A kind of 30mnsibca hot-rolled wire rod for PC steel bar and preparation method thereof

A hot-rolled wire rod and steel bar technology, applied in the field of 30MnSiBCa hot-rolled wire rod for PC steel bar and its preparation, can solve the problems of high cost, frequent adjustment of PC steel bar production process, large fluctuation of raw material performance, etc., and achieve production Reduce cost, improve hardenability and elastic straightening performance, and avoid the effect of heading cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

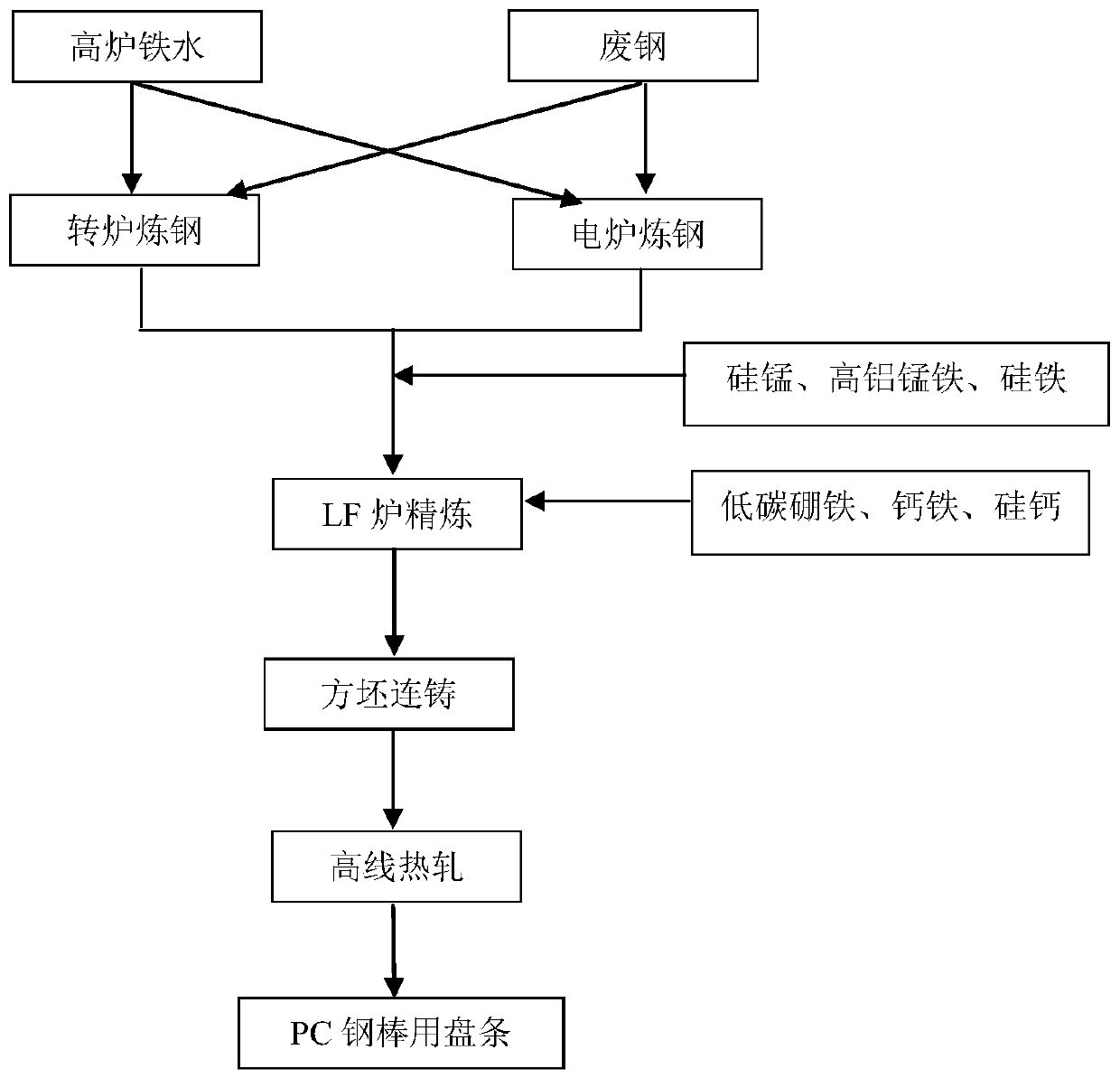

Method used

Image

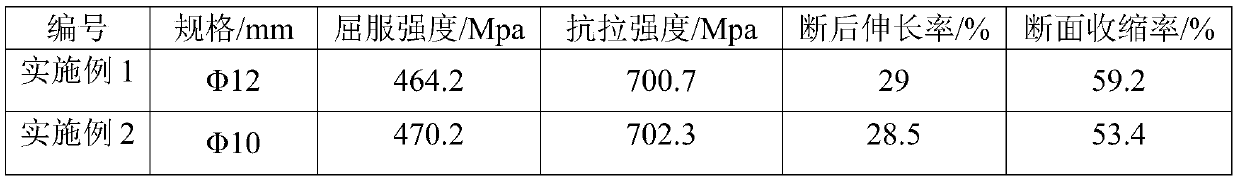

Examples

Embodiment 1

[0050] The present embodiment provides a kind of 30MnSiBCa hot-rolled wire rod for PC steel bar, and its composition weight percent is:

[0051] C 0.29%, Si 0.78%, Mn 1.05%, P 0.011%, S 0.004%, B 0.0023%, Ca 0.0018%, Cr 0.12%, Ni 0.038%, Cu 0.052%, O 0.0008%, N<0.0008% , the rest is Fe and unavoidable impurities,

[0052] The present embodiment also provides a method for preparing the above-mentioned 30MnSiBCa hot-rolled wire rod for PC steel bars, which specifically includes the following steps:

[0053] Step 1. Smelting molten steel: Add 100t of molten iron with S≤0.025%, P≤0.120% and 24t of scrap steel as raw materials into the converter, adopt the top-bottom composite blowing process, add lime with a CaO content of 90% and an activity of 300ml and use high Stretching and blowing far carbon, control the carbon content of the end point to 0.12%, and the tapping temperature to 1600°C;

[0054] Argon is blown throughout the tapping process, and the argon flow rate is 25NL / mi...

Embodiment 2

[0060] The present embodiment provides a kind of 30MnSiBCa hot-rolled wire rod for PC steel bar, and its composition weight percent is:

[0061] C 0.29%, Si 0.81%, Mn 1.06%, P 0.014%, S 0.006%, B 0.0028%, Ca 0.0018%, Cr 0.14%, Ni 0.028%, Cu 0.036%, O 0.0006%, N<0.0009% , the rest is Fe and unavoidable impurities,

[0062] Specifically include the following steps:

[0063] Step 1. Smelting molten steel: Add 100t of molten iron with S≤0.025% and P≤0.120% and 24t of scrap steel as raw materials into the electric furnace, adopt the top-bottom compound blowing process, add lime with a CaO content of 90% and an activity of 300ml and use high Stretching and blowing far carbon, control the carbon content of the end point to 0.12%, and the tapping temperature to 1600°C;

[0064] Argon is blown throughout the tapping process, and the argon flow rate is 24NL / min. High-aluminum-manganese-ferroalloy is added at the beginning of tapping, and silicon-manganese alloy and silicon-ferroalloy ...

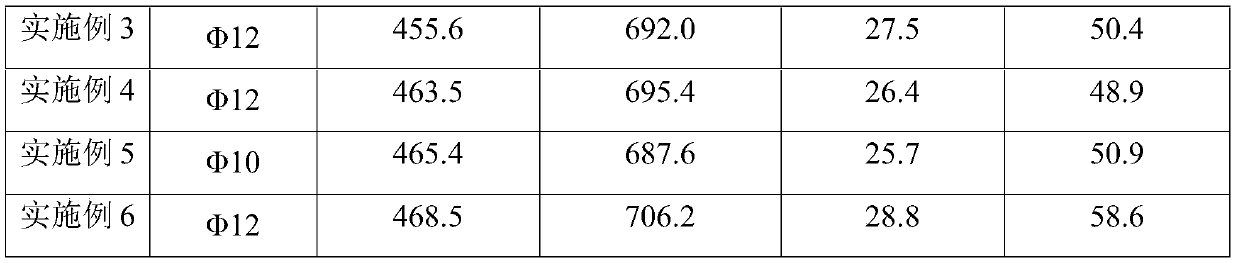

Embodiment 3

[0070] The present embodiment provides a kind of 30MnSiBCa hot-rolled wire rod for PC steel bar, and its composition weight percent is:

[0071] C 0.31%, Si 0.79%, Mn 1.16%, P 0.011%, S 0.008%, B 0.0035%, Ca 0.0022%, Cr 0.12%, Ni 0.048%, Cu 0.066%, O 0.0007%, N<0.0007% , the rest is Fe and unavoidable impurities,

[0072] Specifically include the following steps:

[0073] Step 1. Smelting molten steel: Add 110t of molten iron with S≤0.025% and P≤0.120% and 14t of scrap steel as raw materials into the electric furnace, adopt the top-bottom composite blowing process, add lime with a CaO content of 90% and an activity of 300ml and use high Stretching and blowing far carbon, the carbon content at the end point is controlled to 0.13%, and the tapping temperature is 1620°C;

[0074] Argon is blown throughout the tapping process, and the flow rate of argon is 20NL / min. High-aluminum-manganese-ferroalloy is added at the beginning of tapping, and silicon-manganese alloy and silicon-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com