Welding wire for die-casting aluminum alloy and preparation method of welding wire

A technology of casting aluminum alloy and welding wire, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of slag inclusion and cracks, low joint strength, poor internal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

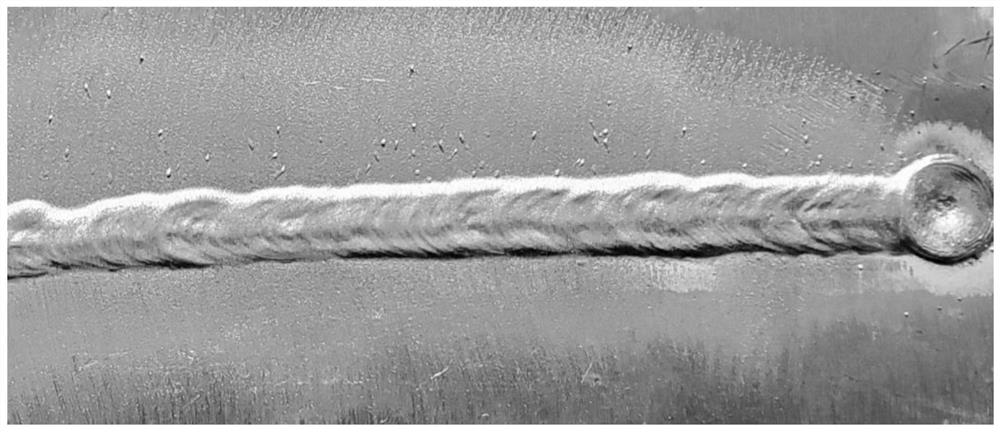

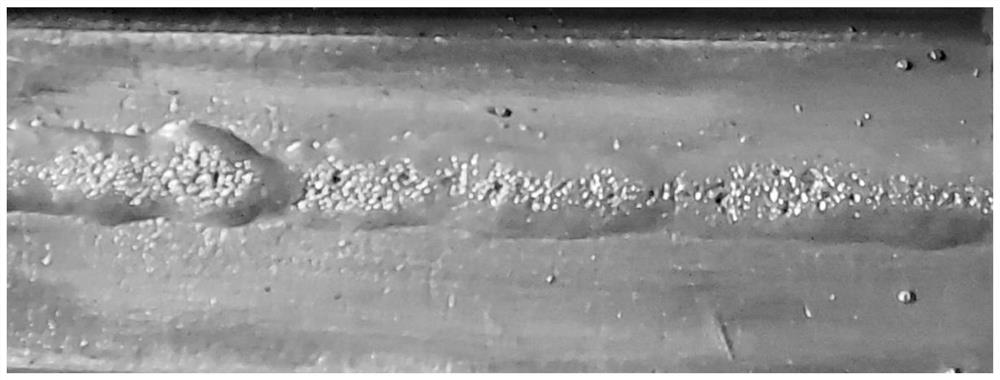

Image

Examples

Embodiment 1

[0044] A welding wire for die-casting aluminum alloy, the welding wire contains the following components and mass percentages: Si: 11.2%, Mn: 0.35%, Zr: 0.21%, Mo: 0.05%, Sr: 0.03%, Ti: 0.05%, Fe : 0.12%, Cu: 0.01%, and the balance is Al.

[0045] A method for preparing welding wire for die-casting aluminum alloys, comprising the following steps:

[0046] Step 1: Semi-continuous casting

[0047] (1) According to the formula of the designed die-casting aluminum alloy welding wire, add pure Al, Al-5Si master alloy, Al-5Zr master alloy, Al-5Ti master alloy, Al-5Mn master alloy in turn, at a temperature of 740 ℃ Melt down for 5 hours to obtain molten aluminum alloy. Smelting, refining and vacuum degassing treatment to obtain partially smelted molten metal; wherein, the time of vacuum treatment is 10min;

[0048] To the partially smelted molten metal after vacuum treatment, add the remaining raw materials in sequence for smelting for 1 hour to obtain a completely smelted molten ...

Embodiment 2

[0065] A welding wire for die-casting aluminum alloy, the welding wire contains the following components and their mass percentages: Si: 11.5%, Mn: 0.4%, Zr: 0.2%, Mo: 0.1%, Sr: 0.05%, Ti: 0.1%, Fe : 0.11%, Cu: 0.02%, and the balance is Al.

[0066] A method for preparing welding wire for die-casting aluminum alloys, comprising the following steps:

[0067] Step 1: Semi-continuous casting

[0068] (1) According to the formula of the designed die-casting aluminum alloy welding wire, add pure Al, Al-5Si master alloy, Al-5Zr master alloy, Al-5Ti master alloy, Al-5Mn master alloy in turn, at a temperature of 740 ℃ Melt down for 5.5 hours to obtain molten aluminum alloy. Smelting, refining and vacuum degassing treatment to obtain partially smelted molten metal; wherein, the time of vacuum treatment is 15min;

[0069] To the partially smelted molten metal after vacuum treatment, add the remaining raw materials in sequence for smelting for 1 hour to obtain a completely smelted mol...

Embodiment 3

[0087] A welding wire for die-casting aluminum alloy, the welding wire contains the following components and mass percentages: Si: 12.5%, Mn: 0.5%, Zr: 0.3%, Mo: 0.1%, Sr: 0.02%, Ti: 0.15%, Fe : 0.15%, Cu: 0.02%, and the balance is Al and unavoidable impurities. The maximum value of a single impurity element is ≤0.05%, and the total is ≤0.15%.

[0088] A method for preparing welding wire for die-casting aluminum alloys, comprising the following steps:

[0089] Step 1: Semi-continuous casting

[0090] (1) According to the formula of the designed die-casting aluminum alloy welding wire, add pure Al, Al-5Si master alloy, Al-5Zr master alloy, Al-5Ti master alloy, Al-5Mn master alloy in turn, at a temperature of 740 ℃ smelting for 3 hours, refining and vacuum degassing treatment for 10 minutes, to obtain partially smelted molten metal;

[0091] Add the remaining raw materials in sequence to the partially smelted molten metal after vacuum treatment, and carry out smelting to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com