Patents

Literature

31results about How to "Increase Si content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

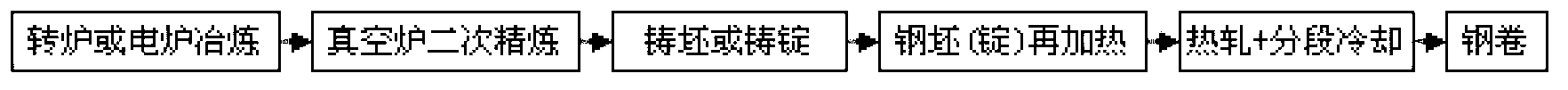

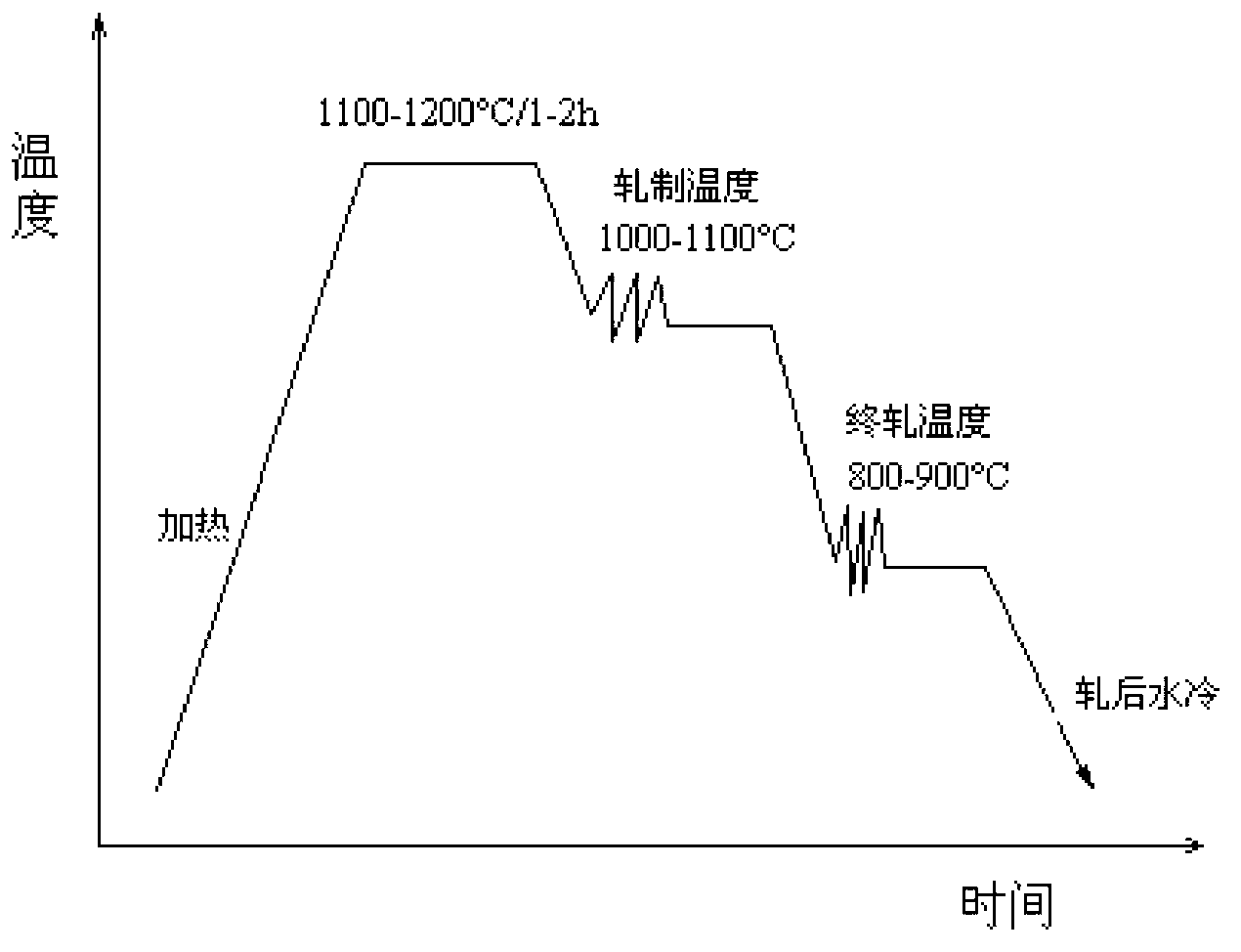

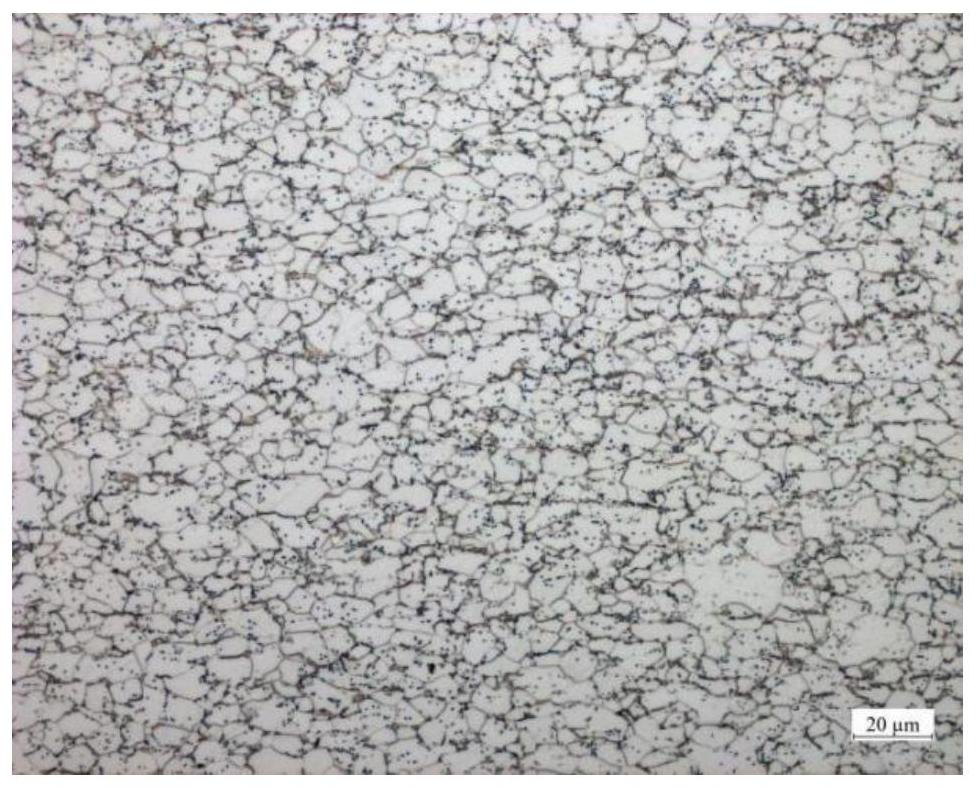

700MPa high strength hot rolling Q&P steel and manufacturing method thereof

ActiveCN103215516AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesAustenite grainChemical composition

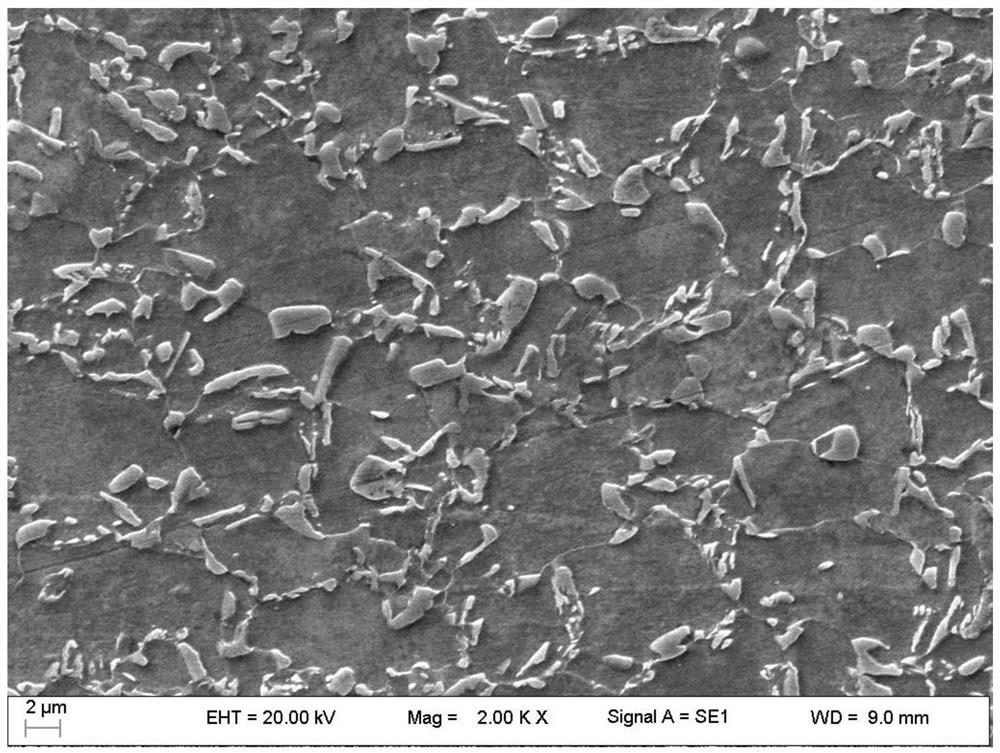

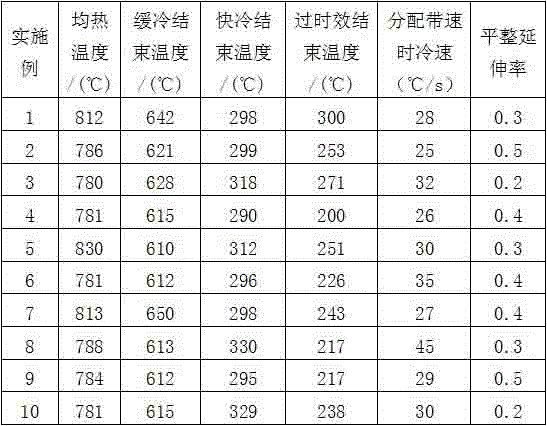

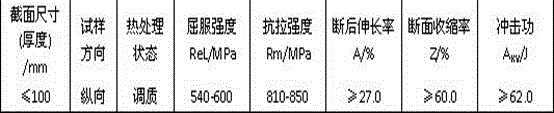

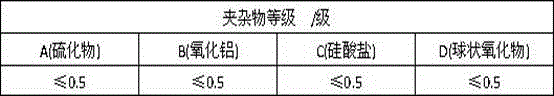

The invention relates to 700MPa high strength hot rolling Q&P steel and a manufacturing method thereof. The steel has the following chemical components in percentage by weight: 0.15-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.3-1.0% of Al, less than or equal to 0.0065% of N, 0.005-0.015% of Ti and the balance of Fe. The yield strength is greater than or equal to 70MPa, the strength of extension is greater than or equal to 1300MPa, and the ductility is greater than 10%. According to the invention, through a reasonable compound design, based on common C-Mn steel components, austenite crystal is refined by micro Ti treatment by improving the content of Si to inhibit separation of cementite, so that the austenite transformation kinetics in the air cooling process is accelerated by improving the content of Al. Meanwhile, a hot continuous rolling process is matched with a sectional cooling process, so that proeutectoid ferrite+martensite+retained austenite tissues are obtained. The cost of the alloy is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi

ActiveCN102943209AImprove radiation resistanceExcellent high temperature mechanical propertiesTemperature resistanceCorrosion

The invention belongs to the technical field of heat-resistant alloy, and specifically relates to radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi. The steel comprises the components in weight percentage: 0.05-0.2% of C, 9.0-12.0% of Cr, 1.0-3.0% of Si, 0.3-3.0% of Mn, 1.0-3.0% of W, 0.1-0.4% of V, 0.03-0.3% of Ta, 0.03-0.15% of N, less than or equal to 0.05% of Al, less than or equal to 0.05% of Ti and the balance of Fe. According to the invention, the content of Si is increased; part of C element is replaced by N; the precipitation of Cr23C6 is reduced so as to ensure the Cr content in matrix, so that a rich Si compact oxide film is formed on the surface when the material serves in the Pb and Pb-Bi under high temperature, and a structure is protected to be free of lead corrosion; activating elements Mo, Ni and Nb are replaced by W, Mn and Ta, so that the low activation is ensured, and the irradiation resistance performance is improved; the types and appearance of the precipitated phase can be controlled according to a reasonable proportion between the C+N content and V+Ta content, so as to ensure the high-temperature performance in the serving process; and the novel martensite heat-resistant steel which serves under a strong radiation condition and has high-temperature resistance, lead corrosion resistance and irradiation resistance can be obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Strip-casting 550-MPa-level weathering resistant steel and production method thereof

PendingCN109881084AReduce C contentGuaranteed bending performanceMetal rolling arrangementsSuperheatingImpurity

The invention discloses strip-casting 550-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.05-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted by a pair of coppercasting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lower than 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 450-600 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 550-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

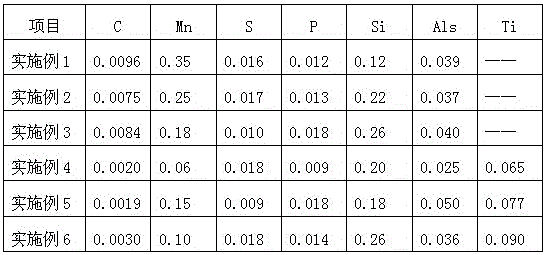

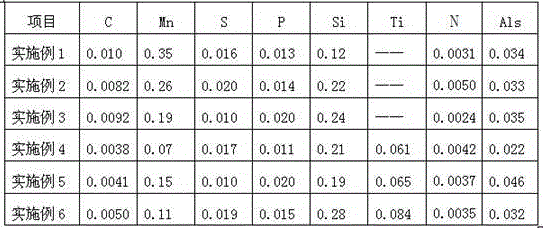

Method for producing ultra-low carbon steel on basis of flexible thin slab casting (FTSC)

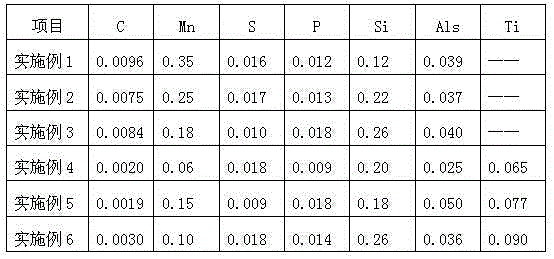

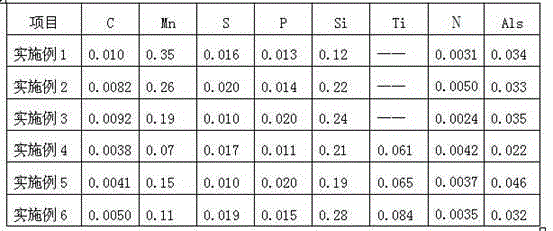

The invention discloses a method for producing ultra-low carbon steel on the basis of flexible thin slab casting (FTSC). The method includes the following steps of (1) molten iron desulfurization, (2) smelting with a converter, (3) Ruhstahl Hausen (RH) vacuum treatment and (4) FTSC. The ultra-low carbon steel comprises, by mass, 0-0.010% of C, 0.06%-0.35% of Mn, 0.12%-0.28% of Si, 0-0.020% of P, 0-0.020% of S, 0-0.09% of Ti, 0-0.0050% of N, and the balance iron and inevitable impurities. According to the method, the ultra-low carbon steel is produced through FTSC, the components, suitable for FTSC production, of the ultra-low carbon steel are redesigned, and ultra-low carbon steel continuous casting slabs meeting the performance requirement are produced by strictly controlling process parameters of all procedures of steel making.

Owner:HEBEI IRON AND STEEL

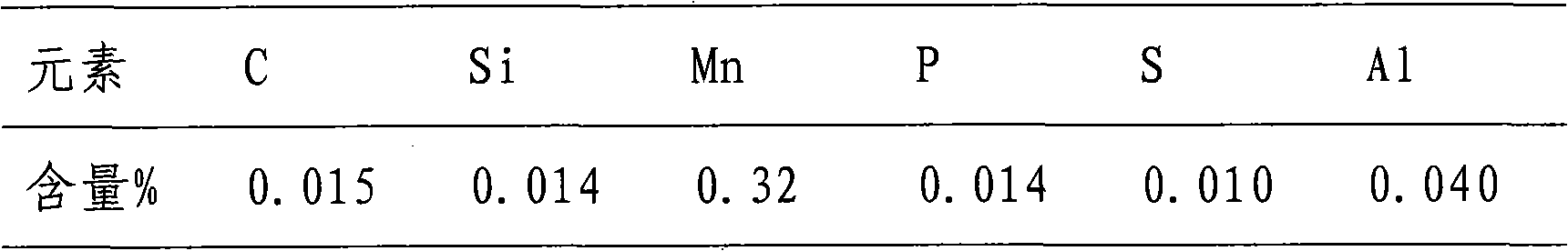

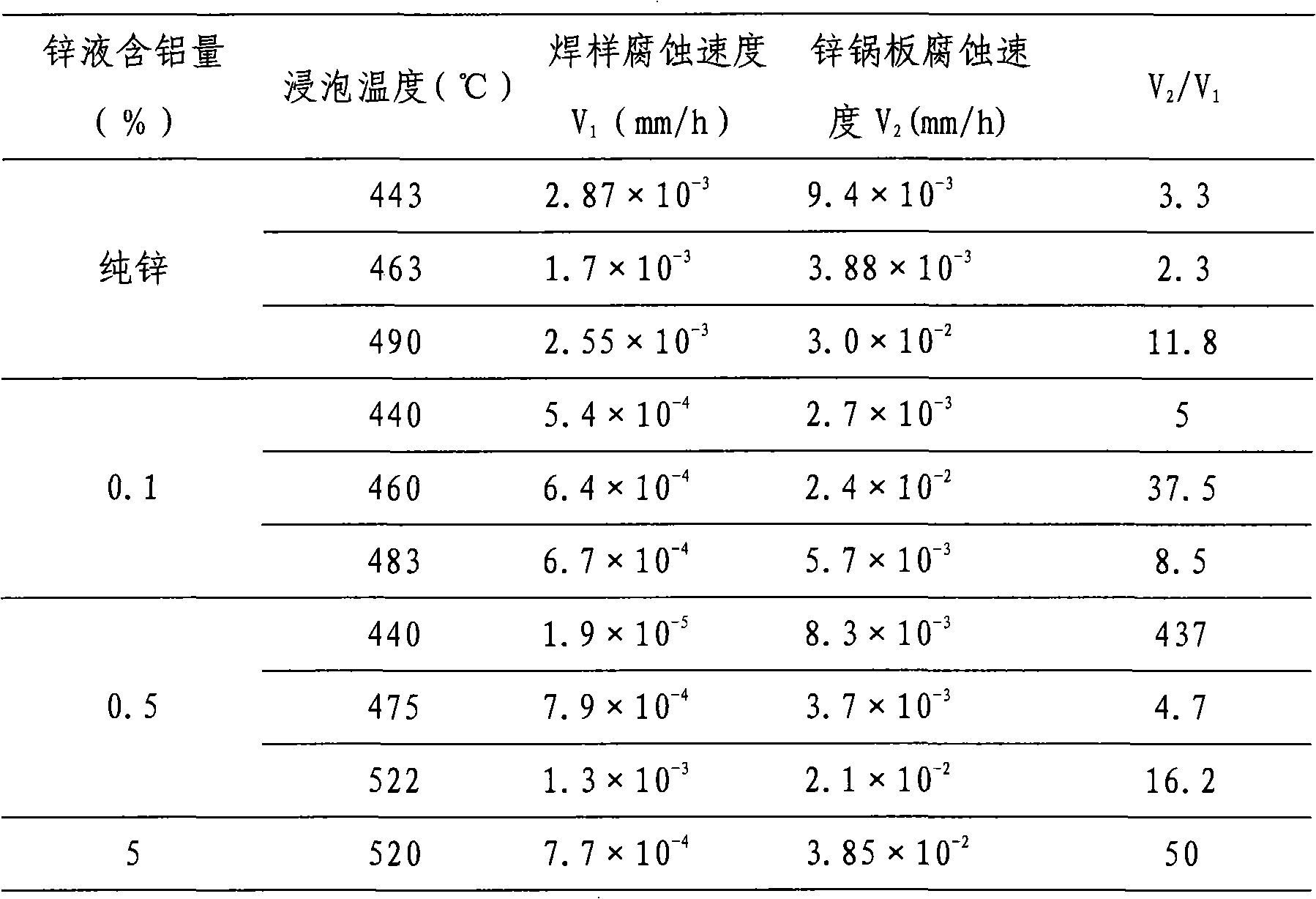

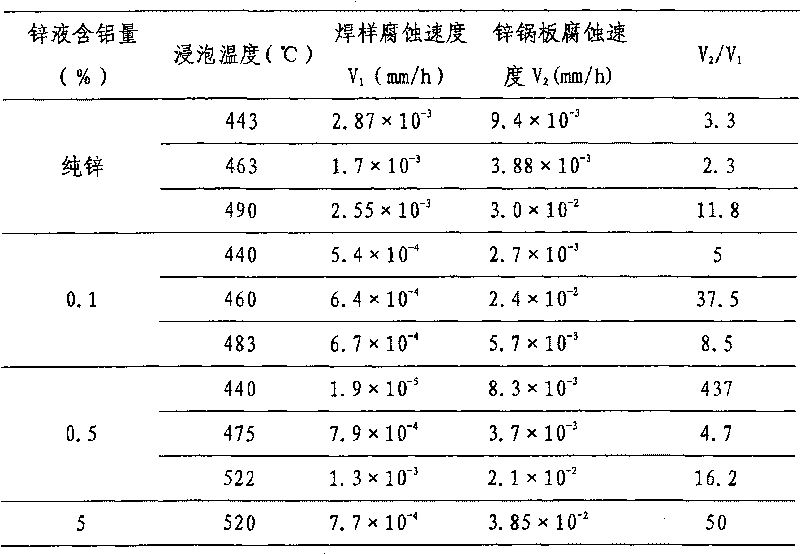

Improved welding material with tolerance of liquid zinc and aluminiferous zinc-base alloy

InactiveCN101301708AIncrease Si contentHigh hardnessWelding/cutting media/materialsSoldering mediaSurface electrodeFerrosilicon

The invention relates to a welding material, in particular to an improved welding material which improves surfacing electrodes or flux-cored wires and resists the corrosion of liquid zinc and aluminium-zinc-based alloy. According to the portions by weight, the electrode coating or flux-cored wire of the welding material comprises the components as follows: 0.1-8 portions of graphite, 1-8 portions of rutile, 8-25 portions of marble, 9-30 portions of fluorite, 5-16 portions of feldspar, 1-5 portions of mica, 0.1-25 portions of chrome powders, 10-40 portions of ferrosilicon, 10-15 portions of ferromanganese, 10-20 portions of molybdenum powder, 0.1-15 portions of aluminium powder, 0.1-25 portions of nickel powder, 1-10 portions of titanium dioxide, 5-20 portions of ferrotitanium, 0.1-5 portions of rare earth, 0.1-15 portions of ferrotungsten, and 1-10 portions of ferroboron. By adopting the proposal of the invention, the usage temperature of the welding material is ranged from 480 to 550 DEG C; furthermore, the welding material of the invention effectively improves the anti-corrosion of zinc and the improved anti-corrosion of liquid zinc and aluminium-zinc-based alloy.

Owner:陈冬

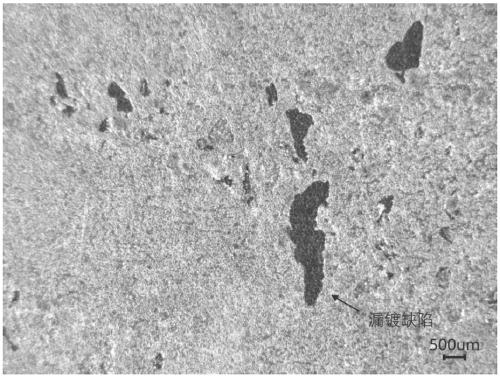

Coated steel sheet with thin aluminum alloy coating and coating method thereof

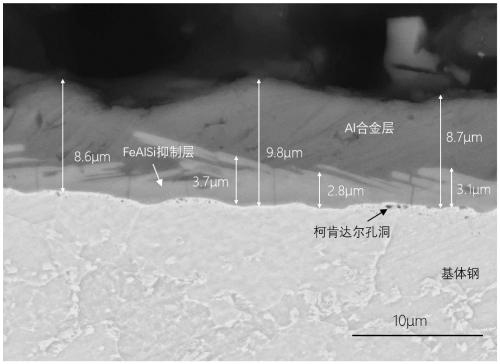

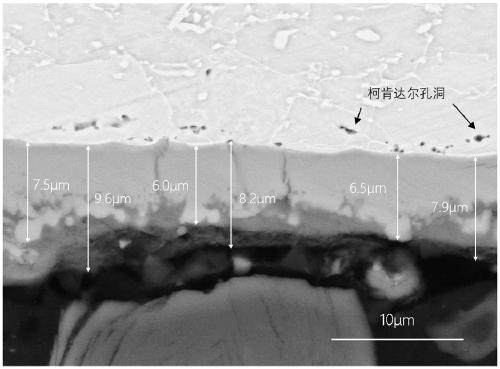

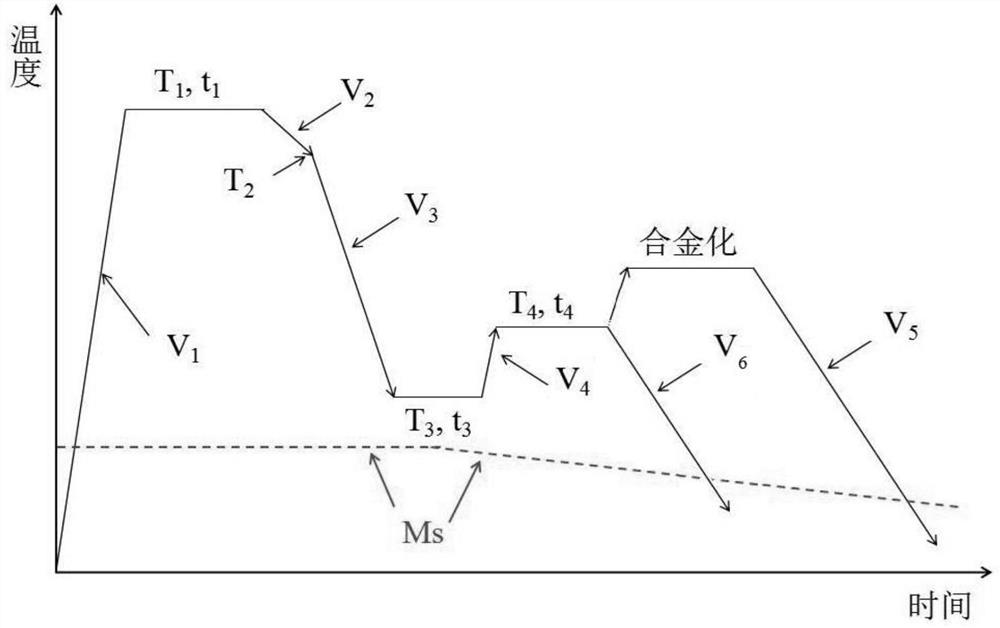

ActiveCN111394679AReduce the temperatureIncrease Si contentHot-dipping/immersion processesFurnace typesHot stampingAlloy coating

The invention relates to a coated steel sheet with thin aluminum alloy coating and a coating method thereof. The coated steel sheet provided by the invention is used for hot stamping forming, coatingthickness of the coated steel sheet is 5-14 microns, wherein the aluminum alloy coating comprises a FeAlSi inhibiting layer close to a matrix steel sheet and an Al alloy layer at outside thereof, thickness of the FeAlSi inhibiting layer is not greater than 60% of thickness of the coating and is 1.5-6.0 microns, diameter of Kirkendall holes from an interface of the FeAlSi inhibiting layer and the matrix steel to less than 2 microns in the matrix steel is less than 2.5 microns, wherein the number of the Kirkendall holes with the diameter of more than 0.5 microns and less than 2.5 microns is notmore than 15 / 35 microns. The invention also discloses a coating method of applying the thin aluminum alloy coating on the matrix steel sheet for hot stamping forming, and the method can eliminate omission of coating and make a hot stamping forming member obtained from the coated steel sheet have excellent resistance spot welding performance.

Owner:IRONOVATION MATERIALS TECH CO LTD

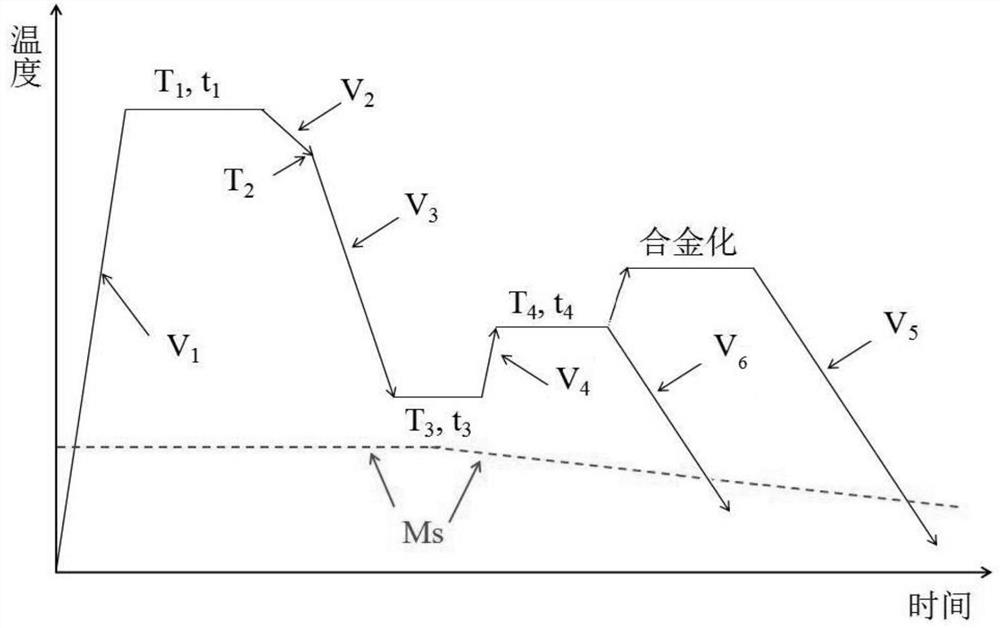

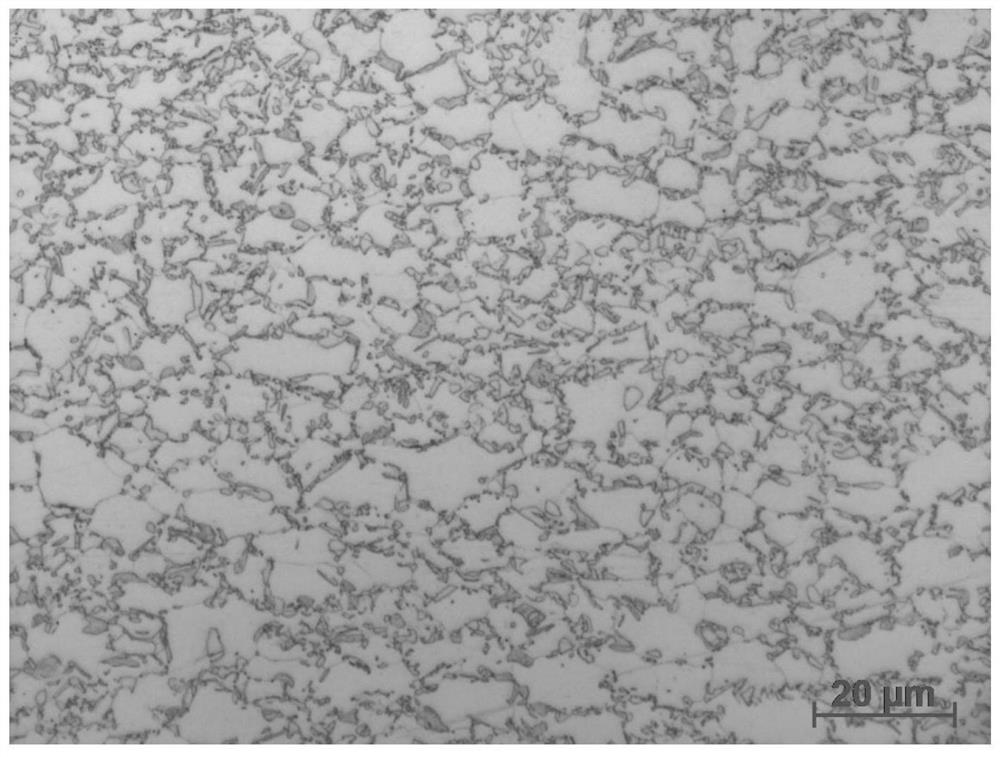

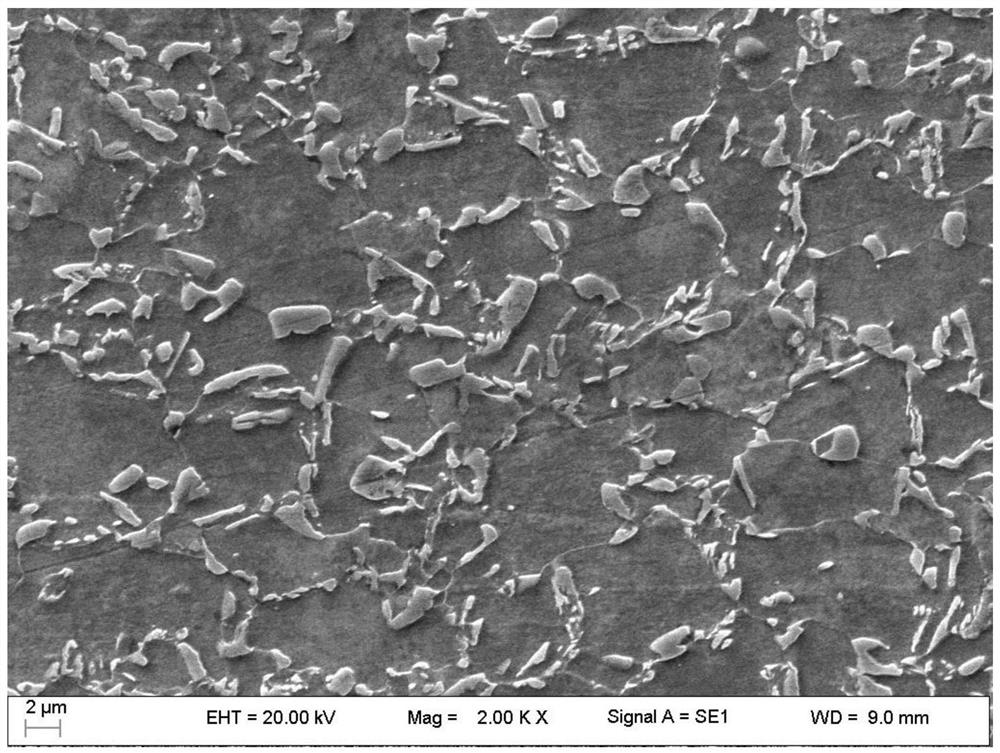

Cold-rolled hot-dip galvanized steel and manufacturing method thereof

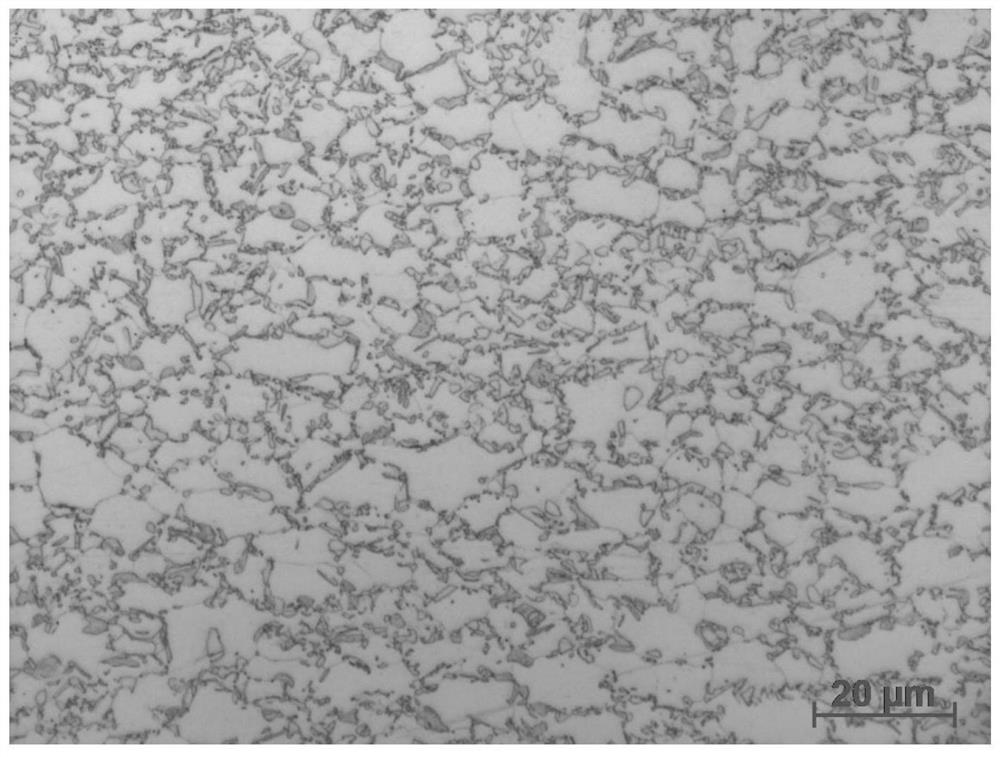

ActiveCN112301293AGood formabilityHigh elongationHot-dipping/immersion processesThermal insulationHeat conservation

The invention discloses cold-rolled hot-dip galvanized steel. The cold-rolled hot-dip galvanized steel comprises the following chemical elements of, in percentage ration by mass, 0.06%-0.14% of C, 1.3%-2.4% of Mn, 0.1%-1.0% of Si, and the balance Fe and inevitable impurities; and the microstructure of the cold-rolled hot-dip galvanized steel is ferrite + martensite + bainite + retained austenite.In addition, the invention further discloses a manufacturing method of the above cold-rolled hot-dip galvanized steel. The manufacturing method comprises the steps that (1) smelting and casting are carried out; (2) hot rolling is carried out; (3) acid pickling is carried out; (4) cold rolling is carried out; (5) hot galvanizing recrystallization annealing is carried out, specifically, a cold-rolled sheet is heated to the soaking temperature T1 for thermal insulation for a period of time; and then the soaked steel plate is cooled to the intermediate temperature T2 at the first cooling speed andthen cooled to T3 at the second cooling speed, thermal insulation is carried out for a period of time, then the temperature is increased to the zinc pool temperature T4 for thermal insulation for a period of time, wherein the cooling speed is less than the second cooling speed, T2 is larger than or equal to 640 DEG C and less than or equal to T1, and T3 is larger than Ms and less than or equal toT4; and (6) cooling is carried out to the room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

800mpa grade cold-rolled dual-phase steel and production method thereof

The invention discloses 800 MPa grade cold-rolled double-phase steel and a production method thereof. The production method comprises a hot rolling process and a cold rolling continuous annealing process. The chemical compositions of a casting entering the hot rolling process comprise, in percent by mass, 0.14-0.17% of C, 0.45-0.55 of Si, 1.6-1.8 of Mn, 0.55-0.65% of Cr, P<=0.016%, S<=0.008%, 0.02-0.05% of Als, N<=0.004%, and the balance Fe. In the double-phase steel, the Si content is increased and the Mn content is reduced on the basis of the compositions of C-Si-Mn-Cr, so that the strength is increased without adding Al, Nb, Mo, Ti and other high-cost elements, and the purposes of reducing production difficulty and production cost while not influencing smelting castability are realized. The method improves the Si content, reduces the Mn content, improves the composition system of the C-Si-Mn-Cr system and realizes the purpose of reducing production cost. By improving the smelting, hot rolling and cold-rolling continuous annealing technologies, the cold-rolled double-phase steel with the tensile strength of 800-850 MPa, the yield strength of 450-550 MPa and the elongation percentage of 15-17% is produced, and the production method has the characteristics of simple technology, low cost and stable product quality.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Molten forging steel for manufacturing crane wheels and smelting method thereof

ActiveCN105543652AHigh toughness wear and corrosion resistanceGood wear and corrosion resistanceCorrosionLadle furnace

The invention discloses molten forging steel for manufacturing crane wheels and a smelting method thereof. The molten forging steel for manufacturing the crane wheels has the following chemical components in percentage by weight: 0.32-0.38 wt% of C, 1.10-1.30 wt% of Si, 1.10-1.25 wt% of Mn, 0.20-0.30 wt% of Cr, 0.015-0.030 wt% of Ti, S not more than 0.004 wt%, P not more than 0.012 wt%, O not more than 0.0010 wt%, H not more than 0.00015 wt%, and the balance of Fe and inevitable impurities. The preparation method comprises such process steps as KR method molten iron pretreatment deep desulfurization, converter smelting, LF steel ladle furnace refining and VD furnace vacuum refining. The molten steel, provided by the invention, is high in cleanness and low in inclusion content; and the forging steel for manufacturing the crane wheels is high in strength and toughness and excellent in wear and corrosion resistance, prominently improves the impact toughness and the fatigue resistance of the crane wheels in the use process, and prolongs the service life of the crane wheels.

Owner:WUKUN STEEL

450 MPa-grade hot-dip galvanized dual-phase steel and production method thereof

ActiveCN113584395ARemarkable effect of fine grain strengtheningStable mechanical propertiesHot-dipping/immersion processesSteel platesDual-phase steel

The invention discloses 450 MPa-grade hot-dip galvanized dual-phase steel and a production method thereof, and belongs to the technical field of cold-rolled strip production. The dual-phase steel comprises the following chemical components in percentage by mass: 0.03%-0.10% of C, 0.20%-0.60% of Si, 1.20%-2.00% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015%-0.070% of Als, less than or equal to 0.0060% of N and the balance of Fe and inevitable impurities. The microstructure of the dual-phase steel comprises the following components in percentage by volume: 90%-96% of ferrite and 4%-10% of martensite. The preparation method comprises the steps of smelting, hot rolling, acid rolling and hot galvanizing. According to the production method of the dual-phase steel, the sparse cooling mode is adopted, and stable control over the structure performance is facilitated; the opening and closing mode of cooling water between descaling and the rack is defined, and good surface quality can be obtained; and through cooperation of smelting and hot galvanizing processes, the good mechanical properties and surface quality of the 450 MPa-grade hot-dip galvanized dual-phase steel plate are achieved, and the good market competitiveness is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

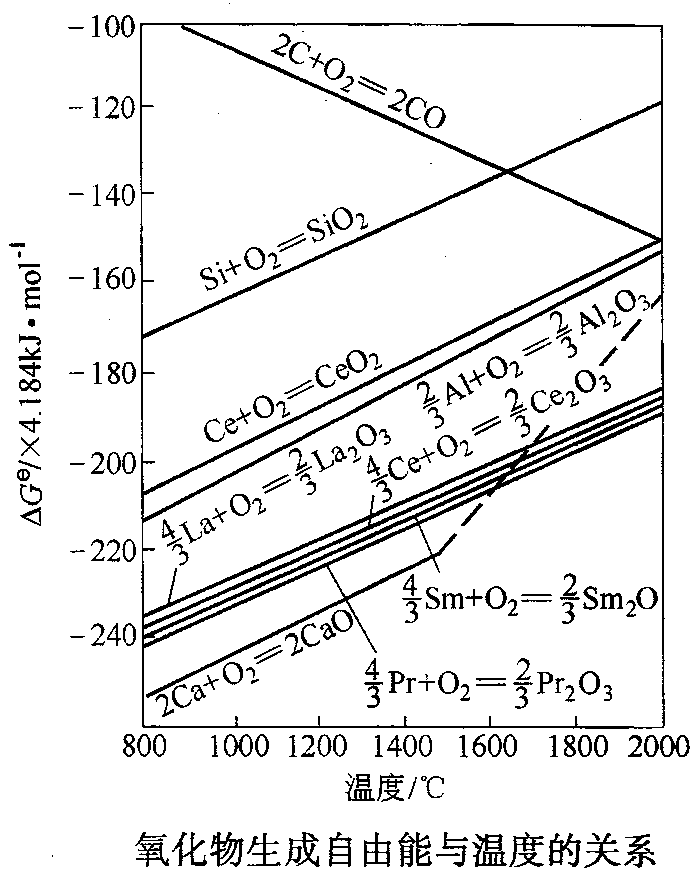

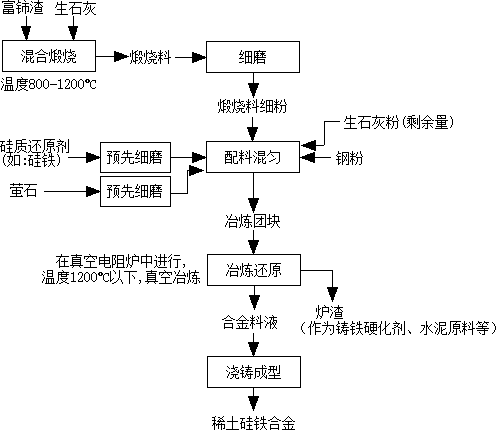

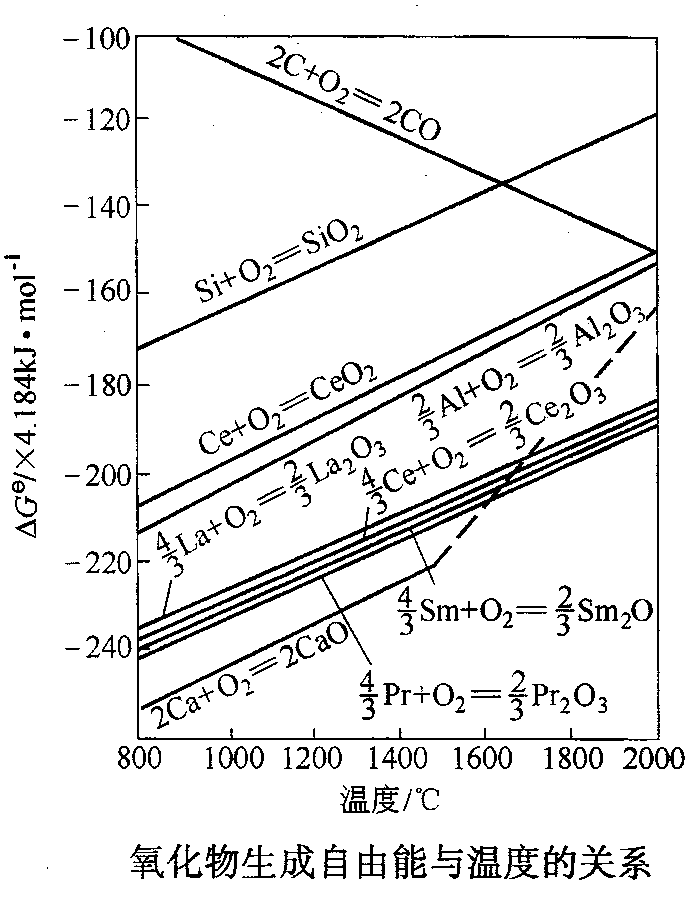

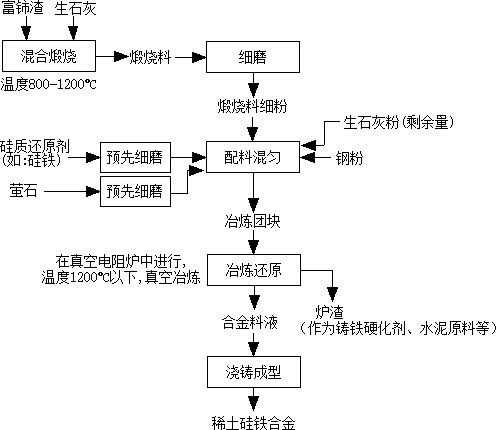

Method for producing rare earth ferrosilicon alloy

ActiveCN108456773AIncrease Si contentImprove conversion utilizationProcess efficiency improvementSmelting processCerium

The invention discloses a method for producing rare earth ferrosilicon alloy. The technical purpose is to provide a method which can increase the yield of rare earth in the alloy, increase the conversion and utilization rate of silicon in a silicon reducing agent, increase the content of Si in the alloy by reducing burning loss of silicon, lower the power consumption for reduction, and reduce thetechnological slag yield based on cerium-enriched slag raw materials aiming at the many insufficiencies of an existing silicothermic method of producing the rare earth ferrosilicon alloy. According tothe method, based on the cerium-enriched slag raw materials, the rare earth ferrosilicon alloy is produced, in the process of smelting the alloy under the temperature of 1,200 DEG C or below, the method can be smoothly implemented, the yield of the rare earth in the process of producing the rare earth ferrosilicon alloy by using the silicothermic process is greatly increased, and the technical purposes of increasing the conversion and utilization rate of the silicon element, and increasing the content of Si in the alloy by reducing the burning loss of silicon are achieved. In the meanwhile, the technology requirement for the smelting reduction temperature is lowered, the production period of the smelting processes is obviously shortened, and therefore, power consumption in the smelting process is obviously lowered.

Owner:包头市华商稀土合金有限公司 +1

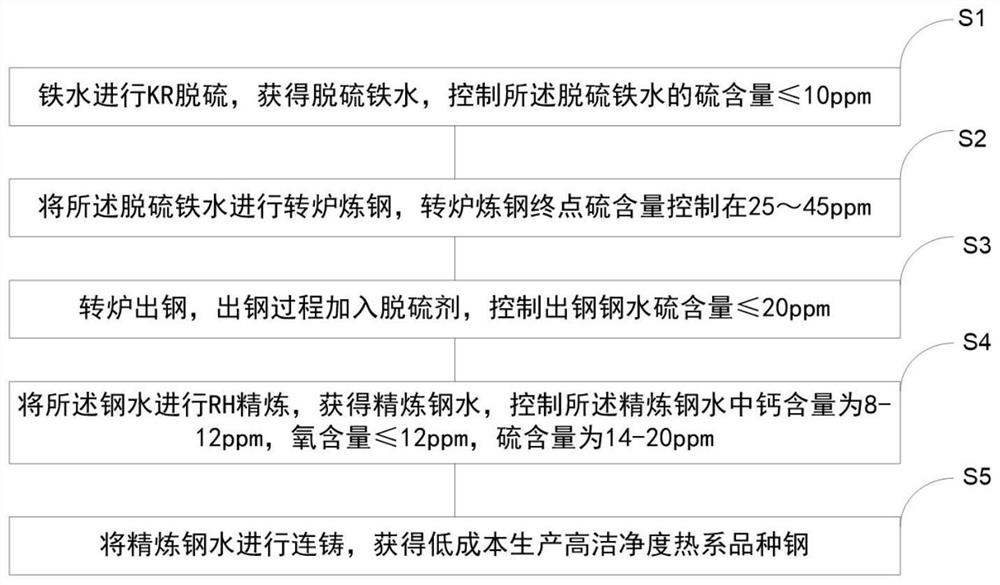

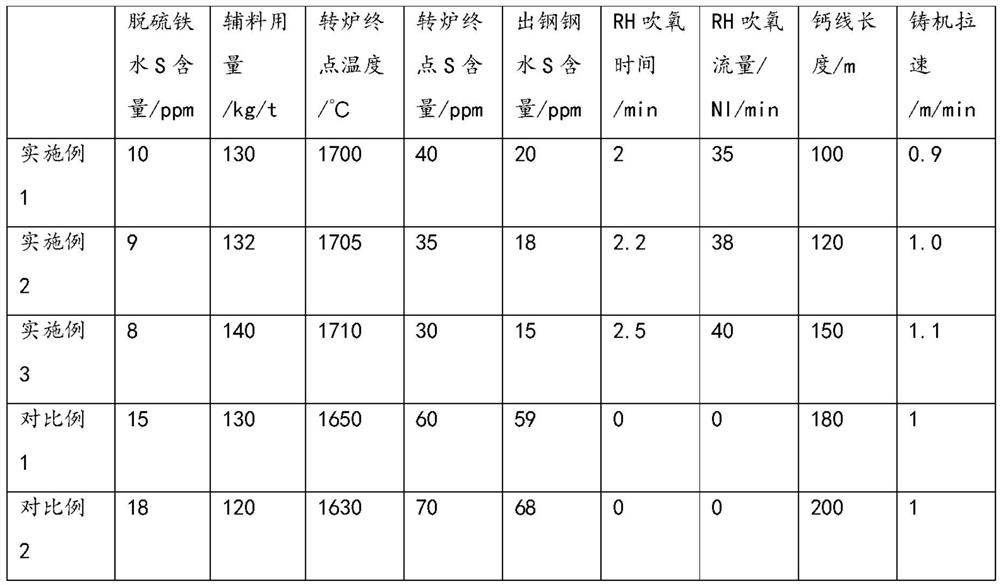

Method for producing high-cleanliness hot-series variety steel at low cost

ActiveCN113293253AAvoid uncontrollableControl contentManufacturing convertersProcess efficiency improvementSteelmakingMetallurgy

The invention provides a method for producing high-cleanliness hot-series variety steel at low cost, and belongs to the technical field of steelmaking processes. The method comprises the steps that KR desulfurization is carried out on molten iron to acquire desulfurized molten iron, and the sulfur content of the desulfurized molten iron is controlled to be less than or equal to 10 ppm; the desulfurized molten iron is subjected to converter steelmaking, and the sulfur content at the converter steelmaking end point is controlled to be 25-45 ppm; converter tapping is carried out, a desulfurizing agent is added in the tapping process, and the sulfur content of tapping molten steel is controlled to be less than or equal to 20 ppm; the molten steel is subjected to RH refining to acquire refined molten steel, the calcium content in the refined molten steel is controlled to be 8-12 ppm, the oxygen content is controlled to be less than or equal to 12 ppm, and the sulfur content is controlled to be 14-20 ppm; and the refined molten steel is subjected to continuous casting to acquire the high-cleanliness hot-series variety steel produced at low cost. The method can reduce the production cost of the clean steel, and effectively control the content of sulfur and inclusions in the clean steel.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

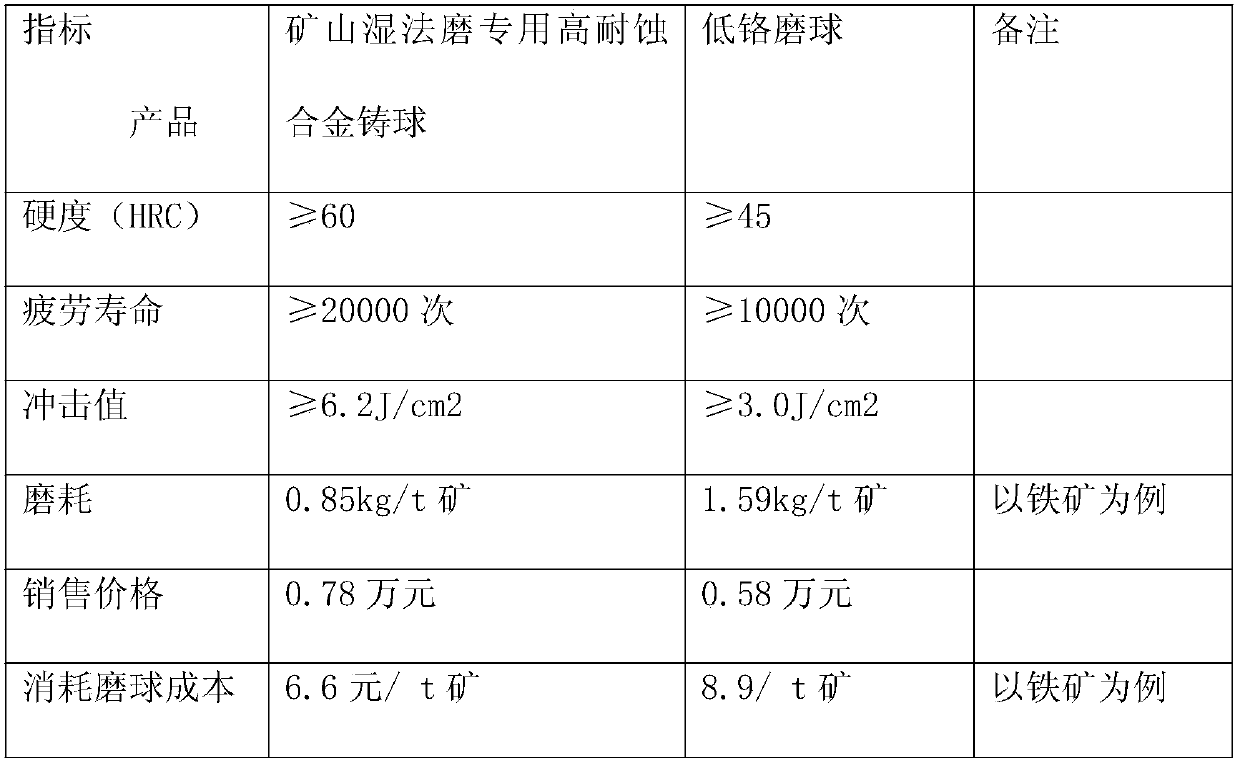

Special highly-anticorrosive alloy cast ball for wet grinding of mine, and production method thereof

InactiveCN107747029AImprove wear resistanceImprove mechanical propertiesFurnace typesHeat treatment furnacesHardnessAlloy

The invention discloses a special highly-anticorrosive alloy cast ball for wet grinding of mine, and a production method thereof. The special highly-anticorrosive alloy cast ball comprises, by weight,2.2-2.5% of C, 1.2-1.4% of Si, 1.0-1.5% of Mn, 10-12% of Cr, 0.006-0.008% of Mo, 0.02-0.025% of Cu, 0.05% or less of P, 0.05% or less of S, and the balance of Fe. The product produced through component optimization design and treatment using a special modifier and a comprehensive modification technology has the advantages of balanced internal and external hardness, no shrinkage cavity or shrinkage porosity on the surface, high hardness, low abrasion, high anticorrosive performance and high wear resistance, meets the use requirements of large mine mills, and is suitable for being used under various conditions; and the abrasion of the product is 50% less than that of low-chromium grinding balls, and the consumption cost is 25% less than that of the grinding balls, so the energy saving effect is obvious.

Owner:安徽中建材开源新材料科技有限公司

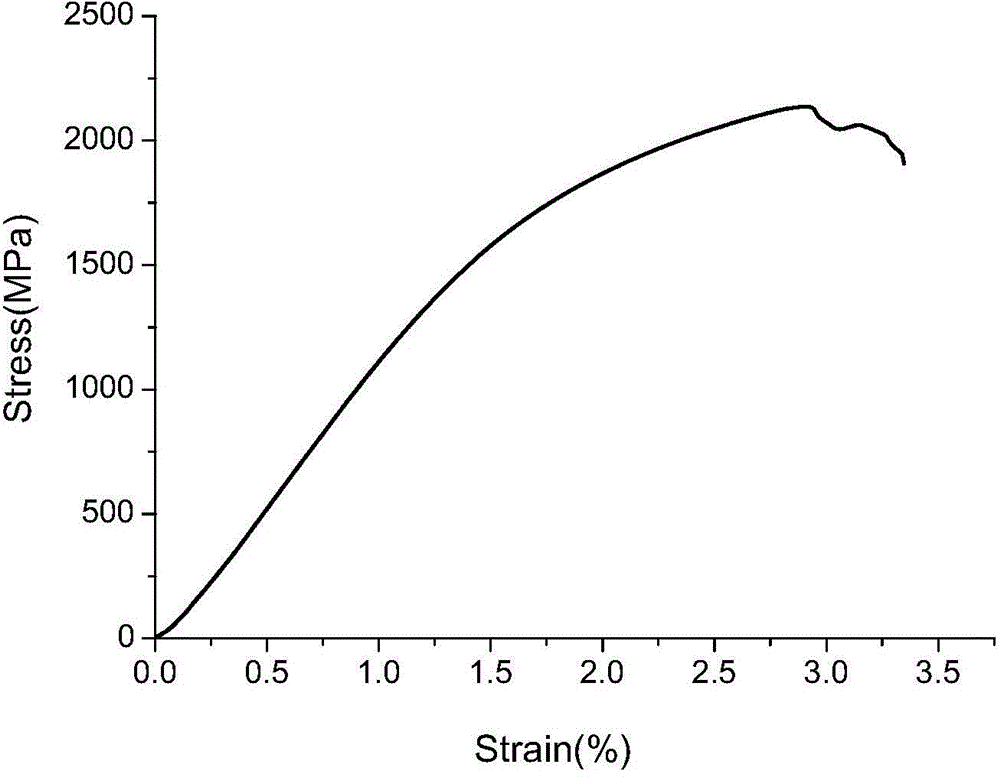

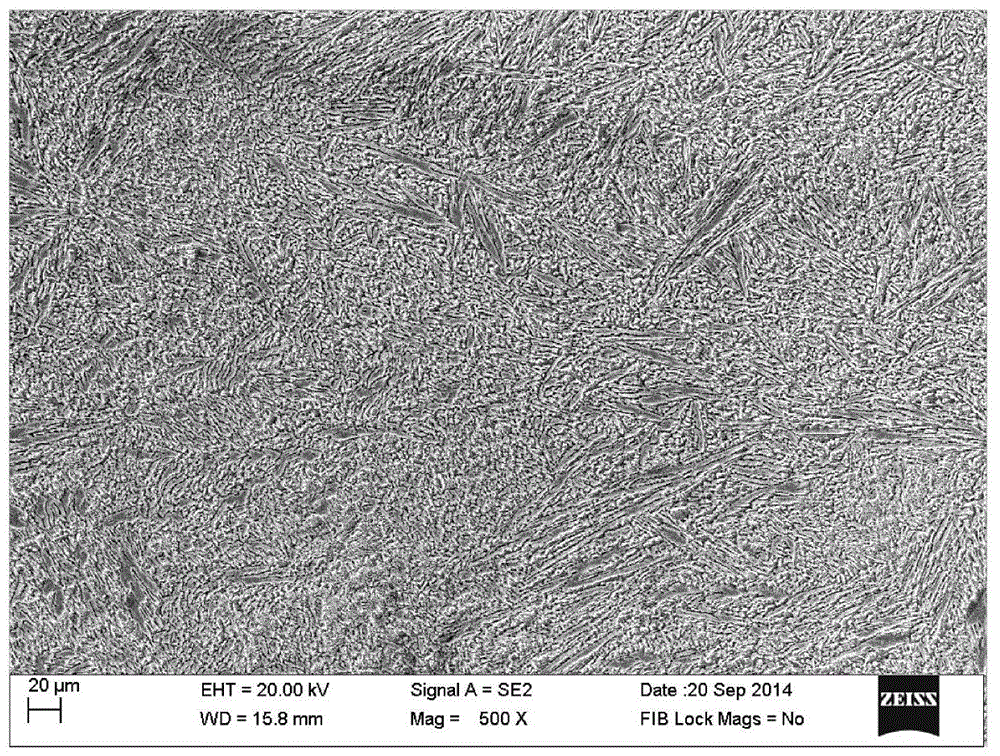

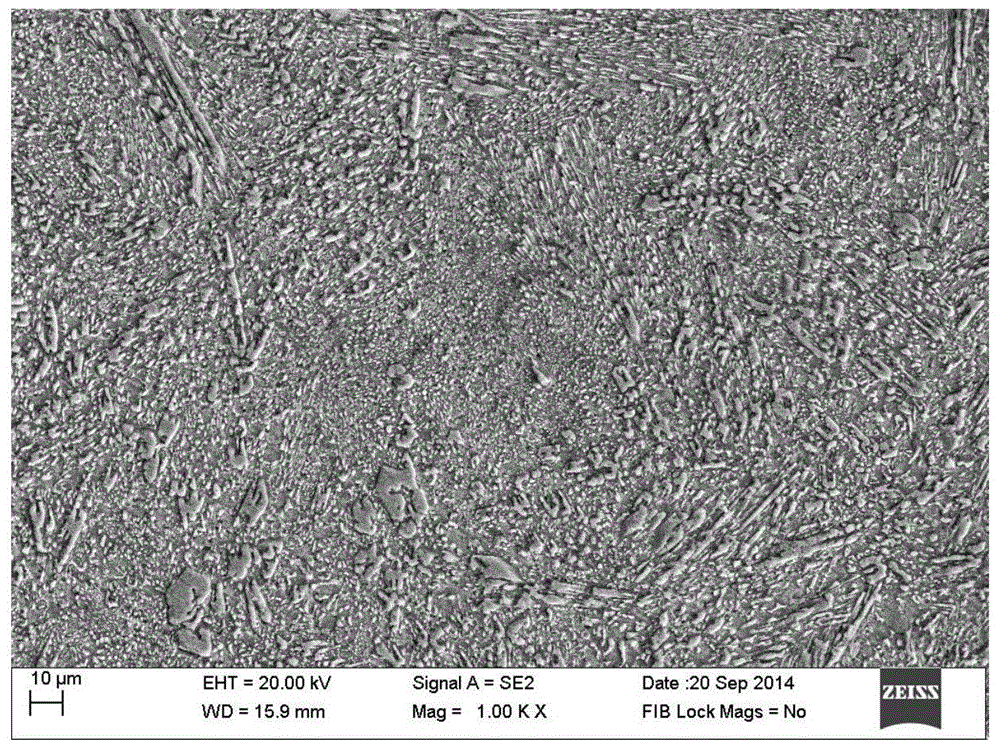

Cast Ti-Si eutectic alloy containing intermetallic compound reinforcement phase

The invention discloses a cast Ti-Si eutectic alloy containing an intermetallic compound reinforcement phase, belonging to the field of a metal material. The cast Ti-Si eutectic alloy comprises the following components in percentage by weight: 8.51-11.5% of Si, 3-9% of Al, 0.5-5% of V, 0.01-0.25% of B, 0.3-10% of stable beta-phase additional elements Mo, Nb and Ta, and the balance of Ti and inevitable impurities. Ti-Si-Al-V-B is taken as basic alloy system and the performance optimization is realized by adding Mo, Nb and Ta and other elements. The alloy has superhigh strength, good high-temperature anti-oxidization and high-temperature wear resistance properties by utilizing high Si content and through optimized cooperation between Si and elements Al, V, Mo, Nb, Ta and B. The maximum compression strength of the Ti-Si alloy is more than 2100MPa, and the hardness is 50HRC. The alloy is suitable for manufacturing parts requiring high temperature, wear resistance, corrosion resistance in the fields of aerospace, automobile, ships and warships, and the like.

Owner:UNIV OF SCI & TECH BEIJING +2

Welding wire for die-casting aluminum alloy and preparation method of welding wire

ActiveCN113385854AUniform tissueStable weldabilityFurnace typesWelding/cutting media/materialsSlag (welding)Wire rod

The invention discloses a welding wire for die-casting aluminum alloy and a preparation method thereof, and belongs to the field of manufacturing of aluminum alloy welding wires. The welding wire for the die-casting aluminum alloy comprises, by mass, 10%-13% of Si, 0.3%-0.5% of Mn, 0.2%-0.3% of Zr, smaller than or equal to 0.2% of Mo, 0.02%-0.05% of Sr, 0.05%-0.15% of Ti, smaller than or equal to 0.15% of Fe and the balance is Al and inevitable impurities, the mass percentage of a single impurity is smaller than or equal to 0.05%, and the total mass percentage of the inevitable impurities is smaller than or equal to 0.15%. The preparation method comprises the steps of semi-continuous casting, machining, preheating, extruding, annealing, wire stretching and welding wire drawing. The welding wire solves the problems that the internal structure is poor, the joint strength is low, air holes, slag inclusion, cracks and the like are prone to occurring in the welding process when a current commercially available welding wire is adopted for welding die-casting aluminum alloy.

Owner:沈阳育成鑫成果转化技术服务有限公司

Three-dimensional graphene-POSS nanocomposite modified polyimide and preparation method thereof

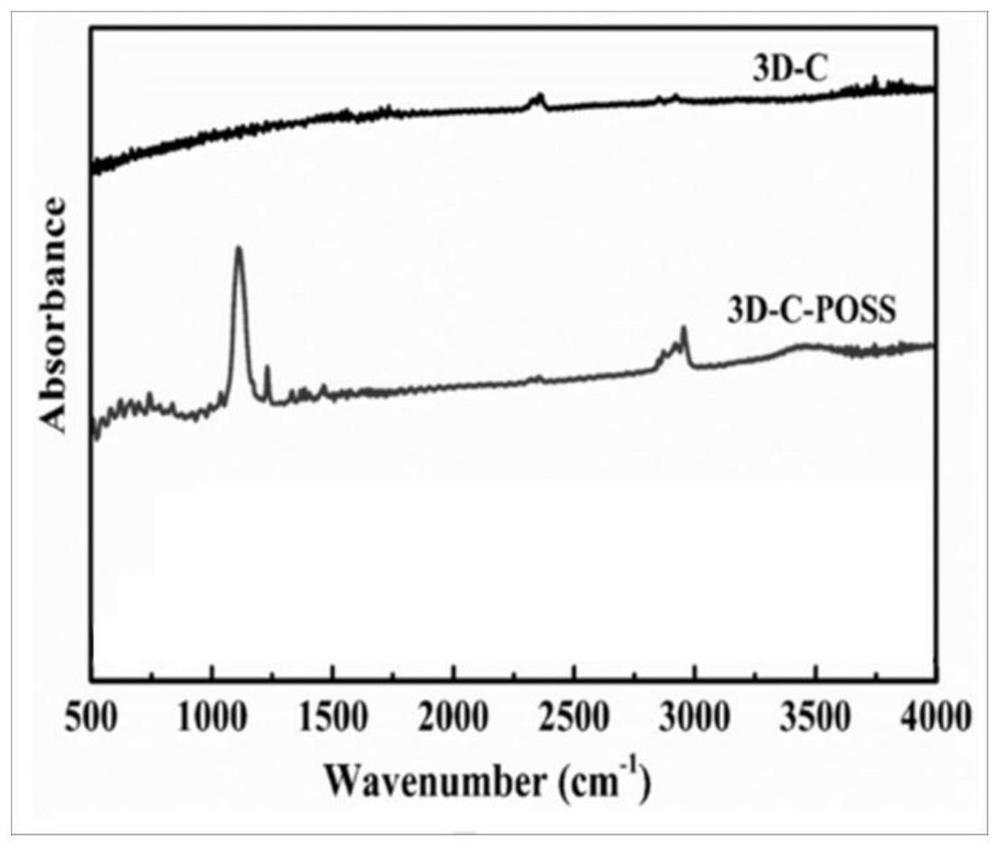

PendingCN114292518AEasy reunionImprove atomic oxygen resistanceMaterial nanotechnologyPolymer scienceGraphene nanocomposites

The invention discloses a preparation method of three-dimensional graphene-POSS (Polyhedral Oligomeric Silsesquioxane) nanocomposite modified polyimide, which is used for preparing nanoscale three-dimensional graphene-POSS with a three-dimensional structure by adopting a thermal chemical vapor deposition technology and a high-temperature heat treatment technology, and solves the problem that two-dimensional materials such as graphene, graphene oxide and the like are easy to agglomerate. The large-proportion three-dimensional graphene-POSS content is realized to be used for modifying polyimide; through a three-dimensional graphene-POSS nano modification technology, the problems that existing polyimide is poor in atomic oxygen resistance and insufficient in space environment adaptability are solved, the surface of the polyimide is free of defects and holes, the polyimide has excellent atomic oxygen resistance on the basis of good mechanical properties and electrical properties, and the atomic oxygen erosion rate is superior to 0.8 * 10 <-24 > cm < 3 > / atom.

Owner:SHANGHAI INST OF SATELLITE EQUIP

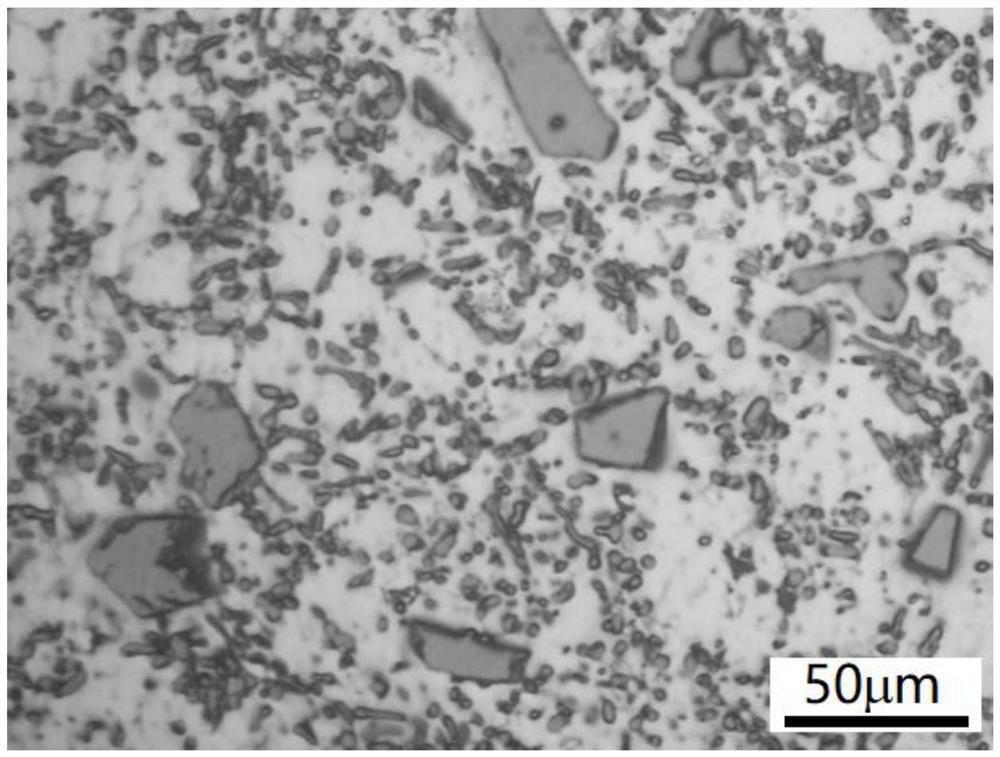

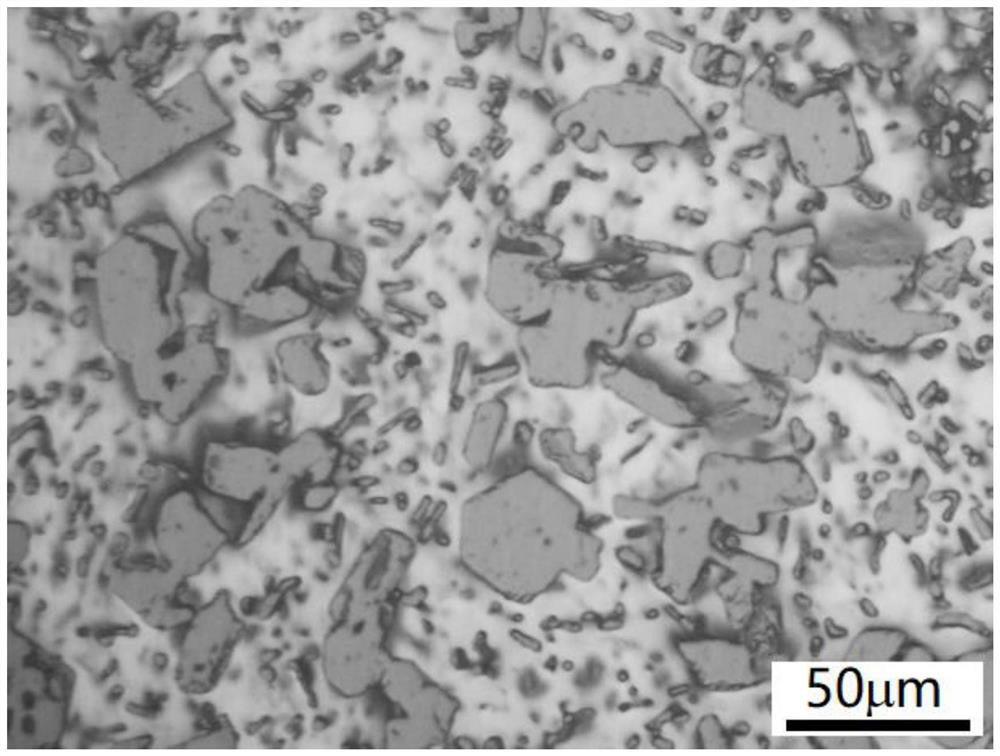

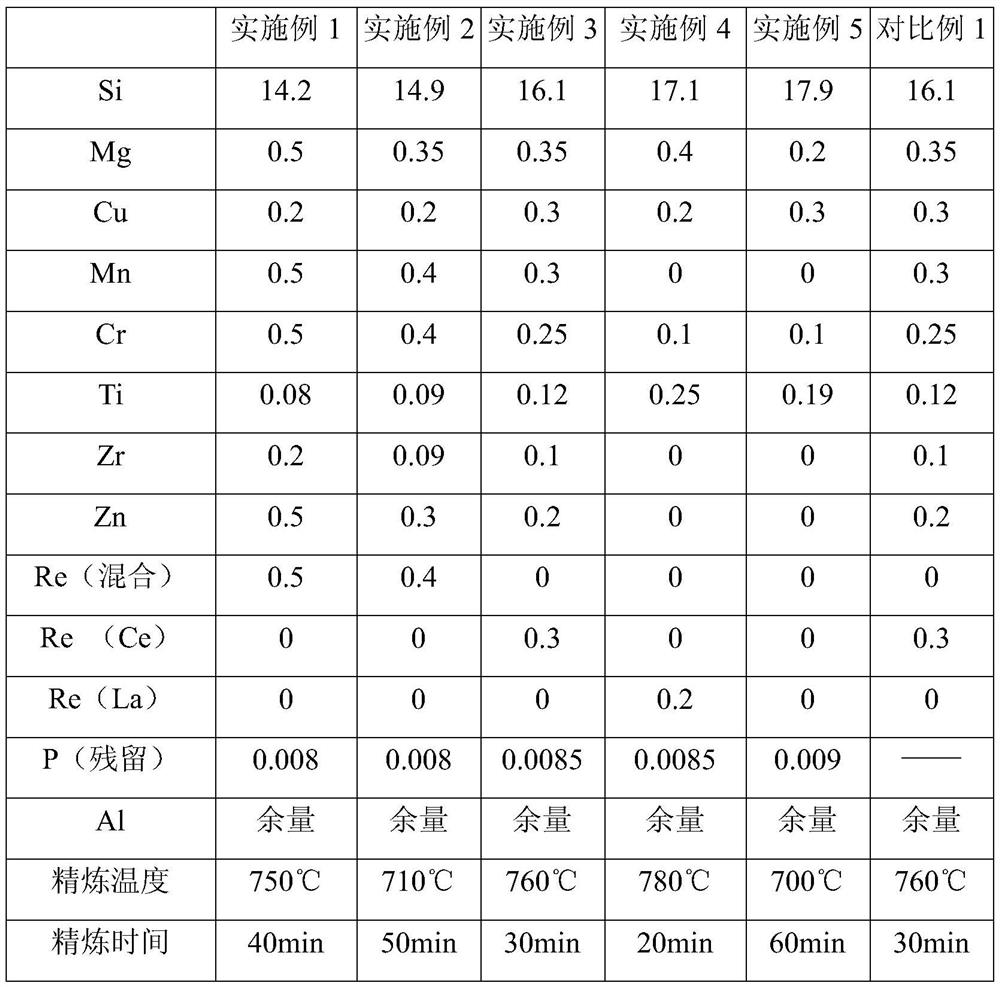

A kind of high elastic modulus and high plasticity aluminum-silicon casting alloy and its preparation method and application

ActiveCN113699418BHigh modulus of elasticityImprove plasticityProcess efficiency improvementSiliconPlastic property

The invention discloses a high elastic modulus and high plasticity aluminum-silicon casting alloy, a preparation method and application, and belongs to the field of casting aluminum alloys. The high elastic modulus and high plasticity aluminum-silicon casting alloy includes components and their mass percentages as follows: Si is 14-18%, Cu is 0-0.4%, Mg is 0.2-0.5%, and Mn is 0-0.5% , Cr is 0.1-0.5%, Zr is 0-0.25%, Zn is 0-0.5%, Ti is 0.05-0.25%, Re is 0-0.5%, and the balance is Al and inevitable impurities. The high elastic modulus and high plasticity aluminum-silicon casting alloy utilizes P to effectively transform primary Si, and has the characteristics of light weight, good casting performance, high elastic modulus and high elongation, and high tensile strength strength. The high elastic modulus and high plasticity aluminum-silicon cast alloy can be applied to automobile parts with special requirements for elastic modulus and plasticity.

Owner:SHANGHAI WANTAI AUTO PARTS +1

A method of producing ultra-low carbon steel based on ftsc thin slab continuous casting

The invention discloses a method for producing ultra-low carbon steel on the basis of flexible thin slab casting (FTSC). The method includes the following steps of (1) molten iron desulfurization, (2) smelting with a converter, (3) Ruhstahl Hausen (RH) vacuum treatment and (4) FTSC. The ultra-low carbon steel comprises, by mass, 0-0.010% of C, 0.06%-0.35% of Mn, 0.12%-0.28% of Si, 0-0.020% of P, 0-0.020% of S, 0-0.09% of Ti, 0-0.0050% of N, and the balance iron and inevitable impurities. According to the method, the ultra-low carbon steel is produced through FTSC, the components, suitable for FTSC production, of the ultra-low carbon steel are redesigned, and ultra-low carbon steel continuous casting slabs meeting the performance requirement are produced by strictly controlling process parameters of all procedures of steel making.

Owner:HEBEI IRON AND STEEL

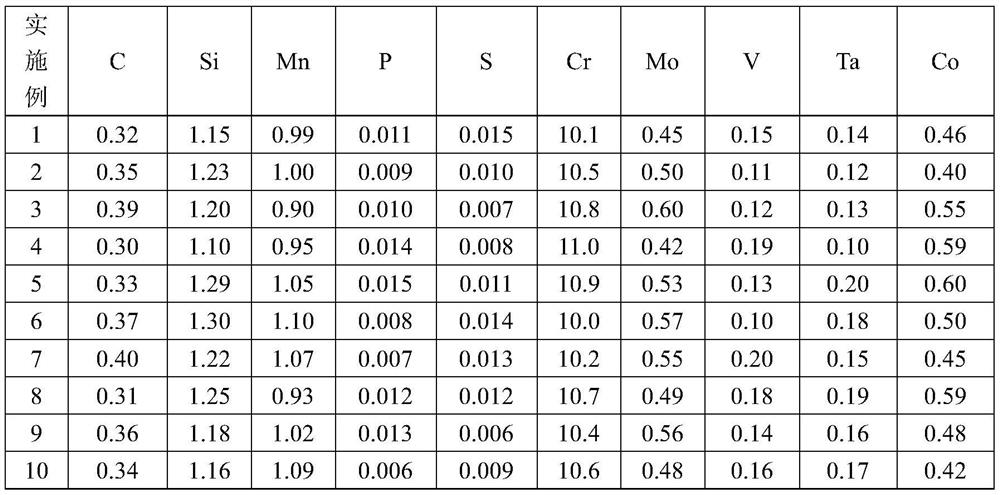

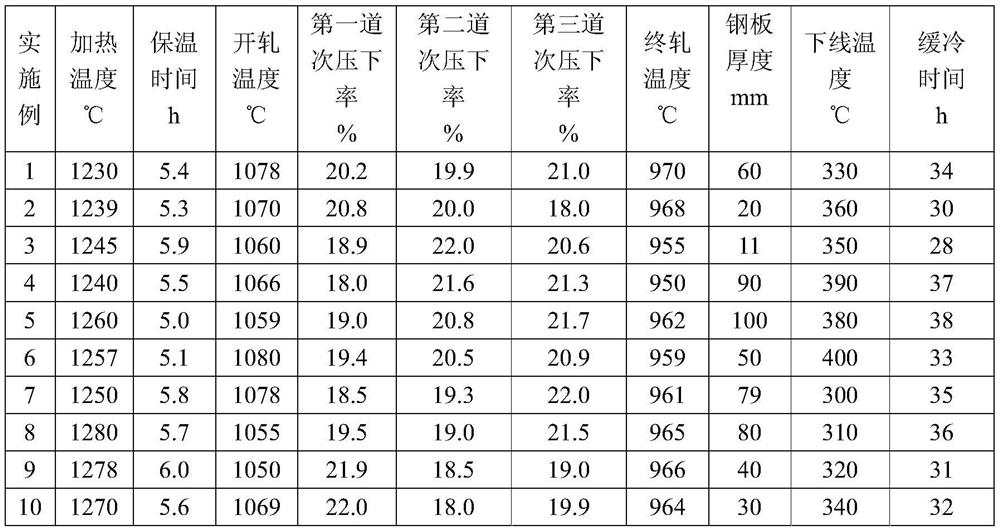

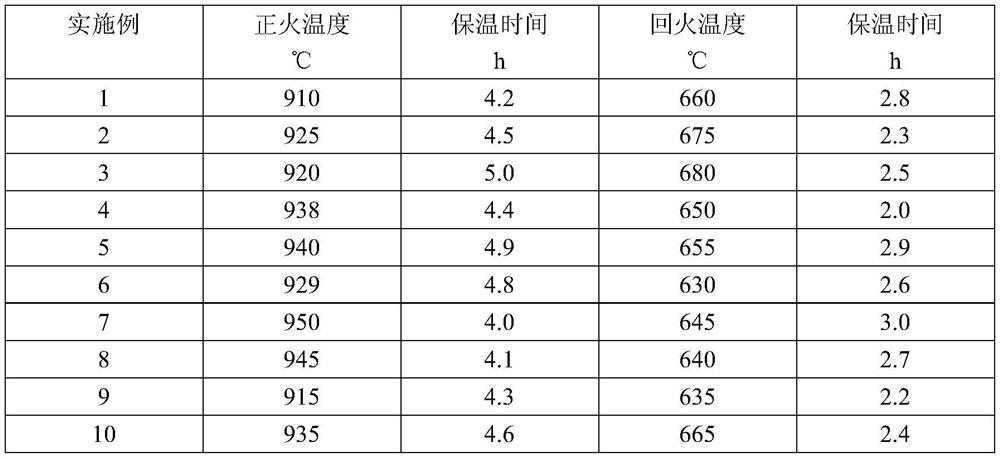

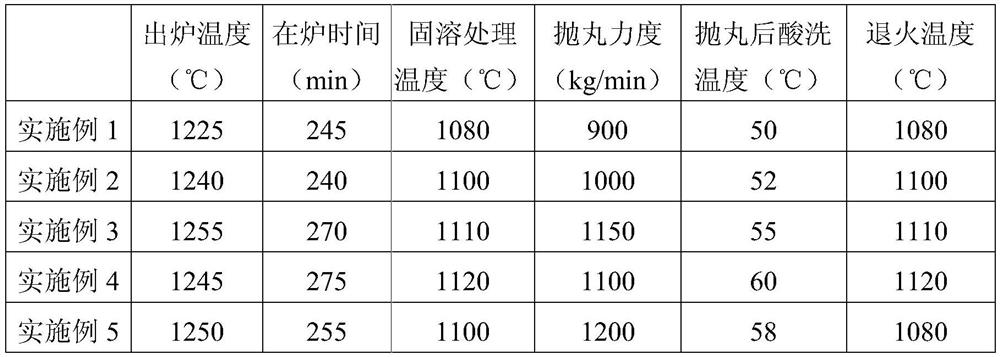

Plastic mold steel with excellent high temperature strength and preparation method thereof

ActiveCN111809114BHigh temperature strengthHardness Efficient and EconomicalTemperingPhysical chemistry

Owner:ANGANG STEEL CO LTD

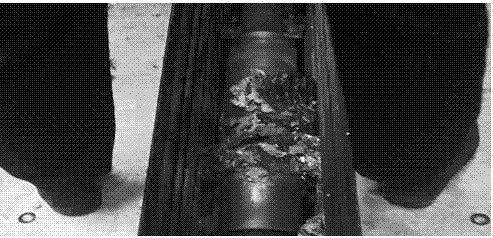

Method for reducing oxidizing and jamming of high-carbon steel intermediate billet in induction heating area

The invention discloses a method for reducing oxidizing and jamming of a high-carbon steel intermediate billet in an induction heating area. The technology route is molten steel, a big ladle rotationtable, a tundish, a crystallizer, a fan-shaped section, rough rolling R1-R2-R3, an induction heating furnace, high-pressure scale removal, finish rolling F1-F2-F3-F4-F5, laminar cooling and a coilingmachine. The technology effectively solves the problem about jamming of oxide scale cracking in an intermediate billet area. Benefits are increased.

Owner:RIZHAO STEEL HLDG GROUP

450mpa-grade hot-dip galvanized dual-phase steel and its production method

ActiveCN113584395BImprove uniformityClear opening and closing methodHot-dipping/immersion processesChemical compositionDual-phase steel

The invention discloses a 450MPa grade hot-dip galvanized dual-phase steel and a production method thereof, belonging to the technical field of cold-rolled strip production. The chemical composition of the dual-phase steel by mass percentage is: C 0.03%-0.10%, Si 0.20-0.60%, Mn 1.20%-2.00%, P≤0.020%, S≤0.010%, Als 0.015%-0.070%, N ≤0.0060%, the remaining elements are Fe and inevitable impurities; its microstructure is: 90-96% ferrite and 4-10% martensite by volume percentage. The preparation method includes the steps of smelting, hot rolling, pickling and hot-dip galvanizing. The production method of the dual-phase steel of the present invention adopts the sparse cooling method, which is beneficial to the stable control of the microstructure and properties; the opening and closing methods of the descaling and the cooling water between the racks are defined, which is beneficial to obtain a good surface quality. Combined with the smelting and hot-dip galvanizing process, the good mechanical properties and surface quality of the 450MPa hot-dip galvanized dual-phase steel sheet have been obtained, which has good market competitiveness.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

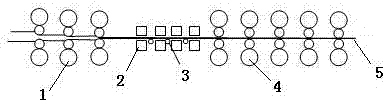

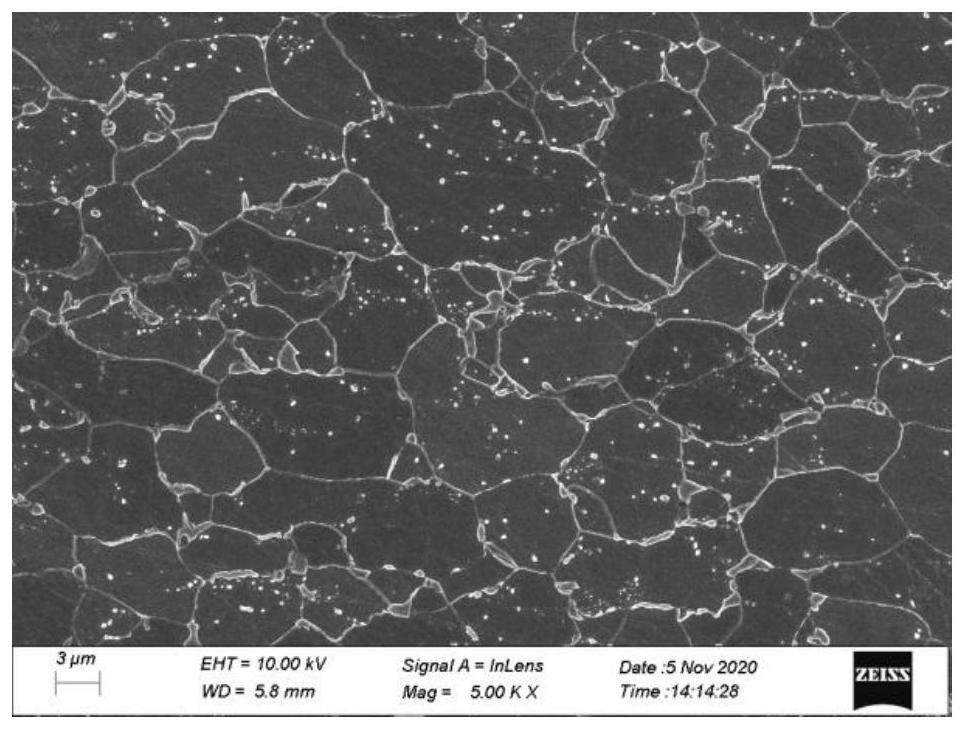

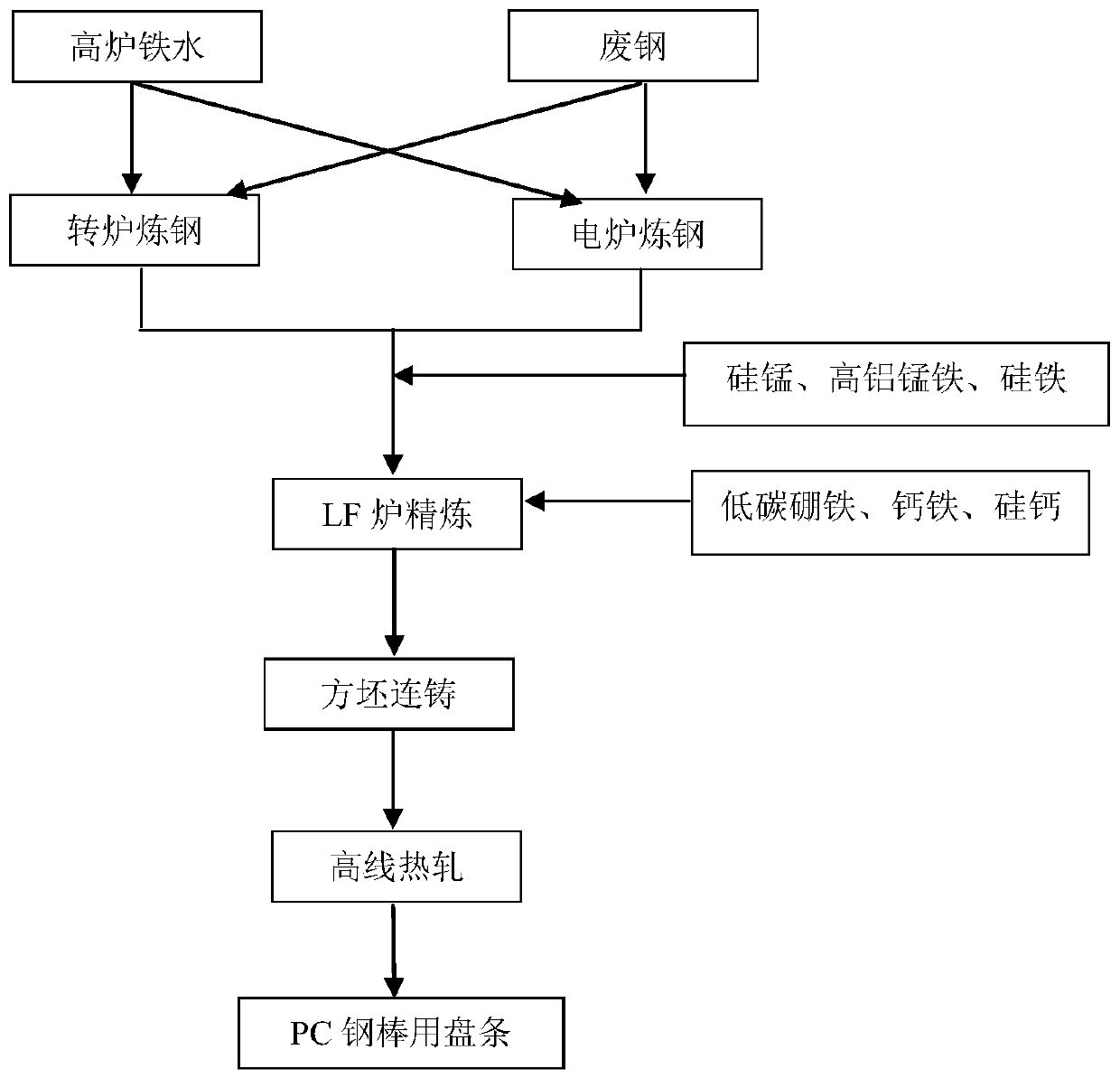

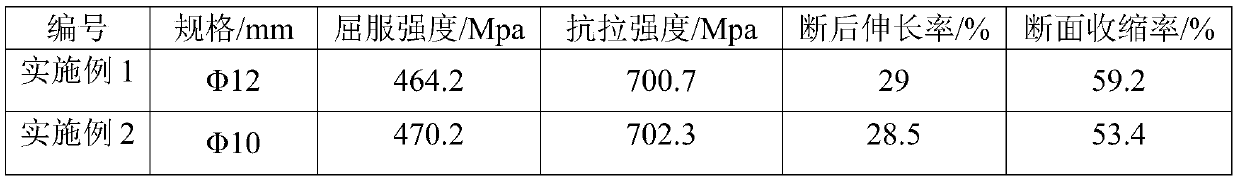

A kind of 30mnsibca hot-rolled wire rod for PC steel bar and preparation method thereof

ActiveCN110527917BImprove hardenabilityIncrease elasticityProcess efficiency improvementWire rodMolten steel

The invention relates to a 30MnSiBCa hot-rolled wire rod for a PC steel bar and a preparation method of the 30MnSiBCa hot-rolled wire rod; B and Ca elements are added into the 30MnSiBCa hot-rolled wire rod, and the hardenability and delayed fracture resistance of the wire rod are improved by controlling the ratio of B to Cr, Mn and Si and the content of Ca and B; meanwhile, an existing preparationprocess of the hot-rolled wire rod is optimized, molten steel is smelted by a converter / electric furnace; lF refining is carried out, and the 30MnSiBCa hot-rolled wire rod is prepared through the process route of continuous casting of steel billets and hot rolling and controlled cooling, so that the same batch of head and tail and different batches of hot-rolled wire rods are stable in performance and small in component fluctuation, the purity of steel is greatly improved, and the technical effects of avoiding frequent adjustment of the subsequent PC steel bar production process and being high in cost are achieved.

Owner:YANGCHUN NEW STEEL CO LTD +1

Manufacturing method for supporting roller for rolling battery pole piece

PendingCN113621866AReduce the content of C elementIncrease Si contentMetal-working apparatusFurnace typesElectrical batteryBackup roll

The invention relates to the technical field of roller manufacturing, in particular to a manufacturing method for a supporting roller for rolling a battery pole piece. Chemical components and weight percentages in the refined steel are added, an LF / VD refining furnace is adopted for refining, impurities are removed, gas in molten steel is removed, and a steel ingot is formed through pouring; the steel ingot is forged, stress relief annealing treatment is performed, and rough machining is performed to obtain a roller blank; and the roller blank subjected to rough machining is subjected to thermal refining, the roller blank subjected to thermal refining is subjected to tempering, finish machining is conducted according to the needed size after tempering is completed, and the battery pole piece supporting roller is manufactured. The method improves the solidification quality of the steel ingot, improves the flaw detection qualification rate of the roller, and improves the accident resistance of the roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

A kind of method of producing rare earth ferrosilicon alloy

ActiveCN108456773BIncrease Si contentImprove conversion utilizationProcess efficiency improvementSmelting processCerium

The invention discloses a method for producing rare earth ferrosilicon alloy. The technical purpose is to provide a method which can increase the yield of rare earth in the alloy, increase the conversion and utilization rate of silicon in a silicon reducing agent, increase the content of Si in the alloy by reducing burning loss of silicon, lower the power consumption for reduction, and reduce thetechnological slag yield based on cerium-enriched slag raw materials aiming at the many insufficiencies of an existing silicothermic method of producing the rare earth ferrosilicon alloy. According tothe method, based on the cerium-enriched slag raw materials, the rare earth ferrosilicon alloy is produced, in the process of smelting the alloy under the temperature of 1,200 DEG C or below, the method can be smoothly implemented, the yield of the rare earth in the process of producing the rare earth ferrosilicon alloy by using the silicothermic process is greatly increased, and the technical purposes of increasing the conversion and utilization rate of the silicon element, and increasing the content of Si in the alloy by reducing the burning loss of silicon are achieved. In the meanwhile, the technology requirement for the smelting reduction temperature is lowered, the production period of the smelting processes is obviously shortened, and therefore, power consumption in the smelting process is obviously lowered.

Owner:包头市华商稀土合金有限公司 +1

Radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi

The invention belongs to the technical field of heat-resistant alloy, and specifically relates to radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi. The steel comprises the components in weight percentage: 0.05-0.2% of C, 9.0-12.0% of Cr, 1.0-3.0% of Si, 0.3-3.0% of Mn, 1.0-3.0% of W, 0.1-0.4% of V, 0.03-0.3% of Ta, 0.03-0.15% of N, less than or equal to 0.05% of Al, less than or equal to 0.05% of Ti and the balance of Fe. According to the invention, the content of Si is increased; part of C element is replaced by N; the precipitation of Cr23C6 is reduced so as to ensure the Cr content in matrix, so that a rich Si compact oxide film is formed on the surface when the material serves in the Pb and Pb-Bi under high temperature, and a structure is protected to be free of lead corrosion; activating elements Mo, Ni and Nb are replaced by W, Mn and Ta, so that the low activation is ensured, and the irradiation resistance performance is improved; the types and appearance of the precipitated phase can be controlled according to a reasonable proportion between the C+N content and V+Ta content, so as to ensure the high-temperature performance in the serving process; and the novel martensite heat-resistant steel which serves under a strong radiation condition and has high-temperature resistance, lead corrosion resistance and irradiation resistance can be obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

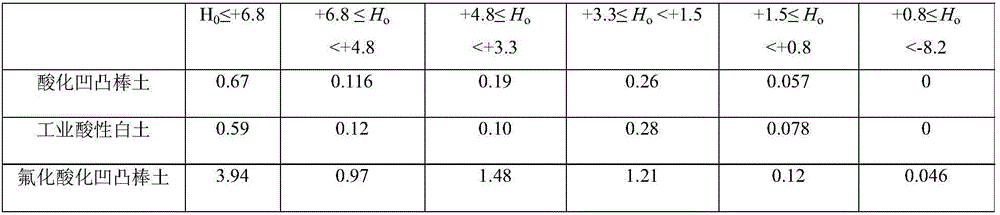

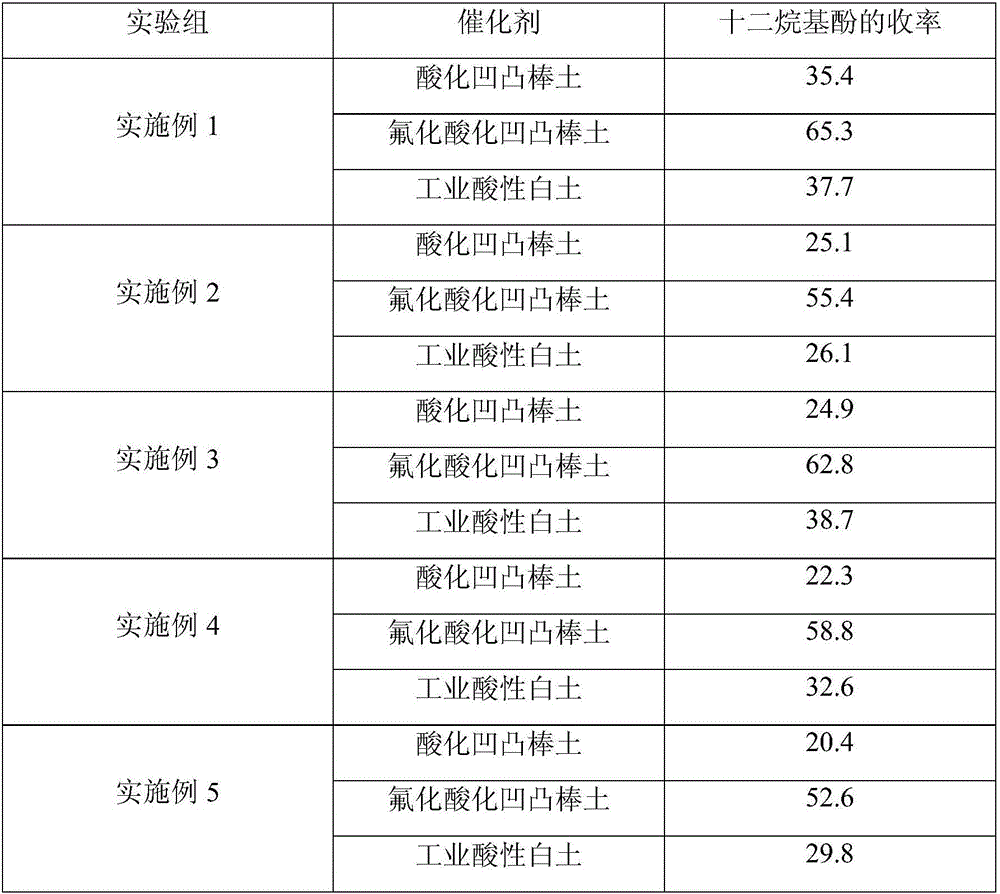

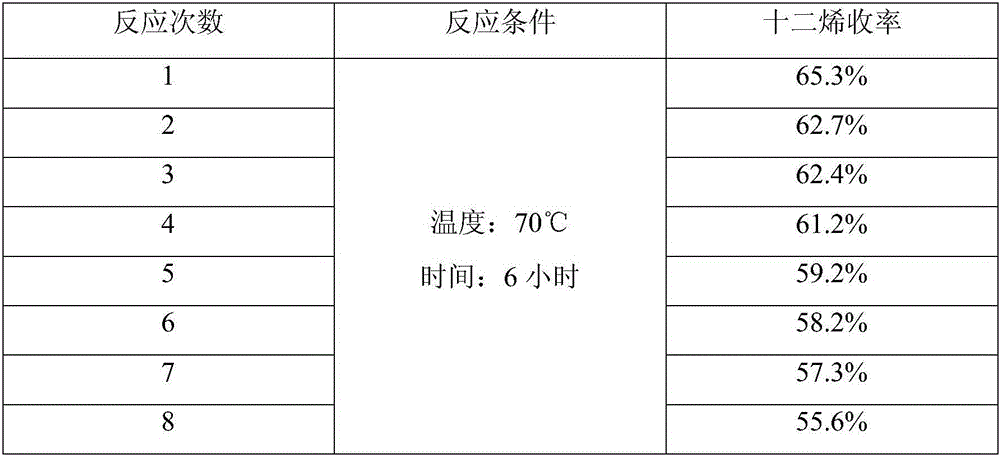

Catalyst of synthetic dodecylphenol and preparation method thereof

ActiveCN106732685AIncrease Si contentRegulate acidityPhysical/chemical process catalystsOrganic chemistryReaction temperatureAmmonium fluorosilicate

The invention provides a catalyst of laurylene and phenol compounded dodecylphenol by taking acidified attapulgite as raw material and fluorating with ammonium fluosilicate. The reaction condition is: under the constant pressure, the reaction temperature is 50-90 DEG C, the reaction time is 4-8 h, the molar ratio of phenol and alkene is 2: 1-10: 1, the catalyst dosage is 0.5-5% (counted by laurylene mass). The catalyst has the advantages of long service life, low dosage, no frequent replacement and high product quality by comparing with the clay catalyst.

Owner:CHANGZHOU UNIV

A kind of cold-rolled hot-dip galvanized steel and its manufacturing method

The invention discloses a cold-rolled hot-dip galvanized steel, whose chemical element mass percentage ratio is: C: 0.06-0.14%, Mn: 1.3-2.4%, Si: 0.1-1.0%, and the balance is Fe and unavoidable Impurities; its microstructure is ferrite + martensite + bainite + retained austenite. In addition, the present invention also discloses the manufacturing method of the above-mentioned cold-rolled hot-dip galvanized steel, which includes the steps: (1) smelting and casting; (2) hot rolling; (3) pickling; (4) cold rolling; (5) ) Hot-dip galvanizing recrystallization annealing: heating the cold-rolled sheet to the soaking temperature T 1 heat preservation for a period of time; then the steel plate after soaking is brought to the intermediate temperature T at the first cooling rate 2 , and then cooled to T at the second cooling rate 3 , hold for a period of time and then heat up to the zinc pool temperature T 4 Keep warm for a period of time; among them, the cooling rate is less than the second cooling rate, 640℃≤T 2 ≤T 1 , Ms<T 3 ≤T 4 (6) cooled to room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Improved welding material with tolerance of liquid zinc and aluminiferous zinc-base alloy

InactiveCN101301708BIncrease Si contentHigh hardnessWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

The invention relates to a welding material, in particular to an improved welding material which improves surfacing electrodes or flux-cored wires and resists the corrosion of liquid zinc and aluminium-zinc-based alloy. According to the portions by weight, the electrode coating or flux-cored wire of the welding material comprises the components as follows: 0.1-8 portions of graphite, 1-8 portionsof rutile, 8-25 portions of marble, 9-30 portions of fluorite, 5-16 portions of feldspar, 1-5 portions of mica, 0.1-25 portions of chrome powders, 10-40 portions of ferrosilicon, 10-15 portions of ferromanganese, 10-20 portions of molybdenum powder, 0.1-15 portions of aluminium powder, 0.1-25 portions of nickel powder, 1-10 portions of titanium dioxide, 5-20 portions of ferrotitanium, 0.1-5 portions of rare earth, 0.1-15 portions of ferrotungsten, and 1-10 portions of ferroboron. By adopting the proposal of the invention, the usage temperature of the welding material is ranged from 480 to 550DEG C; furthermore, the welding material of the invention effectively improves the anti-corrosion of zinc and the improved anti-corrosion of liquid zinc and aluminium-zinc-based alloy.

Owner:陈冬

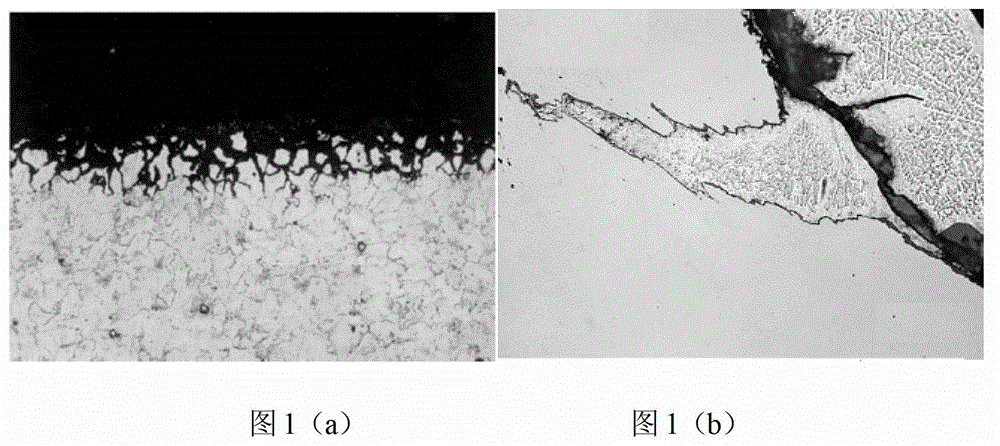

Austenitic heat-resistant steel without peeling on the surface and its manufacturing method

ActiveCN109554609BImprove high temperature strengthReduce typesChemical compositionUltimate tensile strength

A surface-free austenitic heat-resistant steel and a manufacturing method thereof, the chemical composition mass percent of the steel is: C: 0.03-0.08%, Si: 1.5-2.5%, 0<Mn≤2.0%, Cr: 19.0 ~21.0%, Ni: 11.0~13.0%, N: 0.04~0.08%, Mo: 0.6~1.2%, Zr: 0.001~0.01%, P≤0.040%, S≤0.03%, the rest is Fe and unavoidable impurities Elements, and need to meet: 30%≤(Cr+Ni)≤34%, 1.3≤(Creq / Nieq)≤1.8. The austenitic heat-resistant steel produced by the invention has good surface quality, no peeling defects, excellent oxidation resistance and good high-temperature strength, and the specific performance indicators are as follows: at 900°C: the oxidation rate is 0.1-0.5g / m 2 h, yield strength ≥ 69MPa, tensile strength ≥ 88MPa.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Molten steel for forgings used for manufacturing driving wheels and its smelting method

The invention discloses molten forging steel for manufacturing crane wheels and a smelting method thereof. The molten forging steel for manufacturing the crane wheels has the following chemical components in percentage by weight: 0.32-0.38 wt% of C, 1.10-1.30 wt% of Si, 1.10-1.25 wt% of Mn, 0.20-0.30 wt% of Cr, 0.015-0.030 wt% of Ti, S not more than 0.004 wt%, P not more than 0.012 wt%, O not more than 0.0010 wt%, H not more than 0.00015 wt%, and the balance of Fe and inevitable impurities. The preparation method comprises such process steps as KR method molten iron pretreatment deep desulfurization, converter smelting, LF steel ladle furnace refining and VD furnace vacuum refining. The molten steel, provided by the invention, is high in cleanness and low in inclusion content; and the forging steel for manufacturing the crane wheels is high in strength and toughness and excellent in wear and corrosion resistance, prominently improves the impact toughness and the fatigue resistance of the crane wheels in the use process, and prolongs the service life of the crane wheels.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com