Three-dimensional graphene-POSS nanocomposite modified polyimide and preparation method thereof

A nanocomposite material and nanomaterial technology, applied in the field of polyimide modified by three-dimensional graphene-POSS nanocomposite material and its preparation, can solve the problem of insufficient adaptability to space environment, degradation of important properties such as optics, electricity, mechanics, etc. , the decline of spacecraft work efficiency, etc., to achieve the effect of improving the adaptability of space environment, excellent resistance to atomic oxygen, and improving resistance to atomic oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

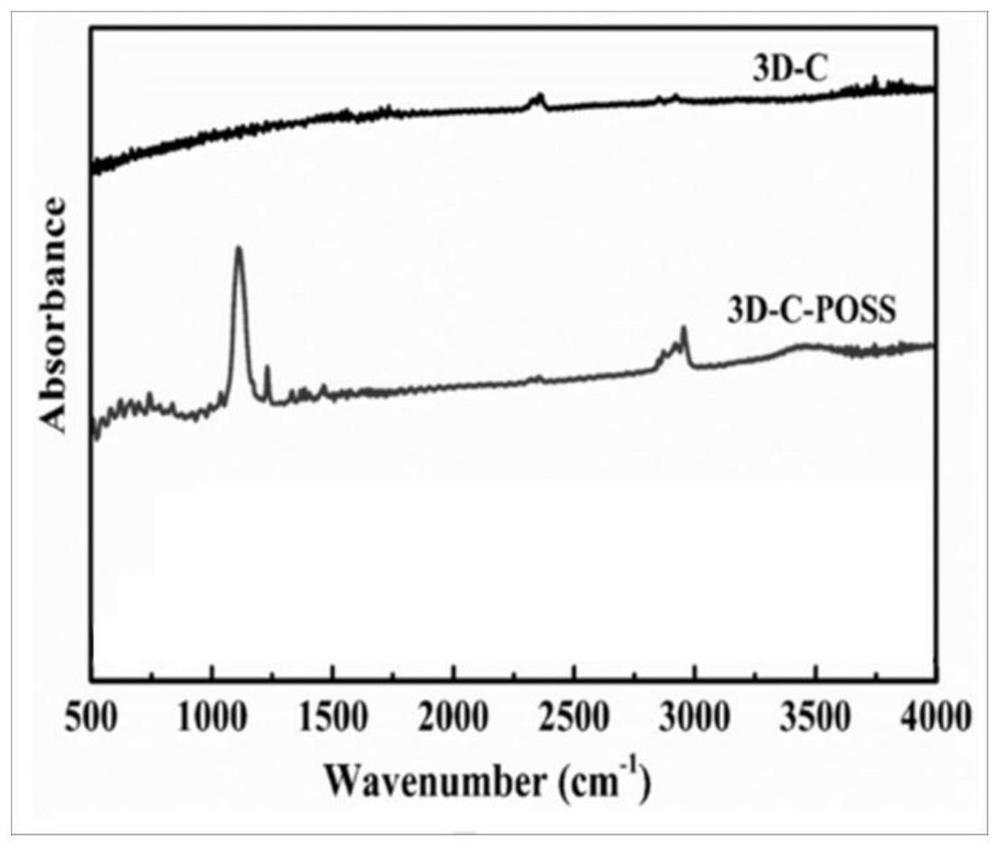

[0055] The preparation of embodiment 1 three-dimensional graphene-POSS

[0056] This embodiment provides a method for preparing nanoscale three-dimensional graphene-POSS.

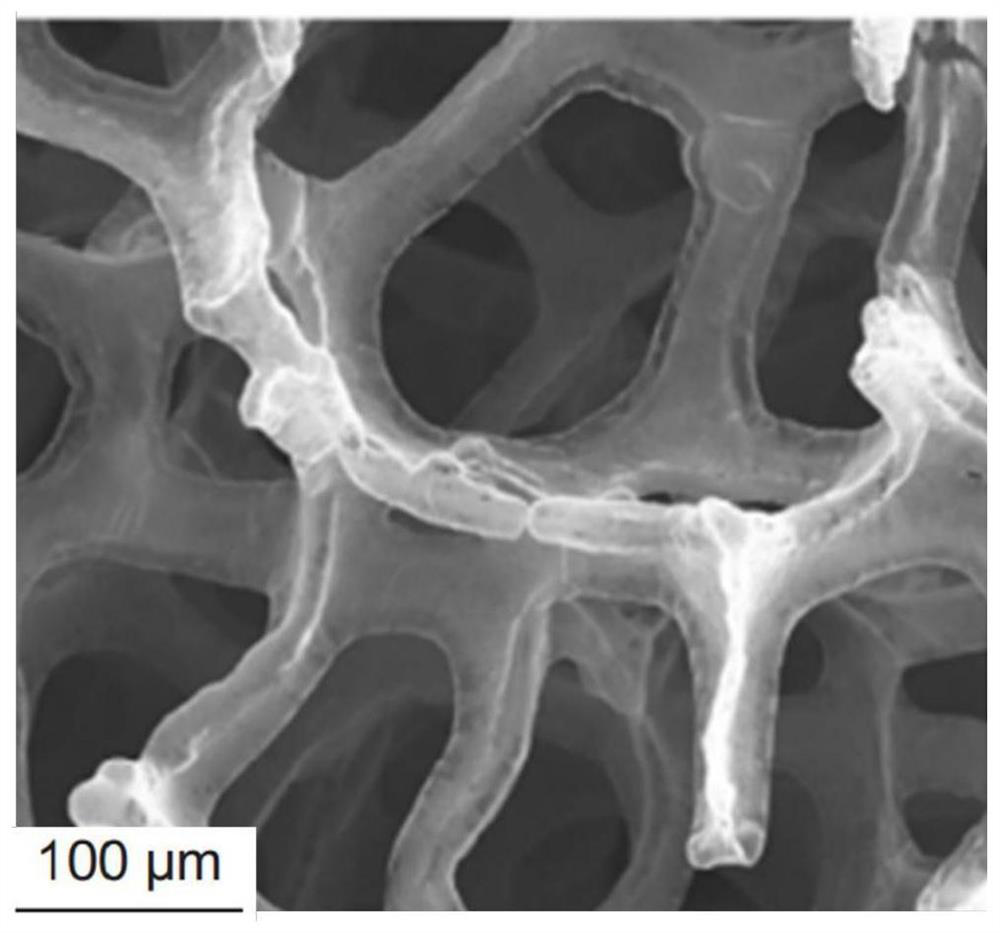

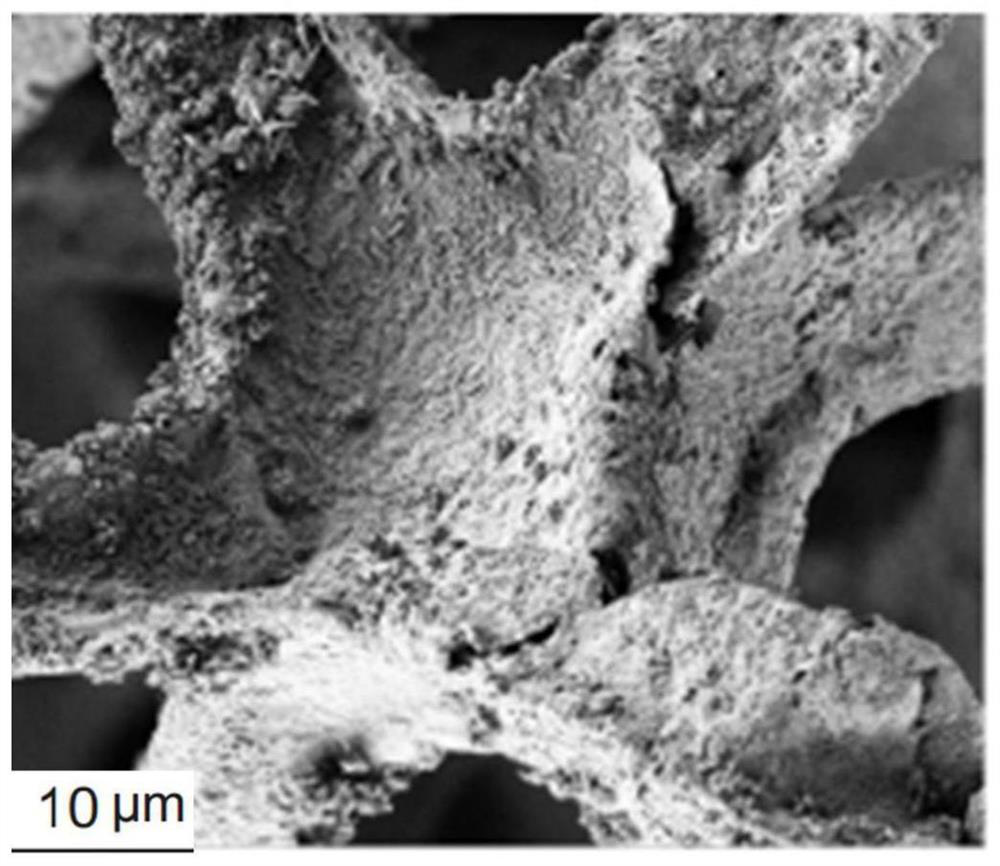

[0057] Put a nickel foam template with a diameter of about 2cm and a length of 10-12cm in a high-temperature quartz tube at 800°C, add 1g of a hydrogen-containing catalyst, and 3 / min flow into a constant argon, hydrogen gas mixture; after 15 minutes of reaction, with 20cm 3 A small amount of methane was introduced at a flow rate of / min, and the reaction time was 1 hour; under the action of argon and hydrogen protective atmosphere, the quartz tube was rapidly cooled to room temperature.

[0058] Take the sample out of the quartz tube, dip-coat it with polymethyl methacrylate, and soak it in hot hydrochloric acid with a concentration of 0.2mol / L for 3 hours after 10 minutes.

[0059] The sample was taken out from the hydrochloric acid solution and rinsed with pure water. The sample was placed in a high-te...

Embodiment 2

[0064] This embodiment provides a preparation method of nanoscale three-dimensional graphene-POSS modified polyimide (3D-C-POSS / PI).

[0065] Weigh 2g of the three-dimensional graphene-POSS (3D-C-POSS) nanocomposite prepared in Example 1, and measure 200ml of the polyamic acid solution. The three-dimensional graphene-POSS (3D-C-POSS) was slowly added to the polyamic acid solution under stirring. The three-dimensional graphene-POSS nanocomposite modified polyimide (3D-C-POSS / PI) was prepared by gradually heating to 400 °C in a nitrogen atmosphere.

[0066] The modified polyimide (3D-C-POSS / PI) prepared by this embodiment is subjected to an atomic oxygen test, and the atomic oxygen erosion rate of the modified polyimide is 1.6×10 -24 cm 3 / atom.

Embodiment 3

[0068] This embodiment provides a preparation method of nanoscale three-dimensional graphene-POSS modified polyimide (3D-C-POSS / PI-POSS).

[0069] Dissolve 10 g of trisilanol phenyl silsesquioxane in 200 ml of polyamic acid solution. Get the three-dimensional graphene-POSS (3D-C-POSS) nanocomposite material that 2g embodiment 1 prepares and polyamic acid solution mix uniformly, be heated to 450 ℃ gradually in nitrogen atmosphere, prepare three-dimensional graphene-POSS nanocomposite material Modified polyimide (3D-C-POSS / PI-POSS).

[0070] The modified polyimide (3D-C-POSS / PI-POSS) prepared by this embodiment is subjected to an atomic oxygen test, and the atomic oxygen erosion rate of the modified polyimide is 0.65×10 -24 cm 3 / atom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com