Non-oriented electrical steel good in weldability and magnetism and production method

A technology of oriented electrical steel and weldability, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of magnetic deterioration of non-oriented electrical steel, reduce magnetic deterioration, improve weldability, Effect of reducing welding porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below:

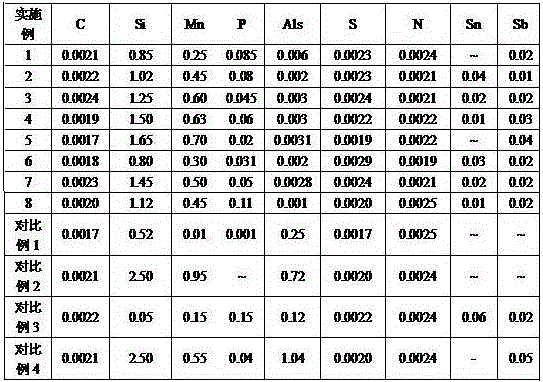

[0026] Table 1 is the list of chemical components of each embodiment of the present invention;

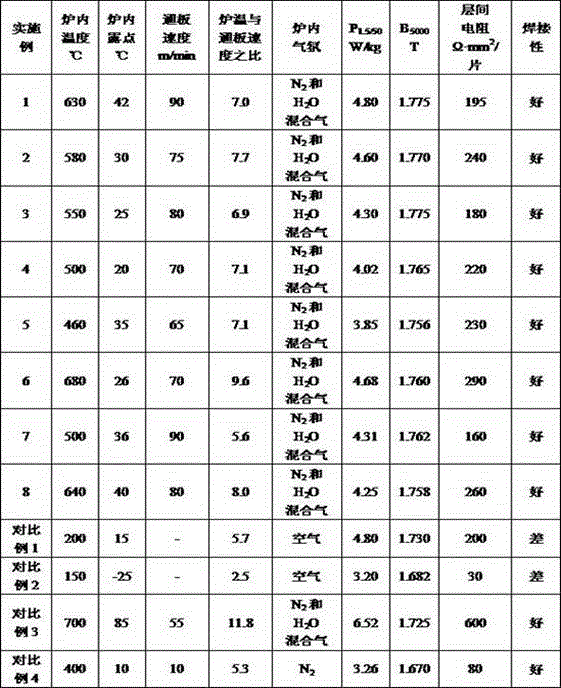

[0027] Table 2 is a list of main process parameters and performance conditions of each implementation case of the present invention.

[0028] Each implementation case of the present invention all produces according to the following steps:

[0029] 1) After steelmaking, hot rolling, pickling and cold rolling to the thickness of the finished product;

[0030] 2) Carry out bluing treatment after finished product annealing: directly carry out bluing treatment after continuous annealing, and the atmosphere for controlling bluing is N 2 and water vapor H 2 The mixed gas of O has a dew point of 20-75°C, a bluing temperature of 450-700°C, a plate-through speed of 50-100m / min, and the ratio of the furnace temperature to the plate-through speed is required to be 5.0-10;

[0031] 3) Carry out sampling, coiling, packaging and ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com