammonia boran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

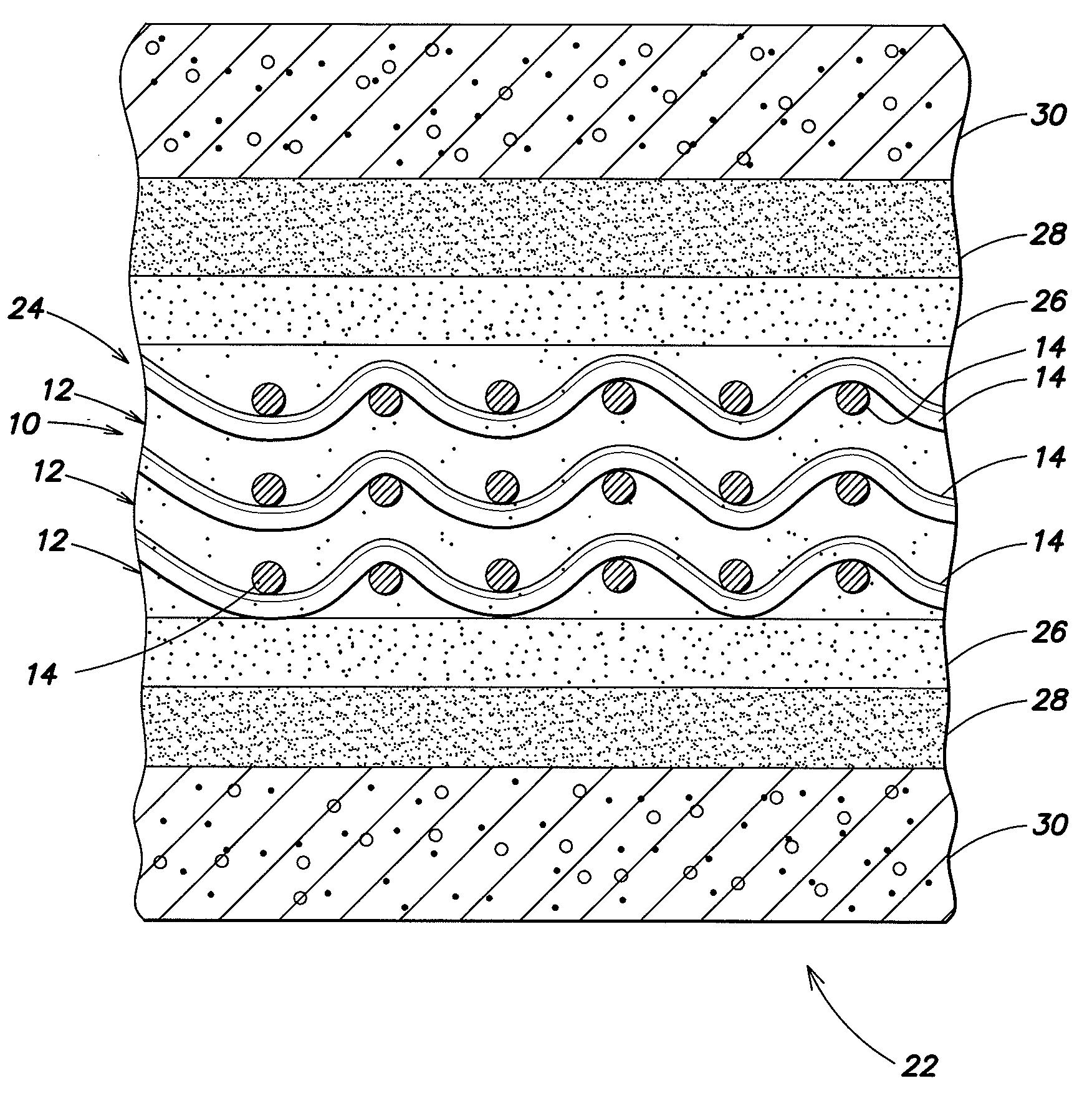

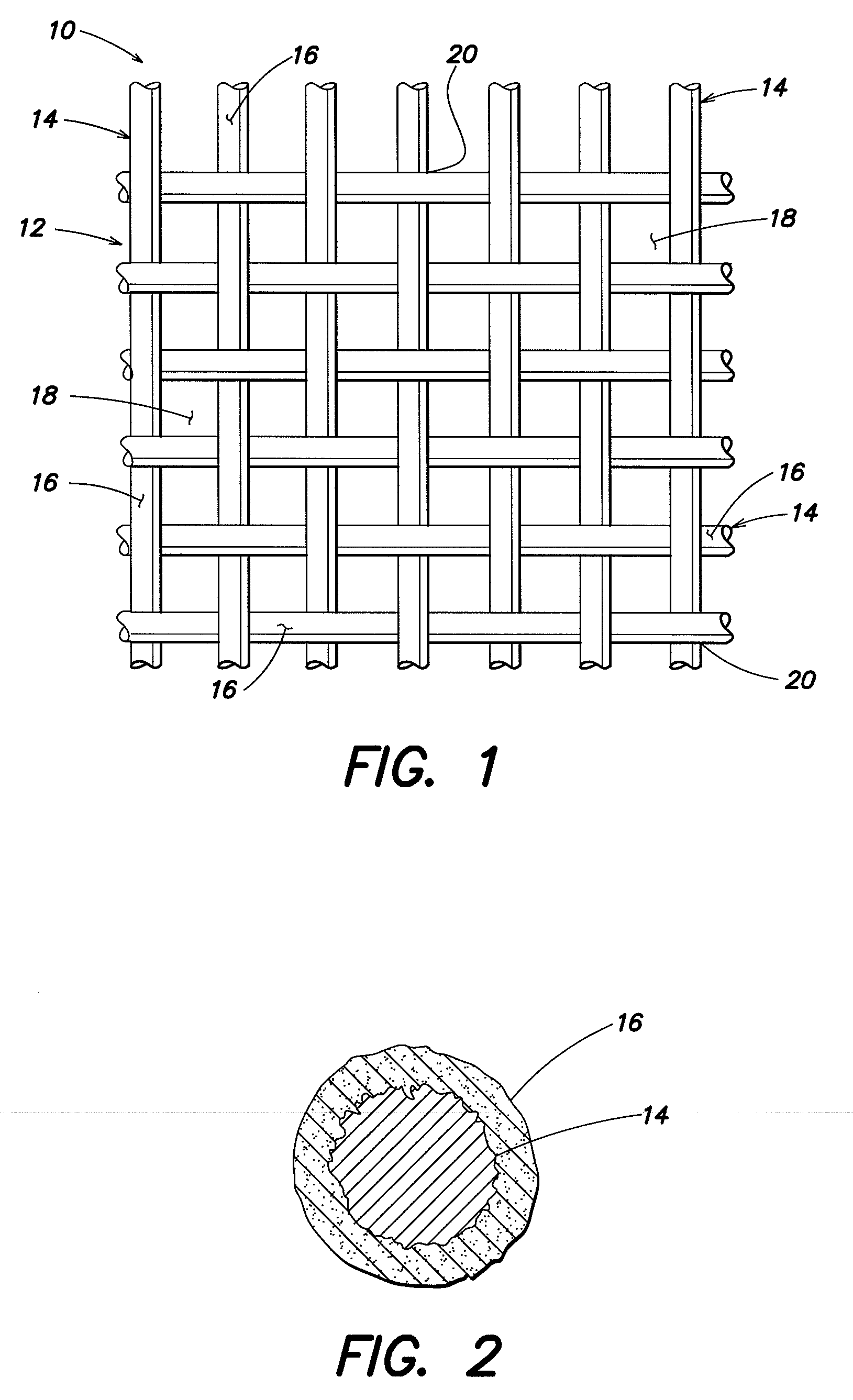

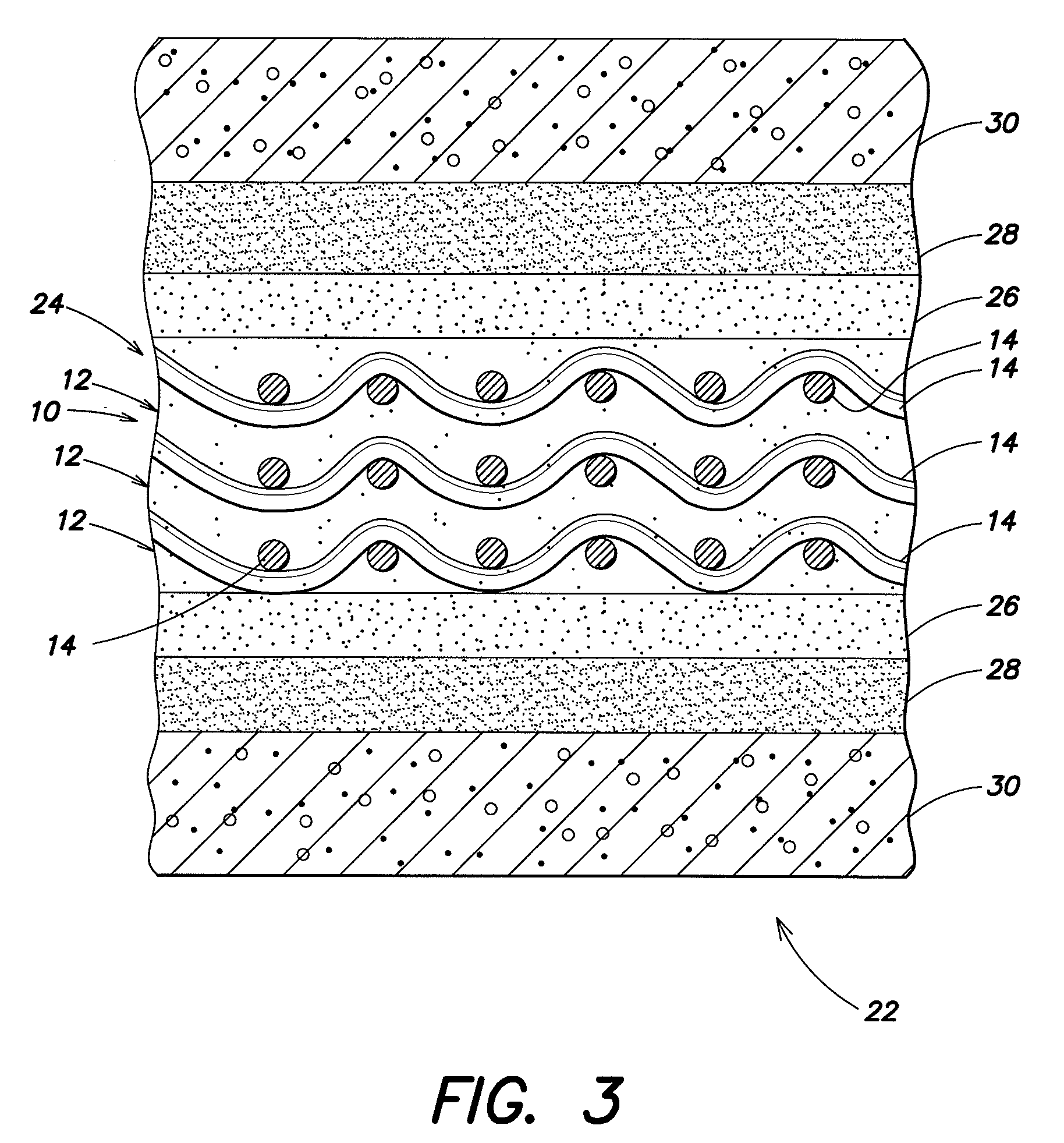

[0013]Referring to FIG. 1, there illustrated is a plan view of a preferred embodiment of a heat generating structure 10 in accordance with the present invention. The structure 10 may comprise at least two constituent portions: a substrate 12 comprised of a plurality of wires 14 of one material, preferably a reactive metal, where the substrate 12 is preferably continuous in all three dimensions; and a coating 16 of a second material, preferably also a reactive metal that is different from the metal comprising the wires 14. The coating 16 is applied on at least a portion of each substrate wire 14 and preferably, on the entirety of each substrate wire 14, to thereby form a substrate 12 of continuously-coated wires 14. Preferably, the three-dimensional structure of the substrate 12 is such that it has an appreciable amount of free volume (i.e., empty space creating voids 18 between crossing wires 14 in the mesh substrate 12). Thus, in FIG. 1 the substrate 12 is preferably a continuous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com