A kind of cold-rolled hot-dip galvanized steel and its manufacturing method

A manufacturing method, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of large cold rolling reduction, small dew point range of annealing furnace, and increased production difficulty, etc. Achieve the effect of improving formability, improving work hardening ability, elongation and hole expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0063] The cold-rolled hot-dip galvanized steel of embodiment 1-6 adopts the following steps to make:

[0064] (1) Smelting and casting are carried out according to the mass percentage of each chemical element shown in Table 1.

[0065] (2) Hot rolling: the slab is heated at 1100-1270°C, the holding time is 0.5-3 hours, the final rolling temperature is controlled to be 800-950°C, and the coiling temperature is 400-650°C.

[0066] (3) Pickling.

[0067] (5) Cold rolling: control the deformation of cold rolling to be 35-85%.

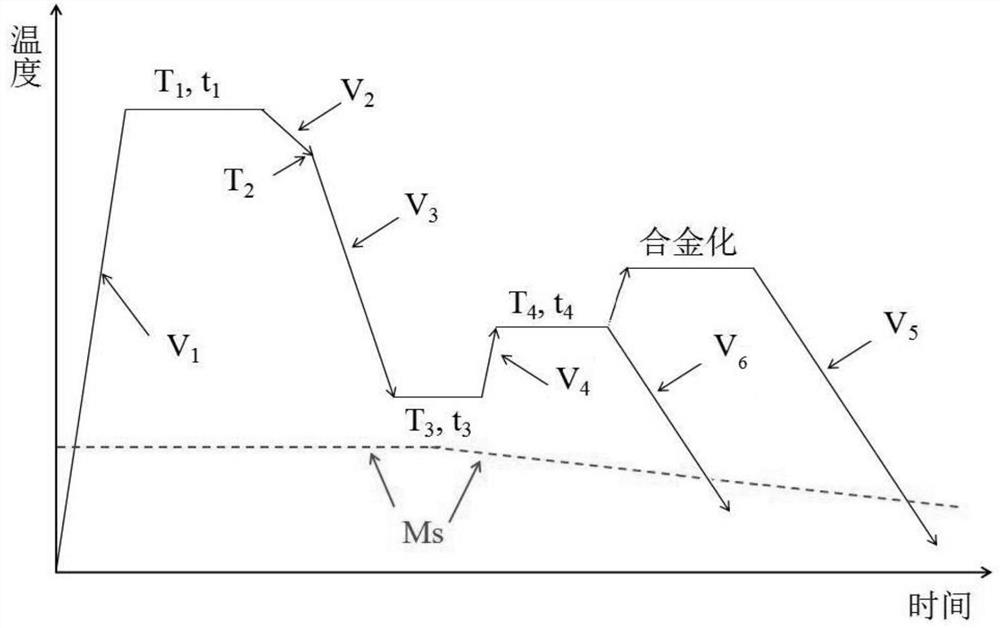

[0068] (5) Recrystallization annealing of hot-dip galvanizing: heating the cold-rolled sheet to the soaking temperature T 1 Keep warm for a period of time t 1 , the soaking rate is recorded as V 1 ; Then the steel plate after soaking is heated at the first cooling speed V 2 to intermediate temperature T 2 , and then at the second cooling rate V 3 Cool to T 3 , keep warm for a period of time t 3 Then heat up to the zinc bath temperature T 4 Keep w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com