Method for producing ultra-low carbon steel on basis of flexible thin slab casting (FTSC)

A thin slab continuous casting and ultra-low carbon steel technology, applied in the field of smelting, can solve the problems of long production cycle, large temperature loss, high production cost, etc., achieve stable production process, solve clogging problem, and improve castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

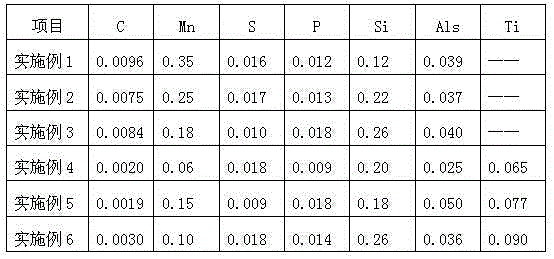

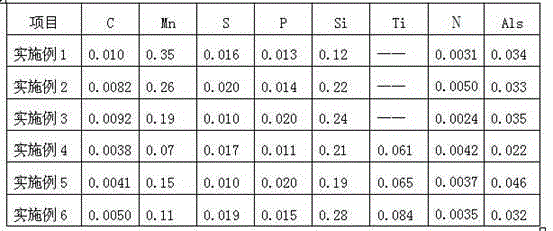

Examples

Embodiment 1

[0031] (1) Desulfurization of molten iron: the ladle is sprayed with granular magnesium and then slag is removed, and the S of molten iron entering the furnace is ≤0.003%;

[0032] (2) Converter smelting:

[0033] a. Molten iron temperature 1350℃, S=0.003%, P=0.120%;

[0034] b. The blowing process takes dephosphorization as the main goal, requires the whole process of slag removal, and the furnace temperature rises steadily;

[0035] c. Final slag basicity is 3.85, molten steel composition (mass percentage) C: 0.05%, S: 0.010%, P: 0.008%; end point temperature: 1680°C, end point oxygen level: 700ppm;

[0036] d. Continuous and clean special RH refining ladle is used for tapping;

[0037] e. Use a slag blocking machine to block slag, the thickness of the lower slag is ≤50mm; the mass percentage of FeO in the final slag is 22%;

[0038] f. Tapping time is 5.8 minutes, and the steel flow is round.

[0039] g. The amount of high-carbon ferromanganese added is 1.0Kg / ton of ste...

Embodiment 2

[0053] (1) Desulfurization of molten iron: the ladle is sprayed with granular magnesium and then slag is removed, and the S of molten iron entering the furnace is ≤0.003%;

[0054] (2) Converter smelting:

[0055] a. Molten iron temperature 1350℃, S=0.003%, P=0.120%;

[0056] b. The blowing process takes dephosphorization as the main goal, requires the whole process of slag removal, and the furnace temperature rises steadily;

[0057] c. Final slag basicity is 3.5, molten steel composition (mass percentage) C: 0.06%, S: 0.009%, P: 0.010%; end point temperature: 1700°C, end point oxygen level: 800ppm;

[0058] d. Continuous and clean special RH refining ladle is used for tapping;

[0059] e. Use a slag blocking machine to block slag, the thickness of the lower slag is ≤50mm; the mass percentage of FeO in the final slag is 23%;

[0060] f. Tapping time is 6 minutes, and the steel flow is round.

[0061] g. The amount of high-carbon ferromanganese added is 1.1Kg / ton of steel;...

Embodiment 3

[0075] (1) Desulfurization of molten iron: the ladle is sprayed with granular magnesium and then slag is removed, and the S of molten iron entering the furnace is ≤0.003%;

[0076] (2) Converter smelting:

[0077] a. Molten iron temperature 1350℃, S=0.003%, P=0.120%;

[0078] b. The blowing process takes dephosphorization as the main goal, requires the whole process of slag removal, and the furnace temperature rises steadily;

[0079] c. Final slag basicity is 4.0, molten steel composition (mass percentage) C: 0.05%, S: 0.007%, P: 0.011%; end point temperature: 1720°C, end point oxygen level: 600ppm;

[0080] d. Continuous and clean special RH refining ladle is used for tapping;

[0081] e. Use a slag blocking machine to block slag, the thickness of the lower slag is ≤50mm; the mass percentage of FeO in the final slag is 28%;

[0082] f. Tapping time is 5 minutes, and the steel flow is round.

[0083] g. The amount of high-carbon ferromanganese added is 1.05Kg / ton of steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com