Method for producing high-cleanliness hot-series variety steel at low cost

A high-cleanliness, low-cost technology, applied in the direction of manufacturing converters, etc., can solve the problem of high production cost of clean steel, shorten the production process, avoid uncontrollable inclusions, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

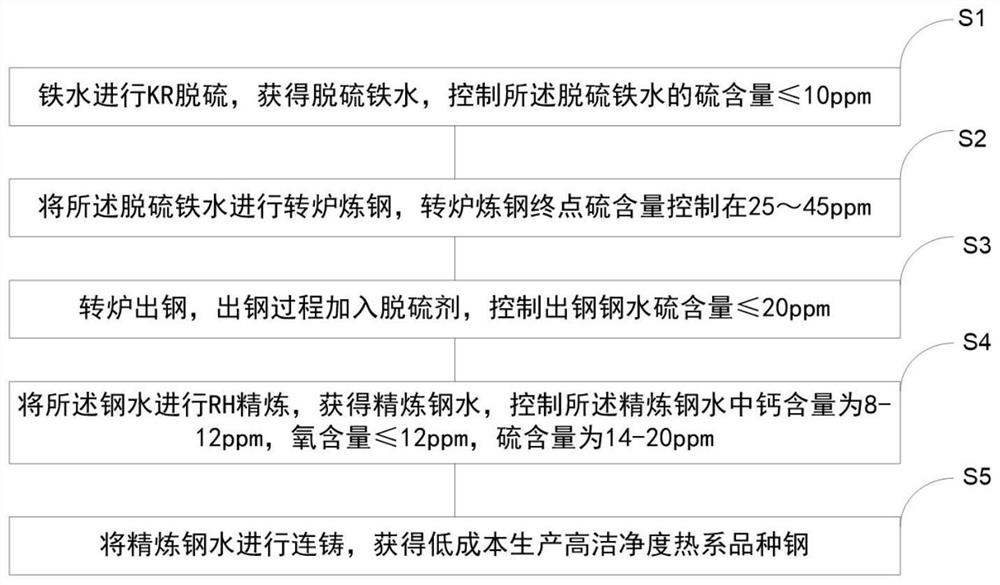

Method used

Image

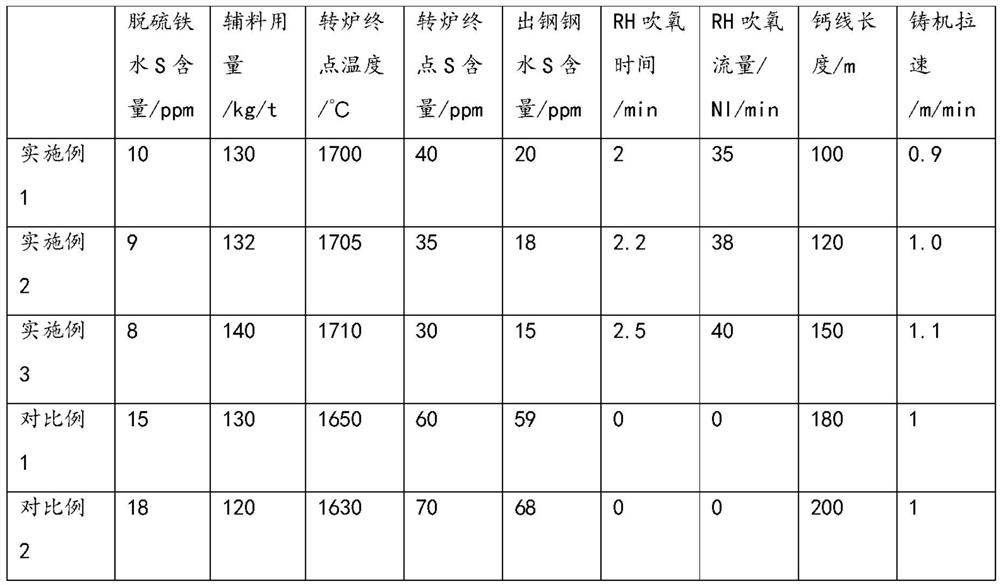

Examples

Embodiment

[0092] A low-cost production of high-cleanliness thermal grade steel, which is produced by the following method:

[0093] (1) Desulfurization of molten iron: adding fluorine-free desulfurizer to molten iron for KR desulfurization, the amount of said fluorine-free desulfurizer is 8kg / t molten iron, and then carry out slag removal, the liquid surface exposure rate of molten iron reaches 99.5%, obtain desulfurized molten iron, control the The sulfur content of the desulfurized molten iron is ≤10ppm.

[0094] In terms of mass fraction, the chemical composition of the fluorine-free desulfurizer is:

[0095] CaO: 92%, Al 2 o 3 : 3%, SiO 2 : 1%, MgO: 1%, Al: 3%.

[0096] (2) Converter smelting: The desulfurized molten iron is subjected to converter steelmaking, and auxiliary materials are added during the converter smelting process. The amount of the auxiliary materials is 130-140kg / t molten steel. The content is controlled at 25-45ppm.

[0097] Optionally, in terms of mass fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com