Technological method for welding 304 stainless steel plate

A technology of 304 stainless steel and process method, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of low production efficiency, slow welding speed, large heat input of joints, etc., and achieve high production efficiency, Reduced heat input, good forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

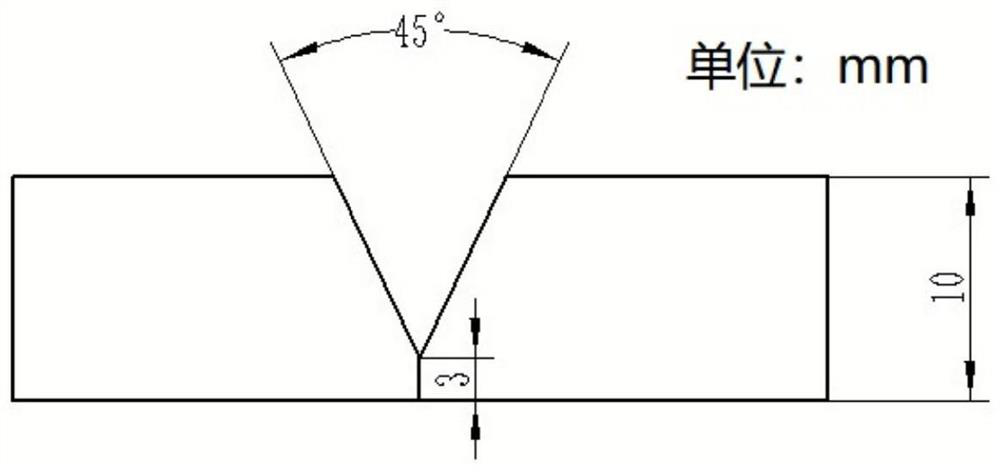

[0051] (1) 304 stainless steel plates with a thickness of 10mm are laser cut to obtain 304 stainless steel plates with a Y-shaped bevel, the thickness of the blunt side of the Y-shaped bevel is 3mm, and the angle between the double slopes is 45 °, as figure 1 shown. Then use acetone to remove the oil stain on the surface of the 304 stainless steel plate, and finally use mechanical polishing to remove the oxide film within 25mm on both sides of the joint until the metallic luster is exposed.

[0052] (2) Fix the surface-treated 304 stainless steel plate on a device with protective gas, and adjust the angle between the laser emitted by the laser and the 304 stainless steel plate to be 80°, and control the laser inclination direction to be consistent with the welding direction.

[0053] (3) Bottom welding: first set the laser parameters and MIG welding parameters, the laser power is 5000W, the defocus is 0mm, the distance between the light wires is 1.5mm, the welding speed is 32m...

Embodiment 2

[0056] (1) 304 stainless steel plates with a thickness of 10mm are laser cut to obtain 304 stainless steel plates with a Y-shaped bevel, the thickness of the blunt side of the Y-shaped bevel is 3mm, and the angle between the double slopes is 45 °, as figure 1 shown. Then use acetone to remove the oil stain on the surface of the 304 stainless steel plate, and finally use mechanical polishing to remove the oxide film within 25mm on both sides of the joint until the metallic luster is exposed.

[0057] (2) Fix the surface-treated 304 stainless steel plate on a device with a protective gas on the back, and adjust the angle between the laser emitted by the laser and the 304 stainless steel plate to be 80°, and control the inclination direction of the laser to be consistent with the welding direction.

[0058] (3) Bottom welding: first set the laser parameters and MIG welding parameters, the laser power is 4000W, the defocus is 0mm, the distance between the light wires is 1.5mm, the...

Embodiment 3

[0061] (1) 304 stainless steel plates with a thickness of 10mm are laser cut to obtain 304 stainless steel plates with a Y-shaped bevel, the thickness of the blunt side of the Y-shaped bevel is 3mm, and the angle between the double slopes is 45 °, as figure 1 shown. Then use acetone to remove the oil stain on the surface of the 304 stainless steel plate, and finally use mechanical polishing to remove the oxide film within 25mm on both sides of the joint until the metallic luster is exposed.

[0062] (2) Fix the surface-treated 304 stainless steel plate on a device with protective gas, and adjust the angle between the laser emitted by the laser and the 304 stainless steel plate to be 80°, and control the laser inclination direction to be consistent with the welding direction.

[0063] (3) Bottom welding: first set the laser parameters and MIG welding parameters, the laser power is 6000W, the defocus is 0mm, the distance between the light wires is 1.5mm, the welding speed is 40m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com