A laser welding method with focus rotation and vertical vibration

A vertical vibration and laser welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of weld penetration reduction and other problems, to improve surface forming, reduce spatter and porosity, and adverse effects of penetration small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

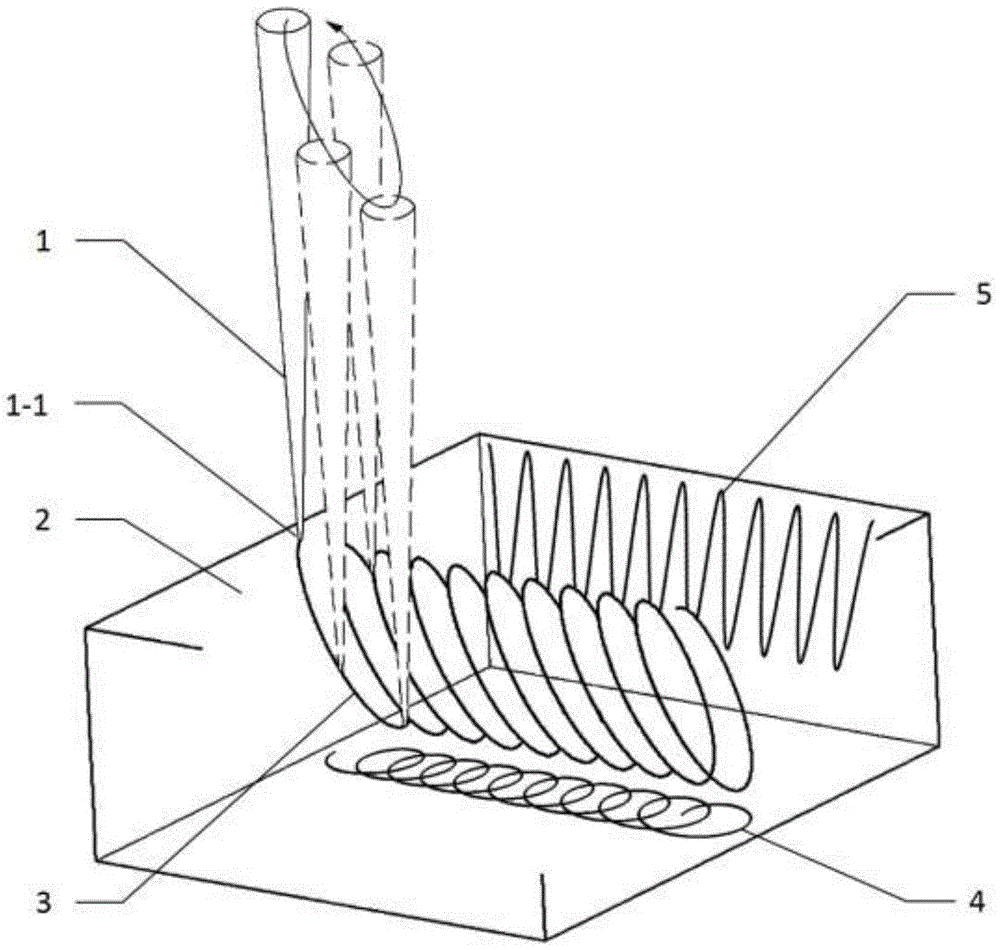

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 welding process parameter is as shown in the table below:

[0019]

[0020] Among them, P is the laser power, v is the welding speed, r xy is the focus horizontal rotation radius, F xy is the focus horizontal rotation frequency, A z is the focus vertical vibration amplitude, F z is the vertical vibration frequency of the focus, d f When the focus has no vertical vibration, it indicates the amount of defocus, and when there is vertical vibration, it is the center position of the focus vibration range.

[0021] The material used in embodiment 1 is 1060 pure aluminum. Before welding, remove the oil stain on the surface of the workpiece to be welded with acetone, remove the surface oxide film with NaOH solution, and use 30% HNO 3 Solution neutralizes residual lye.

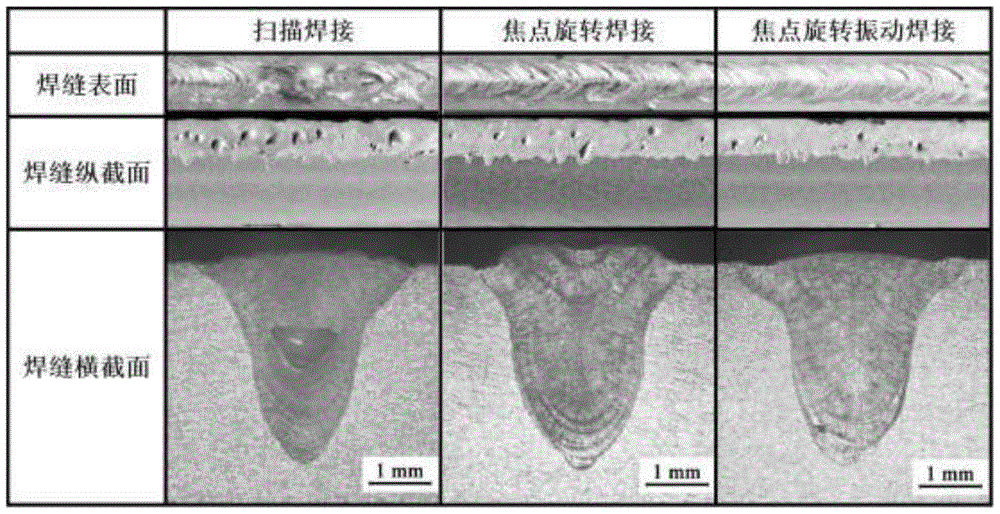

[0022] It can be seen from the weld surface and cross-sectional view ( figure 2 ), for example 1, when only rotating and rotating vibration, the surface shape of the weld seam of laser wel...

Embodiment 2

[0024] Embodiment 2 Welding process parameters are as shown in the table below:

[0025]

[0026] Among them, P is the laser power, v is the welding speed, r xy is the focus horizontal rotation radius, F xy is the focus horizontal rotation frequency, A z is the focus vertical vibration amplitude, F z is the vertical vibration frequency of the focus, d f When the focus has no vertical vibration, it indicates the amount of defocus, and when there is vertical vibration, it is the center position of the focus vibration range.

[0027] The materials used in Example 2 and the way of pre-welding treatment are the same as those in Example 1.

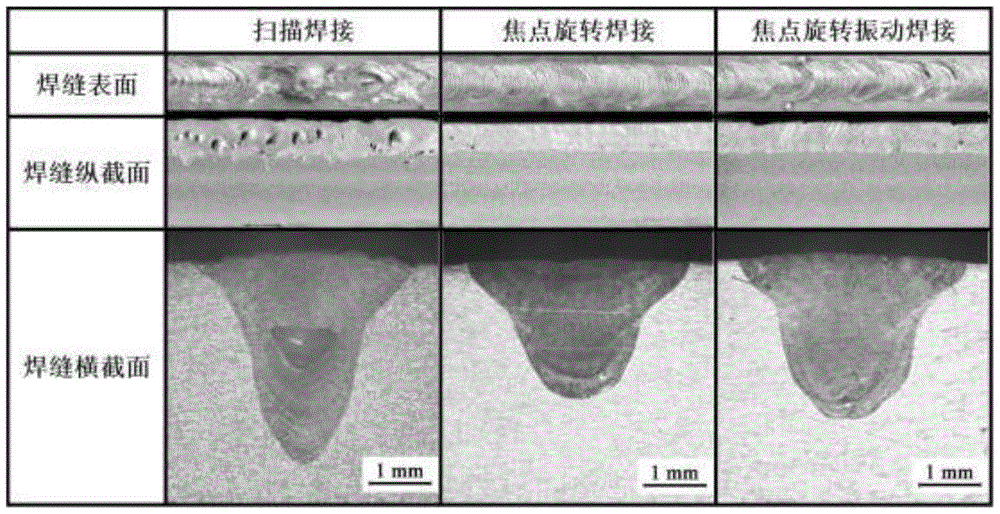

[0028] It can be seen from the weld surface and cross-sectional view ( figure 2 ), for Example 2, only under the condition of rotation and rotation vibration, the weld surface shape of laser welding is significantly better than that of non-vibration welding, the welding process is more stable, and the weld porosity and weld penetration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com