Soft magnetic structural steel resisting salt fog corrosion and its making process

A manufacturing method and technology for structural steel, applied in the direction of metal rolling, etc., can solve problems such as insufficient resistance to salt spray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Embodiment: The manufacturing process of the soft magnetic structural steel plate of the present invention is as follows: smelting in a vacuum induction furnace in a laboratory, and casting starts immediately after the composition of the molten steel reaches the target composition, and the casting temperature of the molten steel is 15252-1550°C. The soaking time of the slab in the heating furnace = plate thickness (mm) × (0.5-1.0) min / mm, the soaking temperature is 1050°C-1100°C, the hot rolling adopts 9-pass rolling process, and the cumulative reduction rate is 70 % to 90%, the finish rolling temperature is 800°C to 850°C, the transfer time between the end of finish rolling and the start of accelerated cooling is 15s to 30s, the surface temperature of the ingot is above 800°C when the accelerated cooling starts, and the accelerated cooling rate is 10°C / s~30°C / s, the stop cooling temperature is 500°C~600°C, then slowly cool to 300°C (slow cooling rate ≤ 1°C / min), and the...

Embodiment 3

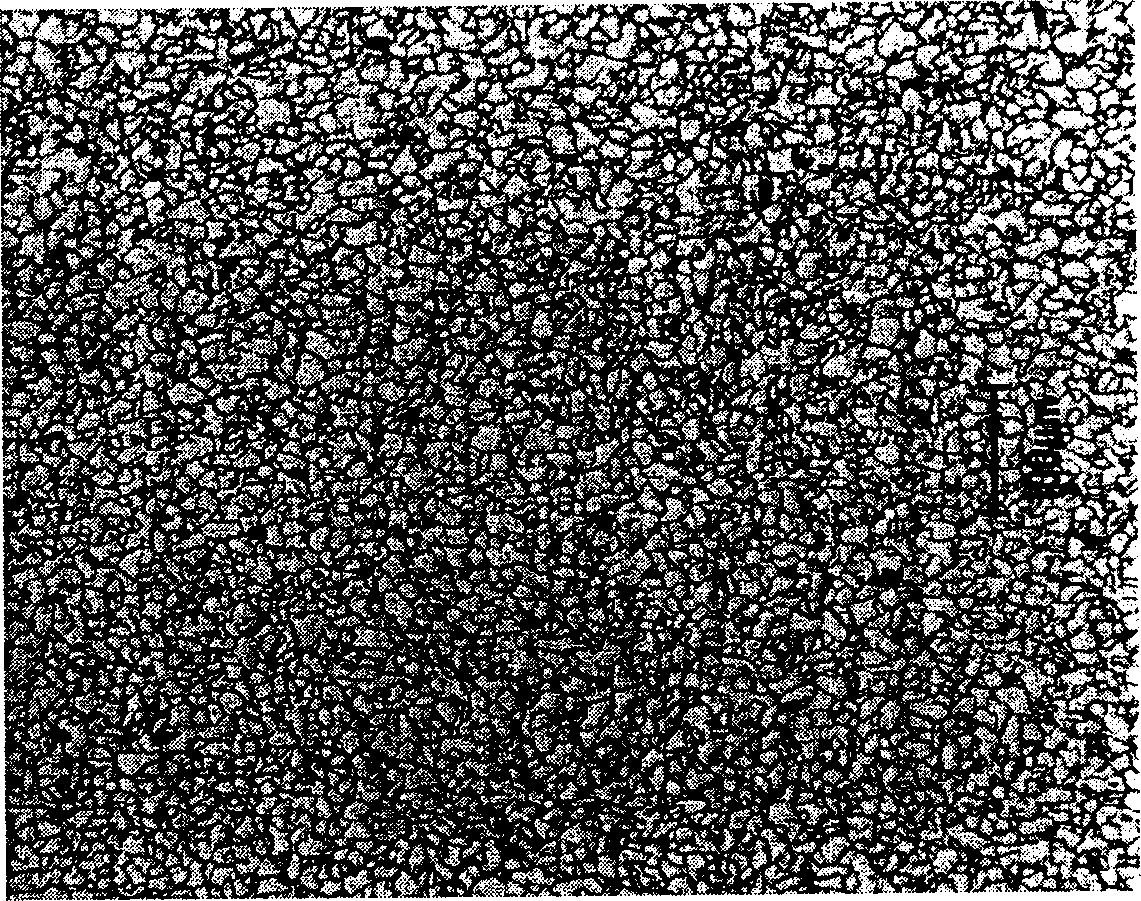

[0062] Embodiment 3 is that the metallographic structure of the present invention C is shown in accompanying drawing

[0063]

[0064] ◆Welding heat simulation parameters: single cycle, simulated peak temperature 1350℃, t 8 / 5 = 50 seconds.

[0065]

[0066] The maglev express train system is a fast, safe, efficient and environment-friendly means of transportation. At present, the fastest maglev train in the world has reached a speed of over 560 km / h. As a fast, safe, efficient and environment-friendly means of transportation, the maglev express train system is more and more favored by people, and there will be a climax in the construction of the maglev express train system at home and abroad; as a key component of the maglev express train system, the side guide Soft magnetic structural steel plates, especially high-performance soft magnetic structural steel plates used in coastal areas, will have broad market prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com