Ultrahigh-power double-beam laser-high-frequency pulse deep penetration TIG composite welding method for thick plate

A high-frequency pulse, composite welding technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of serious porosity and crack tendency, thick weld structure, large heat-affected zone, etc., and achieve welding spatter Small size, few welding defects, large effect area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

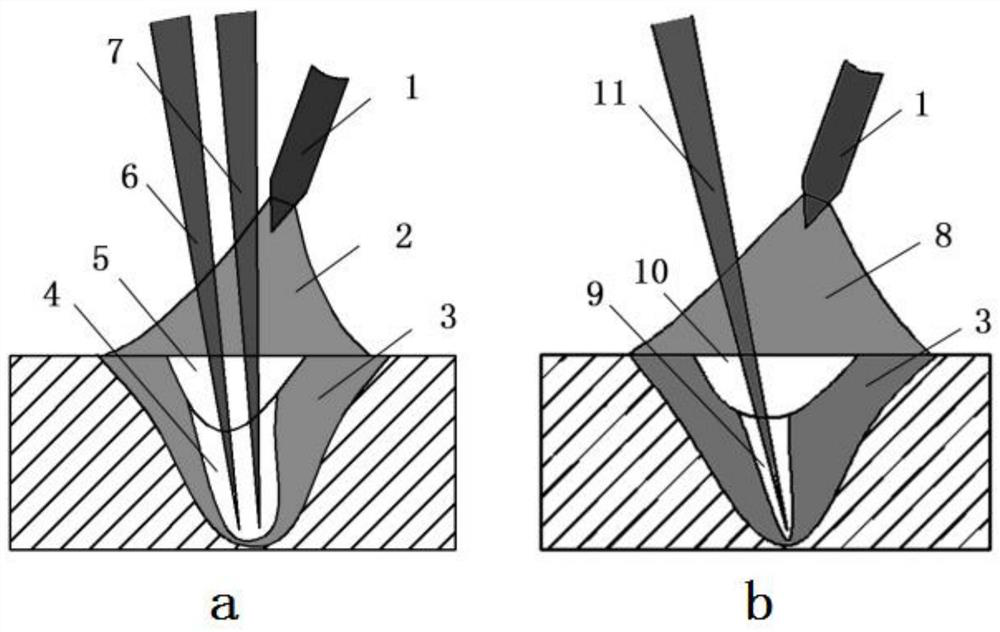

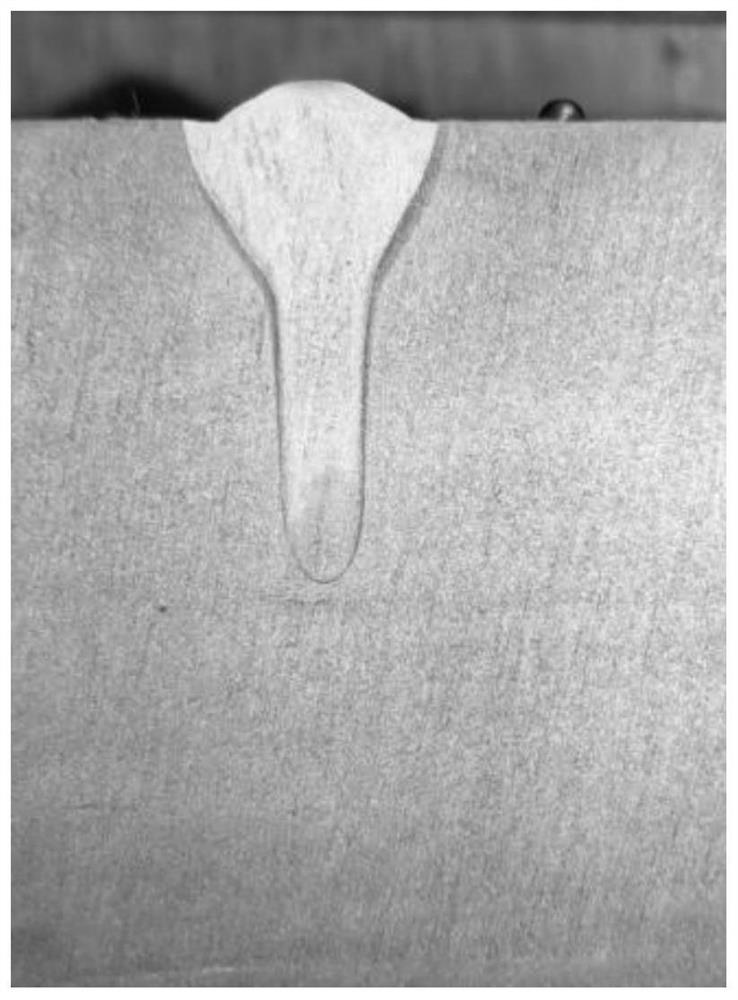

[0038] Embodiment 1 (see figure 1 a): In this embodiment, a double-beam laser-high-frequency pulse deep-penetration TIG composite welding method for thick plates is carried out according to the following steps:

[0039] S1: Grind the groove and surface of the thick plate to be welded (low carbon steel plate of 300mm×150mm×40mm), and then set the thick plate to be welded into a butt joint and fix it;

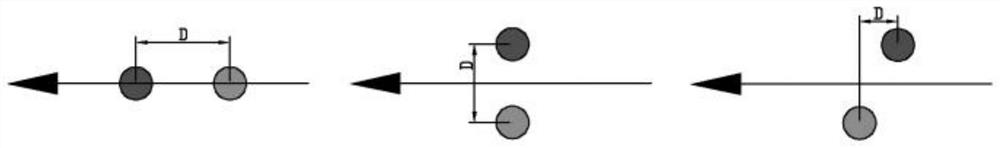

[0040] S2: Set the angle of the laser head and TIG welding torch, the angle between the laser head and the normal direction of the surface of the thick plate to be welded is 15°, the angle between the laser head and the TIG welding torch is 30°, and the distance between the tip of the TIG welding torch and the tungsten electrode to be welded is thick The distance between the midpoints of the centerlines of the two laser spots on the surface of the plate workpiece is 1.5mm;

[0041]S3: Set the parameters of ultra-high-power dual-beam laser-high-frequency pulse deep-penetration TI...

Embodiment 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the total output power of the double-beam laser is 20KW, and the power ratio of the double-beam laser is 1:1. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com