Coated steel sheet with thin aluminum alloy coating and coating method thereof

A technology for coating steel plates and aluminum alloys, which is applied in the direction of metal material coating process, coating, hot-dip plating process, etc., to achieve the effect of stabilizing the thickness of the coating, eliminating leakage plating, and improving the performance of resistance spot welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

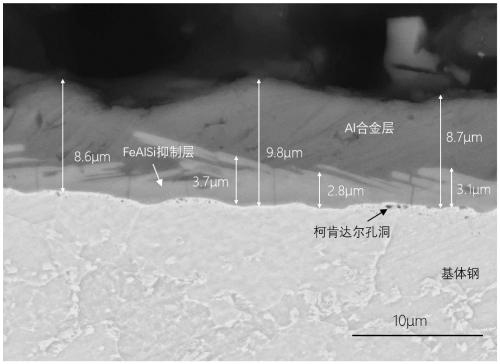

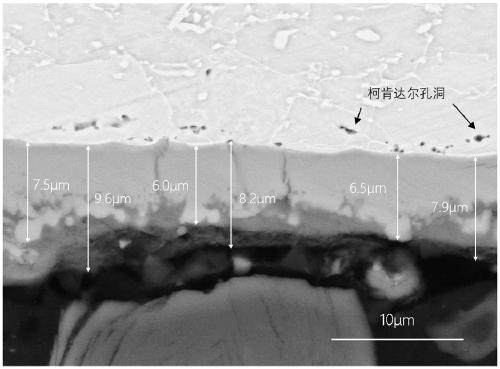

[0079] The coating process parameters of Example 5 and Comparative Example 4 are only different in the temperature of the steel plate into the pot, wherein the comparative example 4 has a significantly higher temperature of the steel plate into the pot. Therefore, the more Kirkendall holes and the thicker FeAlSi inhibition layer in Comparative Example 4 are caused by the high temperature of the steel plate into the pot. From this, it can be seen that a high temperature of the steel plate into the pot is not desirable.

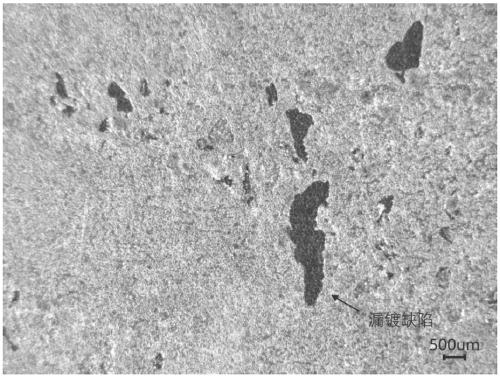

[0080] image 3 It is a typical underplating defect photograph of the plated steel sheet of Comparative Example 4. It is evident that in some areas the underplating is severe. This is because compared with Example 5, the higher temperature of the steel plate in Comparative Example 4 accelerated the diffusion, resulting in a thicker FeAlSi inhibitory layer and a thinner corresponding Al alloy layer, so the air-knife purging requirement was high. It is difficu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com