Insert material for heat-resisting ductile iron stamping die

A technology of stamping die and heat-resistant ductile iron, applied in the field of heat-resistant ductile iron mold material, can solve the problem of high cost of die steel, and achieve the effects of low fatigue crack length, good comprehensive performance and reasonable composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

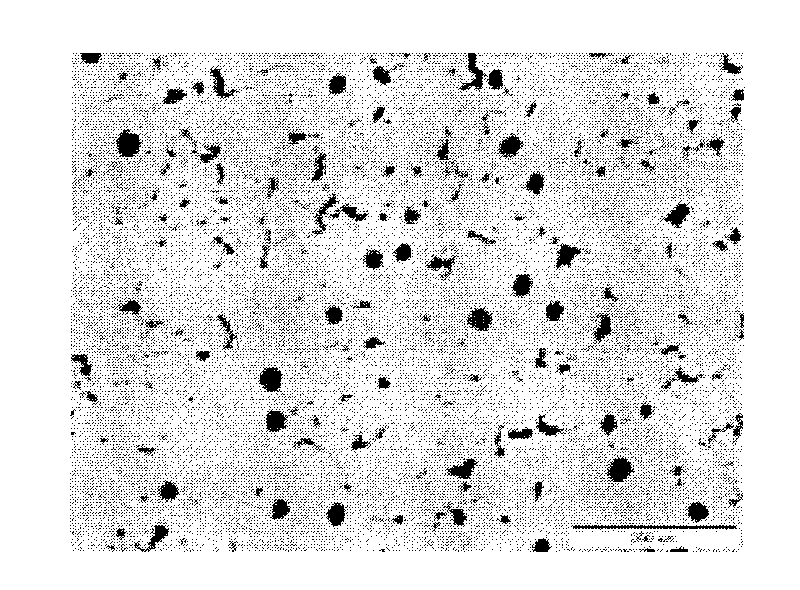

[0035] refer to figure 1 , the components of the heat-resistant ductile iron stamping die insert material according to the present invention and the content by weight percentage (wt.%) are: C: 2.6%, Si: 5.5%, Mn: 0.8%, Cr: 0.6% , the balance being Fe. It is smelted in an alkaline intermediate frequency induction furnace. First, pig iron and scrap steel are melted in the furnace, and then alloy is added to adjust the alloy composition. After the iron alloy is cleared, the slag on the surface of the molten iron is removed, and finally it is poured out of the furnace. Its spheroidizing treatment is the same as that of general nodular cast iron, that is, the punching method is adopted. The molten iron temperature is about 1450°C to 1500°C, and the spheroidizing temperature is about 1350°C to 1450°C. A rare earth magnesium nodulizer is used in an amount of 0.4-1.6% of the total amount (wt.%) of the molten iron. Using green sand casting.

[0036] The shape and distribution of g...

Embodiment 2

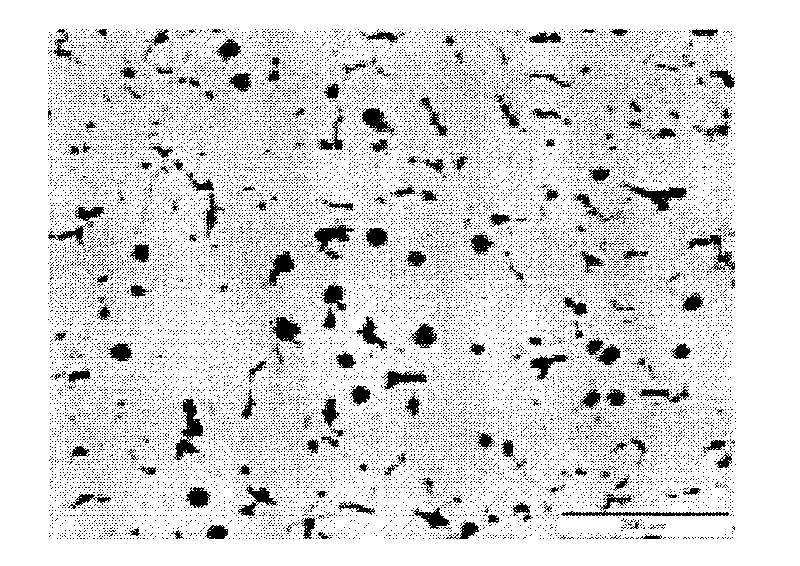

[0038] refer to figure 2 , the components of the heat-resistant ductile iron stamping die insert material according to the present invention and the content by weight percentage (wt.%) are: C: 2.6%, Si: 5.5%, Mn: 1.0%, Cr: 0.8% , the balance being Fe. It is smelted in an alkaline intermediate frequency induction furnace. First, pig iron and scrap steel are melted in the furnace, and then alloy is added to adjust the alloy composition. After the iron alloy is cleared, the slag on the surface of the molten iron is removed, and finally it is poured out of the furnace. Its spheroidizing treatment is the same as that of general nodular cast iron, that is, the punching method is adopted. The molten iron temperature is about 1450°C to 1500°C, and the spheroidizing temperature is about 1350°C to 1450°C. A rare earth magnesium nodulizer is used in an amount of 0.4-1.6% of the total amount (wt.%) of the molten iron. Using green sand casting.

[0039] The morphology and distributio...

Embodiment 3

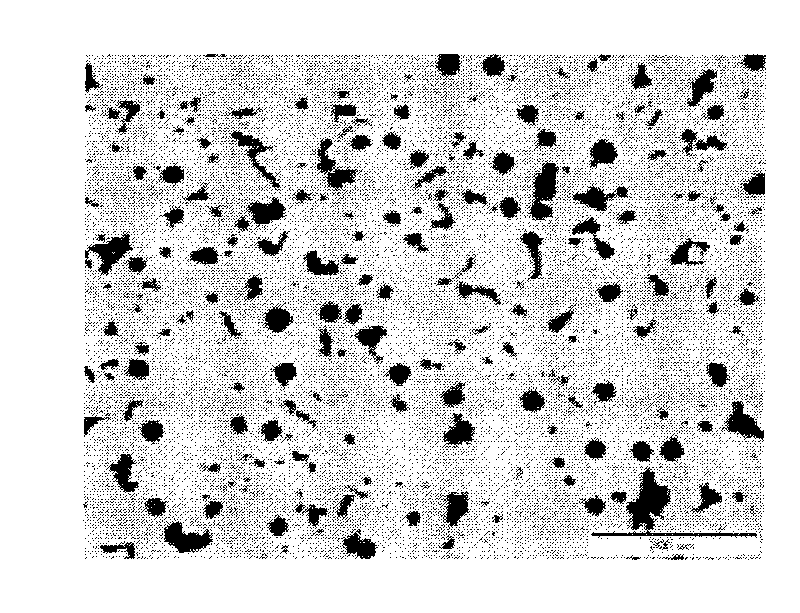

[0041] refer to image 3 , the components of the heat-resistant ductile iron stamping die insert material according to the present invention and the content by weight percentage (wt.%) are: C: 2.6%, Si: 5.0%, Mn: 0.6%, Cr: 0.8% , the balance being Fe. It is smelted in an alkaline intermediate frequency induction furnace. First, pig iron and scrap steel are melted in the furnace, and then alloy is added to adjust the alloy composition. After the iron alloy is cleared, the slag on the surface of the molten iron is removed, and finally it is poured out of the furnace. Its spheroidizing treatment is the same as that of general nodular cast iron, that is, the punching method is adopted. The molten iron temperature is about 1450°C to 1500°C, and the spheroidizing temperature is about 1350°C to 1450°C. A rare earth magnesium nodulizer is used in an amount of 0.4-1.6% of the total amount (wt.%) of the molten iron. Using green sand casting.

[0042] The morphology and distribution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com