Vanadium intermediate layer-added titanium alloy-stainless steel dissimilar metal laser welding method

A technology of laser welding and dissimilar metals, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to reduce brittleness, improve weld surface shape, and improve welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

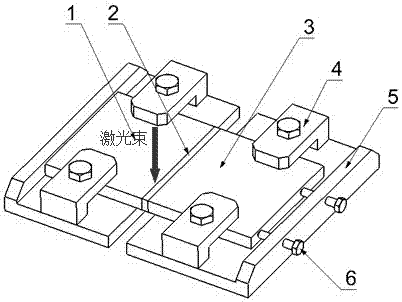

[0024] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

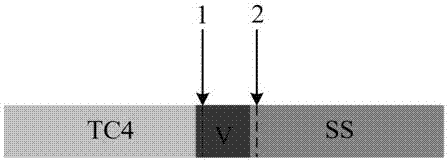

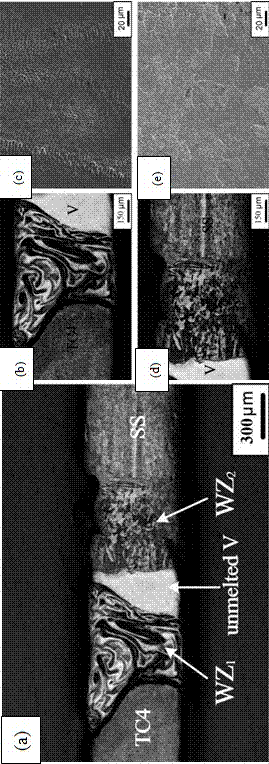

[0025] see Figure 1 to Figure 3 As shown, the titanium alloy-stainless steel dissimilar metal laser welding method with a vanadium intermediate layer of the present invention aims at the brittleness of the titanium alloy-stainless steel dissimilar metal welded joint, adopts laser as the welding heat source, vanadium as the intermediate layer, and accurately controls the welding process parameters, so as to control the formation of ω-brittle phase in titanium alloy-vanadium weld and σ-brittle phase in vanadium-stainless steel weld, and reduce joint brittleness. Two-pass welding is used to obtain high-quality, high-efficiency welded joints of dissimilar metal materials including titanium alloy-vanadium welds, unmelted vanadium layers, and vanadium-stainless steel welds. The process steps are: plate assembly and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com