Radiation-resistant martensite heat-resistant steel having excellent compatibility with Pb and Pb-Bi

A compatibility and martensitic technology, applied in the field of radiation-resistant martensitic heat-resistant steel with good compatibility with Pb and Pb-Bi, can solve the problem that heat-resistant steel cannot meet high temperature resistance and radiation resistance at the same time Lead corrosion and other problems, to achieve excellent high temperature mechanical properties, reduce the amount of precipitation, improve the effect of radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

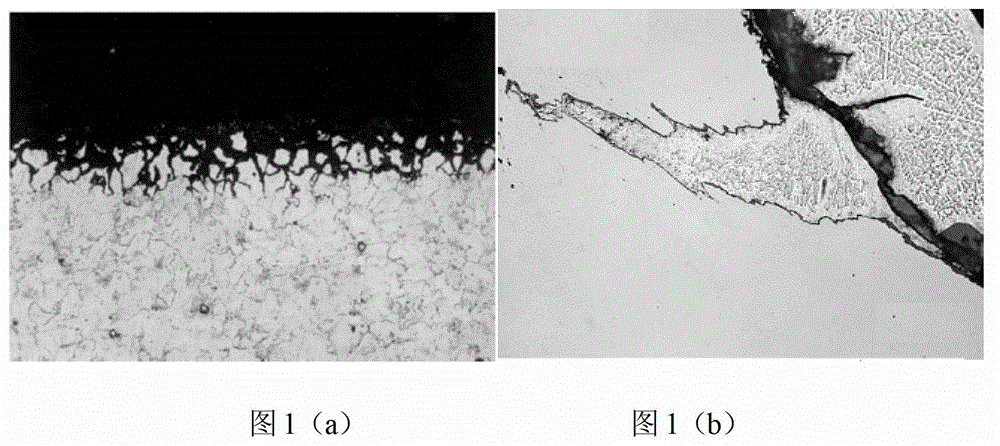

[0045] Table 1 shows a steel grade whose element content is within the scope of the present invention and another commercial heat-resistant steel P91 whose element content is not within the scope of the present invention. The two steel grades were tested for oxidation and lead corrosion respectively after the final heat treatment. As shown in Figure 2(a)-(b), the new steel grade 1 and the commercial P91 are both typical martensitic structures. Through the results of the two oxidation experiments, it is demonstrated that the present invention proposes to use the high Si content and Cr to work together to improve the oxidation resistance of the material, thereby improving the correctness of its lead corrosion resistance.

[0046] Both steels were oxidized for 400 hours at 450°C and 550°C in the atmosphere, and their oxidation conditions were observed. Such as image 3 As shown in (a)-(d), after 400 hours of oxidation, the density and smoothness of the oxide film formed by steel...

Embodiment 2

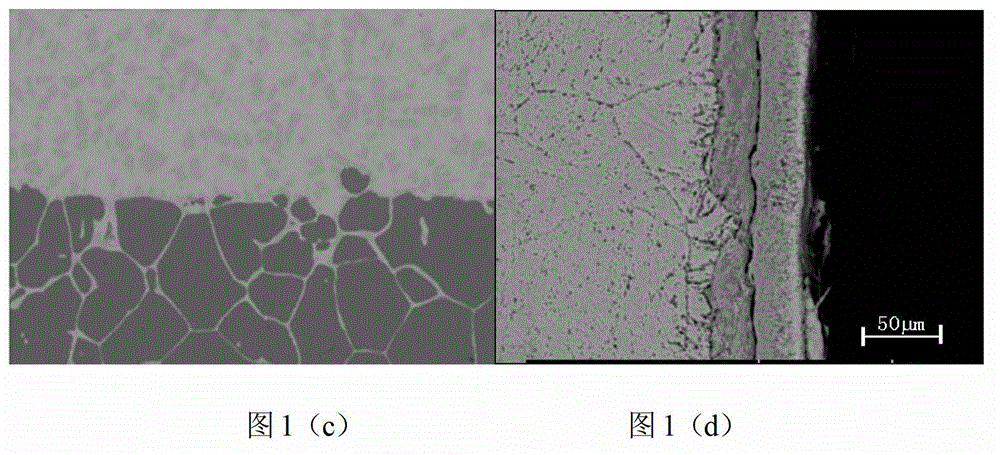

[0052] Table 2 shows the composition comparison between the new steel grade 2 and EP823. EP823 did not consider the reasonable matching of the C+N content and the strong carbonitride forming elements Nb and V in the design, resulting in the formation of As shown in Figure 6(a), the massive precipitates with too high precipitation temperature will cause cracks to easily initiate in these large precipitates, which will affect their mechanical properties. However, the new martensitic heat-resistant steel of the present invention has Reasonably matching the content of C + N and the content of strong carbonitride forming elements Ta and V as shown in Fig. 6(b) shows that the massive precipitates formed during the solidification process were successfully eliminated.

[0053] Also due to the high Si content in the newly invented steel, it has good lead corrosion resistance. As shown in Fig. The corrosion layer of steel type 2 is much thinner than that of P91, and the substrate is wel...

Embodiment 3

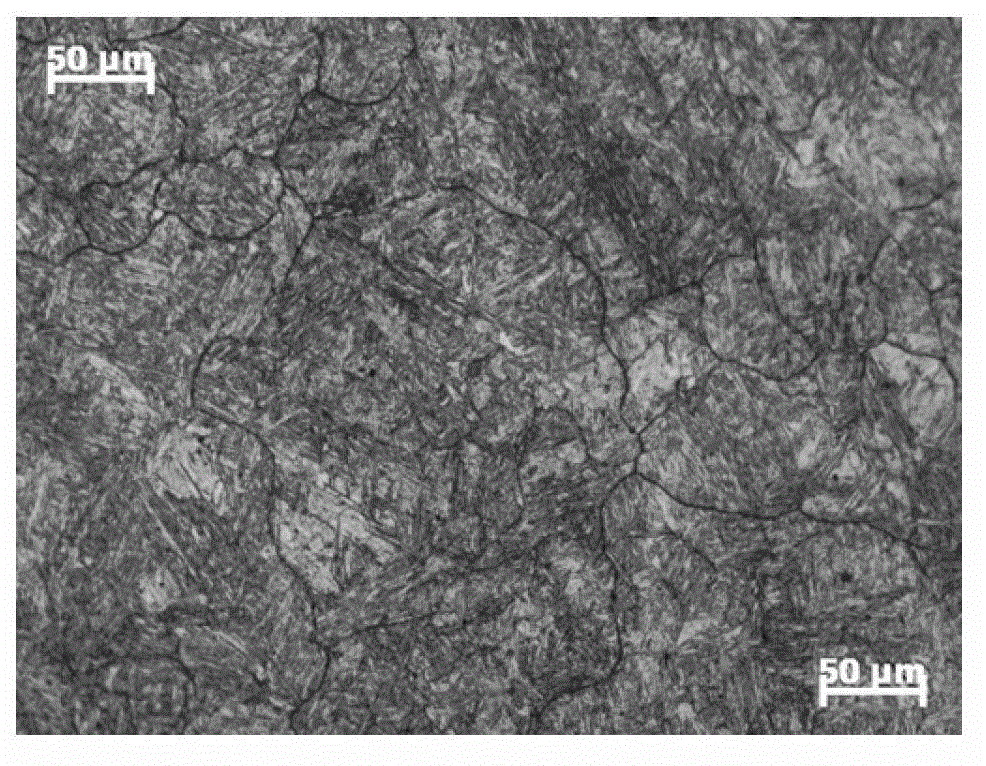

[0057] Table 3 has provided the composition of another kind of new steel type 3 within the scope of the present invention; This steel type obtains tempered martensitic structure after normalizing and tempering, fine M 23 C 6 And MX-type carbonitrides are distributed on the martensite lath boundary and the original austenite grain boundary. Such as Figure 8 As shown, these carbonitrides are uniformly distributed and mainly located at high-energy interfaces. These precipitated phases can effectively pin dislocations and these high-energy interfaces during high-temperature deformation. The lead corrosion resistance of this steel is also excellent. Figure 9(a)-(b) is the result of corrosion of new steel 3 and P91 in Pb-Bi at 450°C for 400h. It can be seen that compared with P91, the new steel has obvious advantages.

[0058] Table 3 New steel grade 3 composition

[0059] the element

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com