Surface active agent and developing solution used for color filter negative photoresist

A surfactant and developer technology, applied in the field of compounds and developers, can solve the problems affecting the development uniformity, the partial erosion of the defoamer pattern, the difference in pattern thickness, etc., and achieve good development fineness, accurate size, and no production Distortion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

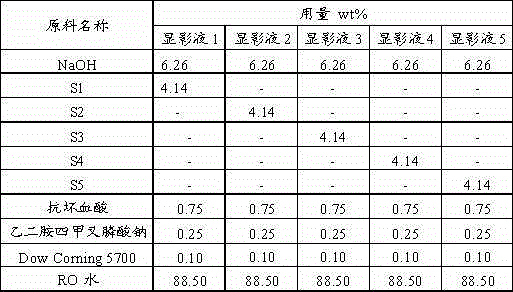

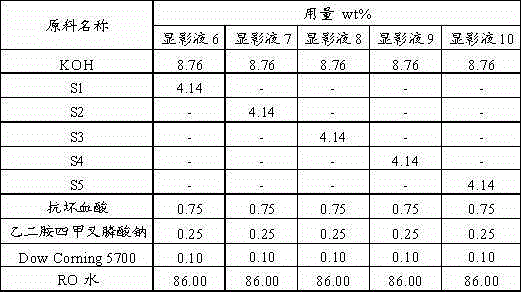

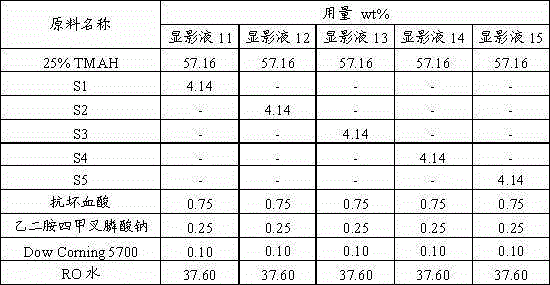

Examples

Embodiment 1

[0027] Provide a kind of surfactant, described surfactant is block type polyether nonionic surfactant, is to have the polyoxyethylene-polyoxypropylene block polymer of structure shown in general formula:

[0028] .

[0029] where R 1 , R 2 Each independently represents a C1-C18 aliphatic or aromatic hydrocarbon group, preferably a C6-C15 aliphatic or aromatic hydrocarbon group. x is an integer of 0-5, preferably an integer of 1-4. EO is a polyoxyethylene chain segment, PO is a polyoxypropylene chain segment, the bonding position of the polyoxyethylene chain segment and the polyoxypropylene chain segment in the general formula can be determined arbitrarily, and the preferred bonding position is the polyoxypropylene chain segment Located at the end of the polyether, the polyether is an EO segment or a PO segment, and the end is far away from R 1one end. m represents an integer of 0-20, n represents an integer of 0-10, the values of m and n are different from 0 at the sa...

Embodiment 2

[0036] The AEO-9 in Example 1 was replaced with OP-10, and the feeding ratio and reaction method were unchanged to obtain the block polyether surfactant S2. Wherein OP-10 is an alkylphenol polyoxyethylene ether nonionic surfactant from Ham Company.

Embodiment 3

[0038] The AEO-9 in Example 1 was replaced with OP-13, and the feeding ratio and reaction method were unchanged to obtain the block polyether surfactant S3. Wherein OP-13 is an alkylphenol polyoxyethylene ether nonionic surfactant from Ham Company.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com