Special highly-anticorrosive alloy cast ball for wet grinding of mine, and production method thereof

A production method and high corrosion resistance technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., to achieve the effect of increasing nucleation particles, refining as-cast grain size, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

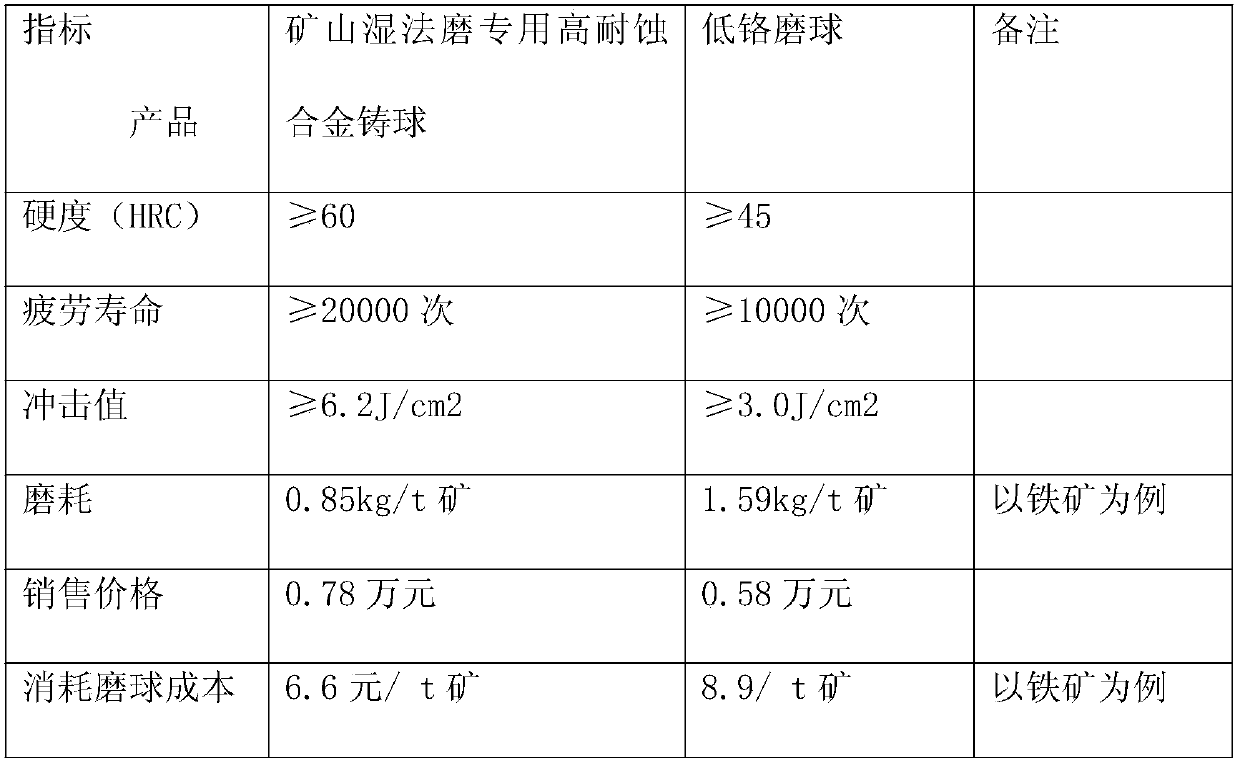

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-corrosion-resistant alloy casting ball for mine wet grinding, containing the following components by weight percentage: C 2.2%, Si 1.2%, Mn 1.0%, Cr 12%, Mo 0.006%, Cu0.025%, P≤0.05 %, S≤0.05%, Fe balance.

[0034] The production method of the high corrosion-resistant alloy cast balls for mine wet grinding comprises the following steps:

[0035] (1) Ingredients: Use clean and dry steel, ferromanganese, ferrochrome, ferromolybdenum, ferrosilicon, ferrochrome, and recarburizer as raw materials, and carry out ingredients according to the stated ratio range;

[0036] (2) Smelting: Put the prepared raw materials into an intermediate frequency induction melting furnace for smelting. When the temperature of the molten iron reaches 1490°C, take samples for chemical composition analysis, and fine-tune the weight percentage of each component through the feeding line;

[0037] (3) Comprehensive metamorphism treatment: including the metamorphic treatment in the primary furn...

Embodiment 2

[0043] A high-corrosion-resistant alloy cast ball for mine wet grinding, containing the following components by weight percentage: C 2.3%, Si 1.3%, Mn 1.2%, Cr 10.5%, Mo 0.007%, Cu 0.022%, P≤0.05% , S≤0.05%, Fe balance.

[0044] The production method of the high corrosion-resistant alloy cast balls for mine wet grinding comprises the following steps:

[0045] (1) Batching: adopt clean and dry iron and steel, ferromanganese, ferrochrome, ferromolybdenum, ferrosilicon, ferrochrome, and recarburizer as raw materials, and carry out batching according to the proportion range described in claim 1;

[0046] (2) Smelting: Put the prepared raw materials into an intermediate frequency induction melting furnace for smelting. When the temperature of the molten iron reaches 1500°C, take samples for chemical composition analysis, and fine-tune the weight percentage of each component through the feeding line;

[0047] (3) Comprehensive metamorphism treatment: including the metamorphic treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com