Cast Ti-Si eutectic alloy containing intermetallic compound reinforcement phase

A technology of intermetallic compounds and eutectic alloys, applied in the field of casting high-strength wear-resistant Ti-Si eutectic alloys and high-strength casting Ti-Si eutectic alloys, can solve the problems of low strength and wear resistance of engineering titanium alloys, Achieve excellent high-temperature mechanical properties, improve compressive strength, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

[0036] The inventor conducted experiments on 15 kinds of Ti-Si alloys, and the compositions of the 15 kinds of alloys in the examples are shown in Table 1.

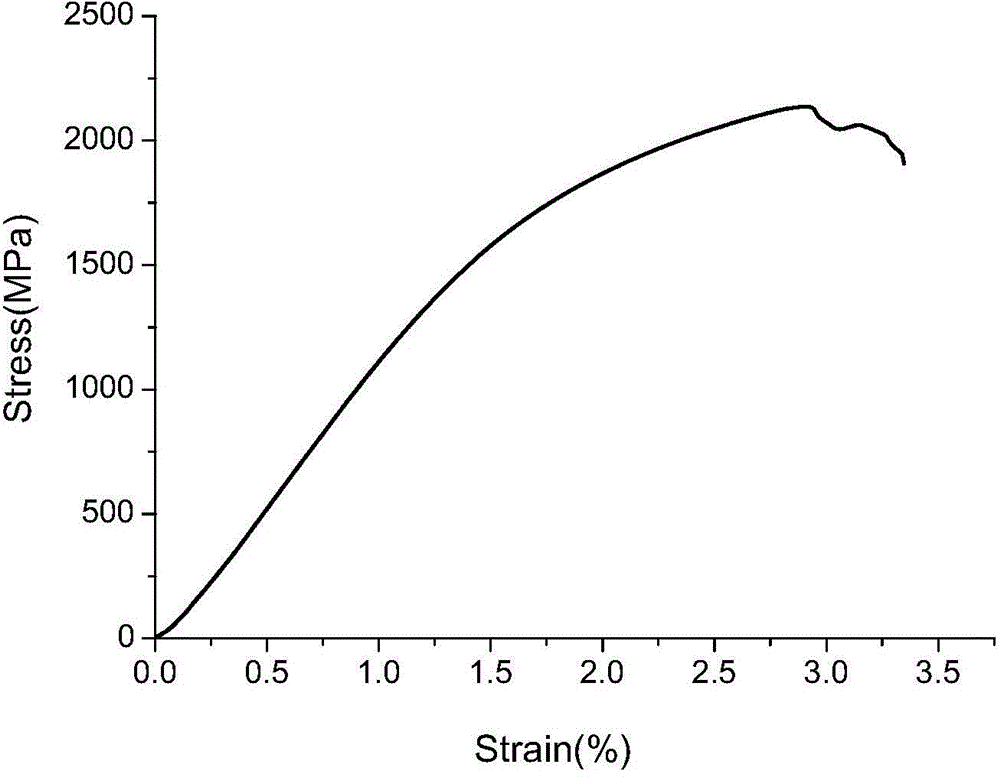

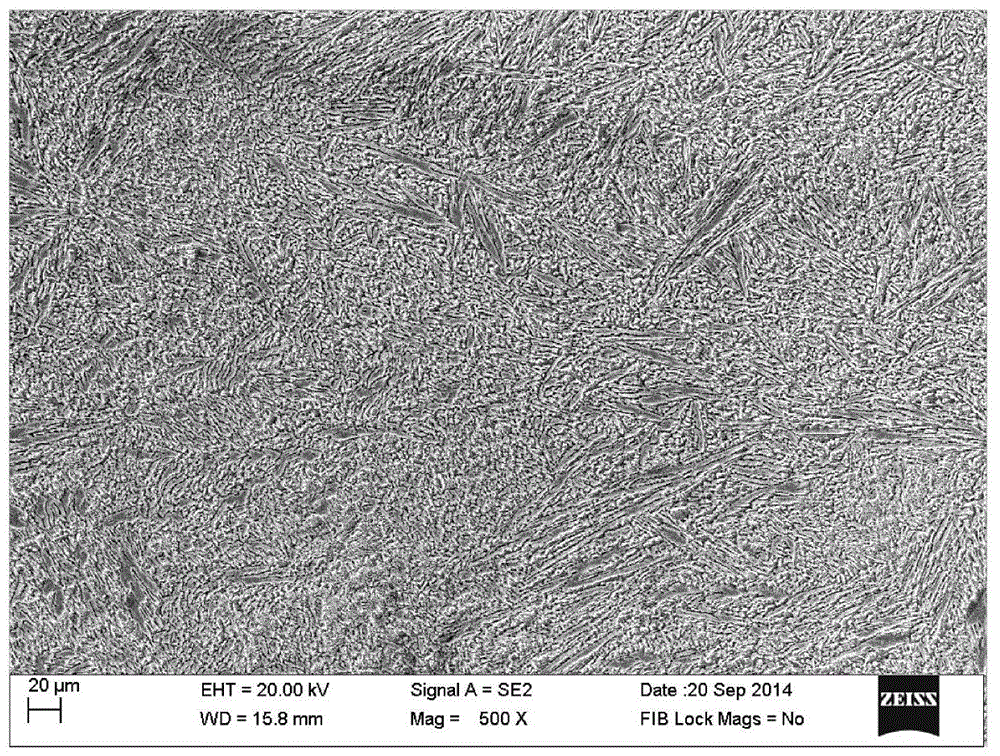

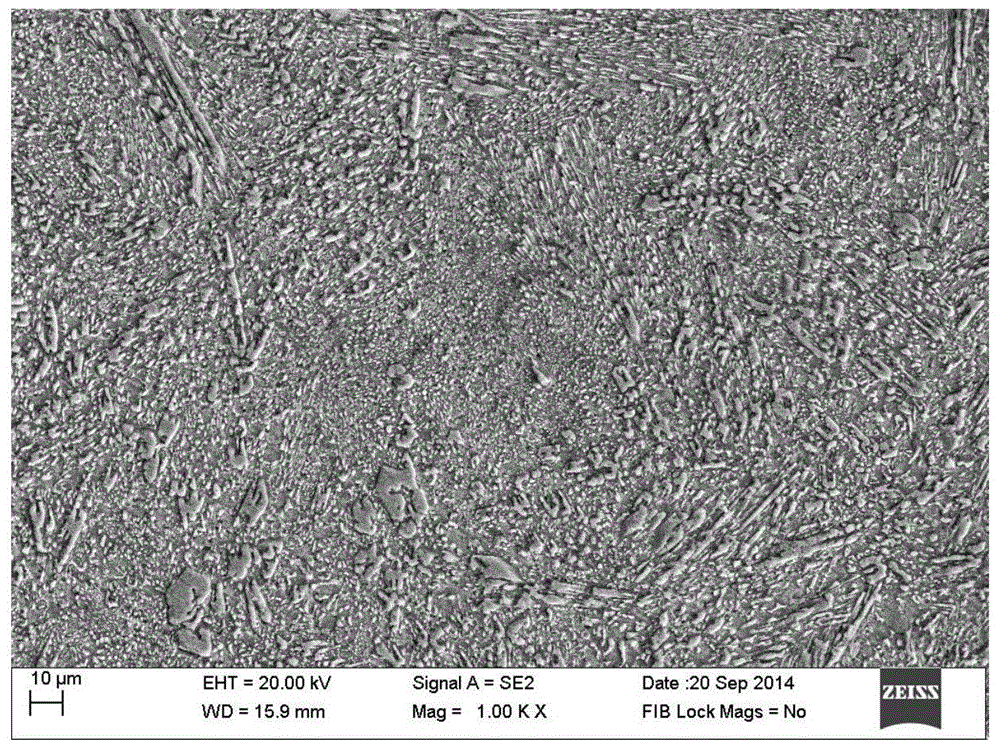

[0037] Casting method 1: The metal raw materials used to prepare the master alloy are all pure metal elemental elements with a purity greater than 99.9%. According to the chemical composition of the alloy, the ingredients are melted in a vacuum induction magnetic levitation melting furnace. The crucible is a water-cooled copper crucible. The melting vacuum is 0.01-1Pa. After the alloy is melted, it is poured into a mold with a diameter of 10mm and a length of 100mm. The microstructure of the embodiment 5 alloy prepared according to the casting method is as follows: figure 1 shown.

[0038] Casting method 2, the metal raw materials used in the preparation of the master alloy are all pure metal elemental elements with a purity greater than 99.9%, prepared according to weight percentage, mixed uniformly, pressed into elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com