Nanometer welding paste and preparation method and welding method thereof

A technology of nano-welding and nano-copper powder, which is applied in welding media, welding equipment, welding equipment, etc., can solve problems such as welding failure and lower welding quality, and achieve the effects of increased shear strength, improved welding quality, and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

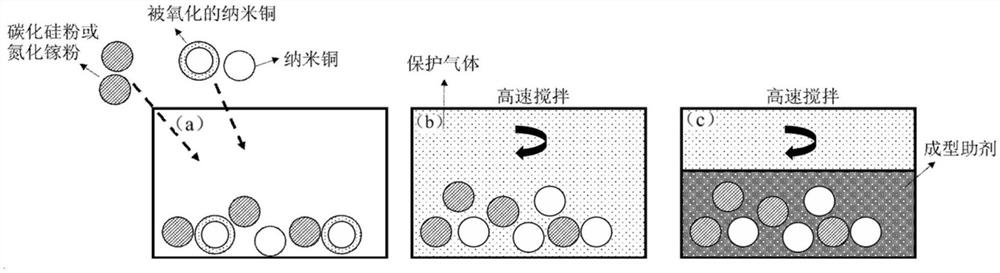

[0053] The present invention also provides a method for preparing the nano-solder paste described in the above-mentioned technical solution, comprising the following steps:

[0054] a) under protective gas conditions, silicon carbide powder / gallium nitride powder and nano-copper powder are mixed to obtain a mixed powder;

[0055] b) under the condition of protective gas, the obtained mixed powder is mixed with a molding aid to obtain a nano-solder paste.

[0056] Wherein, the types and dosages of the silicon carbide powder / gallium nitride powder, nano-copper powder, and forming aids are consistent with those described in the above technical solution, and will not be repeated here. The present invention has no particular limitation on the type of the protective gas, and it can be an inert gas well known to those skilled in the art, such as nitrogen, helium or argon.

[0057] In the step a), the mixing is preferably high-speed stirring and mixing, and the speed is preferably 50...

Embodiment 1

[0072] 1.1 Preparation of solder paste

[0073] Under the protection of argon, 5 parts of nano-copper powder and 4 parts of silicon carbide powder were stirred and mixed at a high speed at 200 rpm for 10 minutes to obtain a mixed powder.

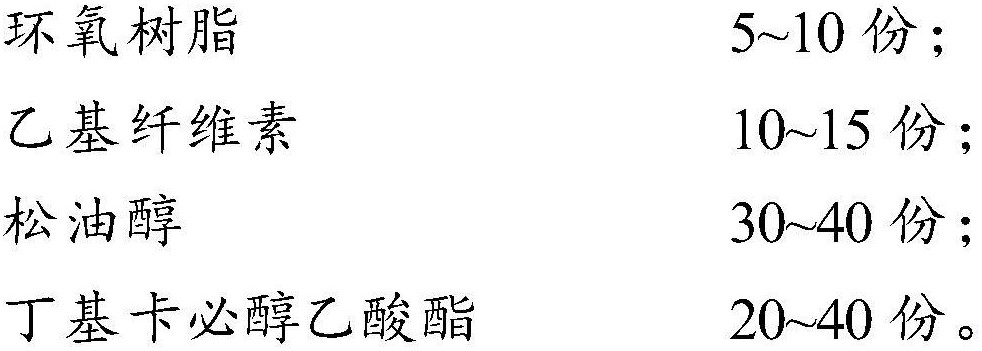

[0074] Mix 7 parts of epoxy resin (the brand is NC-3000), 11 parts of ethyl cellulose, 35 parts of terpineol and 30 parts of butyl carbitol acetate to obtain a molding aid.

[0075] Under the protection of argon, 9 parts of the above mixed powder and 1 part of forming aid were stirred and mixed at a high speed at a speed of 200 rpm for 30 minutes to obtain a nano-solder paste.

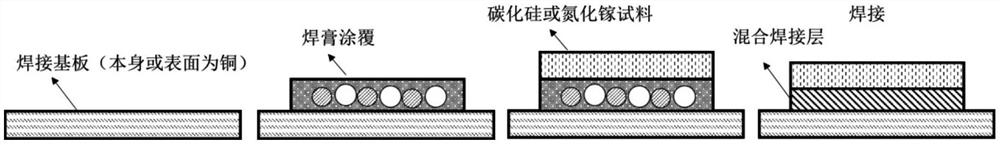

[0076] The above preparation process can be found in figure 1 , figure 1 It is a schematic flow chart of the preparation process of the solder paste in Example 1 of the present invention, wherein, figure 1 a is a schematic diagram of raw materials, figure 1 b is a schematic diagram of powder mixing, figure 1 c is a schematic diagram of powder-liquid mixing.

[...

Embodiment 2~4

[0080] Embodiment 2~4, comparative example 1

[0081] 1.1 Preparation of solder paste

[0082] Examples 2-4: The solder paste preparation process of Example 1 was followed, except that the ratio of raw materials was different. For the ratio of raw materials in each embodiment, refer to Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com