Titanium alloy-stainless steel dissimilar metal laser welding method with composite intermediate layer

A composite intermediate layer, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of small improvement in the performance of welded joints, and achieve good welding process performance, stable welding process, and weld formation. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, the technical scheme in the embodiment of the present invention will be described in conjunction with the embodiment of the present invention, which is apparent from the embodiments of the present invention, and not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

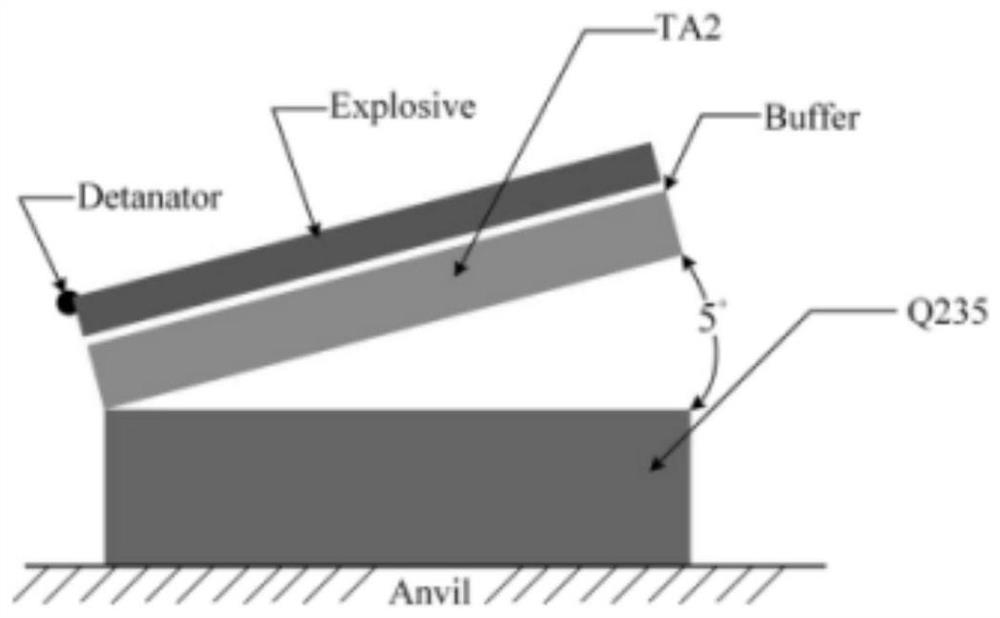

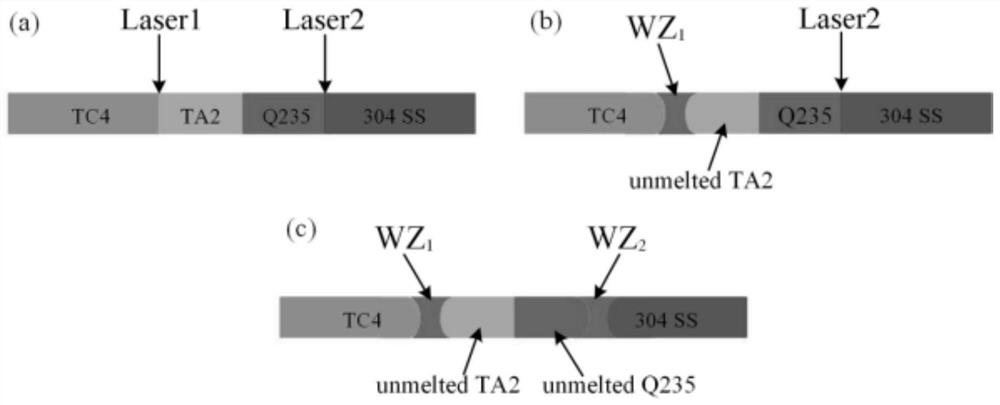

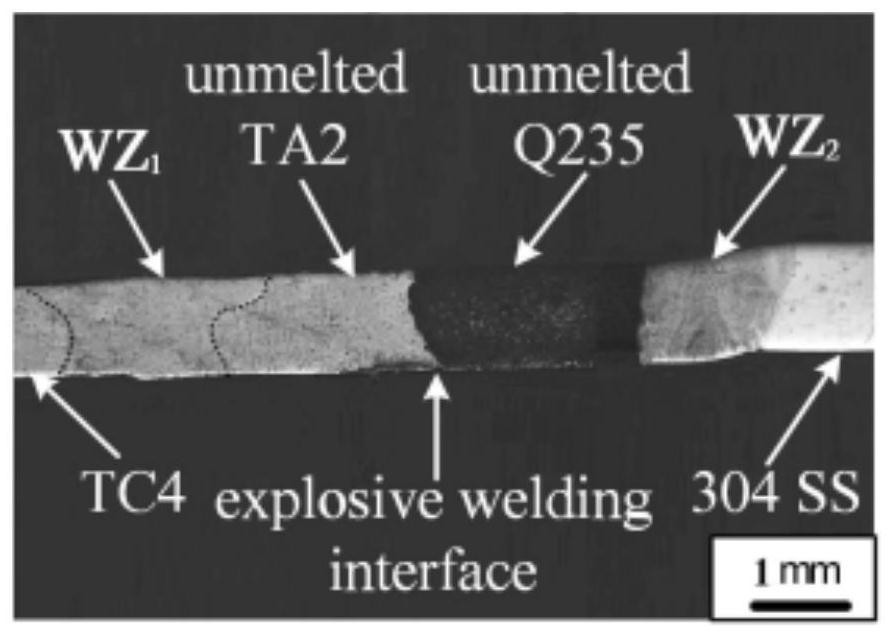

[0023] Please combine Figure 1-4 The present invention provides the following technical solutions:

[0024] A titanium alloy-stainless steel xenograft metal laser welding method for adding composite intermediate layers, according to the following process steps:

[0025] a) Connector: The joint form is the I-shaped port docking. The composite intermediate layer is an explosive welding form. The composite intermediate layer thickness is 4mm, and the group welding clip ensures that there is a certain pre-tension f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com