Method for removing aluminum alloy laser welding air holes

A technology of laser welding and aluminum alloy, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., to achieve the effect of improving stability, stabilizing the welding process, and avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

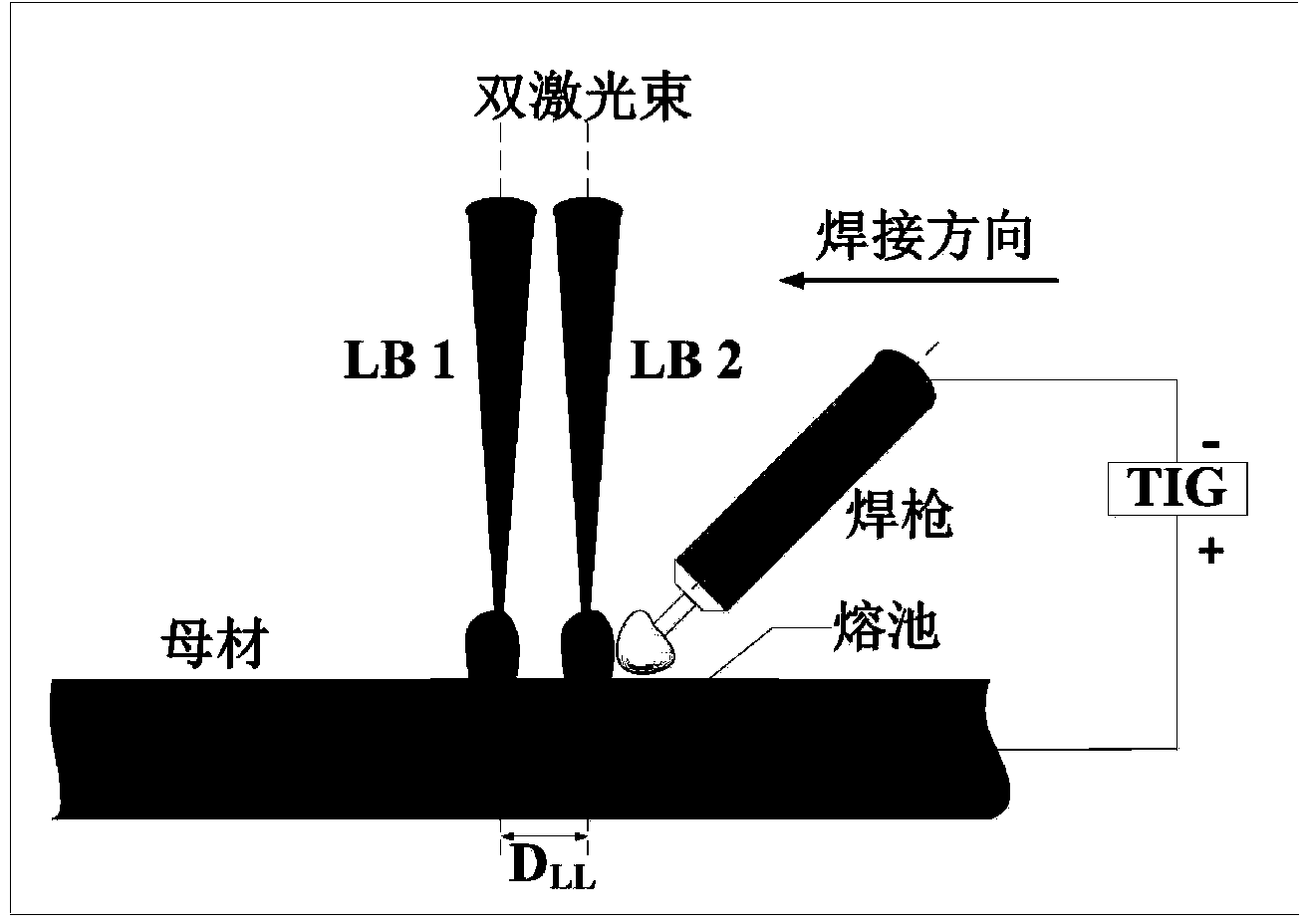

[0043] Specific implementation mode 1: A method for eliminating air holes in aluminum alloy laser welding according to this implementation mode, the specific operations are as follows:

[0044] Step 1: Before welding, grind or clean the surface of the workpiece to be welded, and fix the polished or cleaned workpiece to be welded on the welding fixture;

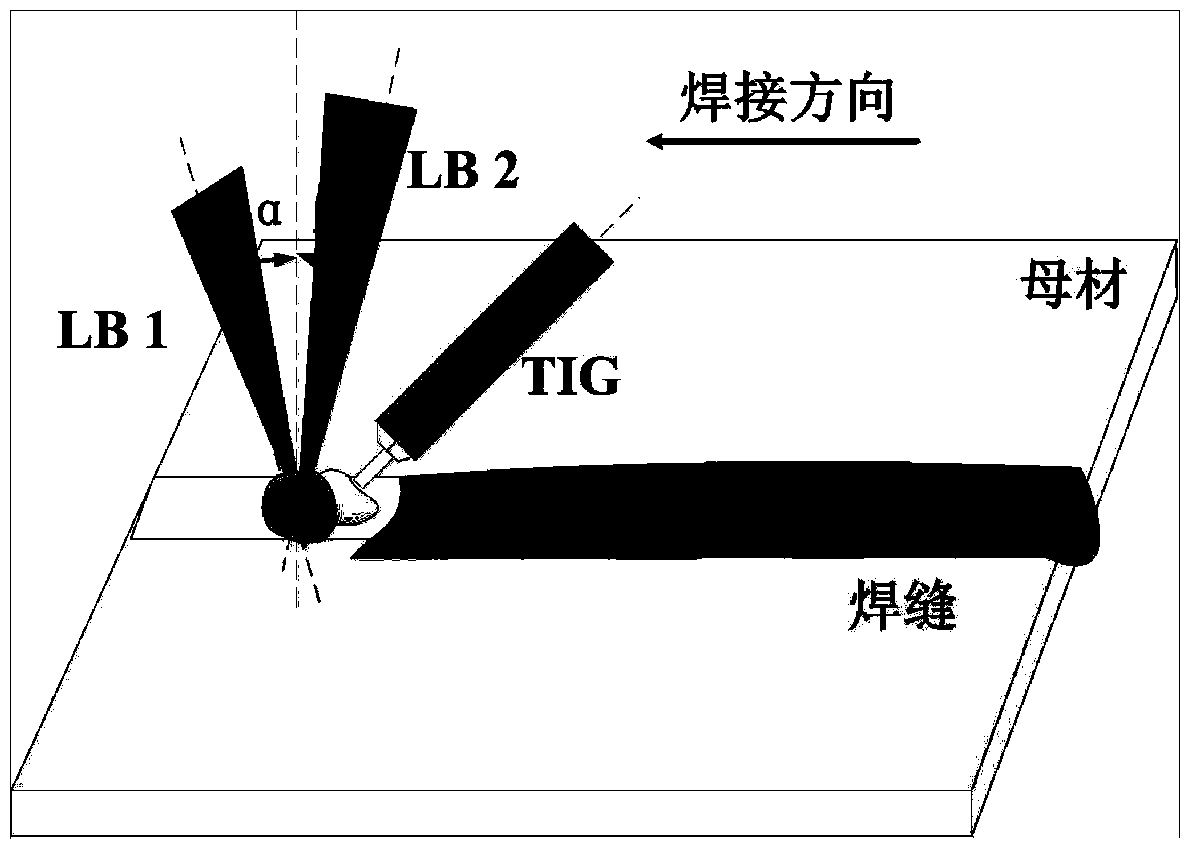

[0045] Step 2: Apply the bifocal laser and the TIG arc together on the area to be welded, set the geometric parameters: the angle between the laser beam and the vertical direction is 3°~10°, the defocus of the beam is -3mm~﹢3mm, the laser spot The diameter is 0.1~0.5mm, and the angle between the TIG welding torch and the vertical direction is 25°~55°;

[0046] Step 3: Set the welding parameters of dual-focus laser-TIG hybrid welding: the welding speed is 0.5-5m / min, the arc current is 50-150A, and the shielding gas is an inert gas;

[0047] Step 4: Start the control switch, first pass in the shielding gas, and then ignite the...

specific Embodiment approach 2

[0056] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that if the distribution of the two laser beams is a tandem distribution along the welding direction, the dual-focus laser and TIG arc welding are divided into two types: Way:

[0057] The first method (single keyhole tandem type) is: the first laser beam LB1 and the second laser beam LB2 act on the two keyholes in series at the same time, and at the same time the TIG arc is close to the second laser beam LB2 for welding; among them, The power ratio of the first laser beam LB1 to the second laser beam LB2 is (3:7)~(5:5),

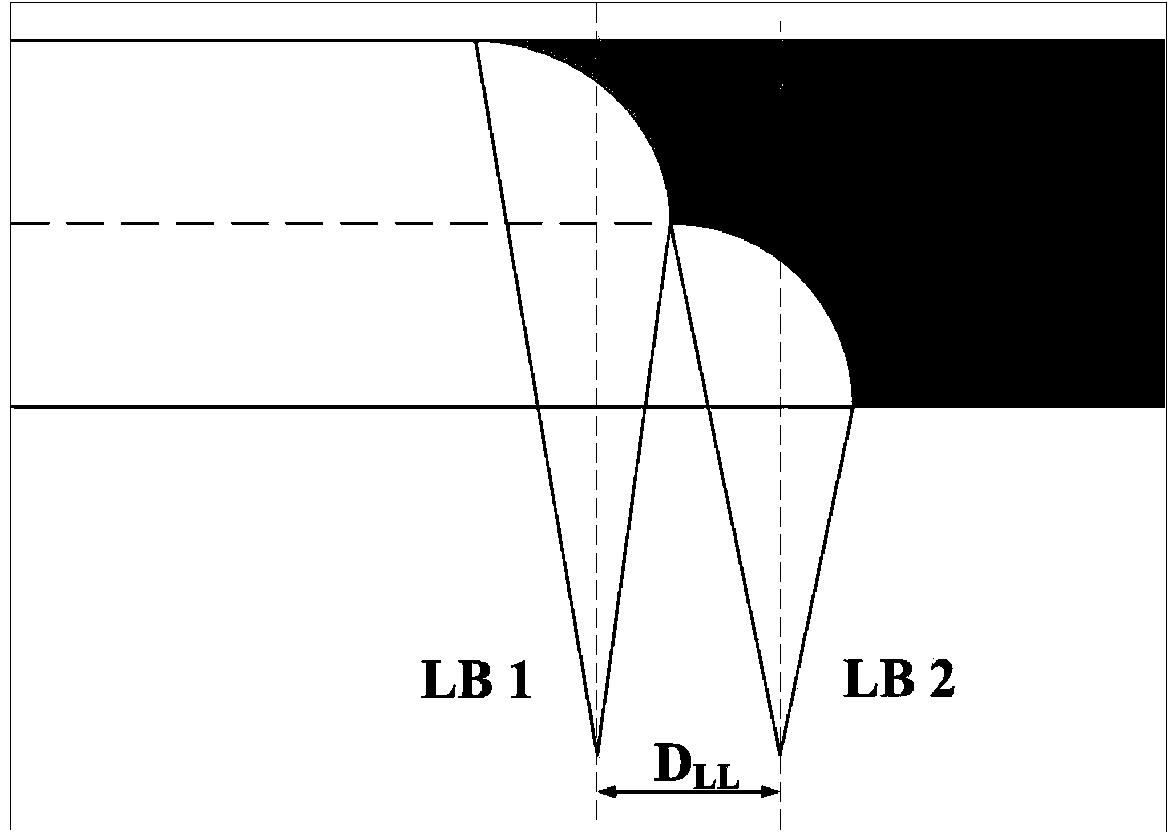

[0058] The second method (double keyhole tandem type) is: the first laser beam LB1 and the second laser beam LB2 act in series at the same time in the same keyhole, and at the same time the TIG arc is welded close to the second laser beam LB2; , the power of the first laser beam LB1 is the same as that of the second laser beam LB2. Others are the same as in th...

specific Embodiment approach 3

[0059] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: if the distribution mode of the two laser beams is a parallel distribution perpendicular to the welding direction, the first laser beam LB1 of the bifocal laser and the second beam The focus of the laser LB2 is at the same part of the weld, and the TIG arc is welded at the back side of the vertical bisector of the laser beam focus line 2-4mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com