A kind of method of producing rare earth ferrosilicon alloy

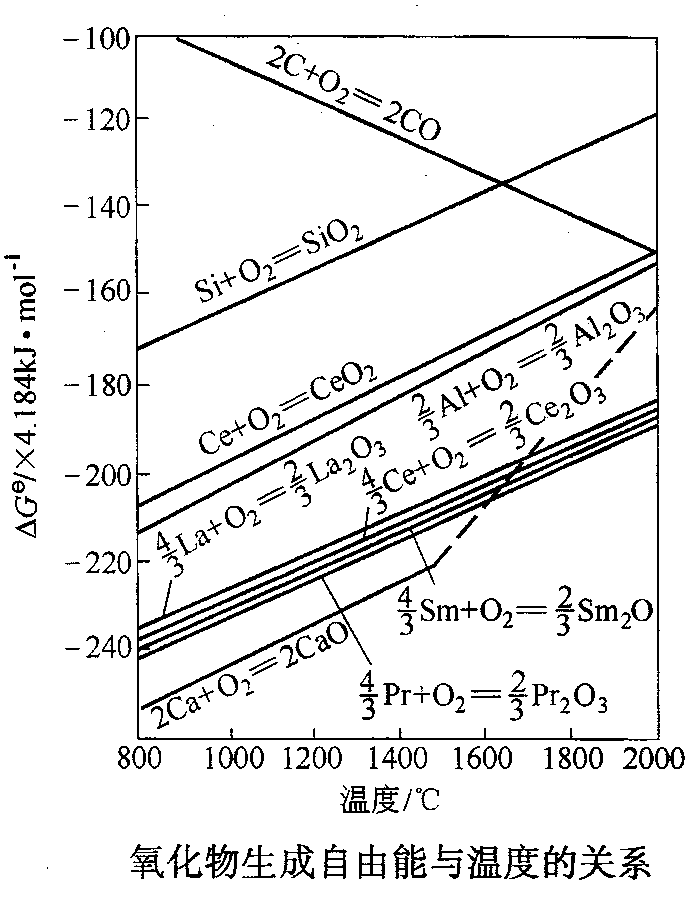

A technology of rare earth ferrosilicon alloy and total amount of rare earth, which is applied in the direction of improving process efficiency, etc., can solve the problems of low recovery rate of rare earth elements, large amount of slag produced in the process, and low Si content, etc., shorten the production cycle and increase the yield of rare earth , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

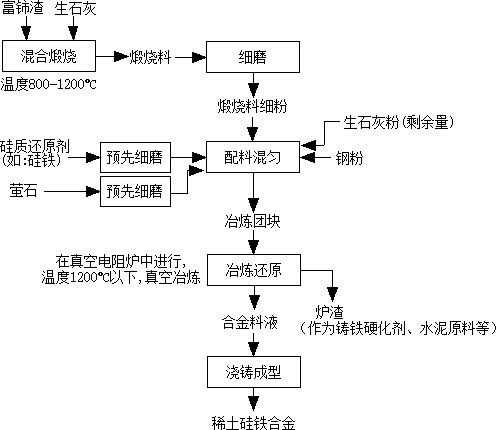

Method used

Image

Examples

Embodiment 1

[0040] The process for preparing rare earth ferrosilicon alloy (Xt30Si) with cerium-rich slag comprises the following steps:

[0041] (1) The cerium-rich slag (from the waste produced by Sichuan bastnaesite hydrometallurgy, of which TREO is 71%), (La 2 o 3 +CeO 2 ) / TREO=95.47%, CeO 2 / TREO=87.00%; average particle size 5mm; BaO≤5%, CaO2 <1%, mixed with quicklime, the mixing amount of quicklime is 80%wt (calculated as CaO) of the total amount of rare earth in the cerium-rich slag (calculated as REO), the calcination temperature is 950℃, and the calcination time is 1.25h.

[0042] After cooling, the calcined material is finely ground by grinding equipment to obtain a calcined material fine powder, and its average particle size (D 50 ) is 0.2mm, spare.

[0043] (2) 72# ferrosilicon powder with the total amount of rare earth (calculated as REO) 125%wt (calculated as elemental silicon in siliceous reducing agent) of the above-mentioned calcined material fine powder and pre-fine...

Embodiment 2

[0053] The process for preparing rare earth ferrosilicon alloy (Xt35Si) with cerium-rich slag includes the following steps:

[0054] (1) The cerium-rich slag (from the waste produced by Sichuan bastnaesite hydrometallurgy, of which TREO is 71%), (La 2 o 3 +CeO 2 ) / TREO=95.47%, CeO 2 / TREO=87.00%; average particle size 5mm; BaO≤5%, CaO2 <1%), mixed with quicklime, the amount of quicklime added is 100%wt (calculated as CaO) of the total amount of rare earths in cerium-rich slag (calculated as REO), the calcination temperature is 950°C, and the calcination time is 1.2h.

[0055] After cooling, the calcined material is finely ground by grinding equipment to obtain a calcined material fine powder, and its average particle size (D 50 ) is 0.2mm, spare.

[0056] (2) 72# ferrosilicon powder with the total amount of rare earth (calculated as REO) 135%wt (calculated as elemental silicon in the siliceous reducing agent) of the above-mentioned calcined material fine powder and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com