Superhard grinding tool ceramic bonding agent, preparation method of superhard grinding tool ceramic bonding agent and superhard grinding tool ceramic bonding agent standard sample

A ceramic bond and superhard abrasive technology, which is used in the preparation of test samples, abrasives, sampling, etc., can solve the problems of unstable test results and low test efficiency, and achieve reasonable composition design, accurate setting and high efficiency. The effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

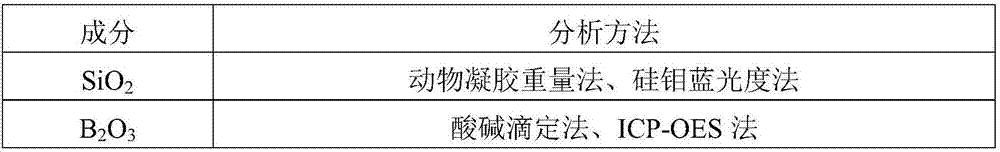

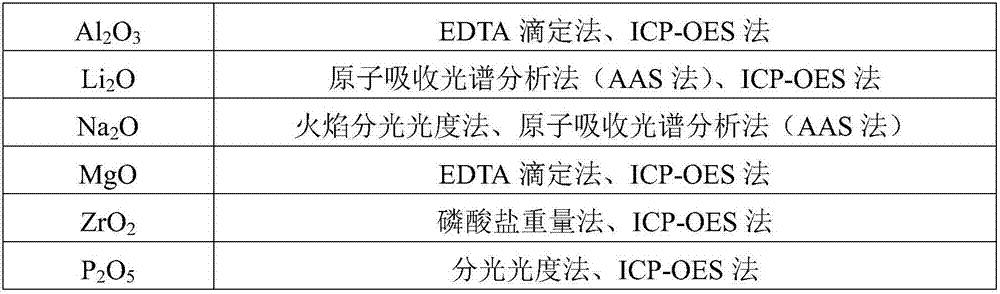

Method used

Image

Examples

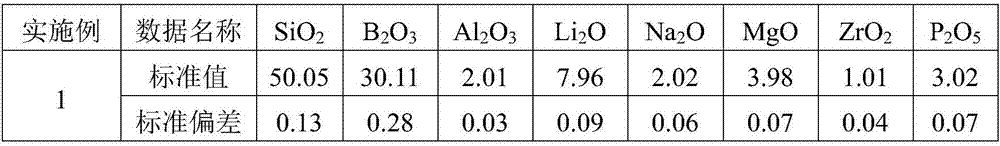

Embodiment 1

[0029] The superhard abrasive vitrified bond of the present embodiment is made of the following raw materials in mass percentage: 50% SiO 2 , 30% B 2 o 3 , 2% Al 2 o 3 , 8% Li 2 O, 2% Na 2 O, 4% MgO, 1% ZrO 2 , 3% P 2 o 5 ; The vitrified bond for superhard abrasive tools is a powdery solid with a particle size not greater than 75 μm.

[0030] The preparation method of the superhard abrasive tool vitrified bond of the present embodiment comprises the following steps:

[0031] 1) According to the material-to-ball ratio of 2:1, take the raw materials in the formula amount, put them into a ball mill, and mix them evenly at a speed of 40r / min for 12 hours, then put them into a high-temperature frit furnace and heat them to 1360°C, and keep them warm for 3 hours Carry out sufficient melting, and then water quenching to obtain glass frit;

[0032] 2) Put the glass frit obtained in step 1) into an oven and dry at 100°C for 5 hours, then put the dried glass frit into a ball m...

Embodiment 2

[0035] The superhard abrasive vitrified bond of the present embodiment is made of the following raw materials in mass percentage: 55% SiO 2 , 23% B 2 o 3 , 3.5% Al 2 o 3 , 6.5% Li 2 O, 3.5% Na 2 O, 3% MgO, 0.5% ZrO 2 , 5% P 2 o 5 ; The vitrified bond for superhard abrasive tools is a powdery solid with a particle size not greater than 75 μm.

[0036] The preparation method of the superhard abrasive tool vitrified bond of the present embodiment comprises the following steps:

[0037] 1) According to the material-to-ball ratio of 1:1, take the raw materials in the formula amount, put them into a ball mill, and mix them evenly at a speed of 45r / min for 15 hours, then put them into a high-temperature frit furnace and heat them to 1360°C, and keep them warm for 3 hours Carry out sufficient melting, and then water quenching to obtain glass frit;

[0038] 2) Put the glass frit obtained in step 1) into an oven and dry at 90°C for 6 hours, then put the dried glass frit into a...

Embodiment 3

[0041] The superhard abrasive vitrified bond of the present embodiment is made of the following raw materials in mass percentage: 60% SiO 2 , 17% B 2 o 3 , 5% Al 2 o 3 , 5% Li 2 O, 5% Na 2 O, 2% MgO, 5% ZrO 2 , 1% P 2 o 5 ; The vitrified bond for superhard abrasive tools is a powdery solid with a particle size not greater than 75 μm.

[0042] The preparation method of the superhard abrasive tool vitrified bond of the present embodiment comprises the following steps:

[0043]1) According to the material-ball ratio of 1.5:1, take the raw materials in the formula amount, put them into a ball mill, and mix them evenly at a speed of 50r / min for 18 hours, then put them into a high-temperature frit furnace and heat them to 1360°C, and keep them warm for 3 hours Carry out sufficient melting, and then water quenching to obtain glass frit;

[0044] 2) Put the glass frit obtained in step 1) into an oven to dry at 110°C for 4 hours, then put the dried glass frit into a ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com