Welding flux matched with nickel-base welding strip with high Mn and high Nb crack-resistant defects, and welding method

An anti-crack and flux technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of immaturity, cracks, crack sensitivity, etc., and achieve the effect of no undercut, low impurity content, and reduction of harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

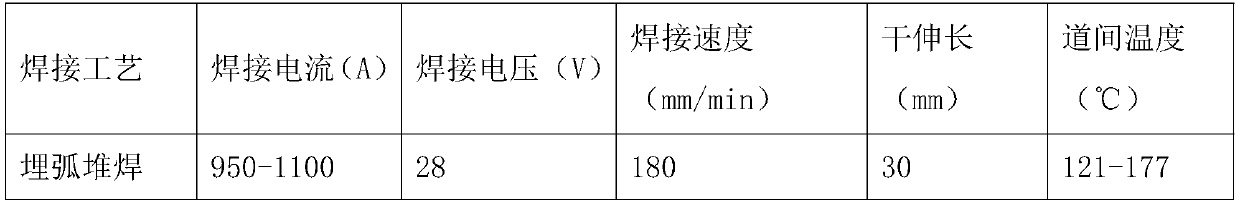

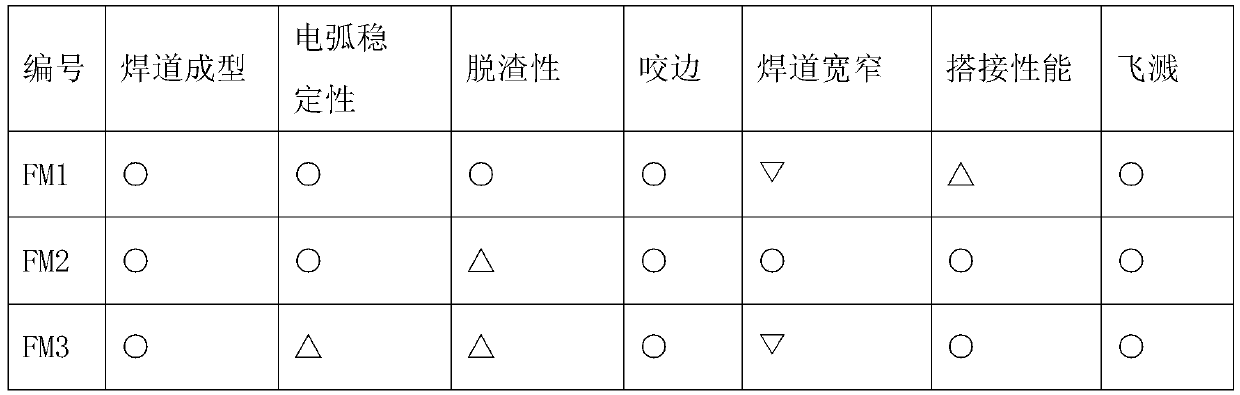

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: a kind of flux that this embodiment is used with high Mn, the high Nb nickel-based welding strip of anti-crack defect is made of 25-50 parts of CaF in parts by mass. 2 , 5-20 parts of SiO 2 , 10-40 parts Al 2 o 3 , 8-20 parts of CaO, 4-15 parts of MgO, Cr 2 o 3 ≤5 parts, iron alloy ≤8 parts, S≤0.015 parts and P≤0.02 parts.

[0019] The manufacturing method of the flux used in conjunction with the high-Mn, high-Nb crack-resistant nickel-based welding strip in this embodiment is as follows:

[0020] Ingredients: Weigh the raw materials and put them in the same container;

[0021] Dry mixing: Stir to mix the powder evenly;

[0022] Wet mixing: add potassium sodium water glass with a modulus of 2.6 and mix evenly;

[0023] Granulation: The wet material is rotated and granulated to achieve 10-60 mesh particles;

[0024] Sintering: Carry out high-temperature sintering in an electric furnace to eliminate the moisture and crystal water ...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the flux is made of 38-45 parts by mass of CaF 2 , 7-14 parts of SiO 2 , 12-35 parts Al 2 o 3 , 11-18 parts of CaO, 4-12 parts of MgO, 1-4 parts of Cr 2 o 3 , iron alloy≤8 parts, S≤0.015 parts and P≤0.02 parts. Others are the same as in the first embodiment.

specific Embodiment approach 3

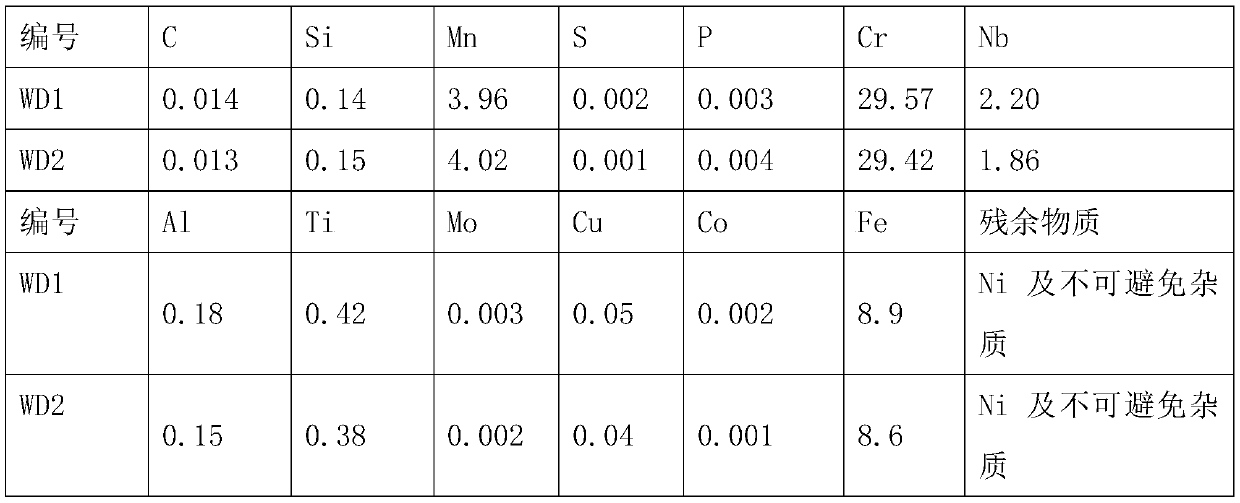

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the weight percent composition of high Mn, high Nb crack defect-resistant nickel-based welding strip is C≤0.04%, Si≤0.50%, Mn≤5.0 %, S≤0.015%, P≤0.020%, Cr: 28.0-31.5%, Fe: 7.0-12.0%, Nb≤2.5%, Cu≤0.30%, Al≤0.50%, Ti≤0.50%, Mo≤0.05% , Co≤0.02%, and the balance is nickel. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com