Austenitic heat-resistant steel without peeling on the surface and its manufacturing method

A technology for austenitic heat-resistant steel and a manufacturing method, applied in the field of austenitic heat-resistant steel and its manufacturing, can solve the problems of material scrap, scale defects, peeling defects, etc., so as to prevent surface peeling and improve high temperature Oxidation resistance, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044]Pour the molten steel smelted by the electric furnace and AOD furnace into the baked ladle, lift it to the refining process to fine-tune the composition, ensure that the chromium-nickel equivalent ratio (Cred / Nieq) is greater than 1.3, and ensure that the ladle temperature reaches When the required temperature is cast, it is hoisted to the continuous casting platform and cast into a slab with a thickness of 200mm. In order to ensure the surface quality of the continuous casting slab, try to ensure a stable casting speed, and slowly reduce the casting speed until the last 10 minutes. The chemical composition of the slab is shown in Table 1.

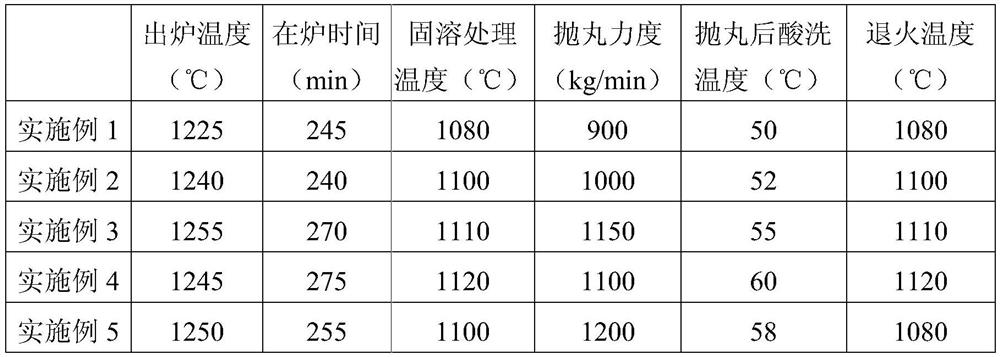

[0045] Send the cast slab to the walking beam heating furnace for heating, control the air-fuel ratio in the heating furnace to <9.8, and make the residual oxygen in the heating furnace <2%; After rolling and cold rolling, annealing and pickling, the finished product with the required target thickness is prepared. The key process pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com