Welding method for high-strength strength weld

A technology for carrying weld seams and welding methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as low service life of the rocker arm, a large number of pores, etc., to improve welding efficiency, high-strength welding, and ensure effective fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] The high-strength load-bearing seam welding method of the present invention comprises the following steps:

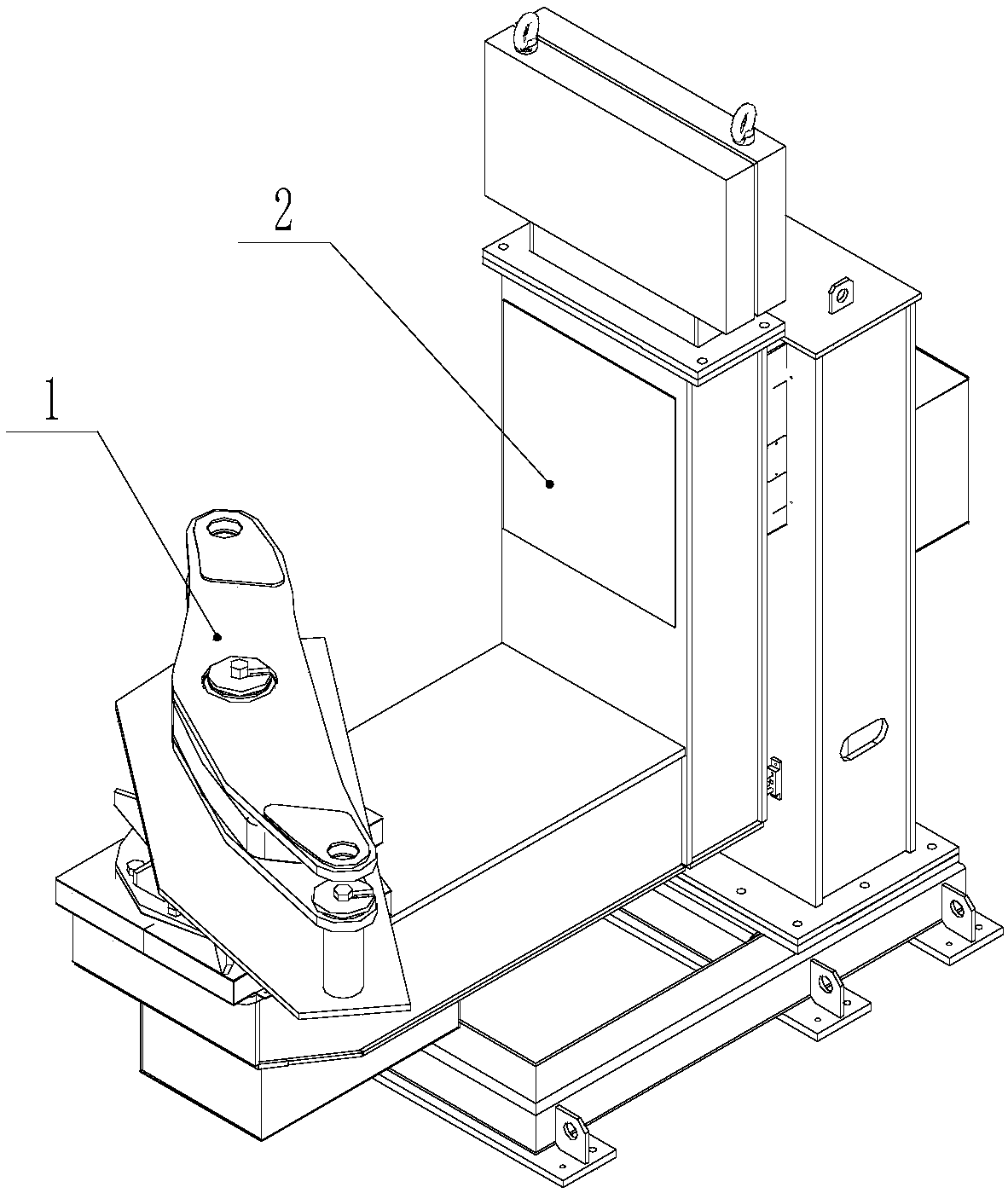

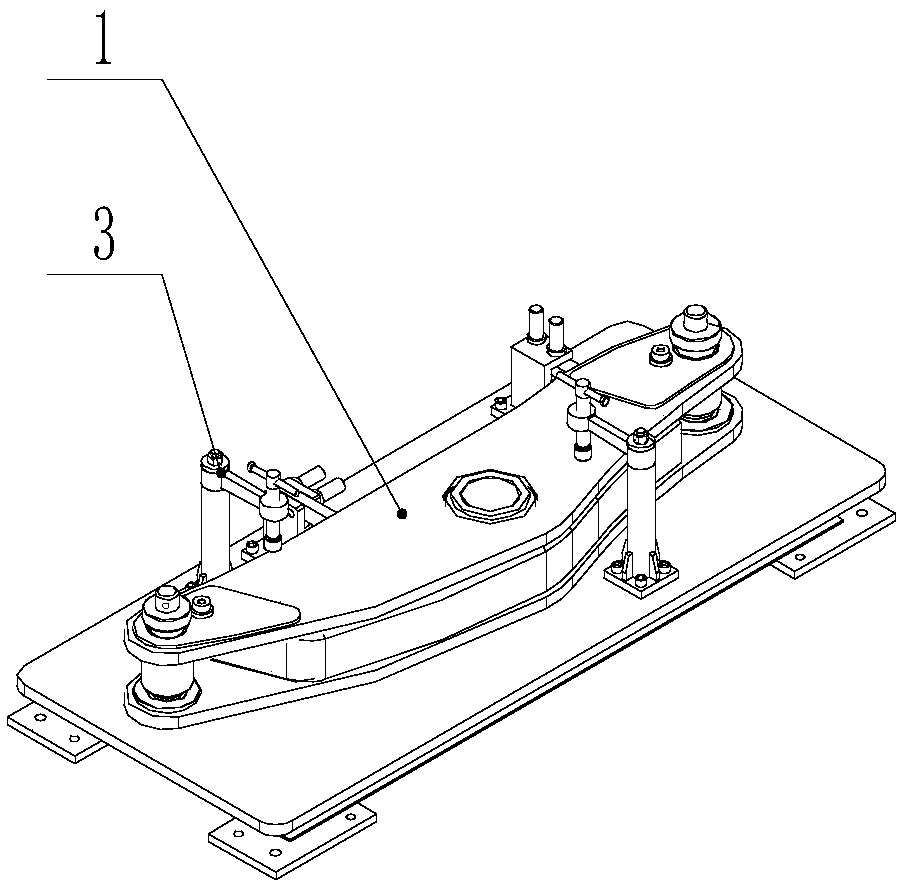

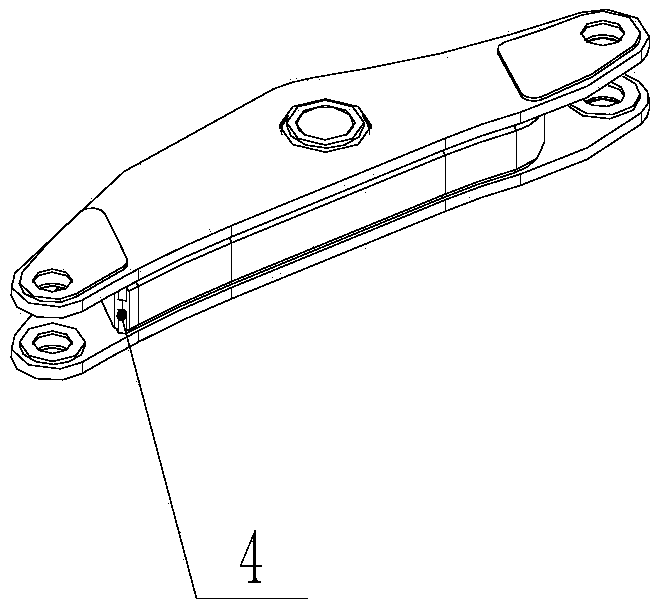

[0032] The first step: group gap adjustment, such as figure 1 , figure 2 As shown, clean the impurities and oil stains on the material surface of the rocker arm 1, accurately position each material on the assembly welding mold 2, adjust the pair gap between the materials of the rocker arm 1 to ≤1mm, and then use the assembly welding tool 2 Compress and fix the materials of the rocker arm 1;

[0033] The second step: tack welding, such as figure 1 , figure 2 As shown, turn the rocker arm 1 to weld the mold 2, perform tack welding between the materials of rocker arm 1, and fix the relative position between the materials. 300mm;

[0034] The third step: bottom welding, such as figure 1 , figure 2 As shown, the rocker arm 1 is fixed on the assembly weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com