Patents

Literature

57results about How to "Reduce welding porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

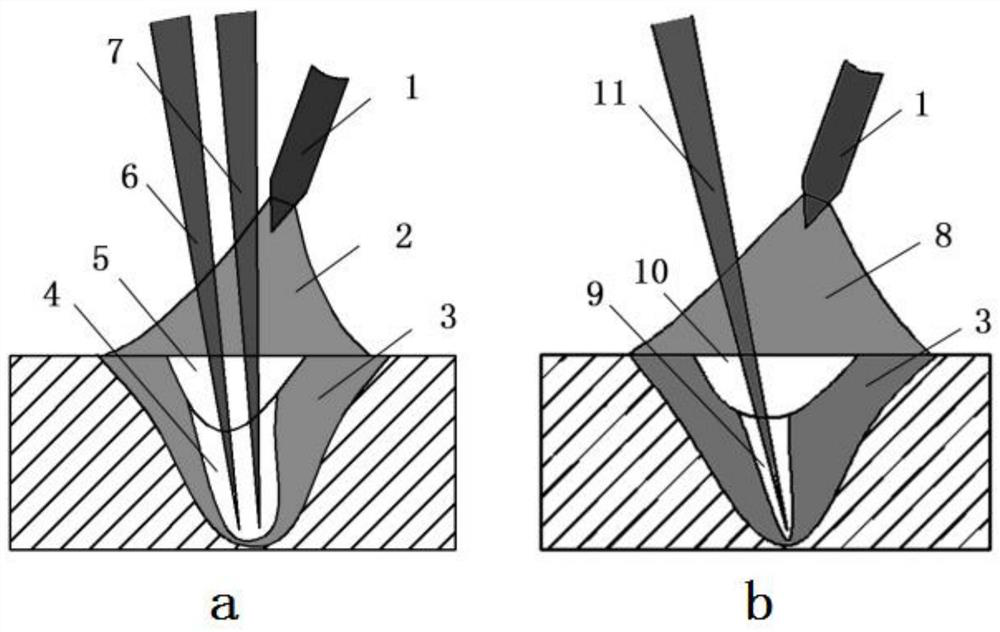

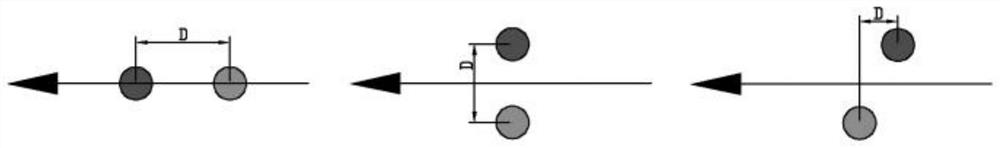

Method for removing aluminum alloy laser welding air holes

InactiveCN103862178ARealize the coupling effectSmall sizeWelding/soldering/cutting articlesLaser beam welding apparatusLaserWelding process

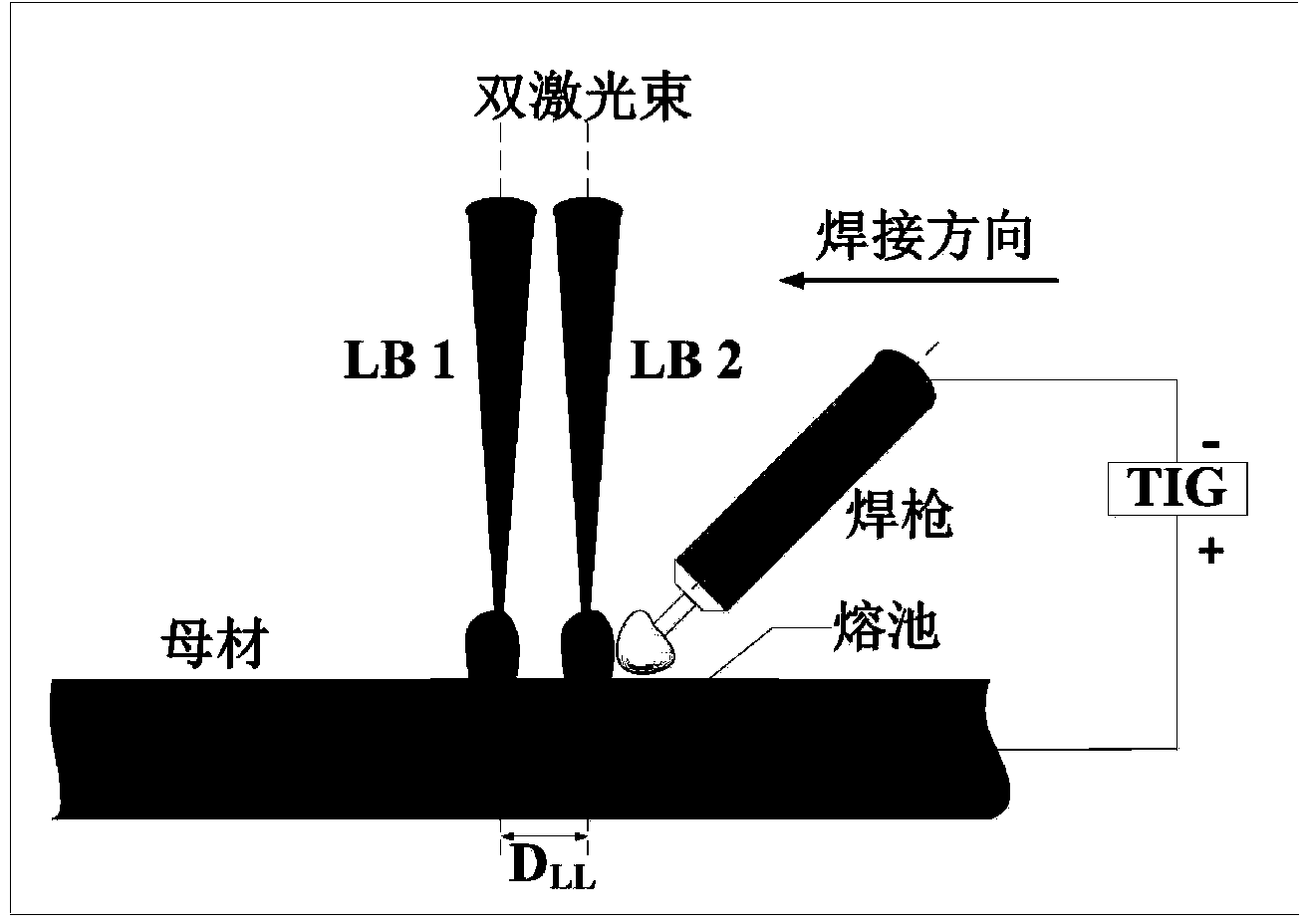

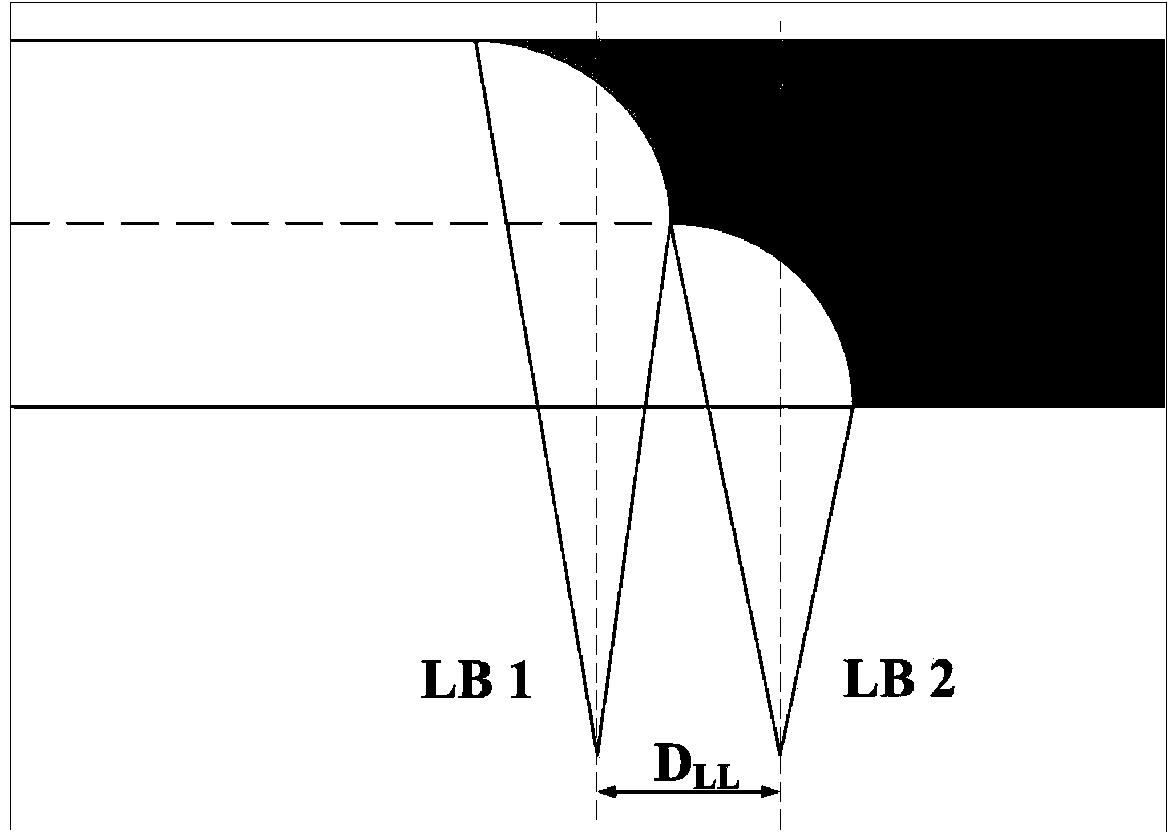

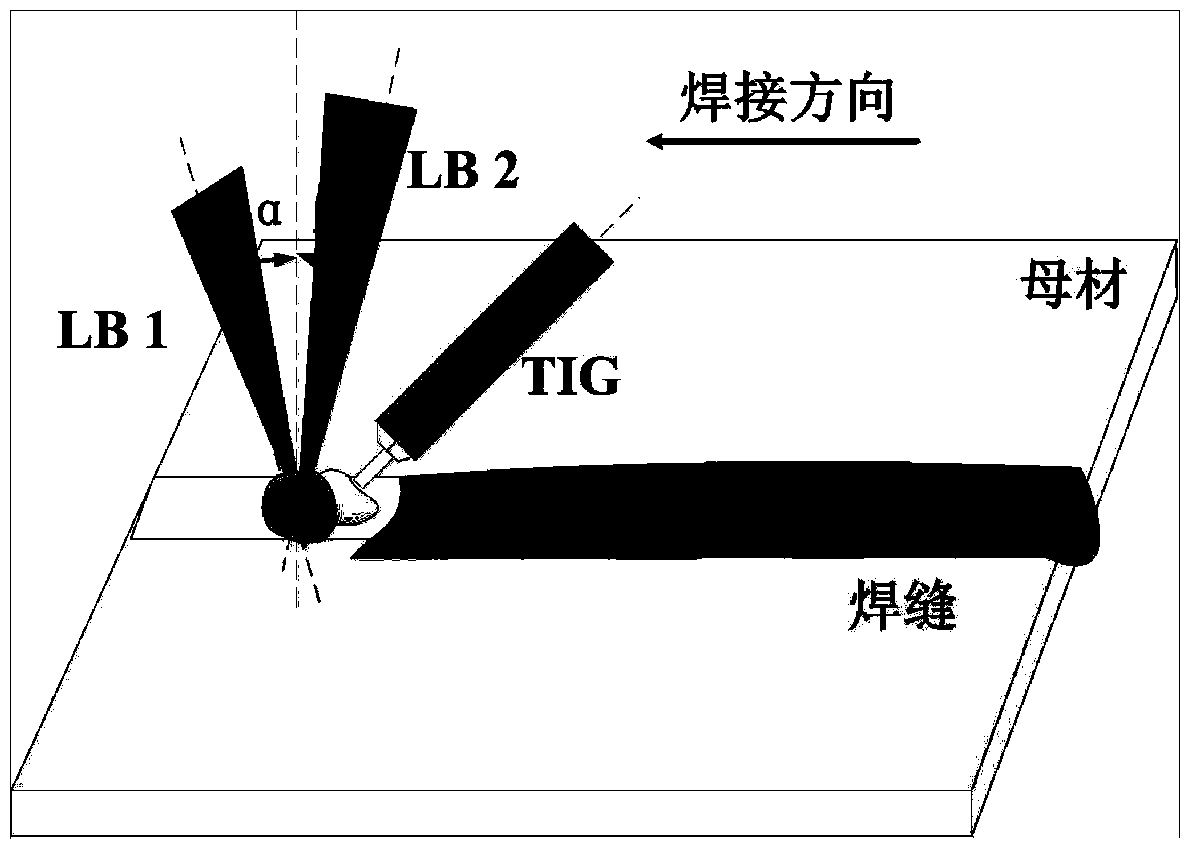

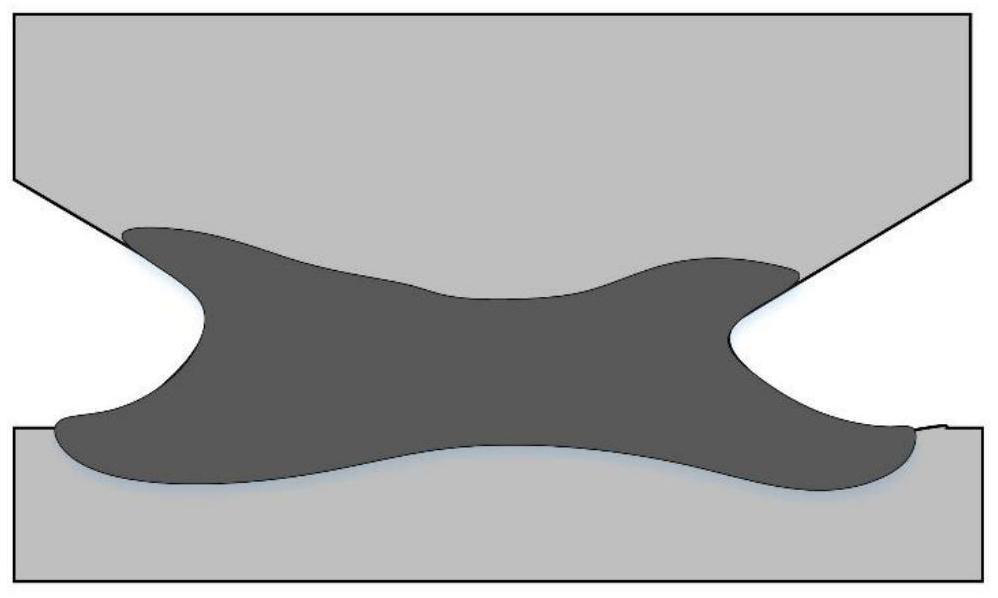

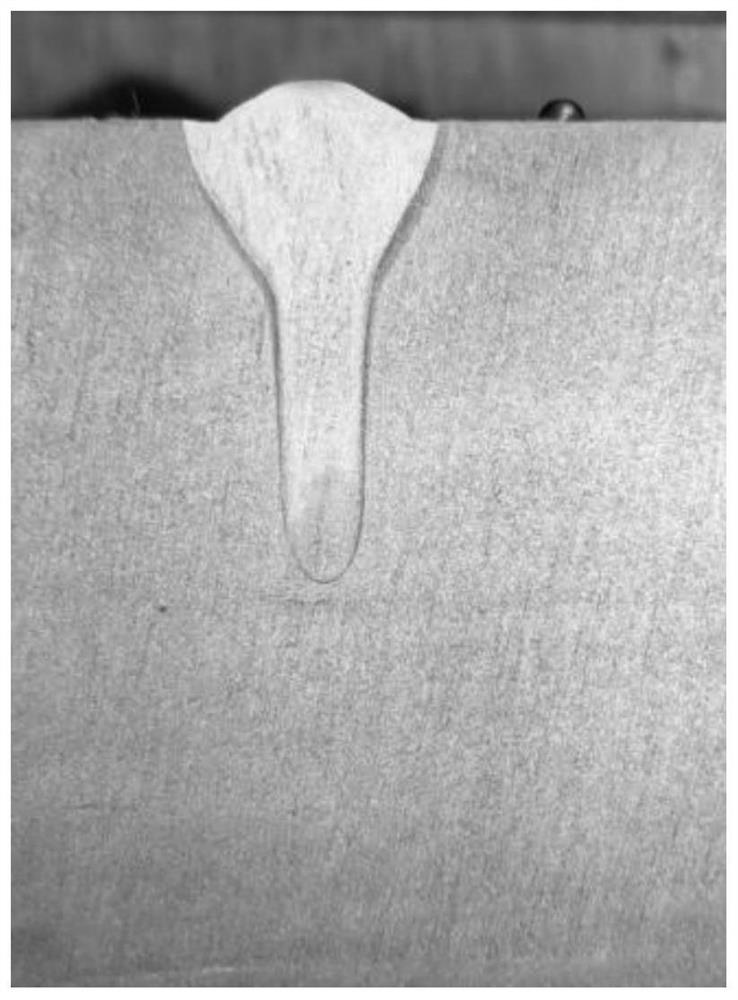

The invention relates to a method for removing aluminum alloy laser welding air holes. The method solves the problem that air hole defects are easily generated in the laser welding and laser-TIG hybrid welding process of aluminum alloy. The method comprises the steps that in the bifocal laser-TIG hybrid welding process of the aluminum alloy, namely, in the aluminum alloy welding process, two beams of lasers (LB1 and LB2) and a TIG electric arc are adopted to jointly act on a welded area, a welding joint bears the combined action of the three heat sources at the same time, and the action modes of the two lasers can be divided into three kinds which comprise a serial distribution mode in the welding direction, a parallel distribution mode perpendicular to the direction of the welding joint and a crossing distribution mode between the serial distribution mode and the parallel distribution mode. According to the welding method, the air hole rate is zero, and air hole defects of the aluminum alloy laser welding are overcome. The method is applied to the field of aluminum alloy laser welding.

Owner:HARBIN INST OF TECH

Method for decreasing laser welding pores

InactiveCN107186339AStable working conditionGood effectLaser beam welding apparatusPorosityButt joint

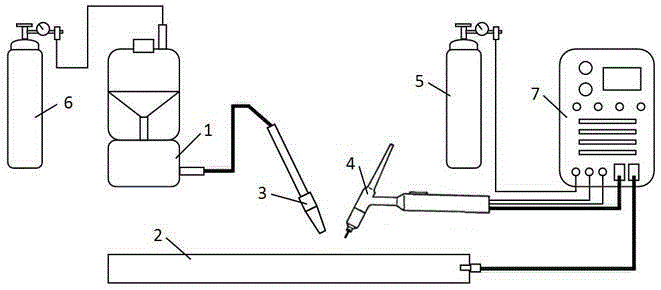

The invention provides a method for decreasing laser welding pores, and relates to the technical field of laser welding. The method for decreasing the laser welding pores comprises the steps of (1) placing two metal to-be-welded parts in a horizontal butt joint manner to form a to-be-welded workpiece; (2) clamping and fixing the two ends of the metal to-be-welded workpiece; (3) preheating the metal to-be-welded workpiece through laser beams; and (4) starting a control switch, introducing a protective gas, igniting electric arcs for 1 s to 2 s, emitting laser, combining laser emitted by a laser A and a laser B into one laser beam, and moving a high pressure air rifle which injects acetone together with the laser A and the laser B. According to the method, a device utilized in the method comprises the two lasers, firstly, the material surface is subjected to preheating treatment, an oxide film generated on the surface is scrubbed through acetone, and then, the two lasers emit the two laser beams to melt the material for welding, so that metal weld joint porosity is obviously decreased, and porosity of 8% to 10% during laser welding is decreased to zero.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

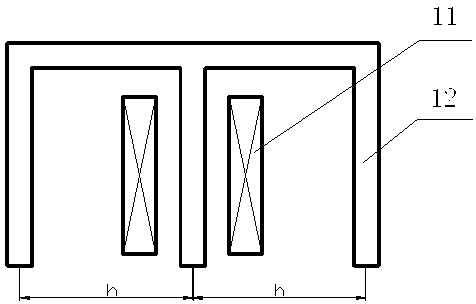

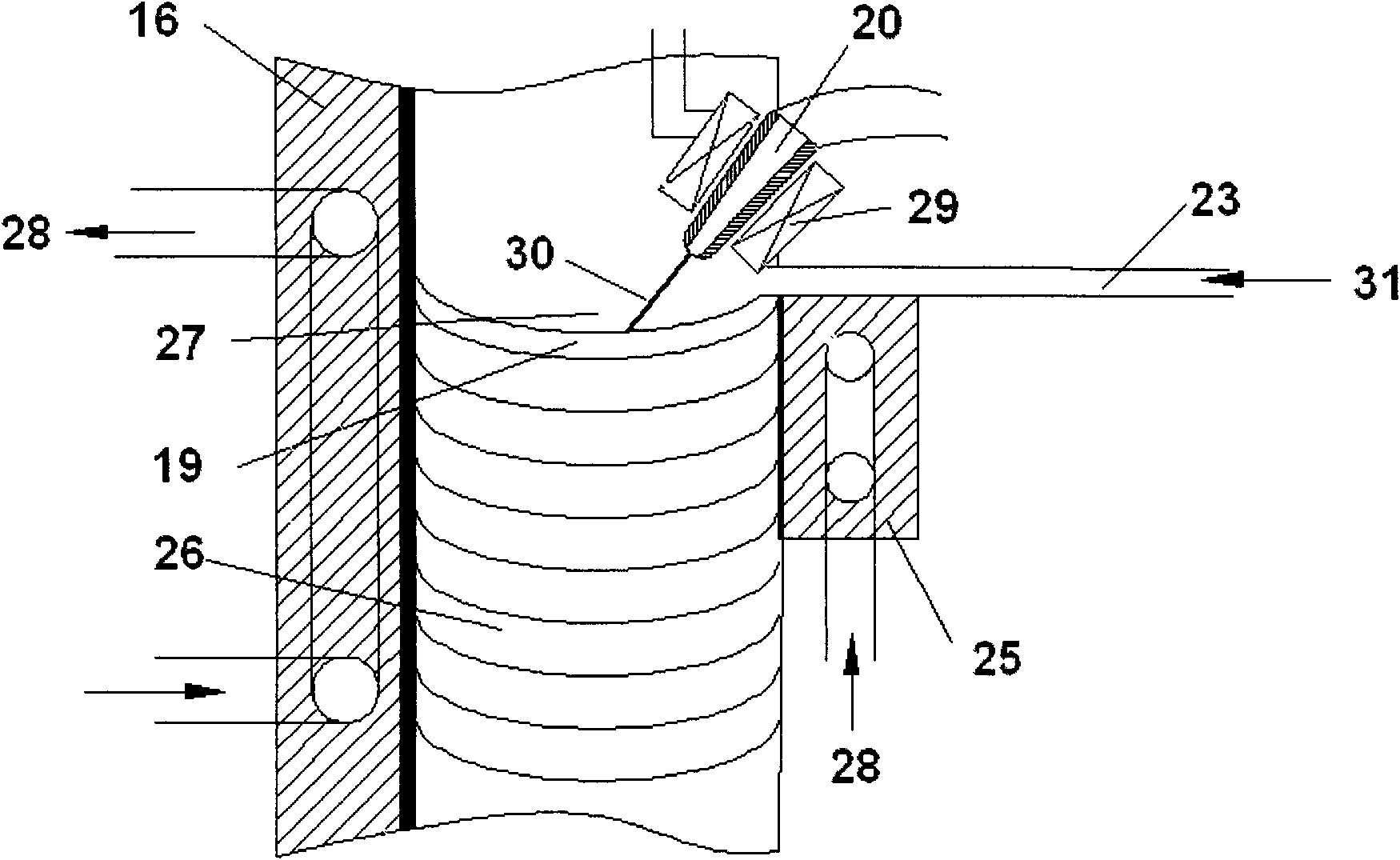

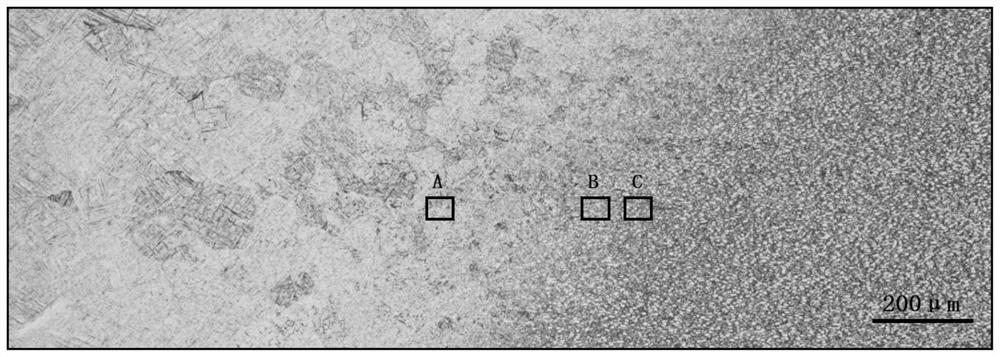

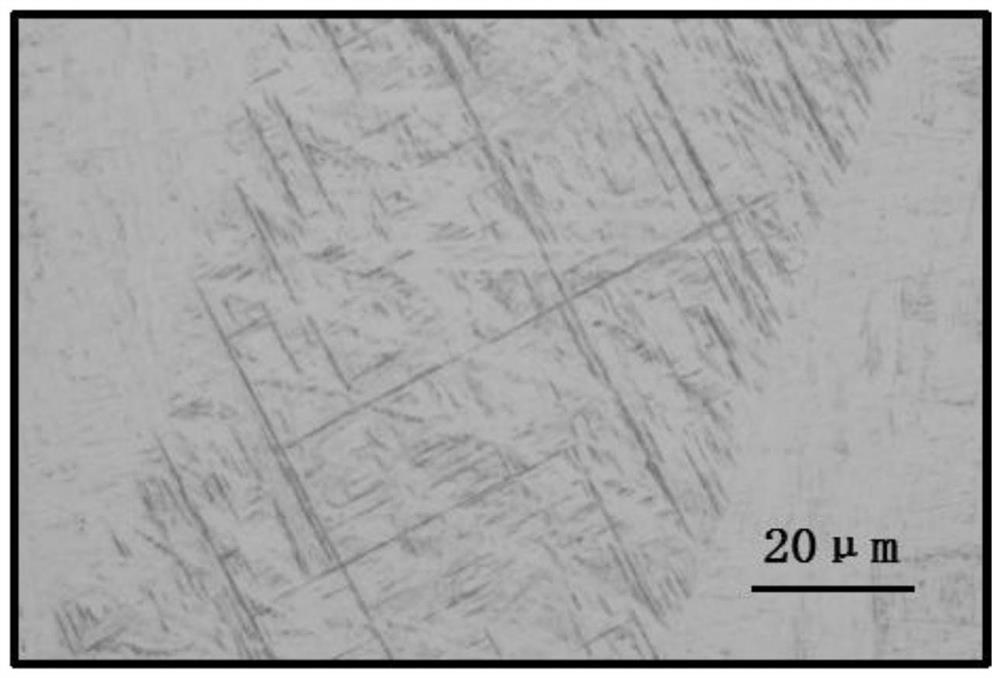

Method and device for refining weld joint structures by using pulsed magnet fields in welding process

ActiveCN102848058AStir wellImprove crystallizationWelding accessoriesWelding defectMaterials science

The invention relates to a processing technology for refining weld joint structures in a welding process, in particular to a method and a device for refining weld joint structures by using pulsed magnet fields in the welding process, and belongs to the technical field of welding. The method for refining weld joint structures by using pulsed magnet fields in the welding process includes that welding is performed by using an ordinary gas metal arc welding method, an applied magnetic field is added above a gas metal arc welding pool, mechanical movement and welding gun movement of the magnet fields are synchronous, electric arc and melt drip transition action is controlled by the magnet fields in a welding process, metal melt in the gas metal arc welding pool is forced to move, an electromagnetic stirring effect is produced, and weld joint structures are finally refined in the welding process. According to the method and the device, in the welding process, the weld joint structures are refined, welding defects are reduced, and further the cost is reduced, and the welding quality and the production efficiency are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

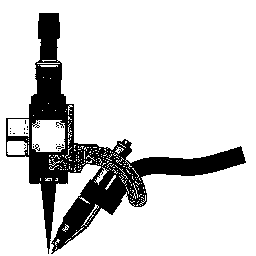

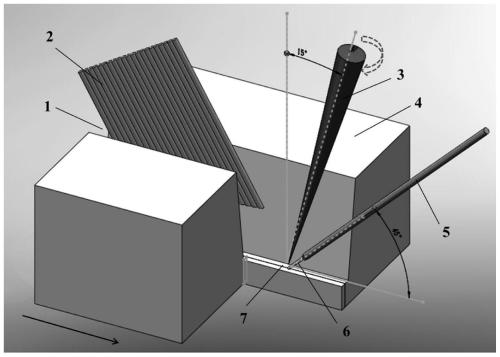

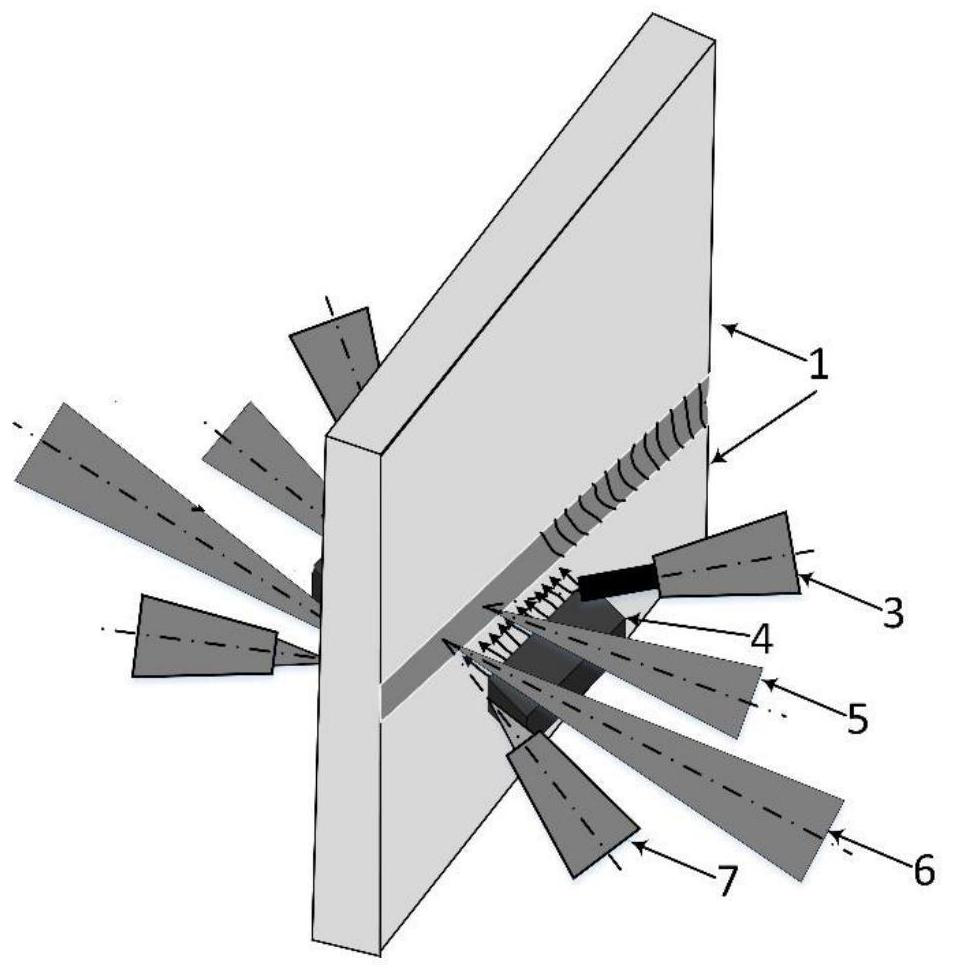

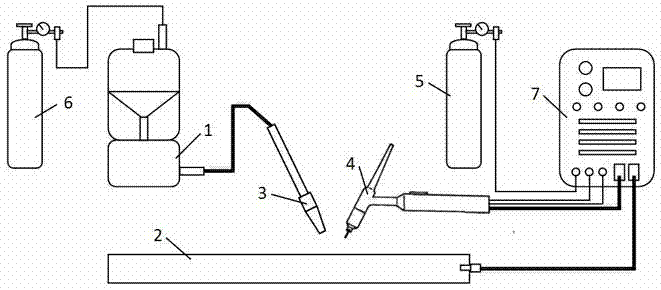

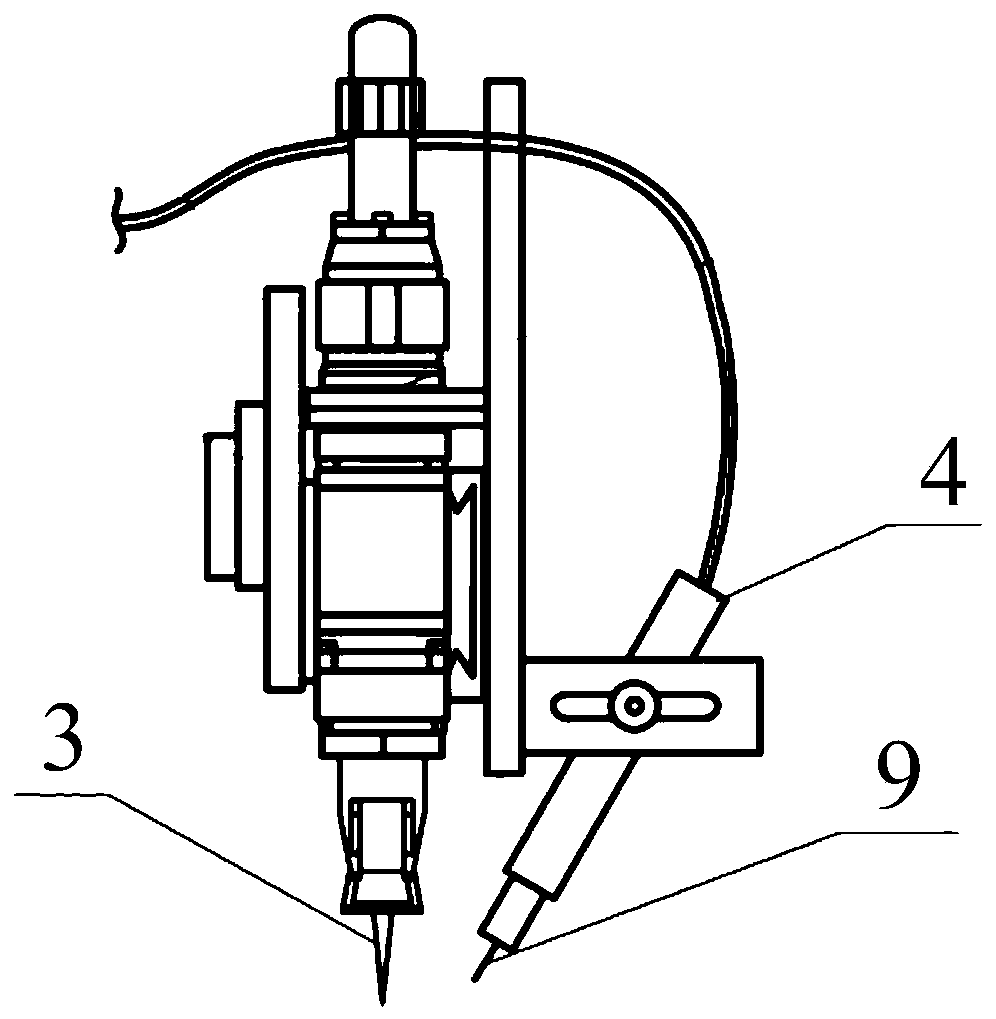

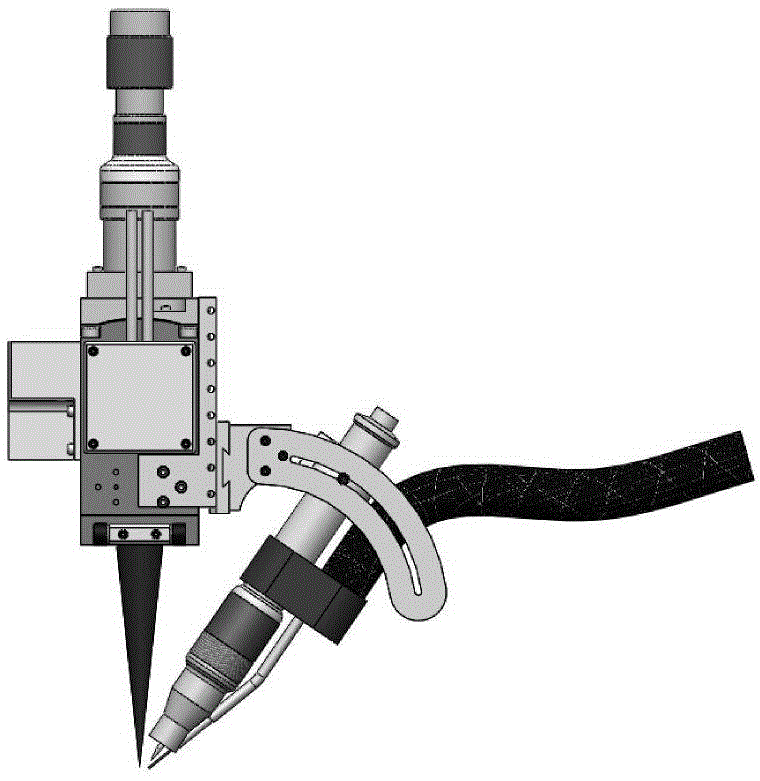

Laser-TOPTIG hybrid welding method

ActiveCN104014933AReduce wire feeding accuracySimplify operating proceduresLaser beam welding apparatusShielding gasCarbon Dioxide / Helium

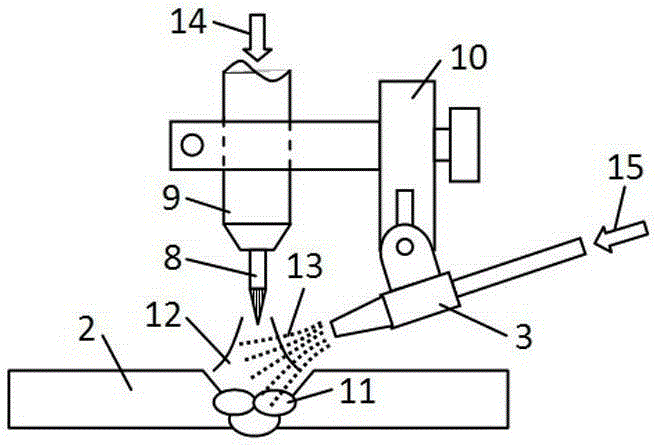

The invention relates to a laser-TOPTIG hybrid welding method. The laser-TOPTIG hybrid welding method includes the following steps: firstly, polishing or cleaning the surface of a workpiece to be welded, and installing a clamp; secondly, setting geometrical parameters; thirdly, setting welding parameters of laser-TOPTIG hybrid welding; fourthly, turning on a control switch, leading in shielding gas, then igniting an electric arc, emitting lasers after 1.0 s to 2.0 s, feeding a welding wire to the area at the highest temperature under mutual effects of laser beams and the electric arc, and then moving a laser device and a welding gun together to carry out laser-TIG electric arc welding. By means of the welding method, an operational program is simplified, efficiency is improved, the welding accuracy and the welding stability are guaranteed, and the welded joint quality is improved.

Owner:HARBIN INST OF TECH

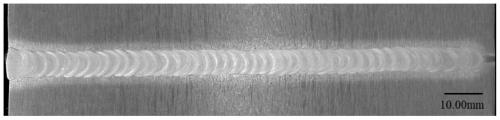

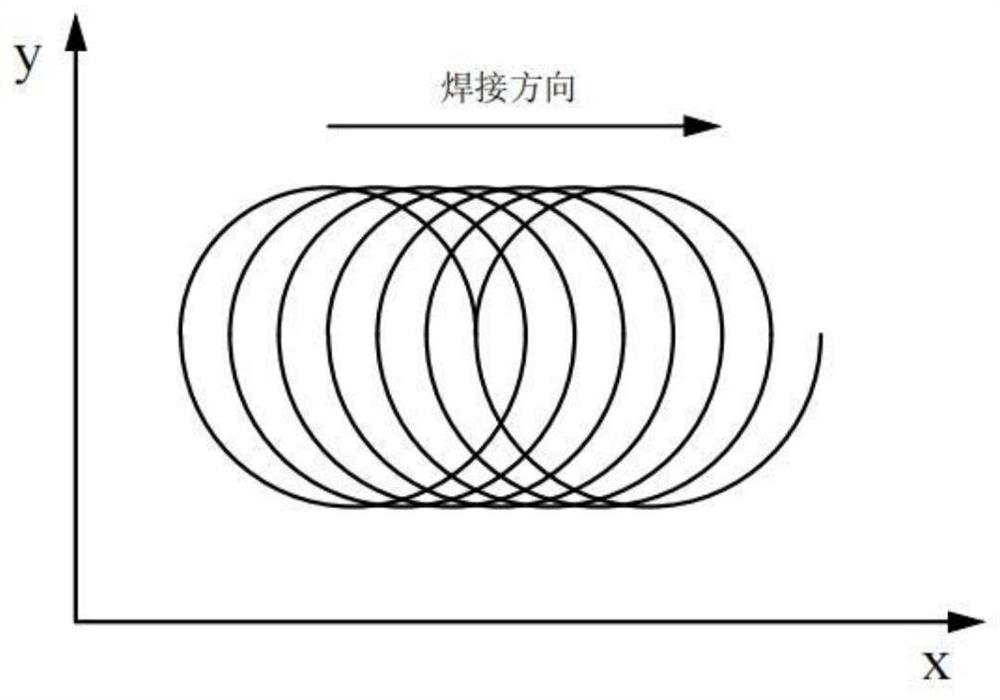

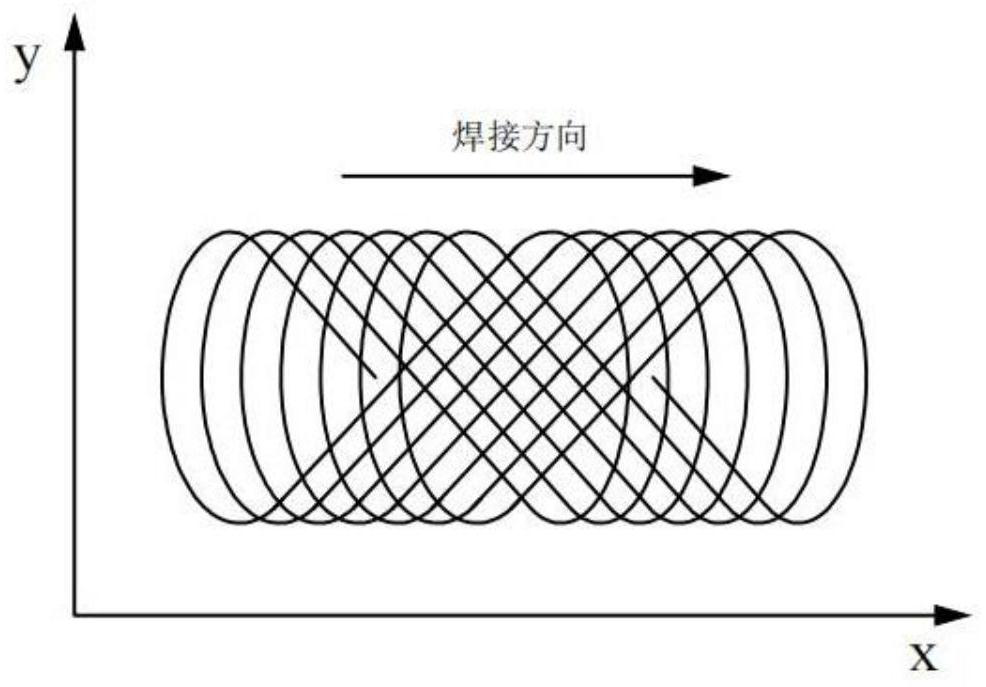

Narrow-gap laser circular oscillation motion filler wire welding method for aluminum alloy thick-wall component

InactiveCN111545912AGood effectIncrease the area of actionLaser beam welding apparatusMaterials processingLaser heating

The invention discloses a narrow-gap laser circular oscillation motion filler wire welding method for an aluminum alloy thick-wall component. The invention belongs to the technical field of laser material processing. The invention aims to solve the technical problems of incomplete fusion and welding air holes which are extremely easy to occur during narrow gap welding of the aluminum alloy thick-wall component. According to the welding method, during welding, the emitting end of a laser beam acts on one end of a to-be-welded area around the laser beam to perform a circular oscillation motion,so that the laser beam enters a narrow-gap groove in a circular oscillation motion track to act on the to-be-welded area to form a welding pool, and filler wires enter the welding pool in a front wirefeeding mode, the filler wires are molten under the combined action of laser heating and molten pool thermal radiation, and the connection of the aluminum alloy thick-wall component is realized by adopting a single-channel multilayer filling mode. The method is large in laser beam heat source action area and controllable in mode, can generate a controllable stirring effect on the liquid molten pool, and has the advantages that the aluminum alloy side wall and interlayer melting is more sufficient, the welding process is more stable, the welding porosity is lower, and the joint stability is higher.

Owner:HARBIN WELDING INST LTD

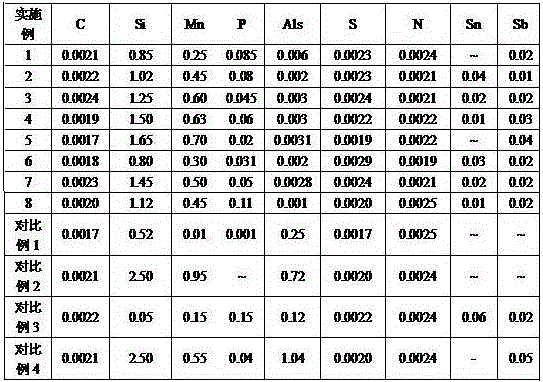

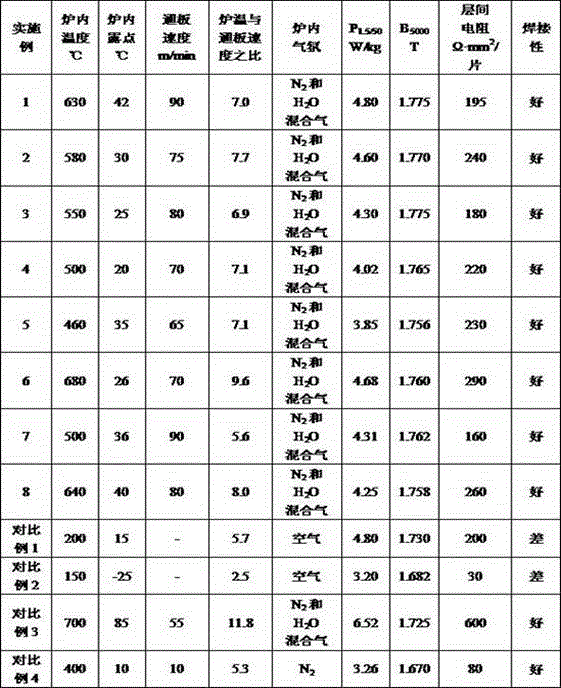

Non-oriented electrical steel good in weldability and magnetism and production method

ActiveCN106756491AGuaranteed MagneticMaintain interlayer resistanceSolid state diffusion coatingPorosityElectrical steel

Non-oriented electrical steel good in weldability and magnetism is composed of, by weight, 0-0.0030% of C, 0.8%-1.7% of Si, 0.2%-0.8% of Mn, 0-0.0050% of S, 0.01%-0.15% of P, 0-0.030% of Al, 0-0.0050% of N, 0-0.05% of Sn and / or Sb. A production method comprises the steps that steel making, hot rolling, pickling and cold rolling are conducted, and then the thickness of a finished product is achieved; after the finished product is subjected to annealing, bluing treatment is conducted; and sampling, reeling, packaging and inspection are conducted. According to the non-oriented electrical steel good in weldability and magnetism and the production method, the weldability of the product is improved while interlamination resistance is kept, weld porosity, broken welding and other defects are decreased; through control over the atmosphere, temperature and dew point of oxidation and bluing, unit speed and bluing temperature of a non-oriented electrical steel sheet, the interlamination resistance is improved, meanwhile, magnetism deterioration caused by surface oxidation can be reduced to the smallest extent, and the magnetism of the finished product is ensured, specifically, a 0.50 mm sheet B50 is larger than or equal to 1.75 T, and P1.5 / 50 is smaller than or equal to 5.0 W / kg.

Owner:武汉钢铁有限公司

Thick plate laser arc composite double-sided synchronous horizontal welding method and device

ActiveCN114012266AImprove liquidityImprove uniformityLaser beam welding apparatusThick plateEngineering

The invention discloses a thick plate laser arc composite double-sided synchronous horizontal welding method and device. The horizontal welding method comprises the following steps that 1, a welding workpiece is prepared; 2, two laser arc devices are arranged on the two sides of the welding workpiece correspondingly, and the positions are adjusted; 3, welding process parameters are set, a laser arc device is started, and a base layer is welded; and 4, welding process parameters are adjusted, a laser arc device is started, and filling layer welding is performed. The method reduces the porosity of the weld joint, solves the problems of incomplete penetration of the weld joint, incomplete fusion of the side wall, weld joint cracks and the like, and ensures the quality of the weld joint and the welding stability. The horizontal welding device comprises a TIG welding gun, a first laser device, a second laser device, a GMAW welding gun and an air injection assembly.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Alloy powder filling tungsten argon arc welding method for aluminum alloys

ActiveCN102489841AQuality improvementEfficient weldingArc welding apparatusWelding/cutting media/materialsFilling materialsTungsten

The invention discloses a tungsten argon arc welding method, which is applied to aluminum alloy materials and uses alloy powder as welding and filling materials. Besides aluminum powder, the aluminum base alloy powder used in the method further comprises an active powder component and an arc stabilizer powder component. The aluminum base alloy powder is added into welding lines of the aluminum alloy materials to be welded by means of automatic filling, homogeneous materials can be welded, dissimilar materials can also be welded, and the technical problems of low welding efficiency and large air hole inclination in the process of tungsten argon arc welding can be solved, so that high-quality welding joints are obtained.

Owner:SUZHOU YUNSHOU SOFTWARE TECH CO LTD

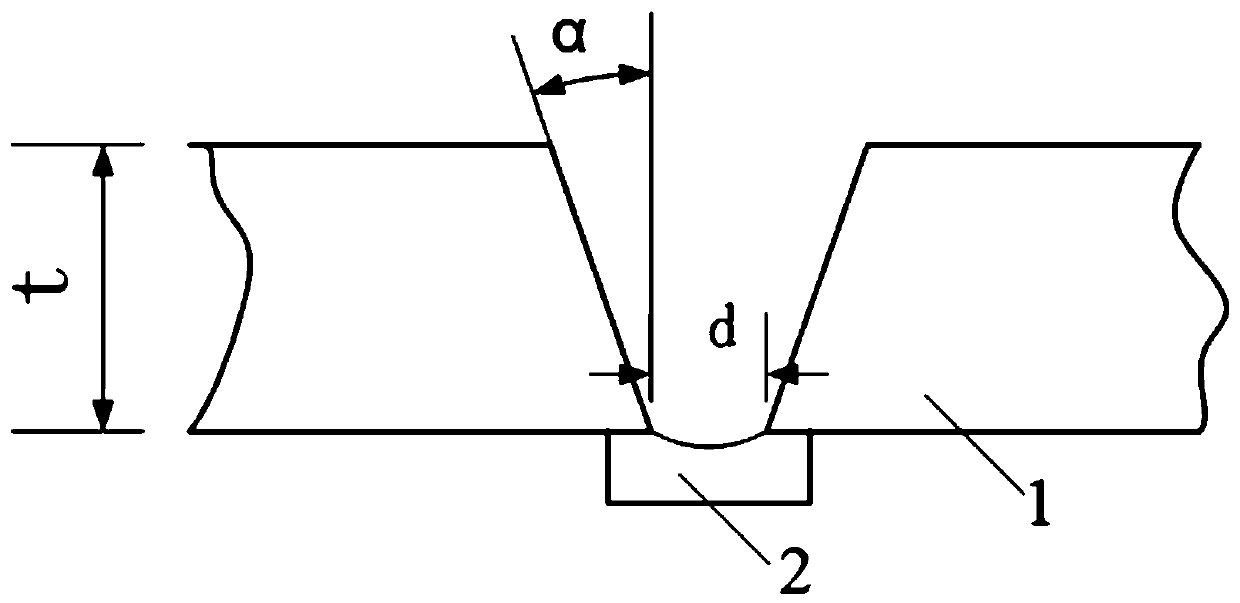

Welding method for one-side welding double-face forming of aluminum alloy plates

InactiveCN110666307ASolve the welding problem in narrow spaceHigh tensile strengthArc welding apparatusWelding/cutting media/materialsAlloySS - Stainless steel

The invention provides a welding method for one-side welding double-face forming of aluminum alloy plates. The welding method is characterized in that the two aluminum alloy plates are subjected to MIG welding at a mean position, a symmetric one-face V-type groove is adopted, the one-side angle of the groove is 30 degrees-35 degrees, the bottom gap width of the groove is 5 mm-7 mm, and a stainlesssteel or aluminum alloy liner is additionally arranged on the back face. The method is especially suitable for one-side welding double-face forming of 6 mm 5083-H116 aluminum alloys, and the problemabout welding in a narrow space of a ship is solved; the appearance of a weld joint meets the quality requirements, and no remarkable surface defects exist; and welding air pores are fewer, and the internal quality X-ray detection grade of the weld joint is not lower than the grade I.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

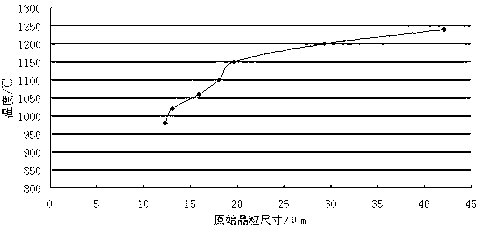

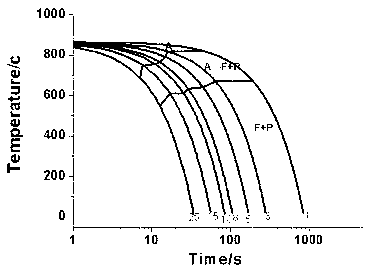

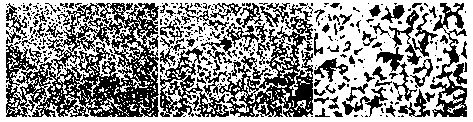

Production method of low-cost easily-welded steel

The invention relates to a production method of low-cost easily-welded steel and belongs to the technical field of metal rolling. According to the technical scheme, the production method is characterized in that alloy elements for improving the welding performance are not required to be added, the content of easily-welded soft-phase ferrites in the microstructure of hot rolling strip steel is controlled on line to account for 70%-95%, and the content of difficultly-welded hard-phase pearlites in the microstructure of the hot rolling strip steel is controlled on line to account for 5%-30%; and an accelerated cooling manner is adopted, the cooling rate is increased by 5-15% on the basis of the original cooling rate, after acceleration, the cooling rates of strip steel laminar cooling water-cooling sections with different thicknesses and sizes are controlled at 65-105 DEG C / s, and the cooling rate of laminar cooling in the whole stage is controlled at 12.56-19.4 DEG C / s, so that the nucleation rate of phase transformation is increased, and the grain growth slows down. According to the production method, the product with the mechanical property and the welding property which are well matched is obtained by controlling the microstructure of the hot rolling strip steel, and the welding quality of the strip steel and the labor productivity are improved; the optimization of alloy compositions is not required, the welding performance is improved by optimization of a production technology, the low-cost production is realized, and the market competitiveness of hot rolling products and cold rolling products is further increased.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

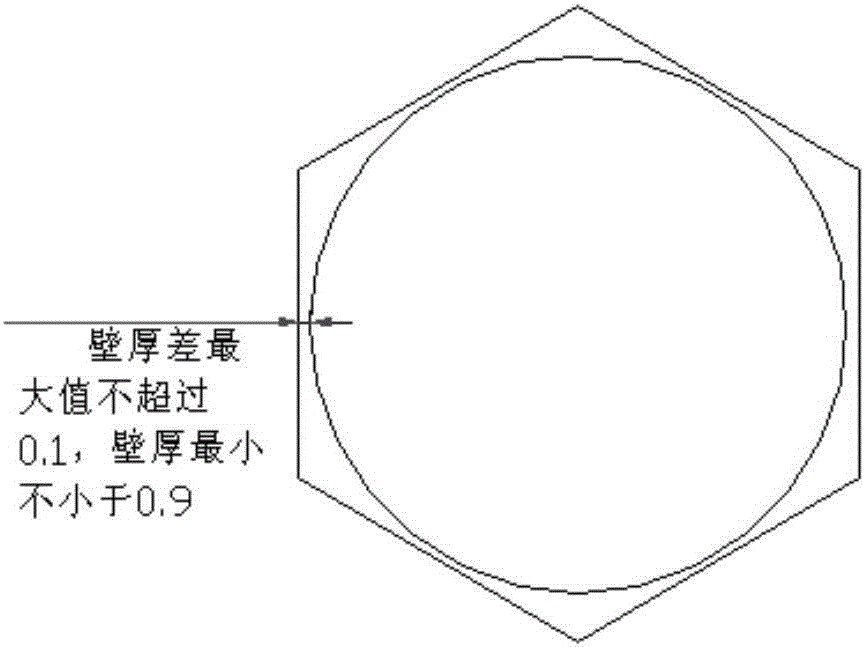

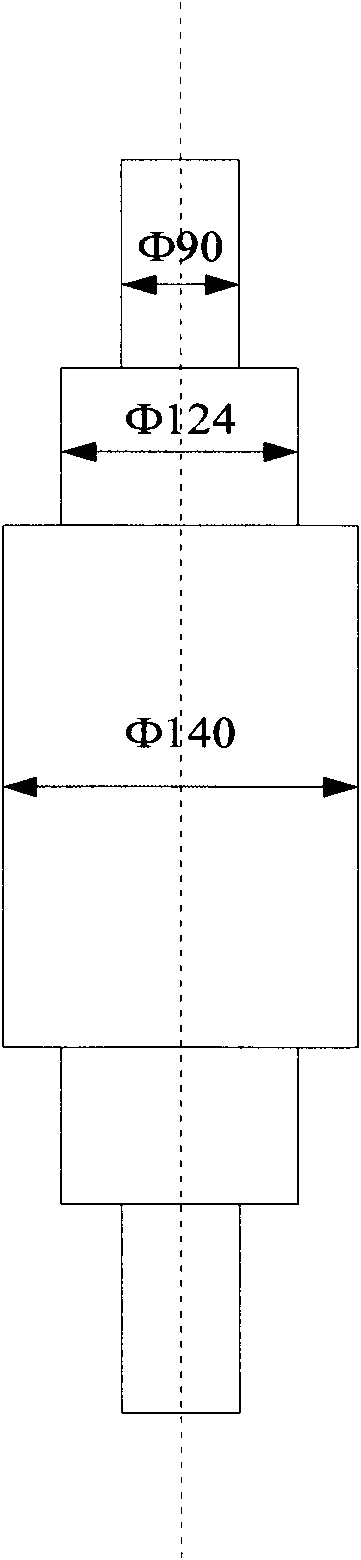

Welding method for tapered aluminum product

ActiveCN106624278ARealize argon arc weldingReduce welding porosityWelding/cutting auxillary devicesArc welding apparatusPower flowEngineering

The invention provides a welding method for a tapered aluminum product. The welding method includes the steps that (a), an aluminum weldment hexagon pipe is chamfered, and the six edges of the hexagon pipe are mechanically chamfered; (b), surface treatment is carried out on the hexagon pipe, and then the hexagon pipe is dried; (c), the hexagon pipe is assembled with a connector to be welded and a welding fixture, after being assembled, the hexagon pipe, the connector and the welding fixture are wholly preheated, and welding arc is used for local preheating before welding; (d), welding is carried out, aluminum silicon welding wires are adopted, according to the welding process parameters, the welding current is 120-160 A, and the flow rate of the protective gas argon is 5-15 L / min. By reasonably selecting and matching groove size design, welding wire selection, a clearing method before welding and parameters such as preheating temperature and argon flow, welding pores and micro cracks are reduced, weld penetration meets the requirement, weld joints meet the I level weld joint standard, and therefore argon arc welding of the tapered aluminum hexagon pipe and the special-shaped connector is achieved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

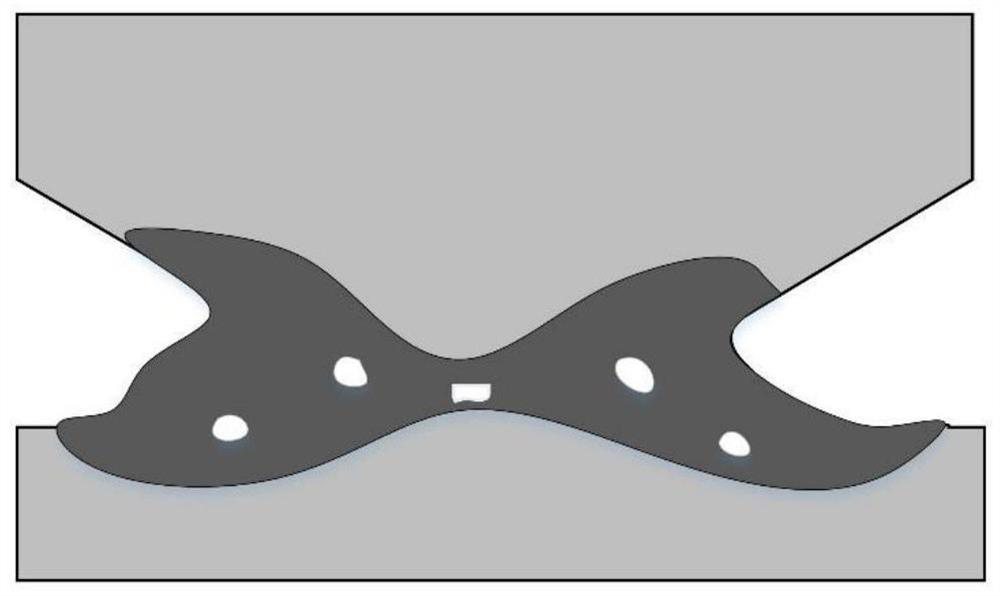

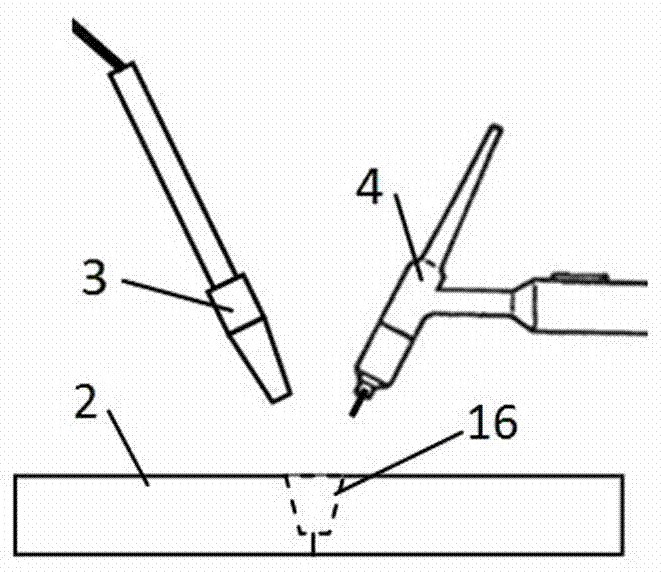

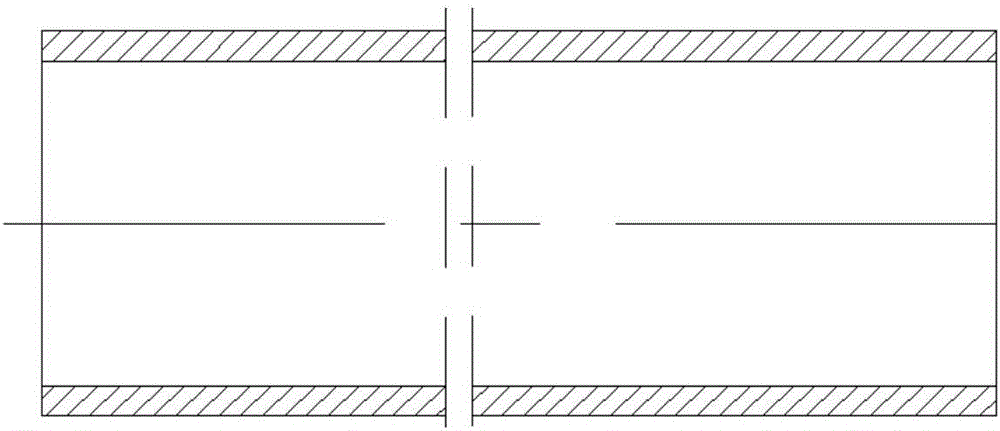

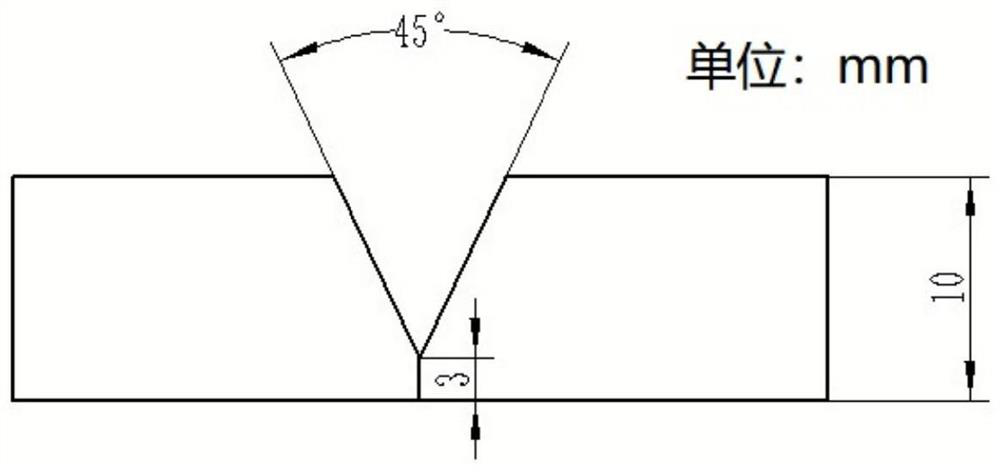

High-nitrogen steel hybrid welding method adopting double-sided simultaneous protection with different protective gases

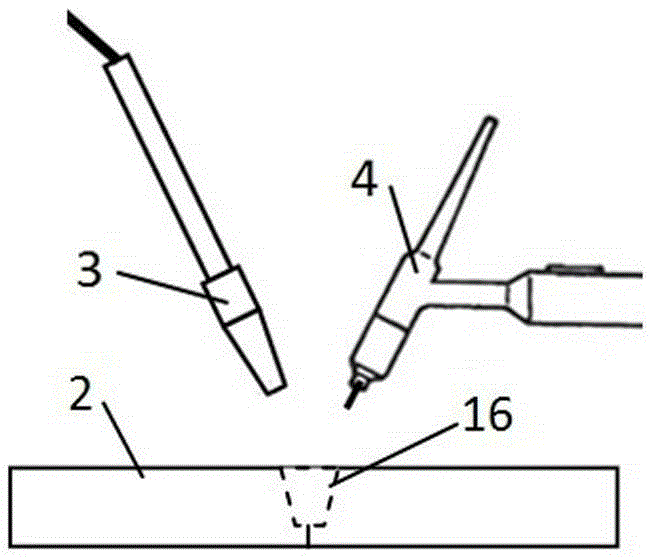

The invention provides a high-nitrogen steel hybrid welding method adopting double-sided simultaneous protection with different protective gases and belongs to the technical field of welding. High-nitrogen steel plates are welded through laser-electric arc welding, two to-be-welded workpieces are placed on a copper plate in a butt joint manner, the copper plate is provided with a rectangular through groove, and the to-be-welded workpieces and the copper plate are fixed to a workbench together; a joint interval of the welded pieces is formed between the two to-be-welded workpieces; a laser beamemitted by a laser welding head is coaxial with the interval of the to-be-welded workpieces and perpendicularly irradiate the front faces of the to-be-welded workpieces, and a welding gun is placed on the front side of the to-be-welded workpieces; 95% Ar+5% CO2 mixed protective gases which are output at the same axis with the welding gun are provided above the workpieces; the rectangular throughgroove on the copper plate is located under the welding interval, the opening of the rectangular through groove is upward, nitrogen is fed from the two ends of the opening of the through groove, a gastemporary storage space is defined by the lower surface of the to-be-welded workpieces and the rectangular through groove, the nitrogen in the rectangular through groove can improve nitrogen activityoutside a molten bath and restrain weld porosity and nitrogen loss; and meanwhile, the protective gases on the upper side adopt Ar and CO2, so that molten drops are refined, and the welding process is more stable.

Owner:CHANGCHUN UNIV OF SCI & TECH

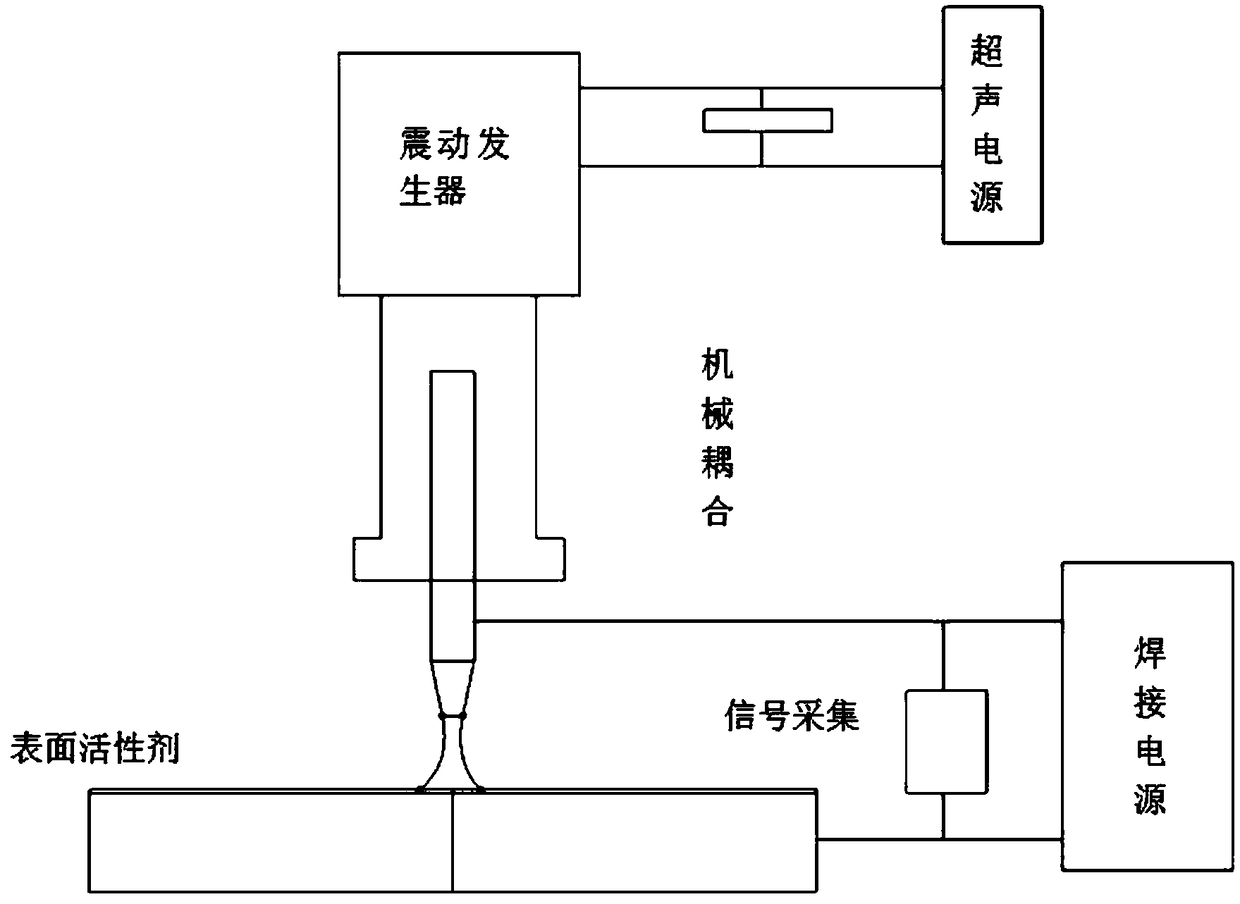

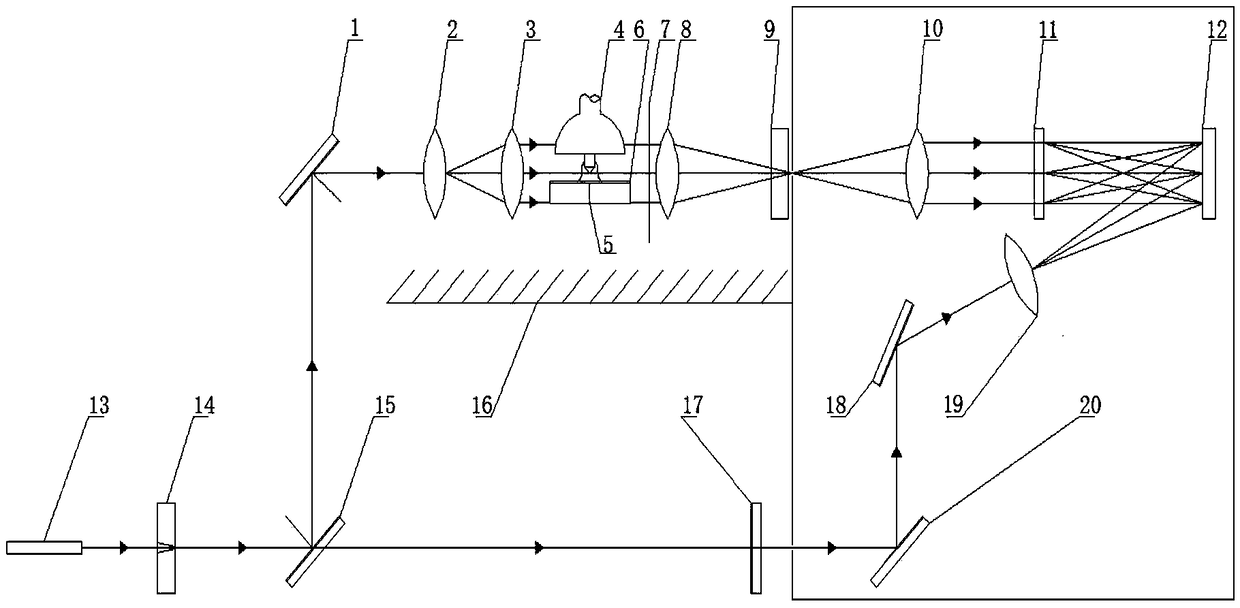

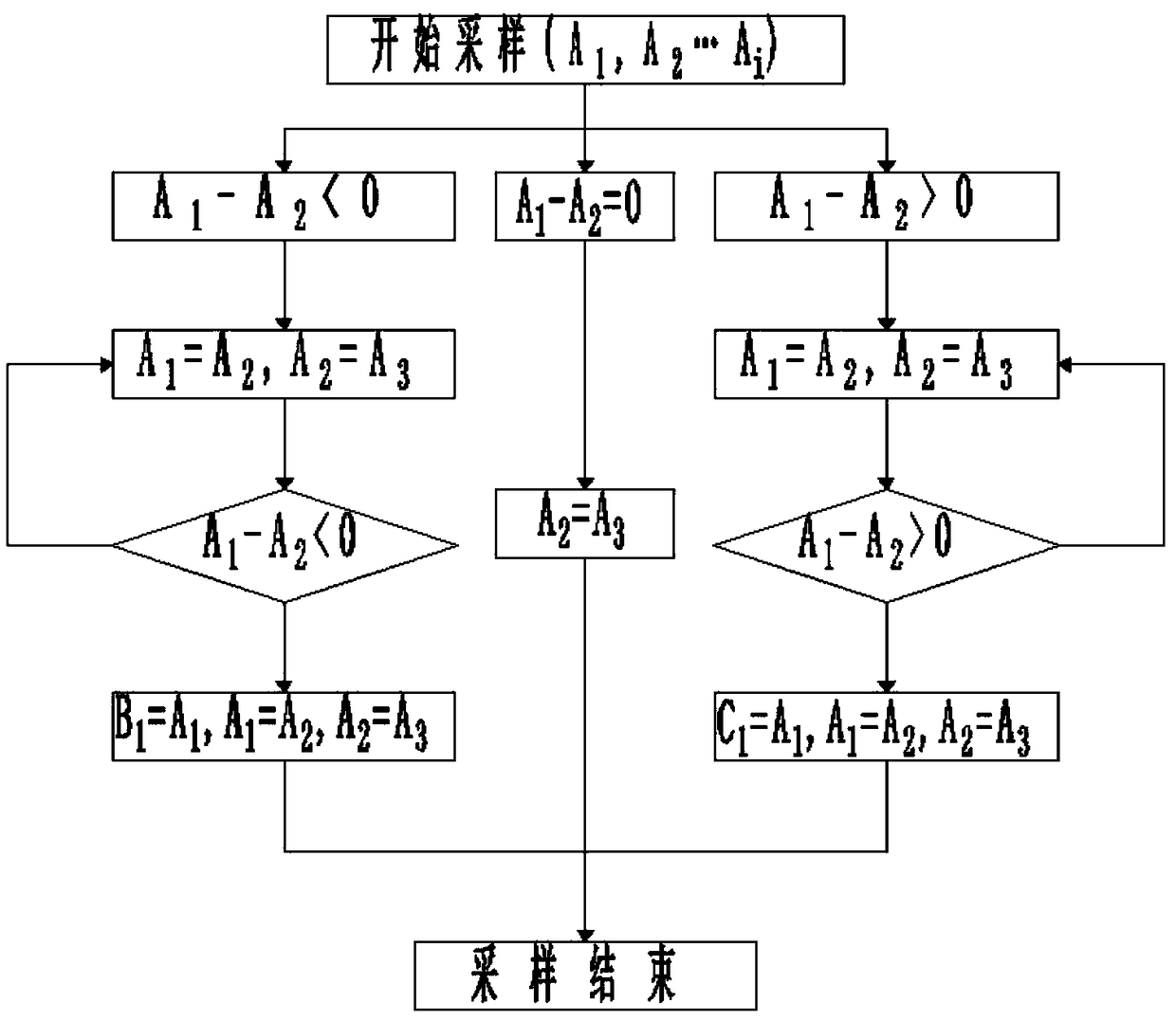

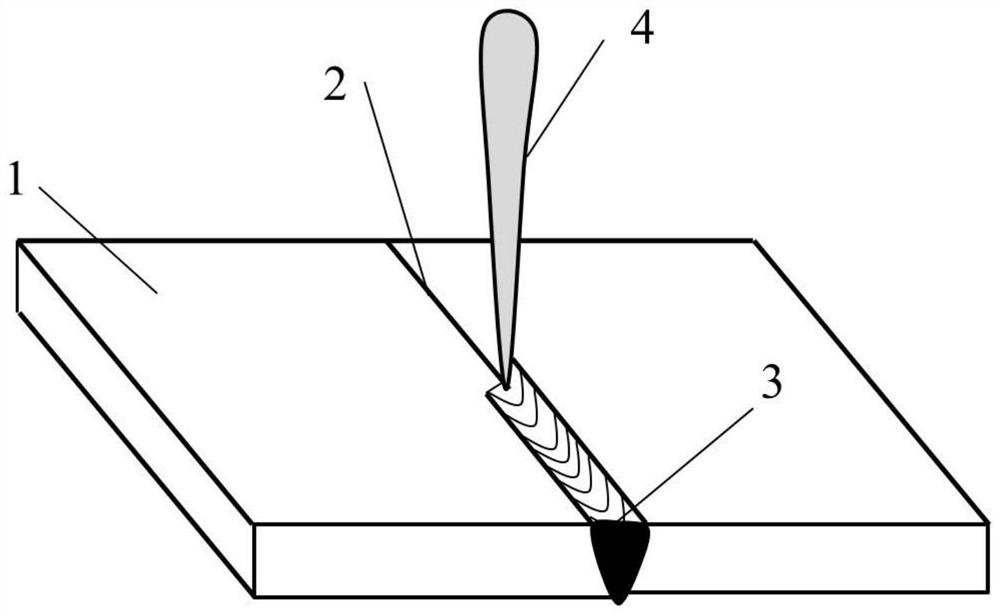

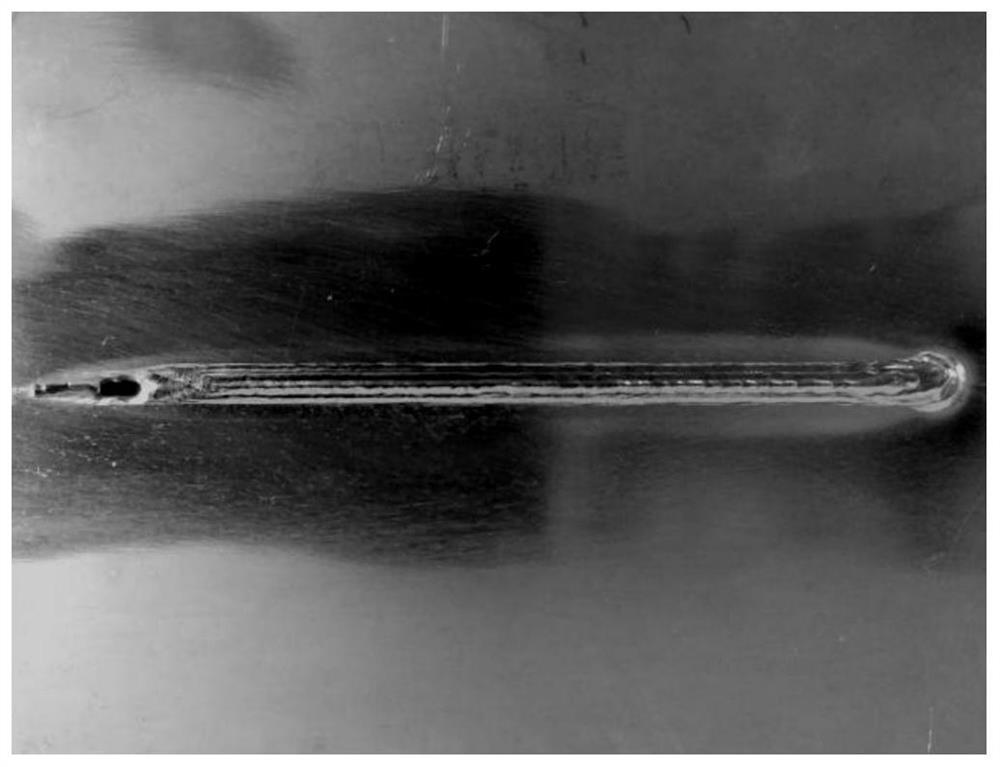

Aluminum alloy TIG tracking method based on ultrasonic electric arc

InactiveCN109128440AReal-time trackingImprove welding efficiencyWelding/soldering/cutting articlesWelding accessoriesWeld seamActive agent

The invention relates to an aluminum alloy TIG tracking method based on an ultrasonic electric arc. The aluminum alloy TIG tracking method is used for overcoming the defects that aluminum alloy TIG single-pass welding is small in weld penetration depth, low in welding efficiency and poor in manual welding weld seam quality. According to the method, a small-angle double-exposure holographic interference method is designed; by means of the method, influences of an oxide active agent, a chloride active agent, a fluoride active agent and a mixed active agent formed by the oxide active agent, the chloride active agent and the fluoride active agent on arc plasmas are confirmed, and the active agent with the best arc gathering effect is selected as an experiment material; the selected active agent is sprayed, and ultrasound is loaded in the coaxial direction of the TIG electric arc; after welding starts, the waveform of welding current is extracted, the envelope curve value of semiconservative filtering is designed, tracking is conducted, and feasibility of the method is verified through the small-angle double-exposure holographic interference method. The method has the beneficial effectthat ordinary ultrasound and electric arc compound welding is achieved, and the ultrasonic electric arc and the surface active agent are fused.

Owner:XIANGTAN UNIV

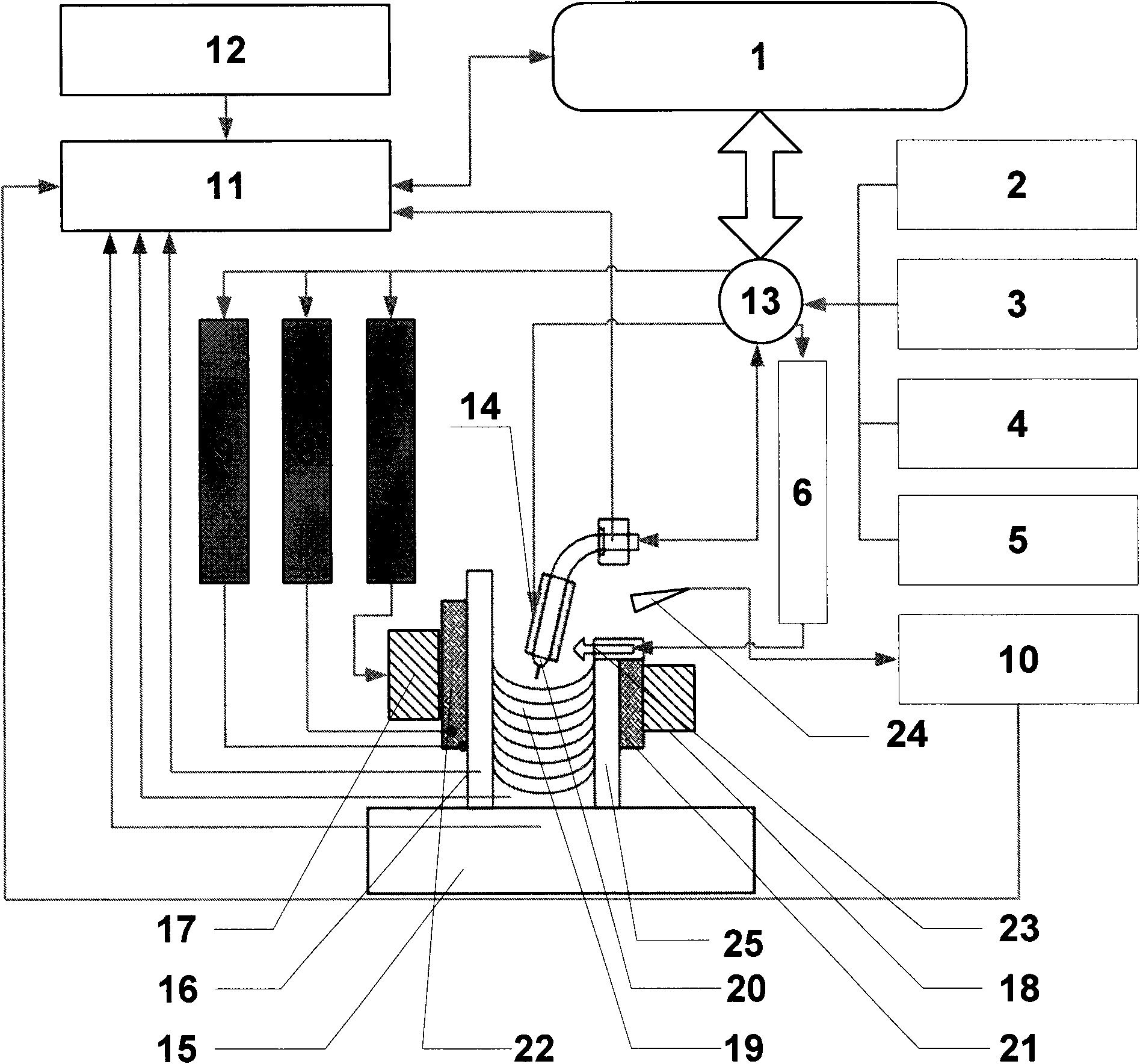

Method and equipment for manufacturing gradient functional structure

InactiveCN102240861BAvoid defectsMeet the needs of high-performance componentsWelding accessoriesNon-electric welding apparatusMelting tankGradient material

The invention relates to a method and equipment for manufacturing a gradient functional structure through arc welding and quick forming. By adopting the technology of outer-field compounding, molding, forcible temperature control, sequential growth, and whole welding forming, a double metal gradient material is subjected to in-situ alloying, and the gradient functional structure is manufactured in a near net way; and in the method, an electromagnetic stirring action, an electromagnetic metallurgical action and an ultrasonic welding action are adopted, the large-volume welding pool liquid metal solidification process is comprehensively controlled, and the gradient functional structure is manufactured by matching a high-speed wire feed system, a mould forcible temperature control system, a near net forcible sequential growth whole forming system, and an in-situ alloying gradient material. The equipment is formed by integrating and combining an electromagnetic welding system, an ultrasonic welding system, and an efficient welding system. By the method and the equipment for quickly manufacturing the gradient functional structure by a non-layered welding structure in a low-cost way, a manufacturing period is reduced, production efficiency is improved, and the high reliability and the long service life of the gradient functional structure are guaranteed.

Owner:CHONGQING UNIV

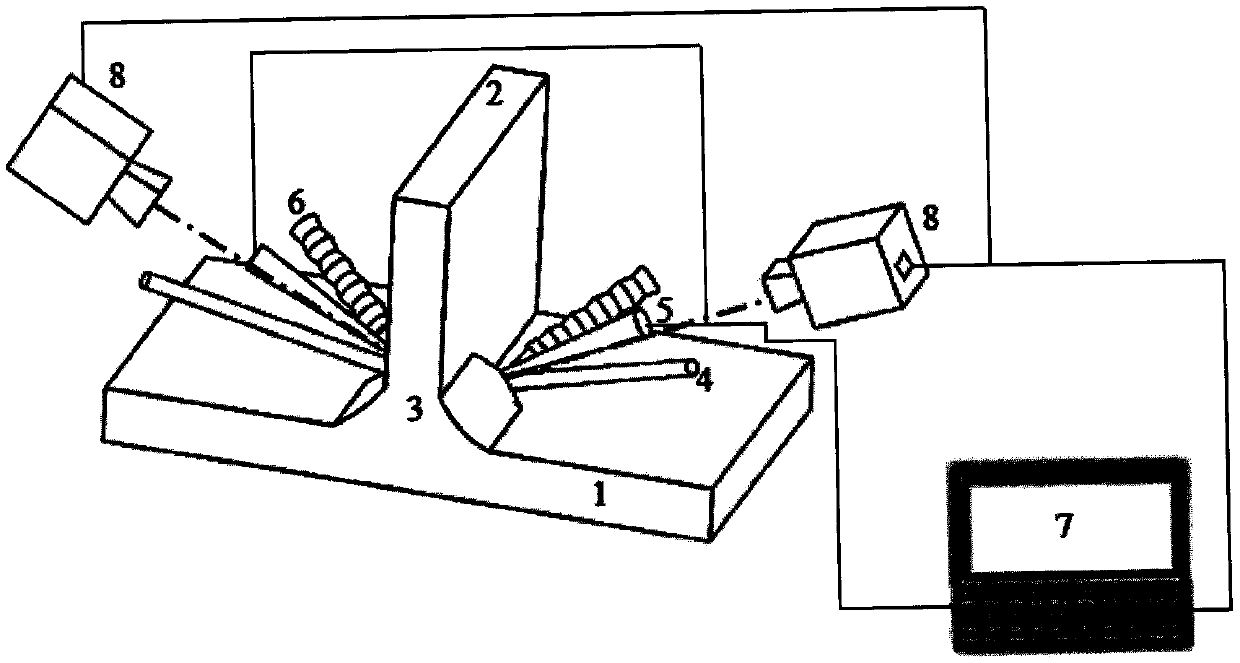

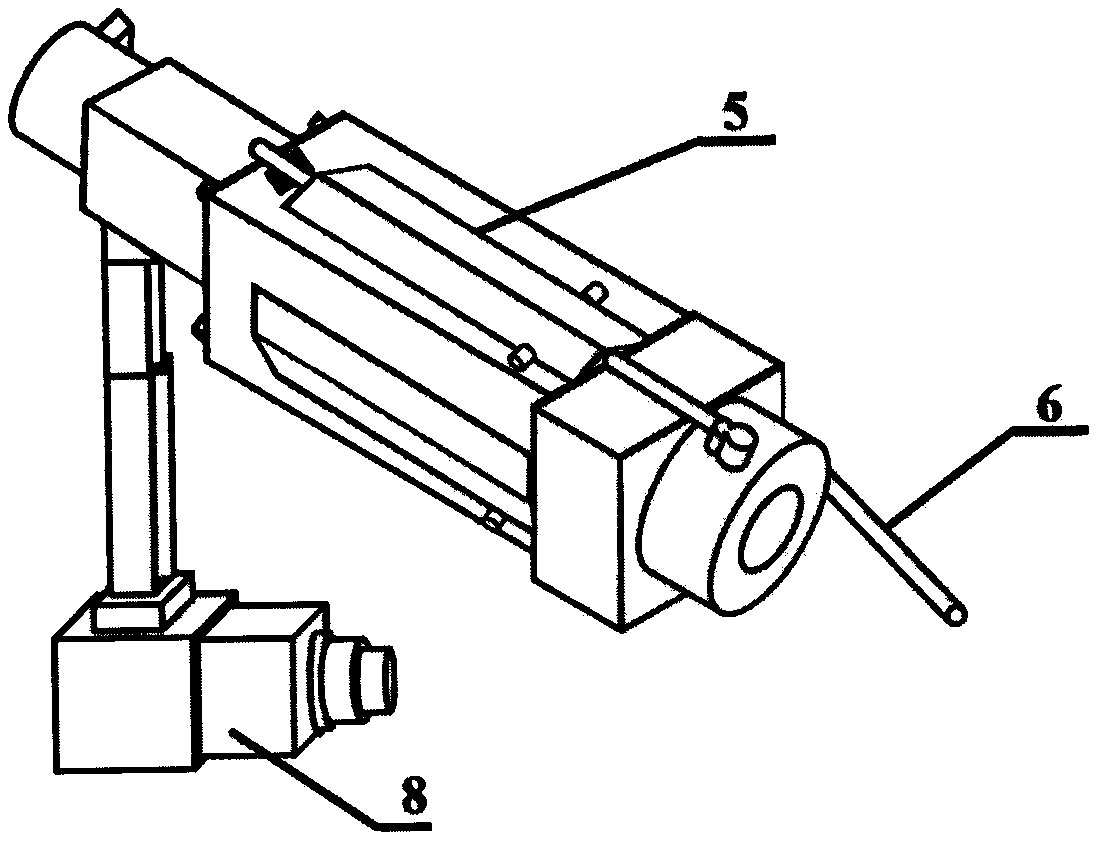

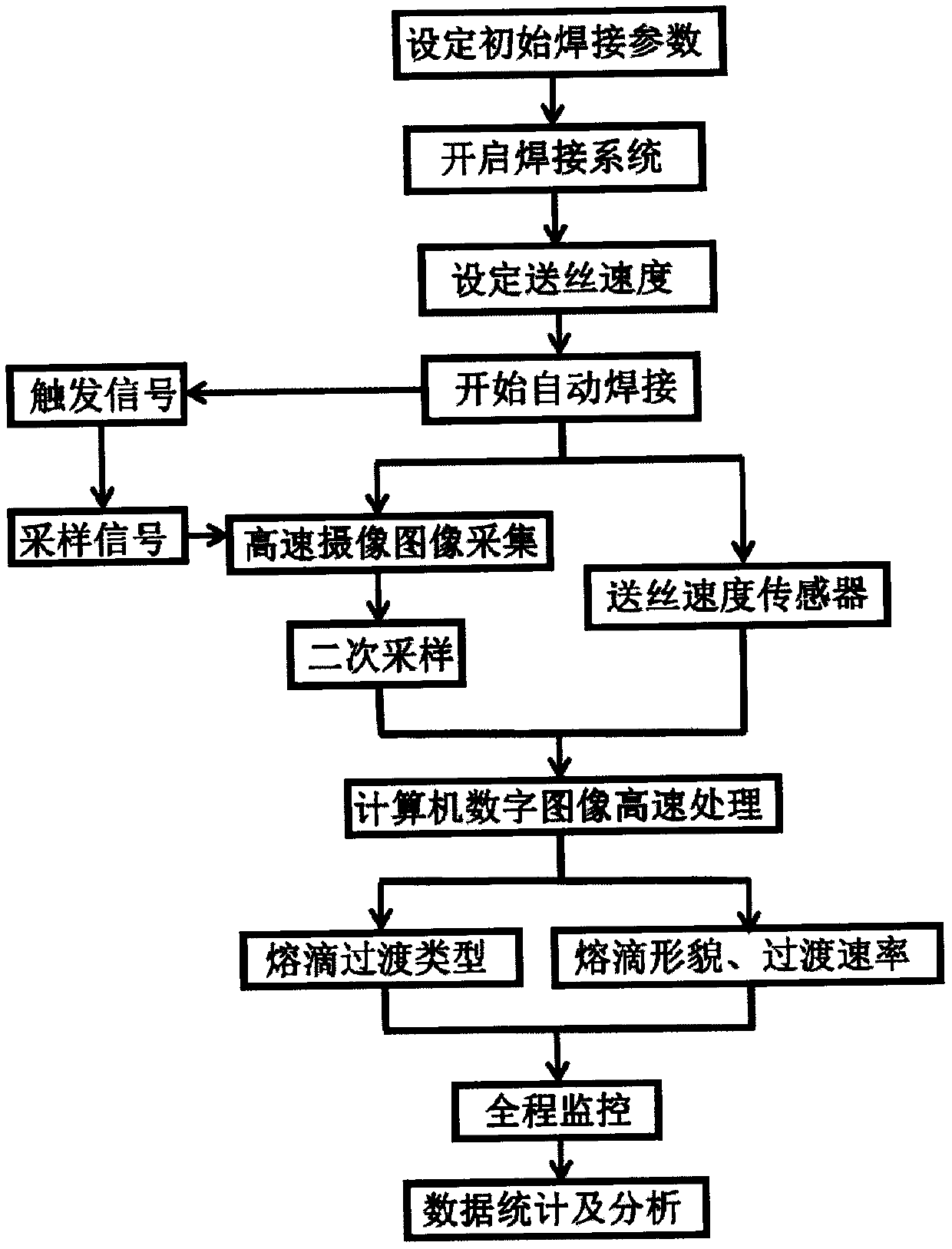

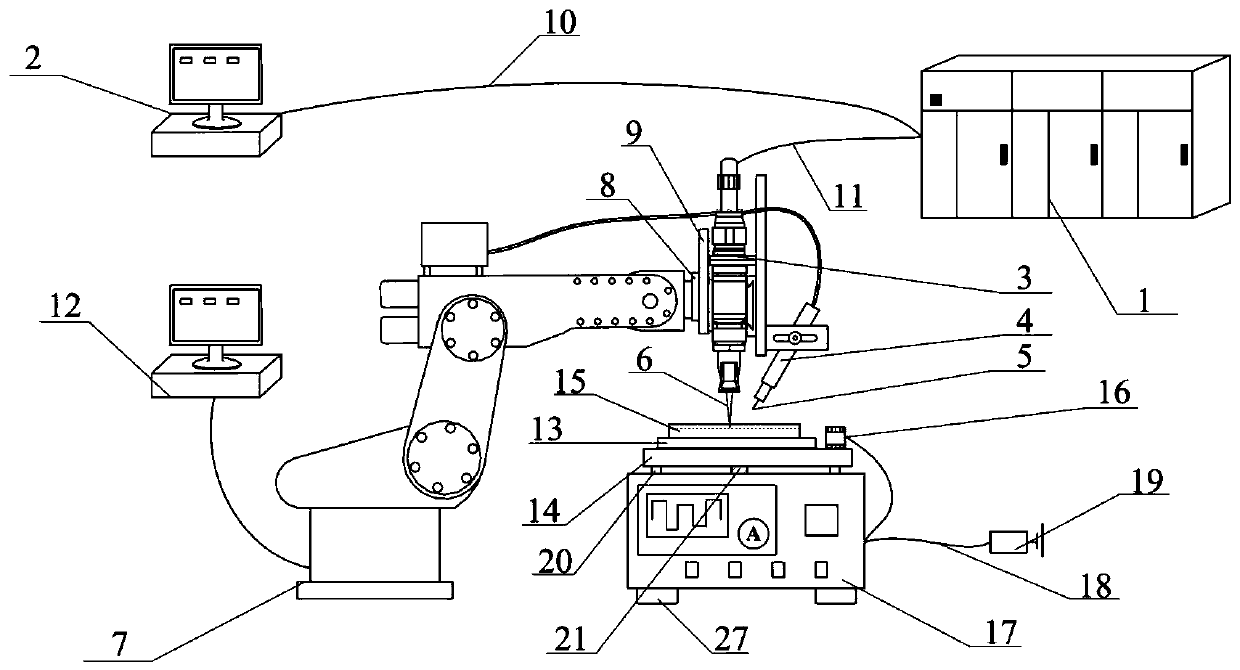

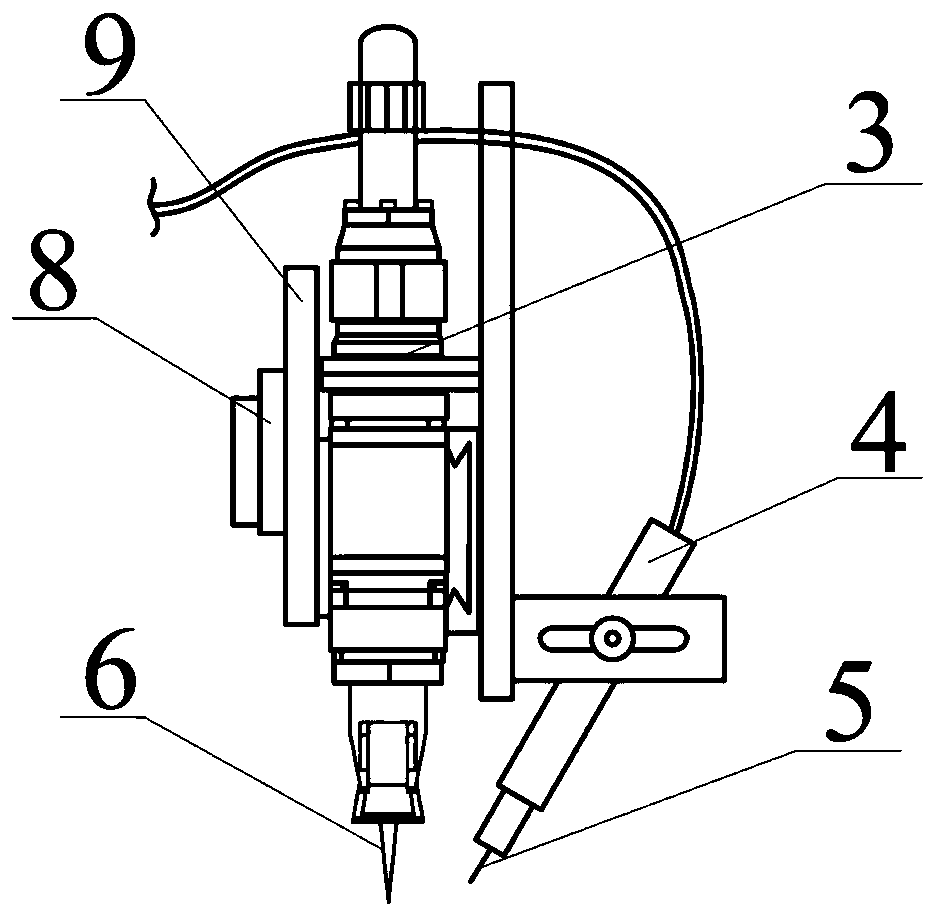

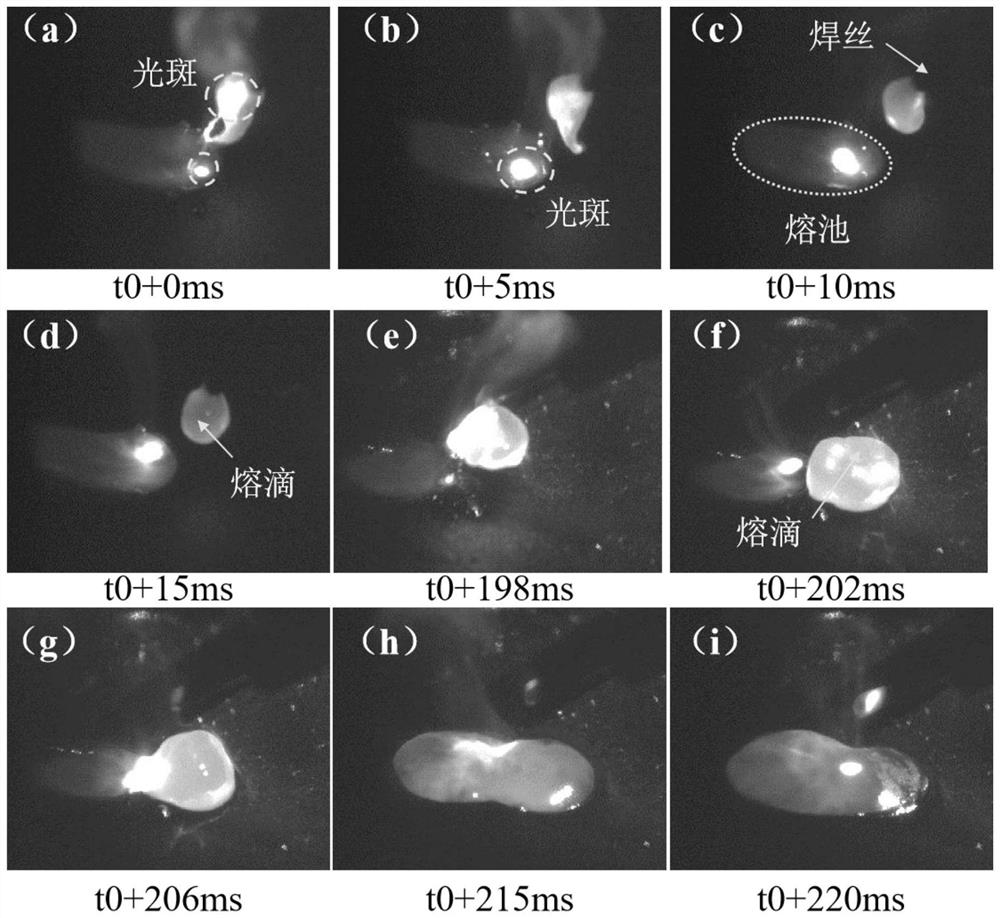

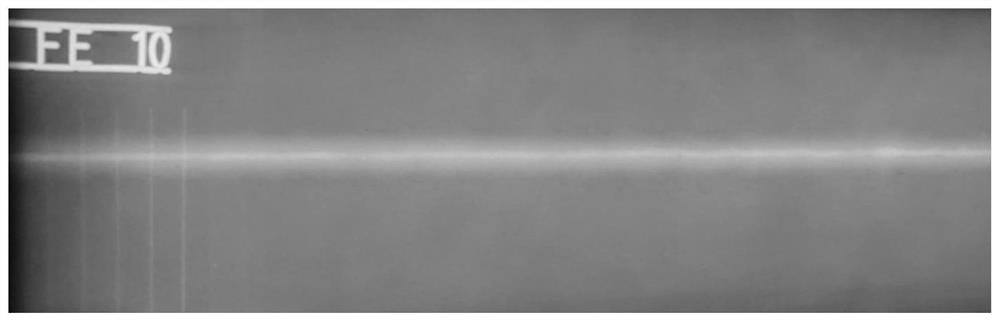

Dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method based on high-speed photography

ActiveCN111203639ADetailed analysisReduce memory requirementsLaser beam welding apparatusImaging processingControl system

The invention discloses a dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method based on high-speed photography. In the process of dual laser beam dual side simultaneous welding wire filling, a droplet transfer mode and frequency are monitored in real-time by a high-speed camera system, so that the purpose of monitoring dual laser beam dual sidesynchronous welding wire filling droplet transfer at different wire feeding speeds in the whole process is achieved. The dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system mainly includes four parts of a duel laser beam duel side simultaneous welding wire filling system, a high-speed video acquisition and processing system, a full digital wire feeding control system and an image processing system, and is characterized in that the droplet transfer on both sides of a stringer is monitored simultaneously by two high-speed cameras, and the acquired images are processed quickly by the digital image processing software, so that the droplet transfer frequency is calculated quantitatively. According to the dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method, the droplet transfer mode and frequency can be monitored in real time, and thus the weld quality of laser welding is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

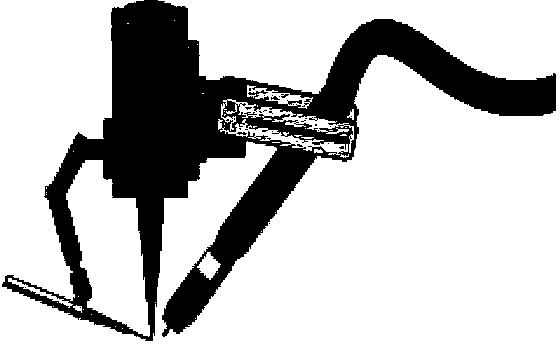

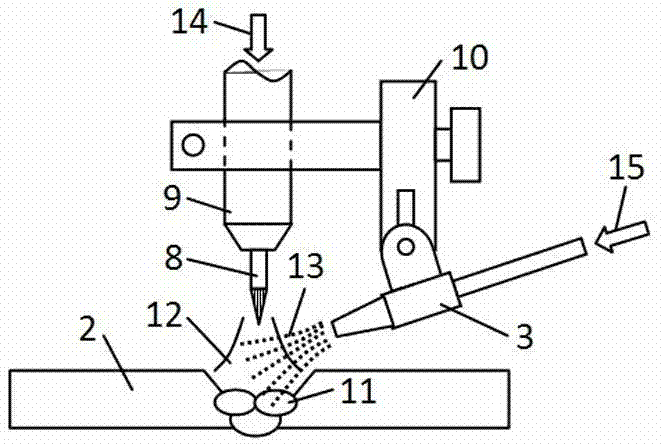

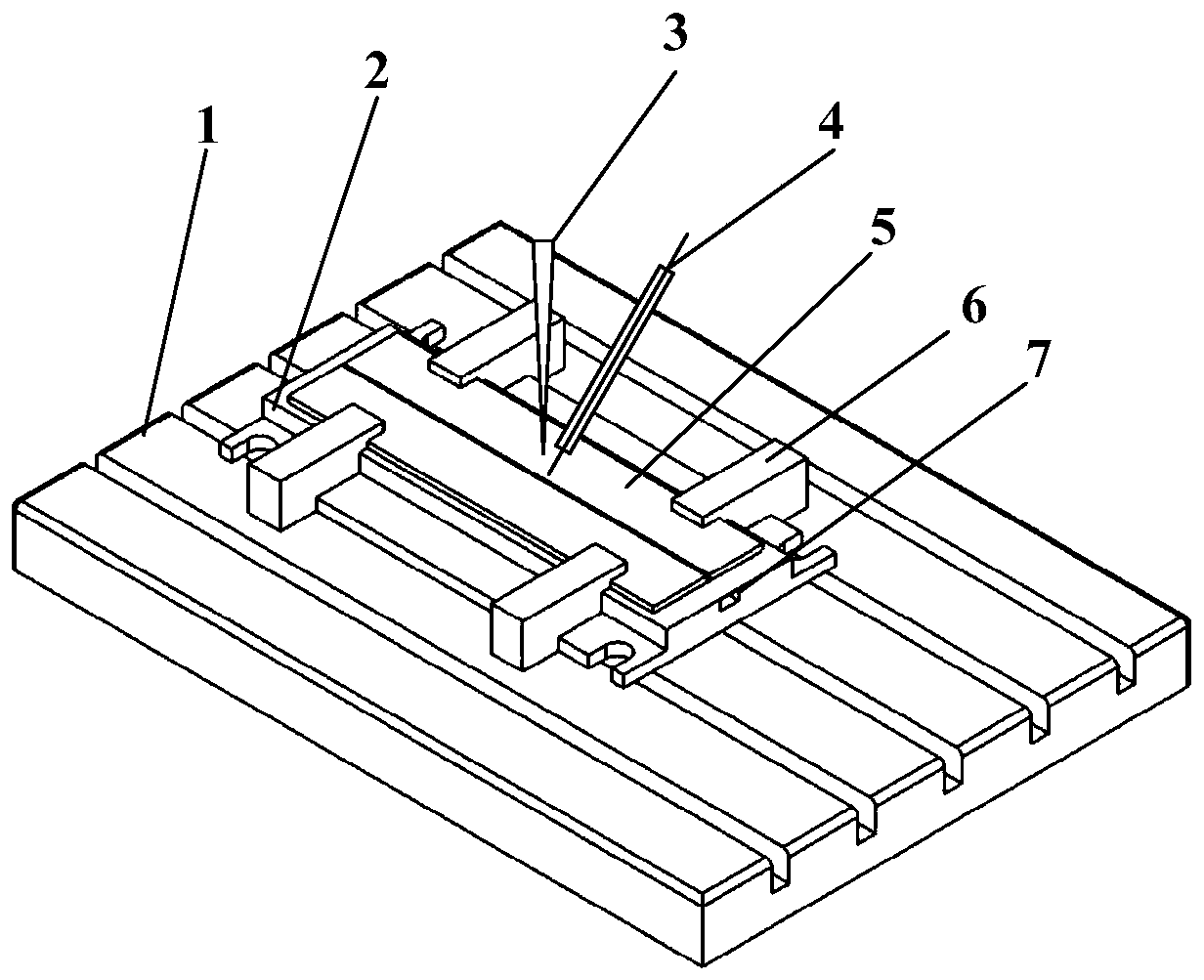

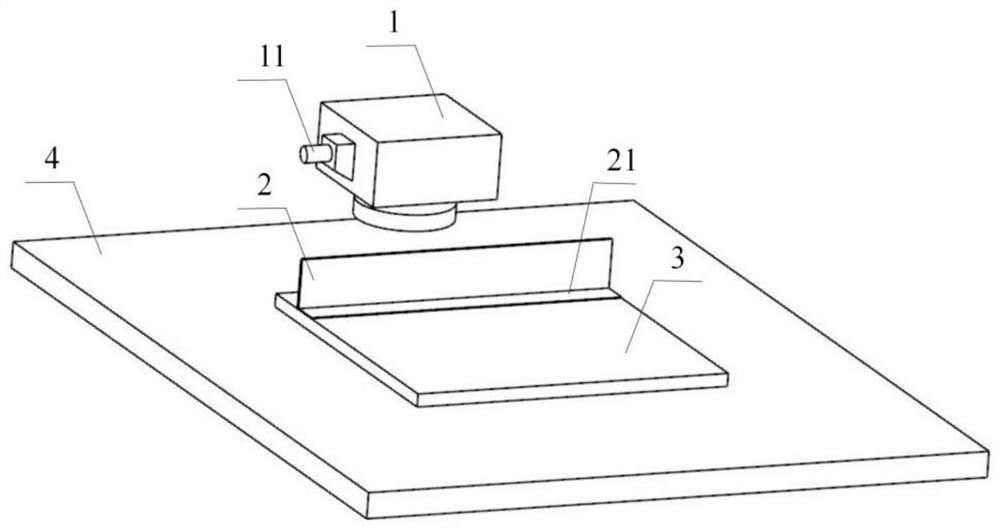

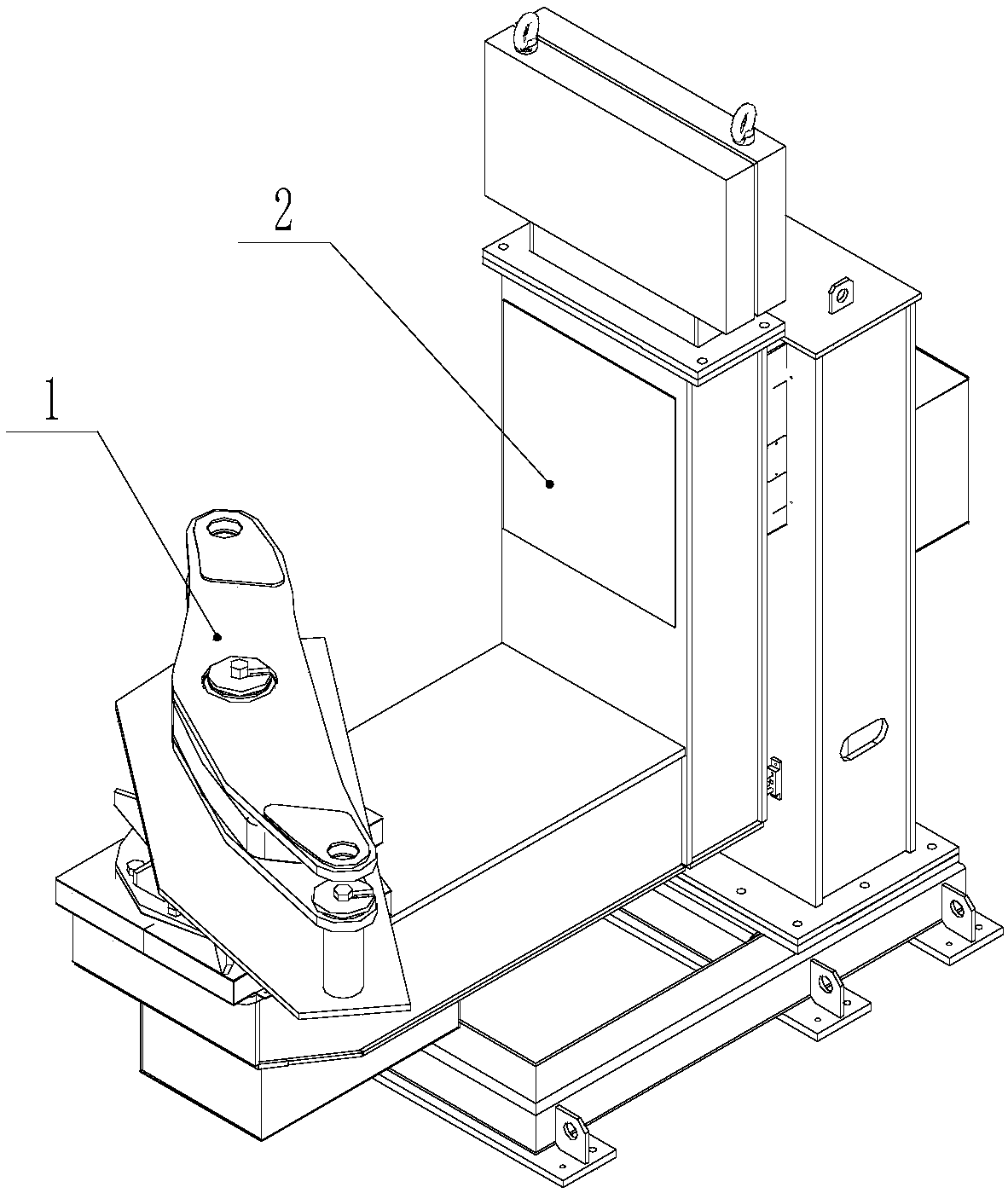

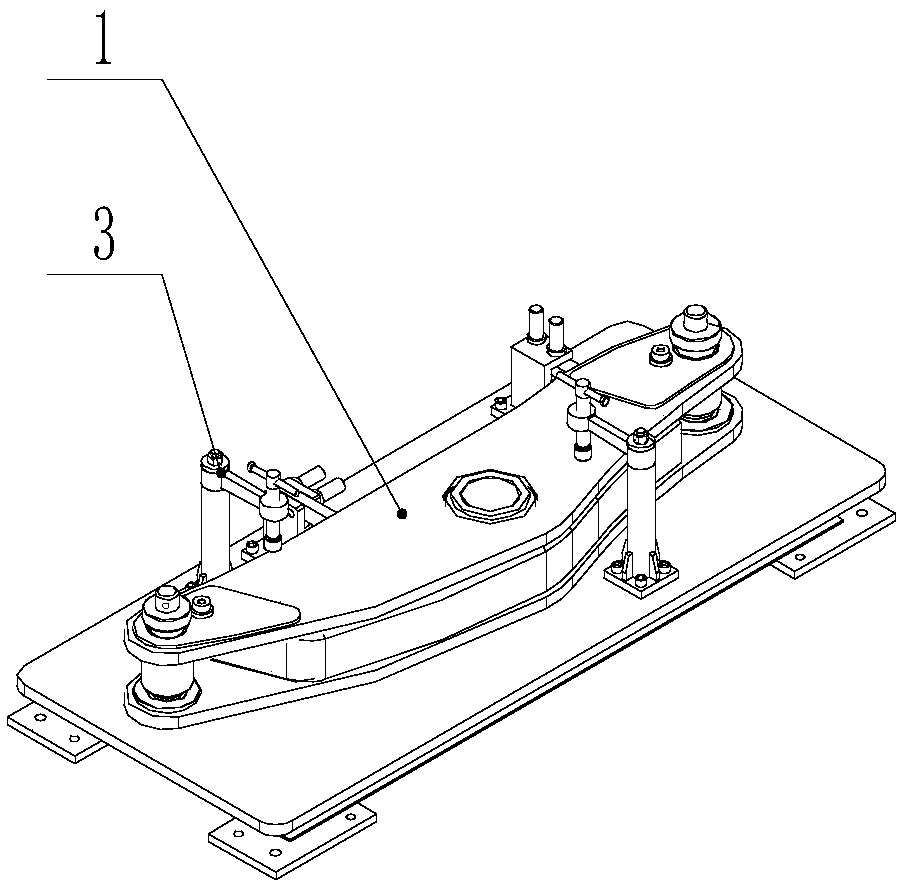

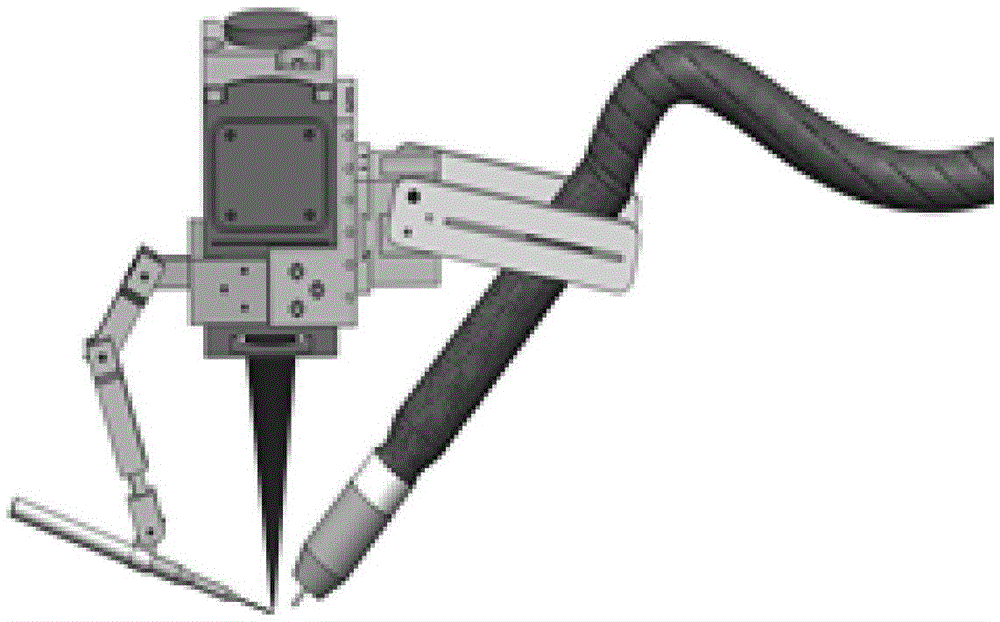

High-nitrogen steel composite welding device and method for reducing air holes assisted by mechanical vibration

ActiveCN110682001AReduce defectsStrong penetrating powerWelding/soldering/cutting articlesLaser beam welding apparatusControl systemLinkage (mechanical)

The invention discloses a device and method for reducing high-nitrogen steel composite welding air holes assisted by mechanical vibration, and belongs to the technical field of welding. A laser welding head of a laser welding device is mounted on a six-axis linkage robot through a flange and a support plate and is connected with a laser; two workpieces to be welded are fixed to a welding workbenchin a butt joint mode, a laser beam generated by the laser welding head is coaxial with a gap between the workpieces to be welded, and a welding gun is arranged on the front surfaces of the workpiecesto be welded; and the welding workbench is fixed to a vibration test bench, the vibration test bench is connected with a connecting rod through a supporting spring, and a vibration sensor detects vibration frequency and feeds the vibration frequency back to a vibration aging control device to control the vibration frequency in real time. Welding seams of the two high workpieces to be welded are processed into the welding seams with two same curve shapes, and a robot control system controls the six-axis linkage robot to drive the laser welding head to carry out welding by taking the curves asmotion tracks. The welding method effectively improves the welding quality.

Owner:CHANGCHUN UNIV OF SCI & TECH

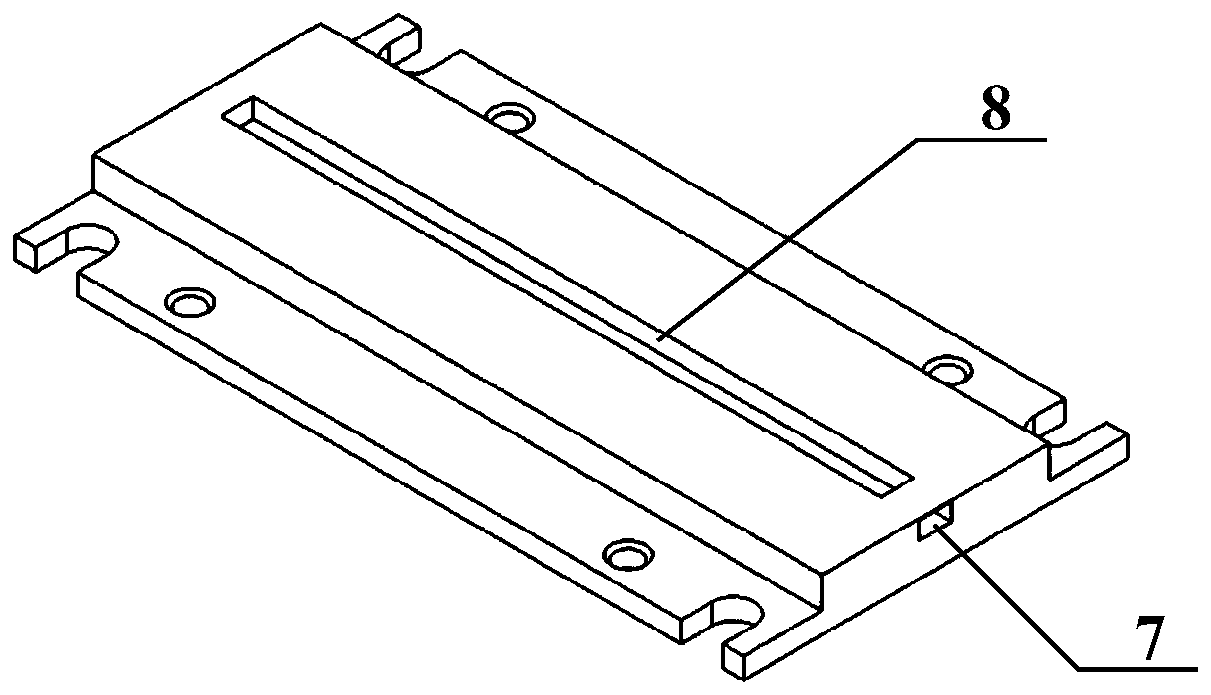

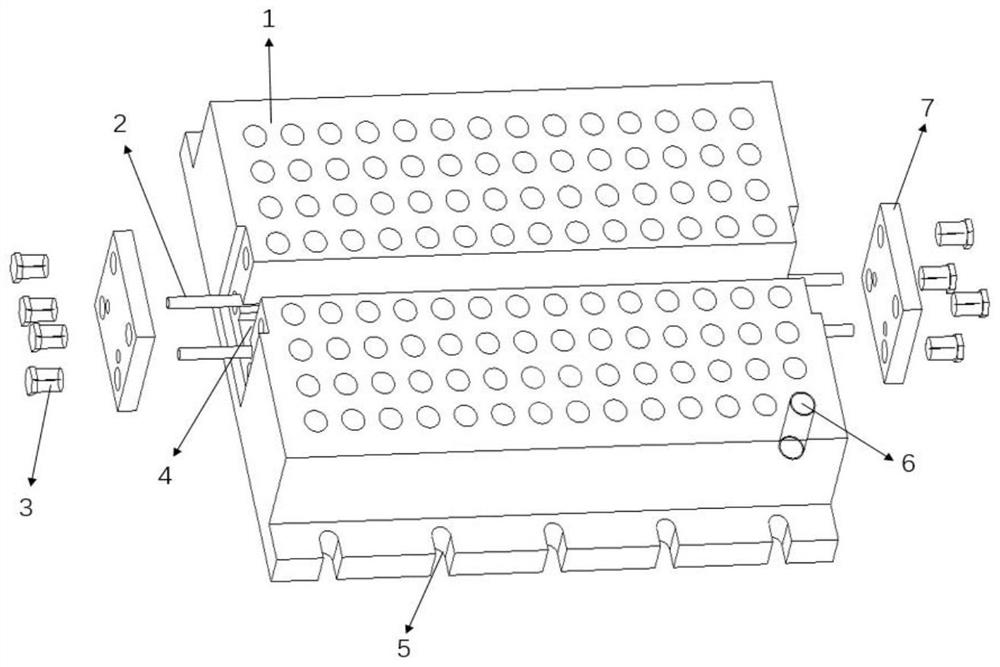

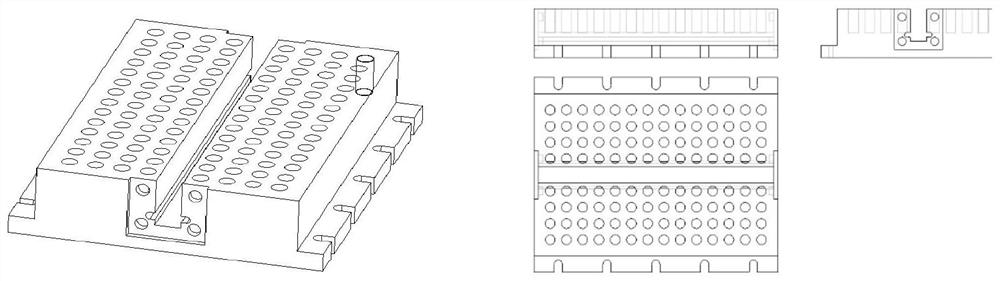

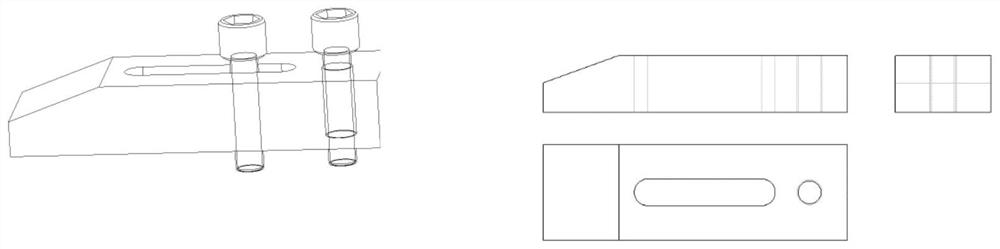

Back shielding gas introducing device and method for laser-MIG hybrid welding of high-strength aluminum alloy

PendingCN112846550AImproved Back FormingReduce weld porosityLaser beam welding apparatusButt jointAluminium alloy

The invention belongs to the field of metal welding, and relates to a back shielding gas introducing device and method for laser-MIG hybrid welding of a high-strength aluminum alloy. The back shielding gas introducing device comprises a workpiece table, a gas guide copper pipe, fixing bolts, a copper base plate, baffle plates and another gas guide copper pipe, wherein the copper base plate is placed in a groove formed in the working face of the workpiece table; the gas guide copper pipes used for introducing back shielding gas are symmetrically placed on the two sides of the bottom in the groove of the workpiece table and symmetrically arranged in U-shaped holes I in the bottom of the groove; and threaded holes are formed in the two sides of the workpiece table, matched with the fixing bolts and used for fixing the baffle plates to the workpiece table. When the device is used for welding a 7-series high-strength aluminum alloy plate, the problems that hot cracks are prone to occurring, the back face is poor in forming, and air holes are prone to being generated can be solved, and a good butt joint is obtained.

Owner:NANJING UNIV OF SCI & TECH

Ti-Al-V-Mo series metal powder core flux-cored wire and preparation method thereof

ActiveCN114473294ALow costRefine the weld grainArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld bead

The invention discloses a Ti-Al-V-Mo series metal powder core flux-cored wire and a preparation method thereof. The invention belongs to the technical field of welding materials. The technical problems that an existing titanium alloy flux-cored wire is high in preparation cost, slag shells need to be cleaned after welding, and the existing titanium alloy flux-cored wire is not suitable for welding of narrow-gap titanium alloy thick-wall components are solved. The Ti-Al-V-Mo series metal powder core flux-cored wire is composed of a Ti-10Mo-4Nb-4V outer skin and a flux core filled in the Ti-10Mo-4Nb-4V outer skin, wherein the flux core is formed by mixing, by mass, 5%-7% of vanadium powder, 10%-15% of aluminum powder, 3%-5% of molybdenum powder, 3%-4% of iron powder and the balance titanium powder. The Ti-Al-V-Mo titanium alloy metal powder core flux-cored wire can be applied to the fields of laser filler wire welding, non-consumable electrode gas shielded welding and the like and is good in welding manufacturability, excellent in comprehensive mechanical property, low in diffusible hydrogen content, high in welding efficiency and good in weld joint forming, slag shell cleaning is not needed after welding, and the welding quality is improved. And the groove angle is wide in application range for welding of the TC4 titanium alloy and other double-phase titanium alloy, and the good application prospect is achieved.

Owner:HARBIN WELDING INST LTD +1

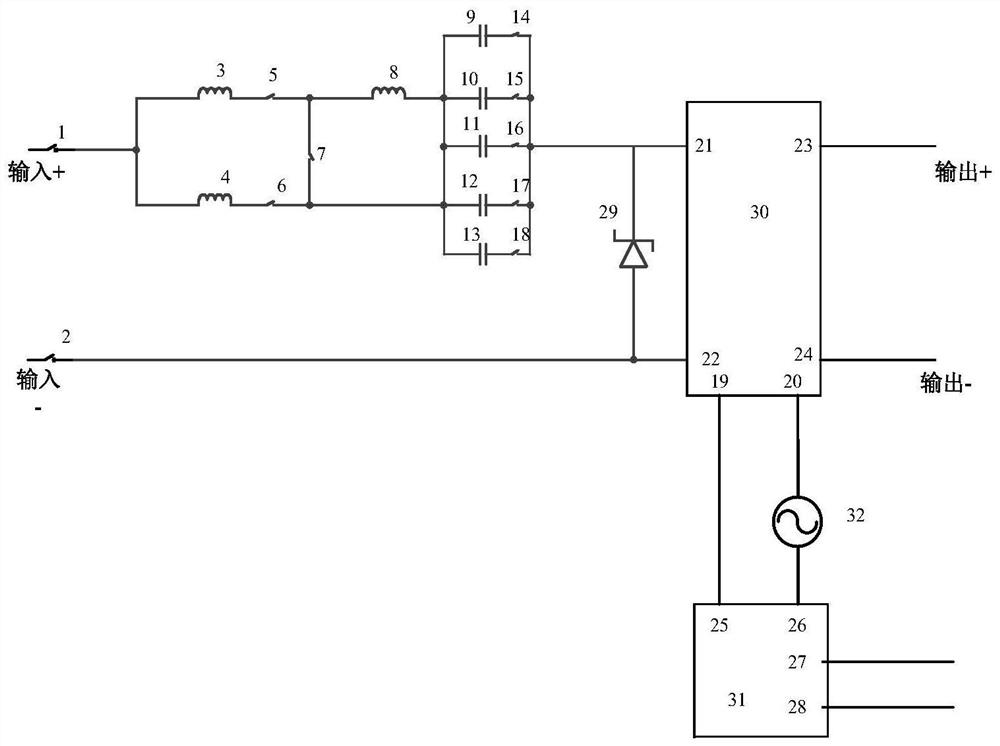

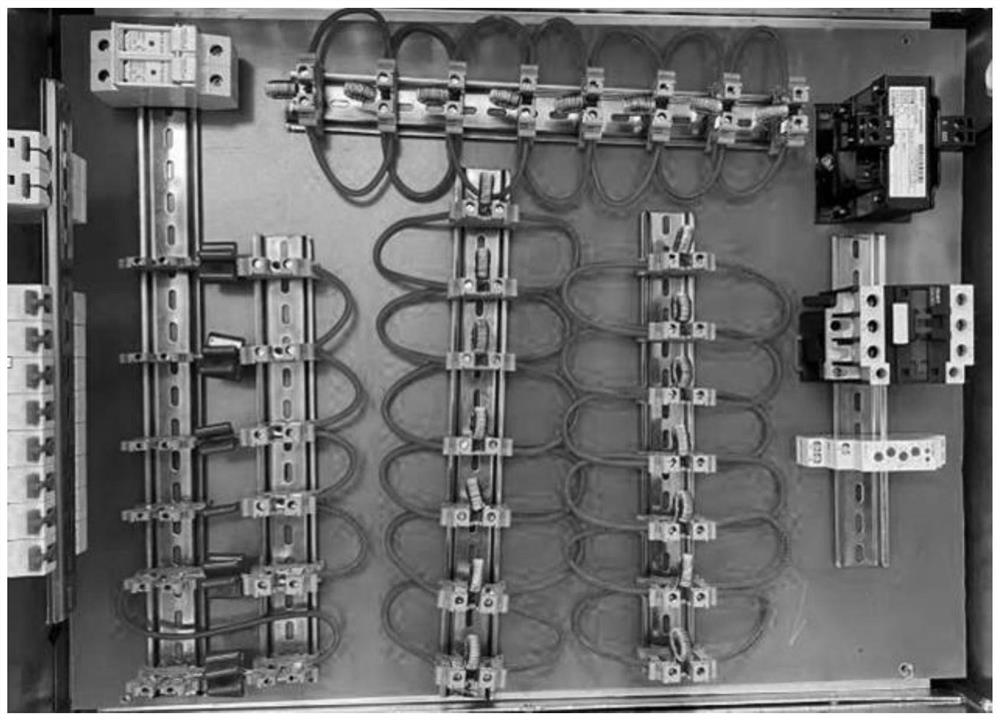

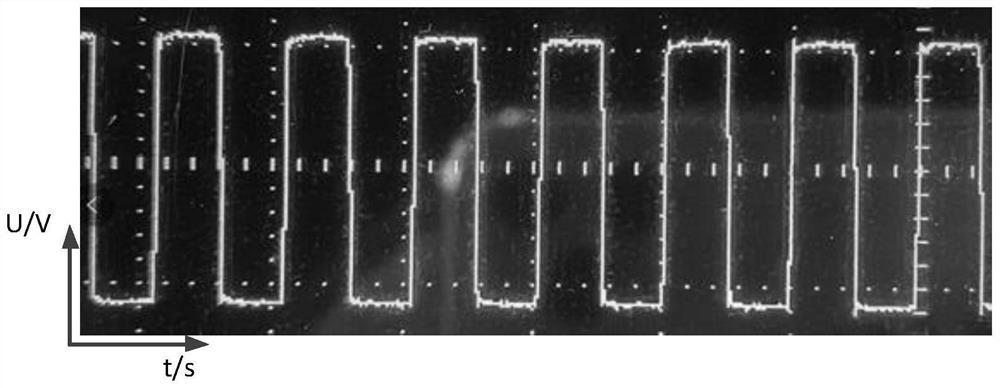

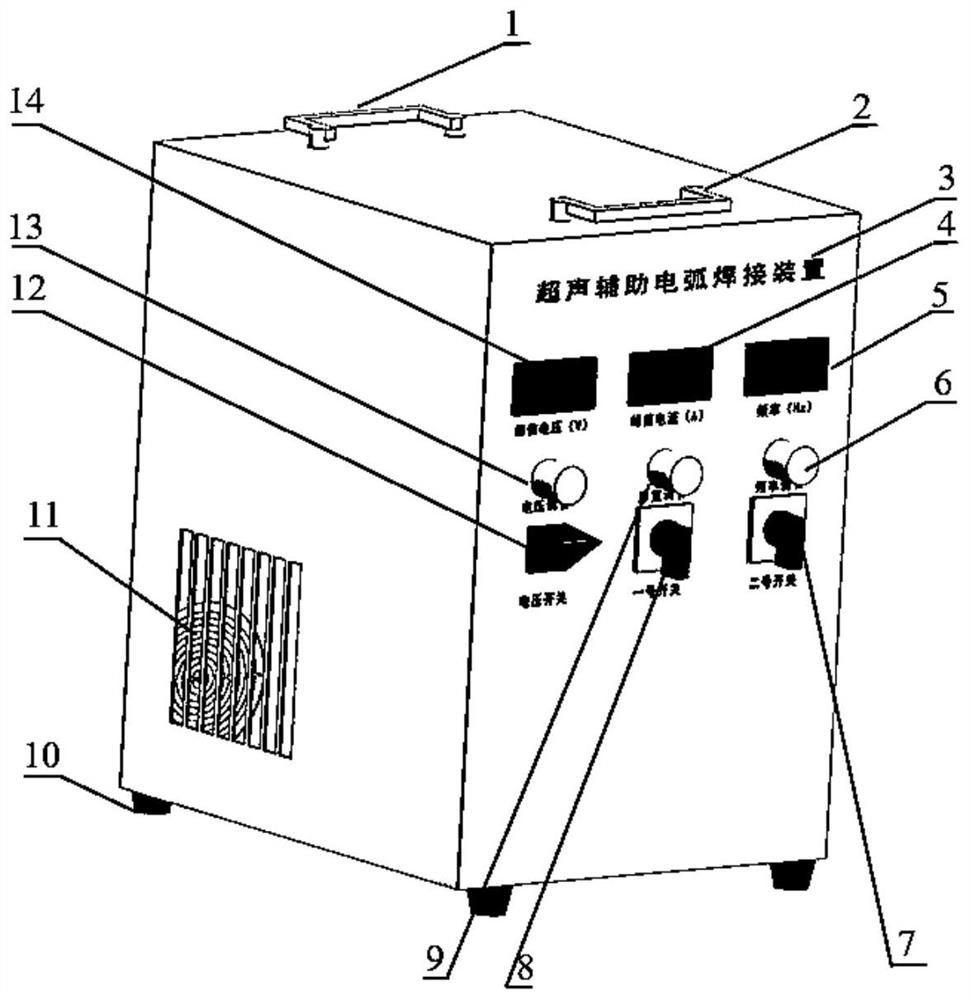

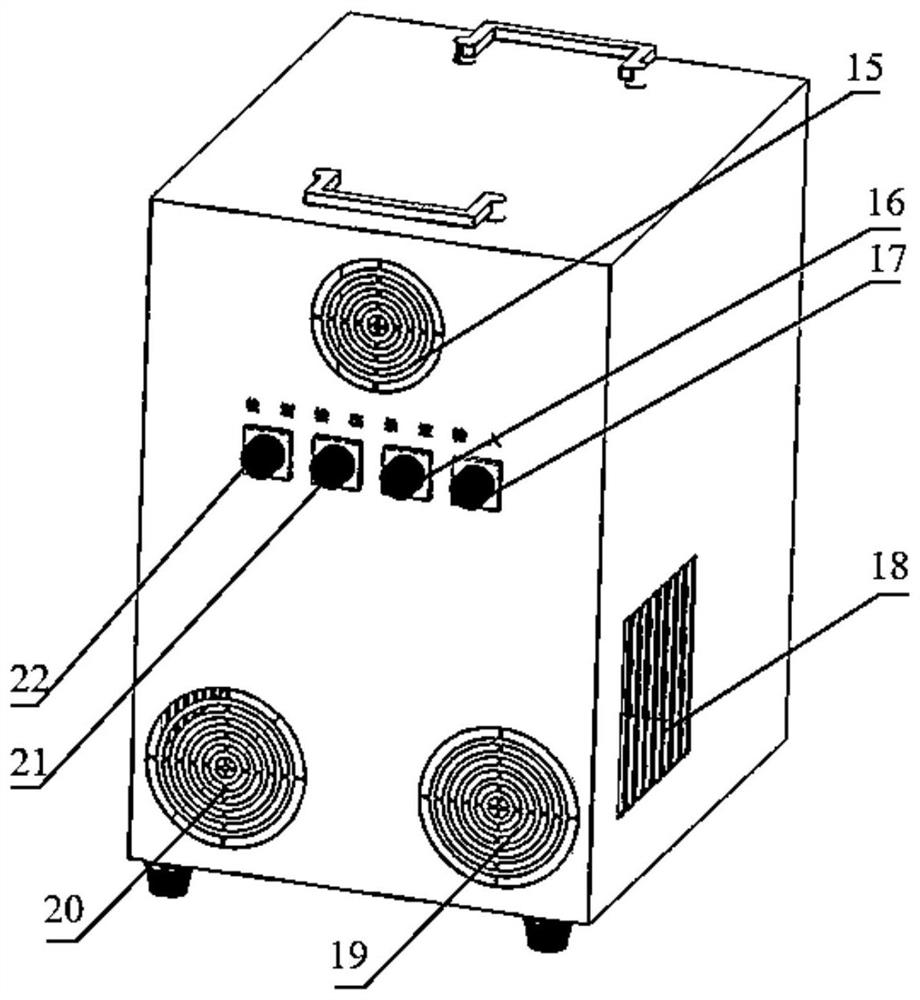

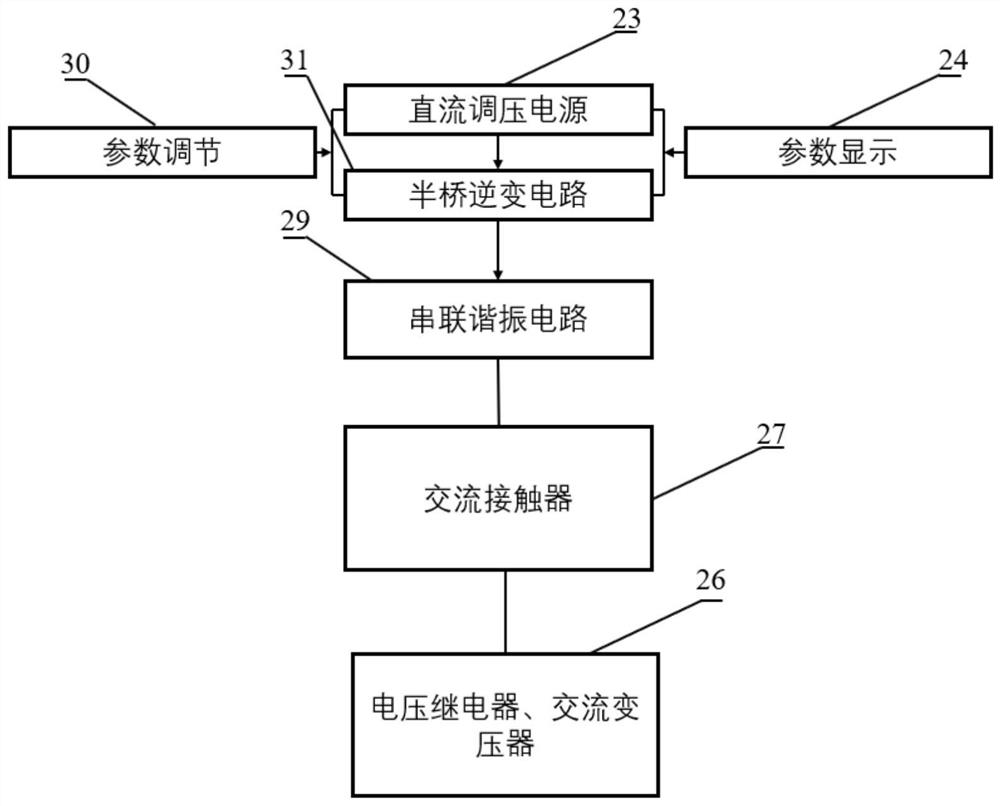

Isolation coupling and automatic switch control device for ultrasonic arc welding

PendingCN113458560AEnhanced interactionSolve the low efficiency of controlWelding accessoriesPhysicsAutomatic control

The invention relates to an isolation coupling and automatic switch control device for ultrasonic arc welding, in particular to an isolation coupling and automatic switch control device between a welding power supply loop and an ultrasonic power supply loop. According to the device, the conduction of an ultrasonic power supply is controlled by detecting the voltage at the positive and negative ends of a welding machine through a voltage relay, a good ultrasonic waveform can be coupled, and the device protects internal components of the ultrasonic power supply through a transient suppression diode.

Owner:JIANGSU UNIV

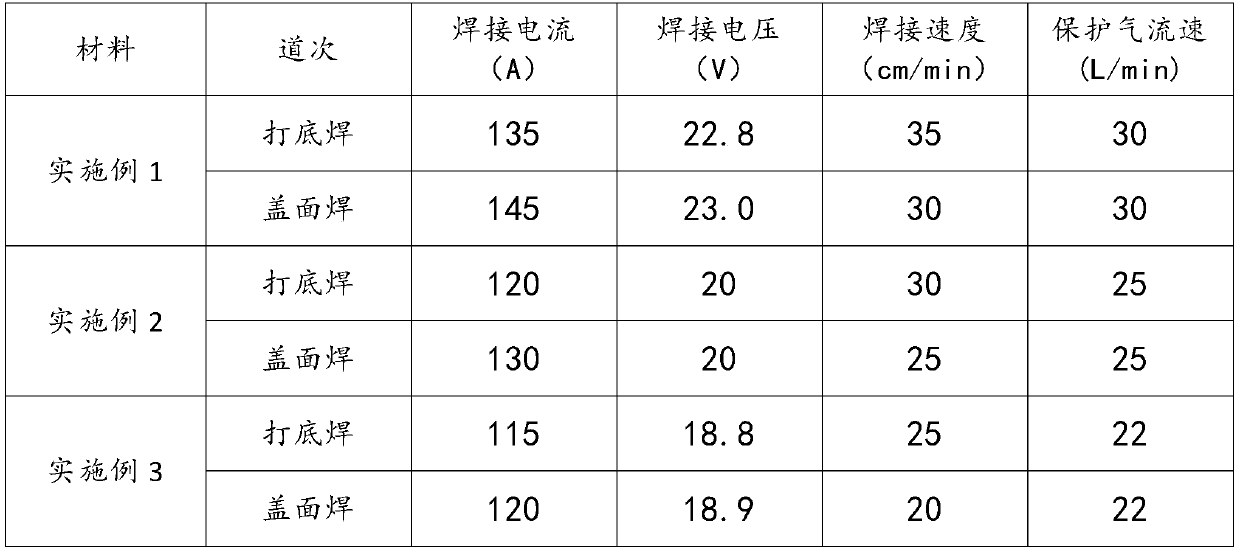

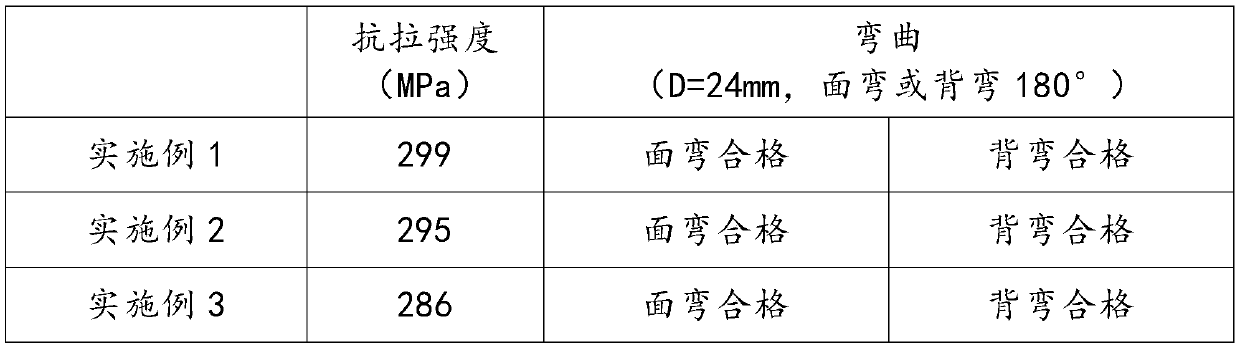

Technological method for welding 304 stainless steel plate

ActiveCN111702335ALow heat inputReduce sensitivityWelding/cutting media/materialsWelding/soldering/cutting articlesShielding gasGas metal arc welding

The invention relates to the technical field of plate welding, and discloses a technological method for welding a 304 stainless steel plate. The technological method for welding the 304 stainless steel plate comprises the following steps that (1) the 304 stainless steel plate is machined to obtain a 304 stainless steel plate with a Y-shaped groove; (2) g the 304 stainless steel plate obtained in the step (1) is pretreated, and then the 304 stainless steel plate is fixed to a device with protective gas introduced; (3) the included angle between the laser emitted by a laser and the 304 stainlesssteel plate obtained in the step (2) is adjusted to enable the included angle to be 70-90 degrees; and (4) backing welding and cover welding are carried out in sequence. The method is simple and easyto operate, and the production efficiency is high; and through the coupling between laser parameters and gas metal arc welding parameters, the heat input of a 304 stainless steel plate joint is reduced, the thermal crack sensitivity of a welding line is reduced, and the porosity of the welding line is greatly reduced.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Welding method for heat pipe radiator fins based on scanning galvanometer laser welding

PendingCN113523554AImprove surface roughnessAdd DiffuseLaser beam welding apparatusResistance welding apparatusLaser solderingGalvanometer

The invention discloses a welding method for heat pipe radiator fins based on scanning galvanometer laser welding. The welding method comprises the following steps that S1, shot blasting treatment is conducted on welding faces of the L-shaped fins to be welded; S2, spot welding and pre-fixing are conducted on the L-shaped fins subjected to shot blasting and a heat conduction substrate of a heat pipe radiator; and S3, a welding path is generated based on the welding faces of the L-shaped fins, a laser galvanometer scanning mode is set, the power of a blue laser is adjusted, welding is started from one sides of the welding faces of the L-shaped fins and finished on the other sides of the welding faces of the L-shaped fins, the positions of the L-shaped fins are kept fixed in the welding process, and a laser galvanometer moves along a movement path at the set speed so that welding of the current L-shaped fins can be completed. According to the welding method, the problems of incomplete infiltration, air holes, large laser welding power of copper alloy and aluminum alloy fins, low absorption rate and the like existing when the heat conduction substrate and the fins of the heat pipe radiator are welded through reflow soldering and high-frequency induction heating at present can be solved.

Owner:武汉光谷机电科技有限公司

Aluminum alloy welding wire containing Ga and Pr and manufacturing method and application thereof

ActiveCN109604860AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaPorosityHydrogen content

The invention provides an aluminum alloy welding wire containing Ga and Pr and a manufacturing method and application thereof, belongs to the technical field of material processing engineering, and solves the problem that the welding effect is poor when an existing aluminum alloy welding wire is welded with an aluminum alloy section bar. The aluminum alloy welding wire containing Ga and Pr comprises the components of, by mass percentage, 0.01-0.5% of Ga, 0.01-0.5% of Ga2O3, 0.01-0.05% of Pr, 0.01-0.5% of Pr2O3, 0.01-0.5% of Mg, and the balance Al. According to the aluminum alloy welding wire containing Ga and Pr and the manufacturing method and application thereof, trace of Ga and Pr are added, and the problem of hydrogen dissolution during smelting and welding of an Al-Mg aluminum weldingwire is solved, so that the hydrogen content in an aluminum alloy wire is greatly reduced; and when the welding wire is used in welding, the weld seam porosity is less, the weld seam crack is less, and the weld seam strength coefficient is high and close to the base metal strength.

Owner:ZHEJIANG YUGUANG ALUMINUM MATERIALS

Welding method for high-strength strength weld

InactiveCN109175612AImprove welding efficiencySimple processArc welding apparatusFriction weldingHigh intensity

The invention discloses a welding method for a high-strength strength weld, and belongs to the field of welding methods. The welding method comprises the following steps: first, adjustment of an assembly gap; second, positioned welding; third, backing welding, and nonwelding of one reserved section at each of the intersection positions of short edges on two sides of a rocker rib plate; fourth, filling and cover surface welding; and fifth, welding of the intersection positions of the short edges on two sides of the rocker rib plate. Through the adoption of the welding method, welding air holesare effectively decreased, effective fusion of the weld is ensured, high-strength welding of a loader rocker is realized, the welding efficiency of the rocker is improved, and the production cost is reduced.

Owner:SHANDONG LINGONG CONSTR MACHINERY

Welding wire for die-casting aluminum alloy and preparation method of welding wire

ActiveCN113385854AUniform tissueStable weldabilityFurnace typesWelding/cutting media/materialsSlag (welding)Wire rod

The invention discloses a welding wire for die-casting aluminum alloy and a preparation method thereof, and belongs to the field of manufacturing of aluminum alloy welding wires. The welding wire for the die-casting aluminum alloy comprises, by mass, 10%-13% of Si, 0.3%-0.5% of Mn, 0.2%-0.3% of Zr, smaller than or equal to 0.2% of Mo, 0.02%-0.05% of Sr, 0.05%-0.15% of Ti, smaller than or equal to 0.15% of Fe and the balance is Al and inevitable impurities, the mass percentage of a single impurity is smaller than or equal to 0.05%, and the total mass percentage of the inevitable impurities is smaller than or equal to 0.15%. The preparation method comprises the steps of semi-continuous casting, machining, preheating, extruding, annealing, wire stretching and welding wire drawing. The welding wire solves the problems that the internal structure is poor, the joint strength is low, air holes, slag inclusion, cracks and the like are prone to occurring in the welding process when a current commercially available welding wire is adopted for welding die-casting aluminum alloy.

Owner:沈阳育成鑫成果转化技术服务有限公司

A laser-toptig hybrid welding method

ActiveCN104014933BGuarantee welding qualityGuaranteed stabilityLaser beam welding apparatusLaser-hybrid weldingShielding gas

Owner:HARBIN INST OF TECH

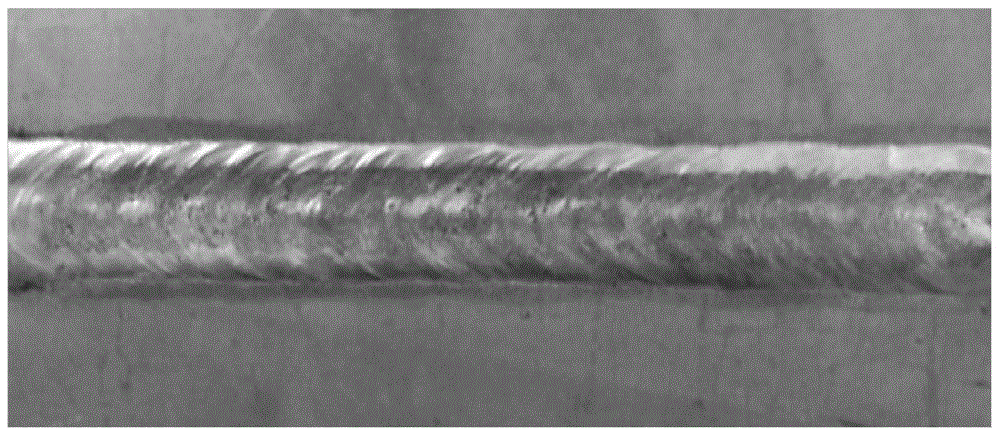

Ultrahigh-power double-beam laser-high-frequency pulse deep penetration TIG composite welding method for thick plate

ActiveCN113941776AGood effectStrong penetrating powerLaser beam welding apparatusThick plateDual beam

The invention discloses an ultrahigh-power double-beam laser-high-frequency pulse deep penetration TIG composite welding method for a thick plate. The method belongs to the field of welding. The method aims to solve the technical problem of serious tendency of air holes and cracks in conventional ultrahigh-power laser-deep penetration TIG composite welding. The method comprises the steps that S1, a groove and a to-be-welded surface are polished or cleaned, and a butt joint is formed and fixed; S2, angles of a laser head and a TIG welding gun are set, and the distance between the tip end of a TIG welding gun tungsten electrode and a midpoint of a connecting line of centers of two laser spots on the surface of a to-be-welded thick plate is set; S3, parameters of the ultrahigh-power double-beam laser-high-frequency pulse penetration fusion TIG composite welding are set; S4, protective gas is set; and S5, the protective gas is introduced, and the ultrahigh-power double-beam laser-high-frequency pulse penetration fusion TIG composite welding is synchronously carried out. The method can inhibit weld pores and cracks and improve the welding quality.

Owner:HARBIN WELDING INST LTD

Alloy powder filled tungsten argon arc welding method for aluminum alloy

ActiveCN102489841BIncrease weld penetrationImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsFilling materialsTungsten

The invention discloses a tungsten argon arc welding method, which is applied to aluminum alloy materials and uses alloy powder as welding and filling materials. Besides aluminum powder, the aluminum base alloy powder used in the method further comprises an active powder component and an arc stabilizer powder component. The aluminum base alloy powder is added into welding lines of the aluminum alloy materials to be welded by means of automatic filling, homogeneous materials can be welded, dissimilar materials can also be welded, and the technical problems of low welding efficiency and large air hole inclination in the process of tungsten argon arc welding can be solved, so that high-quality welding joints are obtained.

Owner:SUZHOU YUNSHOU SOFTWARE TECH CO LTD

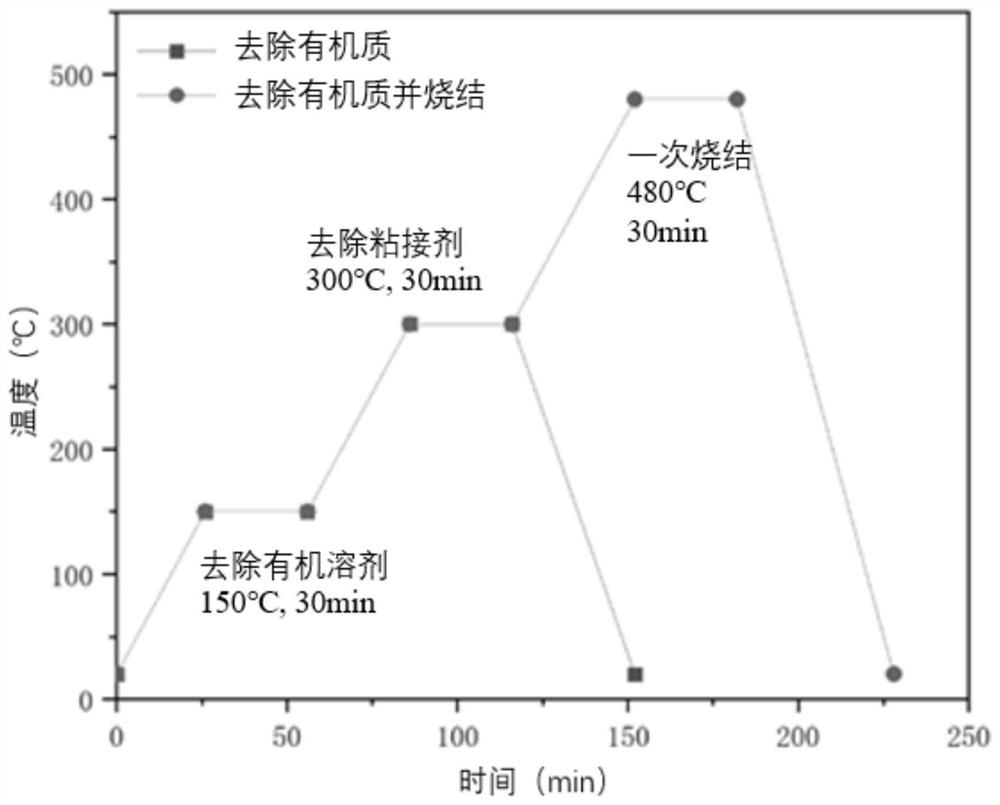

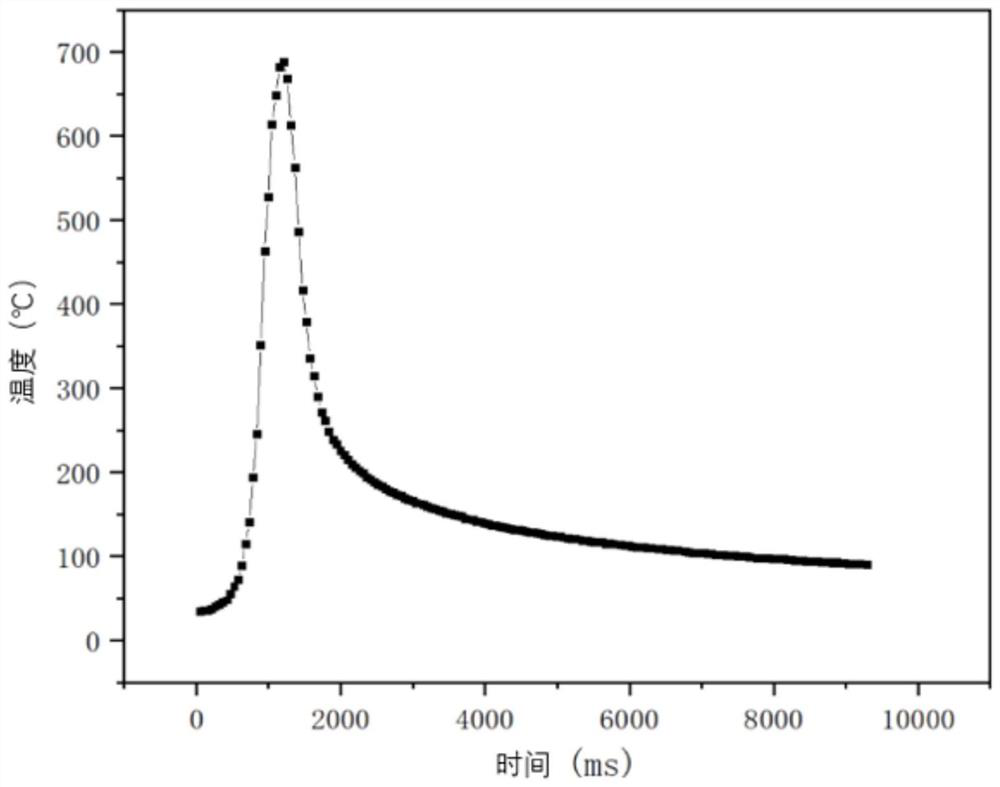

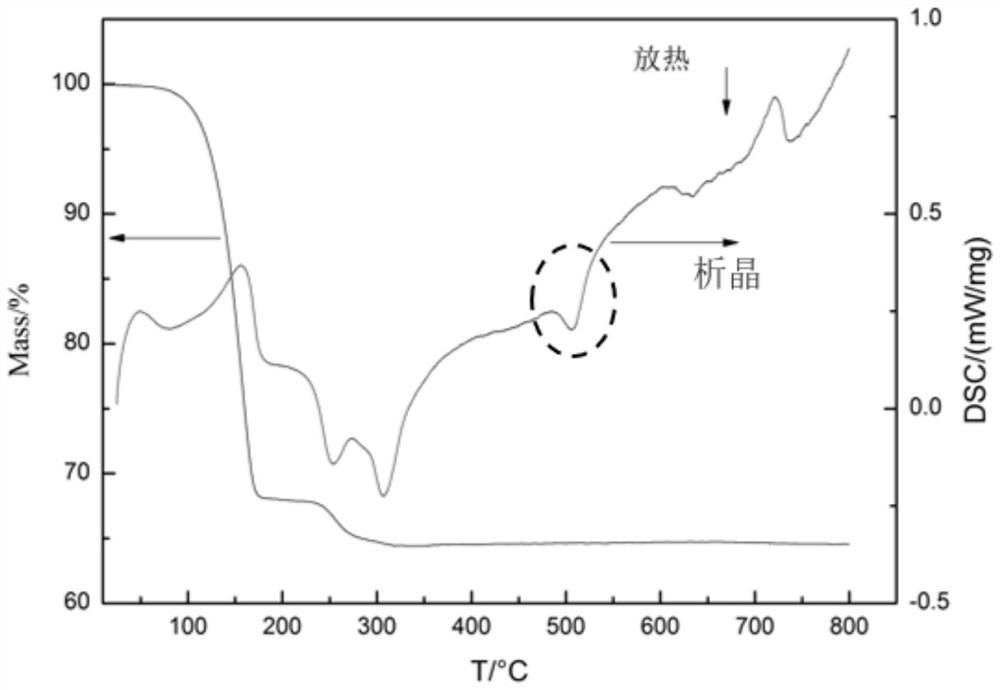

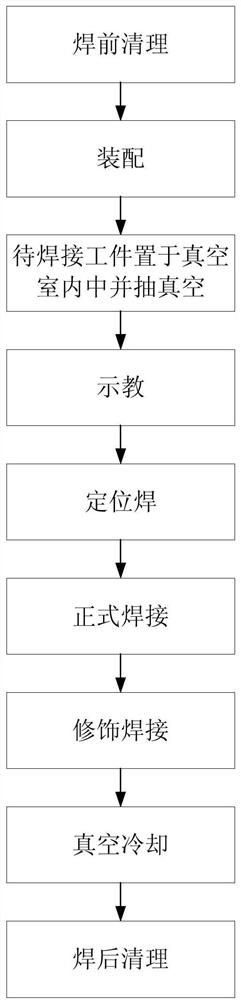

Glass connection method and device based on frit

The invention relates to a glass connection method and device based on frit, and the connection method is realized according to the following steps: step 1, coating frit on a glass substrate to obtain a frit coating; 2, the glass substrate coated with the frit coating is heated in a heating furnace, organic impurities in the frit coating are removed, and a heated glass substrate test piece is obtained; 3, covering the test piece in the step 2 with a glass cover plate, mounting the test piece in a special device placed on a workbench, lifting the glass cover plate, and carrying out laser sintering on the frit coating in the step 2; and step 4, pressing down a glass cover plate on the glass substrate test piece which is subjected to laser sintering in the step 3 and is provided with the frit coating, and connecting the glass substrate and the glass cover plate. Laser is used for carrying out sufficient sintering treatment on the frit coating, hidden defects in the coating are exposed, device scrapping caused in the laser welding process is avoided, formation of air holes in the follow-up laser welding process is effectively restrained, the process range of laser welding is widened, the quality requirement for the frit coating is lowered, and the production efficiency is improved. And the processing time is saved.

Owner:HUNAN UNIV

A kind of electron beam welding method of bti6431s high temperature titanium alloy material

ActiveCN108857034BAvoid burnsLow heat inputElectron beam welding apparatusHeat-affected zoneButt joint

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Ultrasonic-assisted electric arc welding device

PendingCN114346374AAvoid damageEnhanced interactionWelding accessoriesVoltage pulseAC - Alternating current

The ultrasonic-assisted electric arc welding device comprises a device case body, and an ultrasonic signal generator, an isolation coupling circuit and an automatic switching device are fixedly installed in the case body. Isolation protection is conducted on the ultrasonic power source and the isolation coupling device through the multiple sets of parallel alternating current contactors, the ultrasonic power source is prevented from being damaged by large currents and high-frequency high-voltage pulses in the welding process, interaction between the welding power source and the ultrasonic power source can be effectively promoted, ultrasonic signals are well coupled into welding arcs, and the welding quality is improved. And an ultrasonic arc is excited to act on the whole welding process from arc starting to arc extinguishing. A voltage detection device and a Hall current detection device are designed, the electric signal characteristics of the output end of the welding machine can be automatically recognized, and automatic coupling and cut-off control over an ultrasonic signal in the whole welding process from arc starting to arc extinguishing is achieved.

Owner:JIANGSU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com