Narrow-gap laser circular oscillation motion filler wire welding method for aluminum alloy thick-wall component

A technology of oscillating motion and welding method, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unfused and welding porosity, and achieve reduced weld porosity, enhanced stability, and joint quality stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

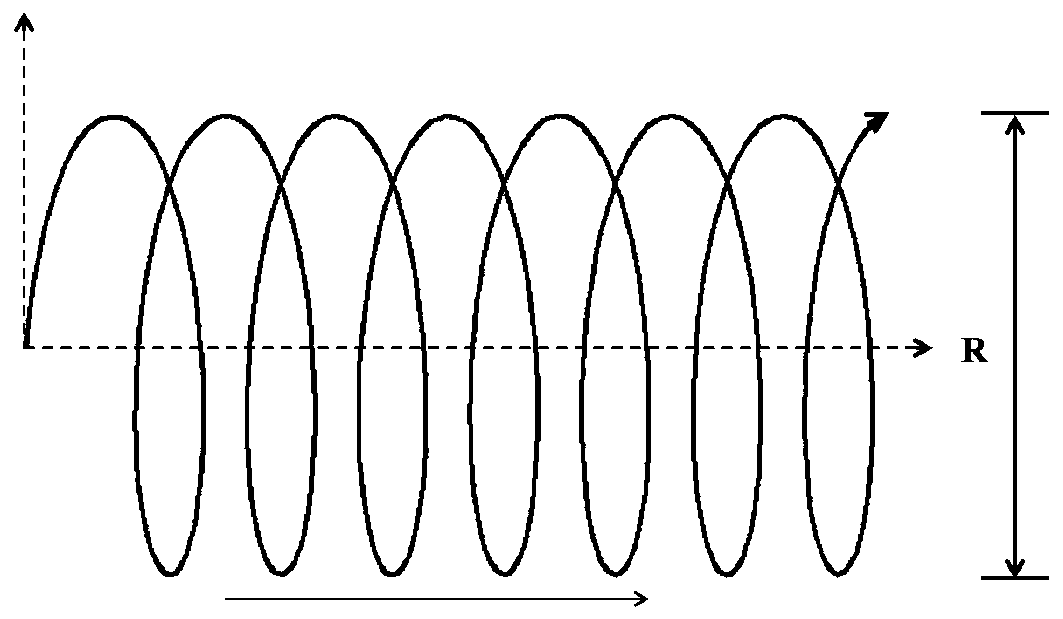

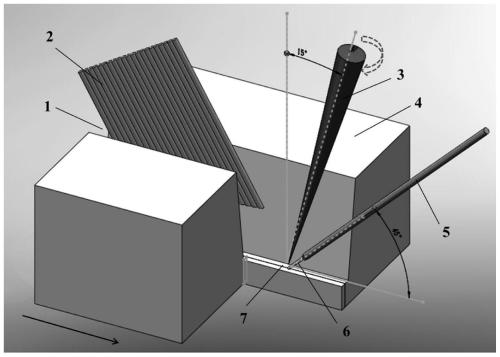

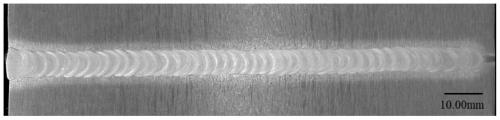

[0024] Specific embodiment one (refer to the attached figure 1 And figure 2 ): A narrow gap laser circular oscillation motion filler wire welding method for aluminum alloy thick-walled components of this embodiment. During welding, the emitting end of the laser beam 3 acts on the end of the area to be welded around the laser beam 3 for circular oscillation motion , The laser beam 3 enters the narrow gap groove 1 with a circular oscillating motion track and acts on the area to be welded 7 to form a welding pool. Filling the welding wire 6 into the molten pool by feeding the wire before, in the laser heating and molten pool heat radiation Melt under common action, and realize the connection of aluminum alloy thick-walled member 4 by single-pass multi-layer filling method;

[0025] The specific welding parameters are as follows:

[0026] The aluminum alloy thick-walled member 4 is 5A06 rust-proof aluminum alloy with a thickness of 130mm;

[0027] The width of the lower end of the narr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com