Aluminum alloy TIG tracking method based on ultrasonic electric arc

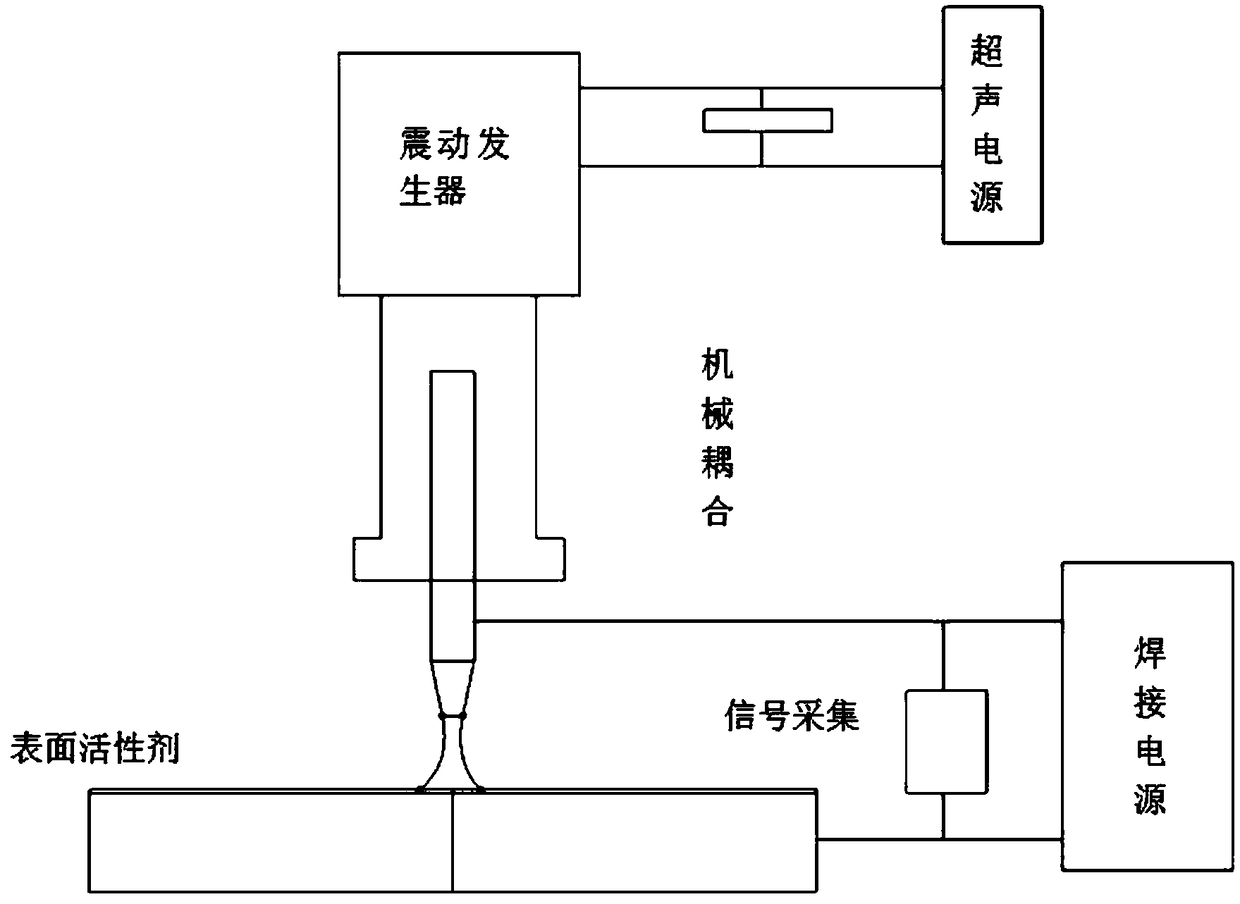

An ultrasonic arc and aluminum alloy technology, applied in arc welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of low welding efficiency, limited application of aluminum alloy plates, and inability to guarantee the welding quality of aluminum alloy thick plates. Efficiency and other issues, to achieve the effect of real-time tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

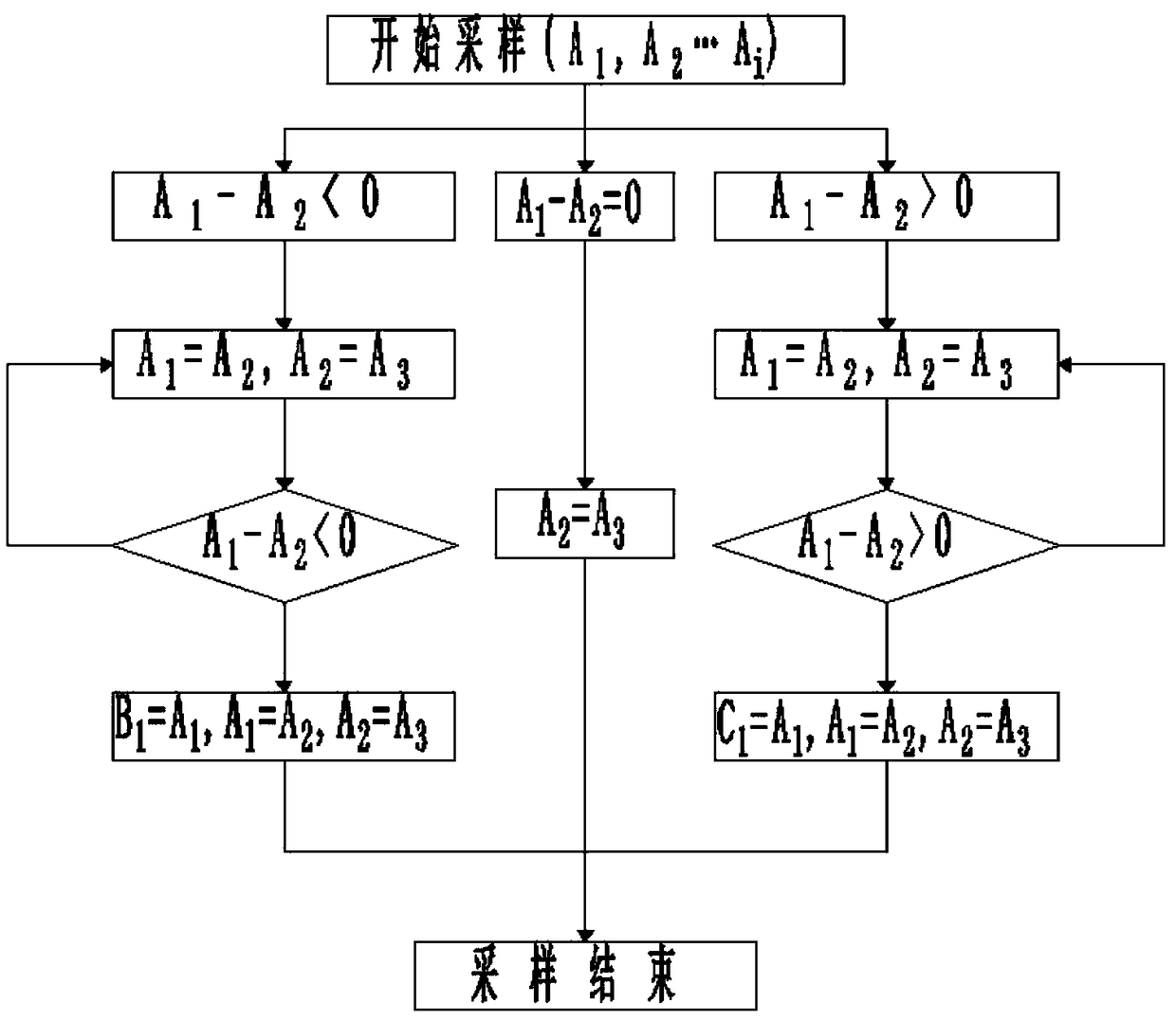

Method used

Image

Examples

Embodiment 2

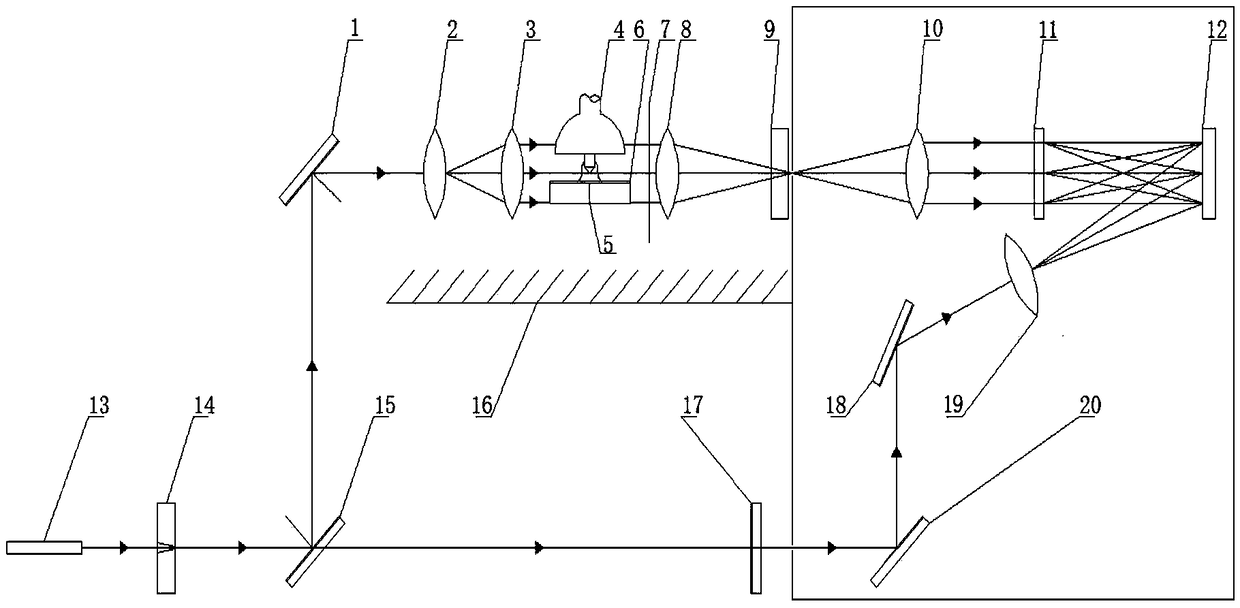

[0026] Implementation 2 The holographic experimental equipment used in this experiment is mainly composed of laser light source, anti-vibration table, optical mirror group, timing exposure device and dark box. The holographic experiment uses HB1200 He-Be laser, and the optical components involved mainly include beam splitter, reflector, expander Beam mirror and collimating lens, in order to better complete the holographic interferometric experiment of the arc plasma field, the optical path is equipped with an exposure shutter, a filter, an attenuator, an obscura, and the center of the object light and reference light path on the anti-vibration table. In addition, the object parameter angle was adjusted from 45° to 25°. Exposure was performed twice in the test (i.e., small-angle secondary exposure holographic interferometry). 3AiB, after waiting for the surrounding environment to stabilize, ignite the arc for the second exposure, the exposure time is equal to the first exposure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com