Laser-mig Composite Heat Source Welding Method for Thick Aluminum Alloy

A composite heat source and welding method technology, which is applied in laser welding equipment, welding equipment, metal processing, etc., can solve the problems of poor penetration ability and many pores, and achieve strong penetration ability, stable welding process, and stable laser welding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

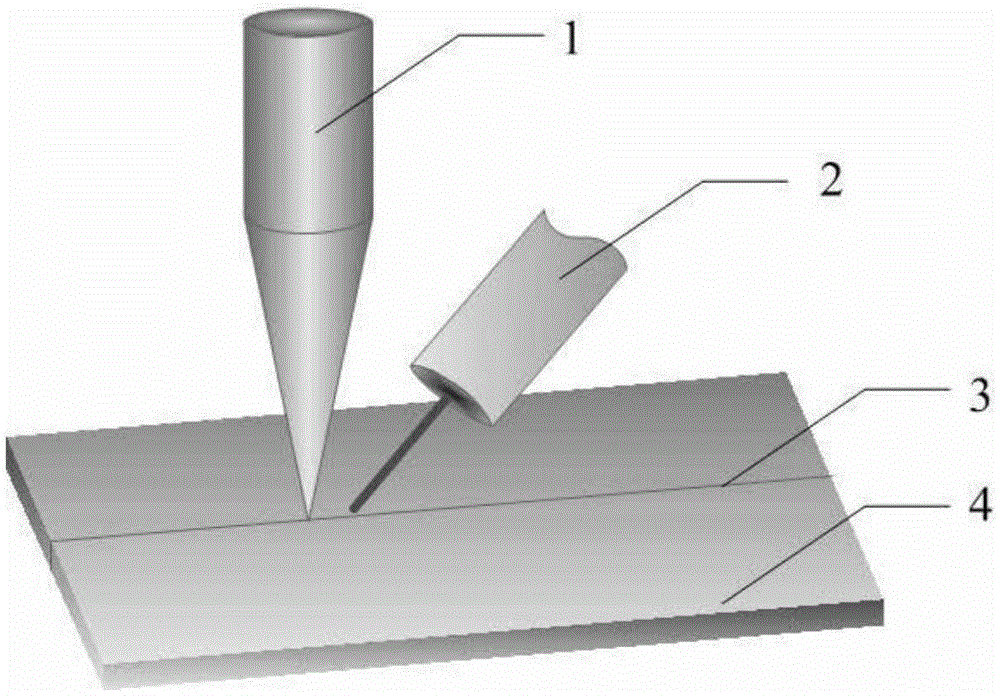

[0019] Specific implementation mode 1: In this implementation mode, the laser-MIG composite heat source welding method for thick plate aluminum alloy is as follows:

[0020] 1. Soak the thick plate aluminum alloy workpiece to be welded in acetone for 5-8 minutes, then put it in an aqueous solution of sodium hydroxide with a mass concentration of 5-8% at 40-50°C for 4-10 minutes, and clean it with water. Rinse, then soak in nitric acid with a mass concentration of 20-30% for 2-4 minutes, rinse with water, and dry at 80°C for 30 minutes;

[0021] 2. Fix the thick-plate aluminum alloy workpiece to be welded on the workbench after step 1, and the welding assembly gap of the thick-plate aluminum alloy workpiece to be welded is less than 15% of the thickness of the thick-plate aluminum alloy workpiece to be welded;

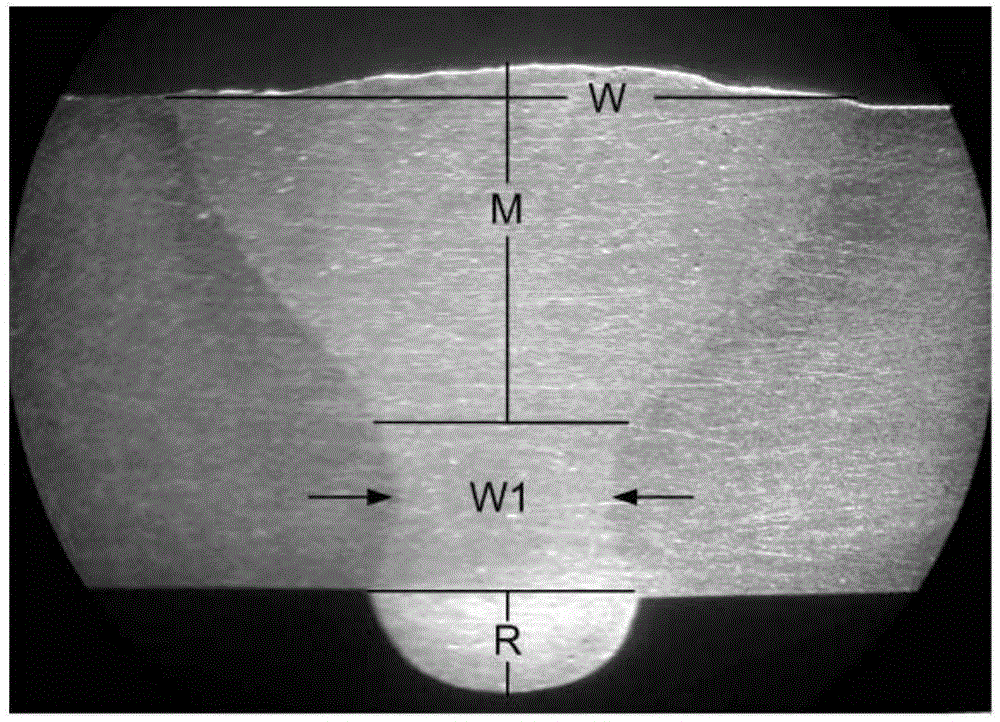

[0022] 3. The laser generator is used to emit the laser beam, and the gas-shielded welding power source is used to generate an arc at the same time, and the laser-MIG c...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the laser beam described in step 3 is CO 2 Gas laser beam, Nd:YAG solid-state laser beam, semiconductor laser beam or fiber laser beam. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 1, it is placed in nitric acid with a mass concentration of 25%, soaked for 3 minutes, and then rinsed with water. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com