Back shielding gas introducing device and method for laser-MIG hybrid welding of high-strength aluminum alloy

A composite welding and shielding gas technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor back forming and easy generation of pores, so as to reduce weld porosity, improve back forming and welding efficiency The effect of improving the quality of the weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, scheme and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with schematic diagrams of the device and specific embodiments. The embodiments described below are only used to explain the present invention, and the present invention is not limited to this application way.

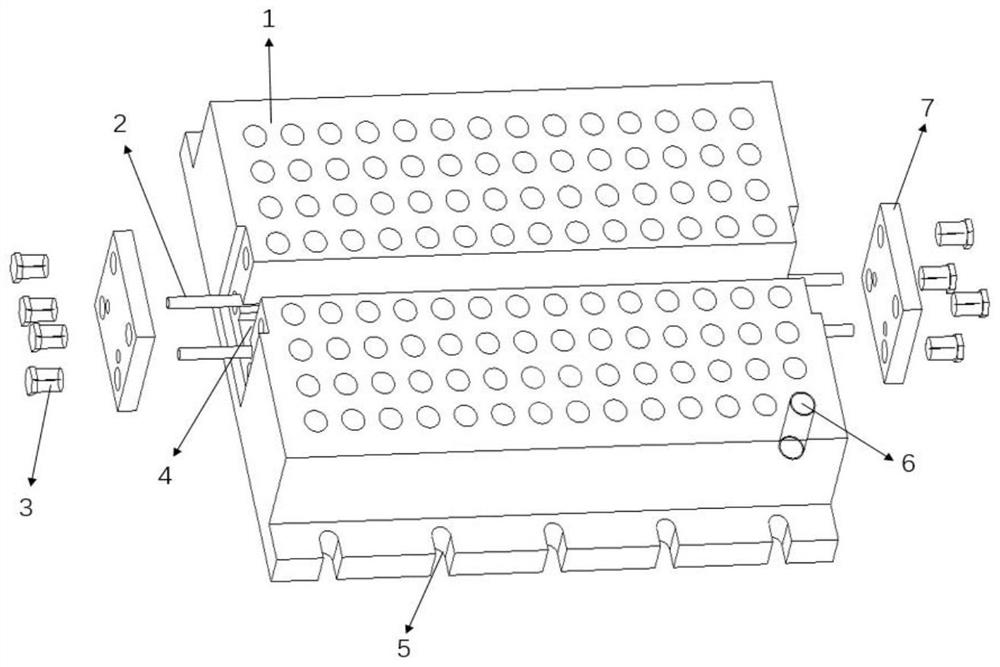

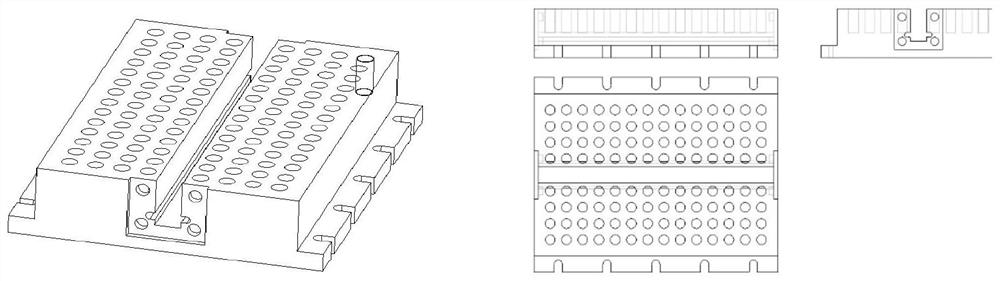

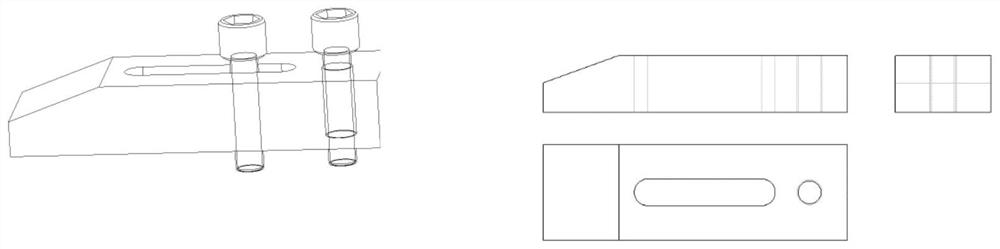

[0044] An aluminum alloy laser-MIG composite welding back-pass protective gas device includes a workpiece table 1, a gas-guiding copper pipe 2, a fixing bolt 3, a copper backing plate 4, and a baffle plate 7. The air guide copper pipe 2 is symmetrically placed on both sides of the workpiece table; the copper backing plate 4 is placed in the groove of the workpiece table;

[0045] The workpiece table 1 has a size of 1.6m*1m*0.6m, and its material is 304 stainless steel.

[0046] The front of the workpiece table 1 is a working surface for placing materials to be welded, and the front is provided with a thread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com