Dual laser beam dual side simultaneous welding wire filling droplet transfer monitoring system and method based on high-speed photography

A high-speed camera and droplet transfer technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as periodic instability, unfavorable laser energy transition, etc., to improve memory usage efficiency and speed up processing speed , Reduce the effect of welding porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

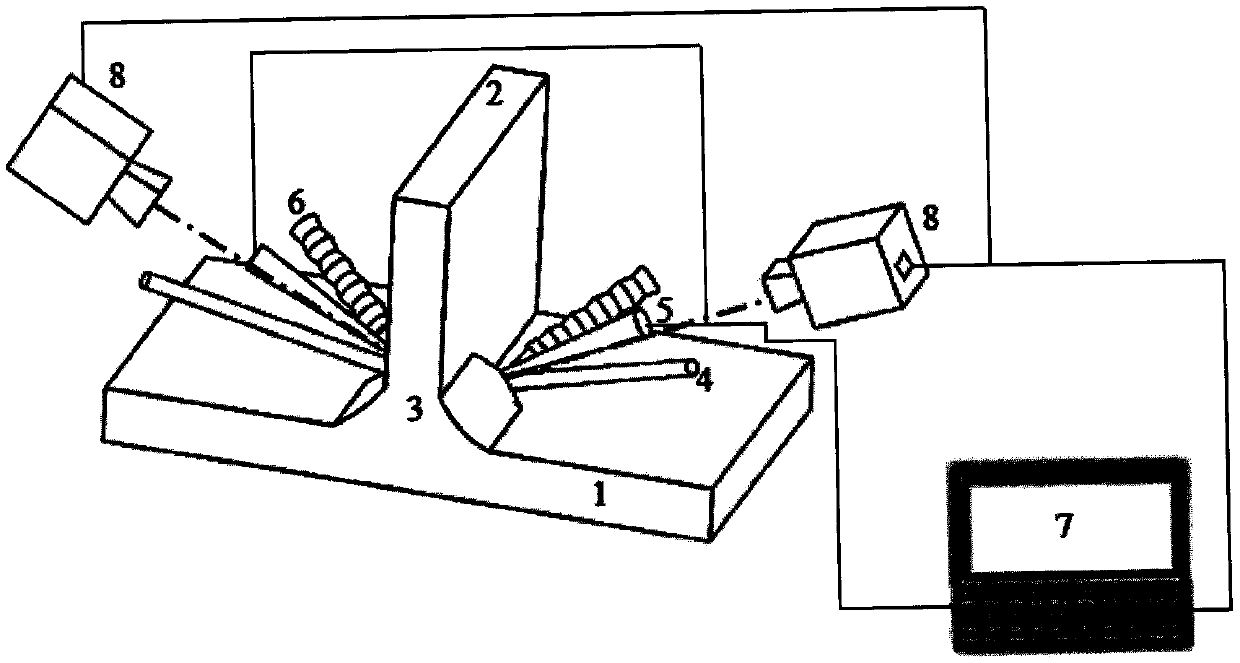

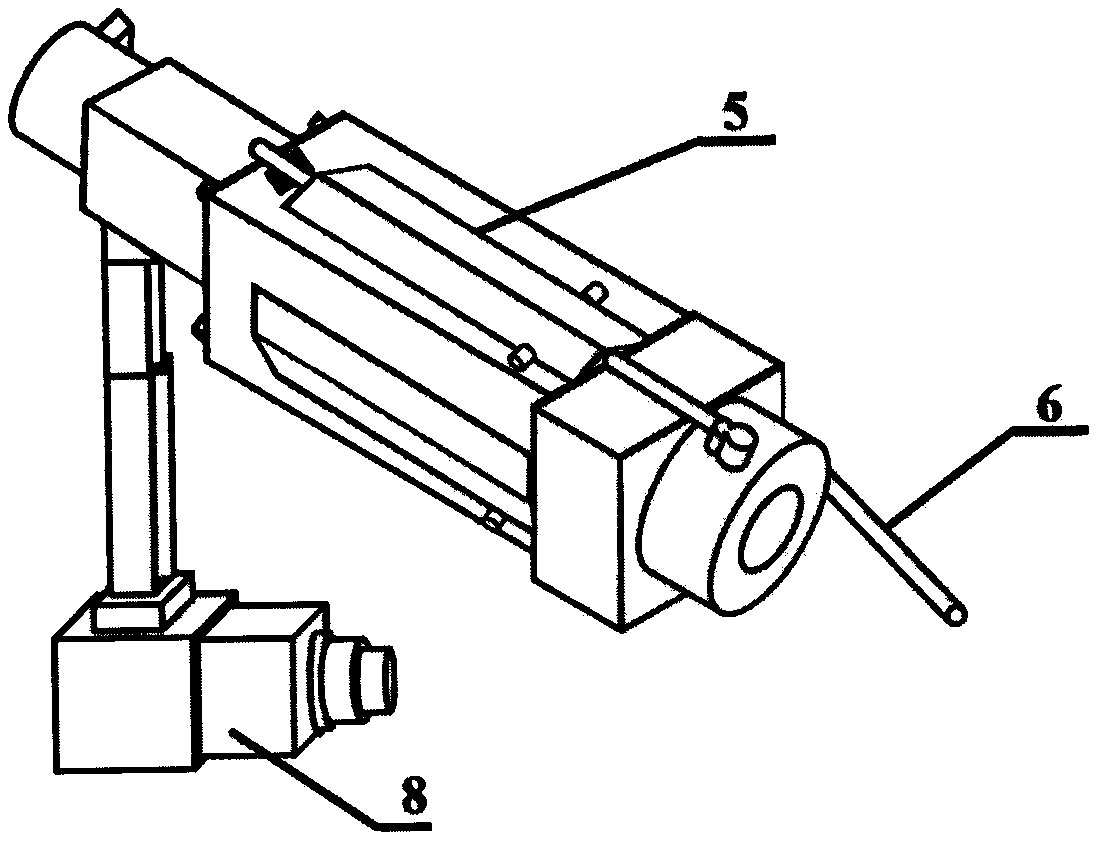

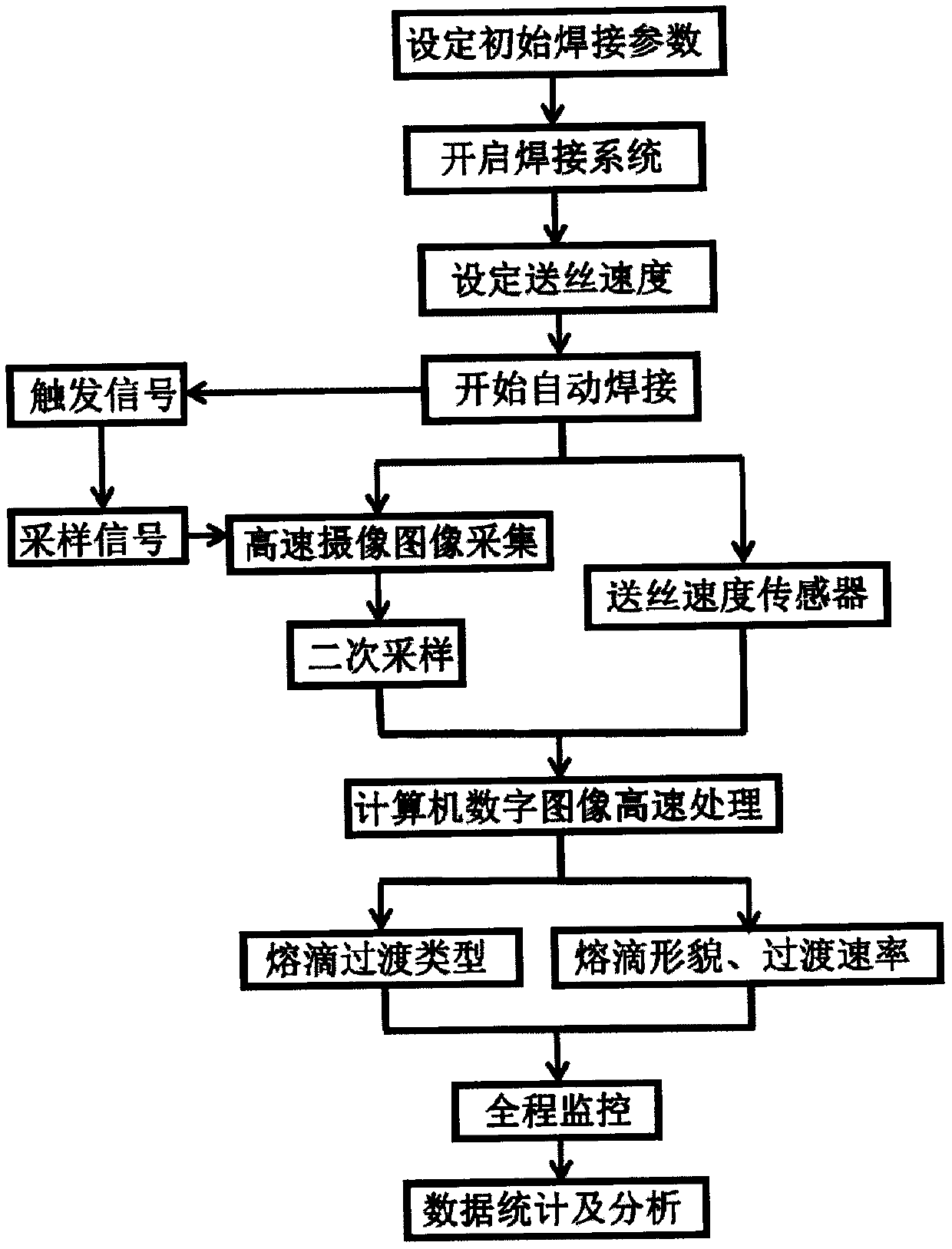

[0035] In order to further illustrate the monitoring of droplet transition of 2060 / 2099 aluminum alloy droplet transition based on high-speed imaging based on high-speed camera bilateral synchronous wire filling welding 2060 / 2099 aluminum alloy in the following with reference to the accompanying drawings and examples.

[0036] The filler material used in welding is 4047 aluminum alloy welding wire with a diameter of 1.2mm, the stringer is 2099 aluminum alloy, and the skin is 2060 aluminum alloy. During the welding process, the thickness of the skin and stringers is 2mm, the joint type is T-joint, and the relevant parameters of the laser beam are: laser power 2-10kW, welding speed 4-7m / min, wire feeding angle 20 °~55°. The droplet transfer forms of laser wire filling welding mainly include liquid bridge transition and large droplet transition. Among them, the liquid bridge transition droplet transfer is stable, and the welding speed and wire filling speed have good adaptability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com