A kind of laser welding method of stainless steel-titanium alloy dissimilar metals

A technology of dissimilar metals and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory joint connection performance, high welding cost, long welding time, etc., and achieve stable laser welding process and smooth welding Good process performance and beautiful weld shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

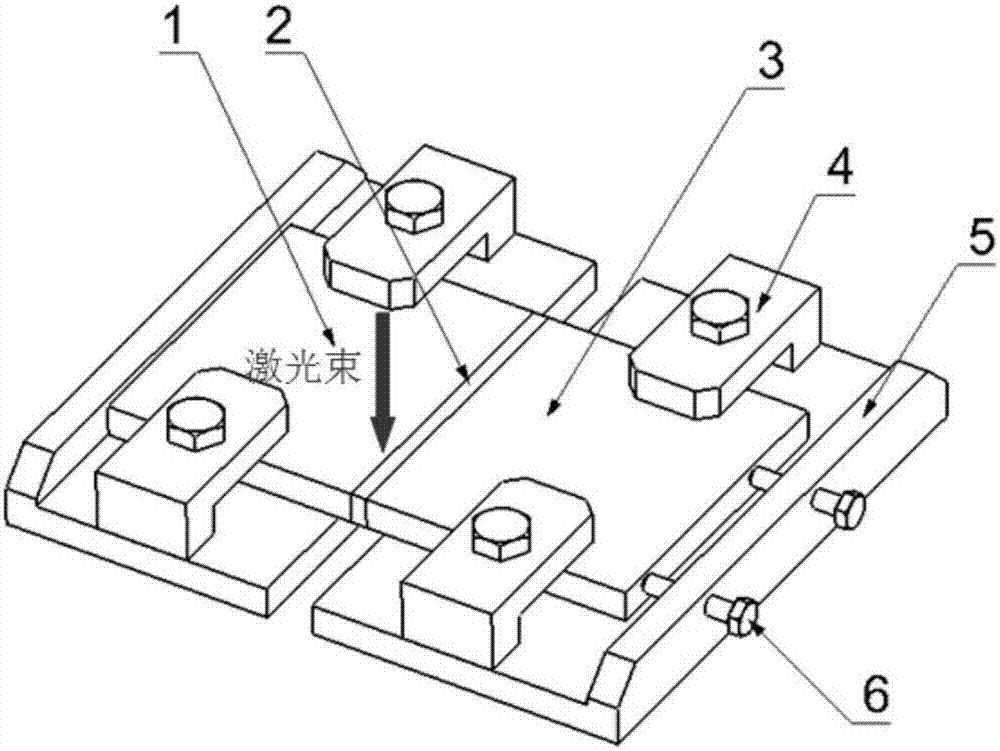

[0032] like figure 1 , adopt the method of the present invention to carry out the welding of stainless steel-titanium alloy dissimilar metals, at first stainless steel 3 and titanium alloy 1 are clamped on the welding positioning platform 5 with pressing plate 4; Place thickness between stainless steel 3 and titanium alloy 1 is 0.5~1.5 mm thick niobium intermediate layer 2, and maintain a certain pressure between the stainless steel-niobium-titanium alloy by adjusting the pre-tightening screw 6.

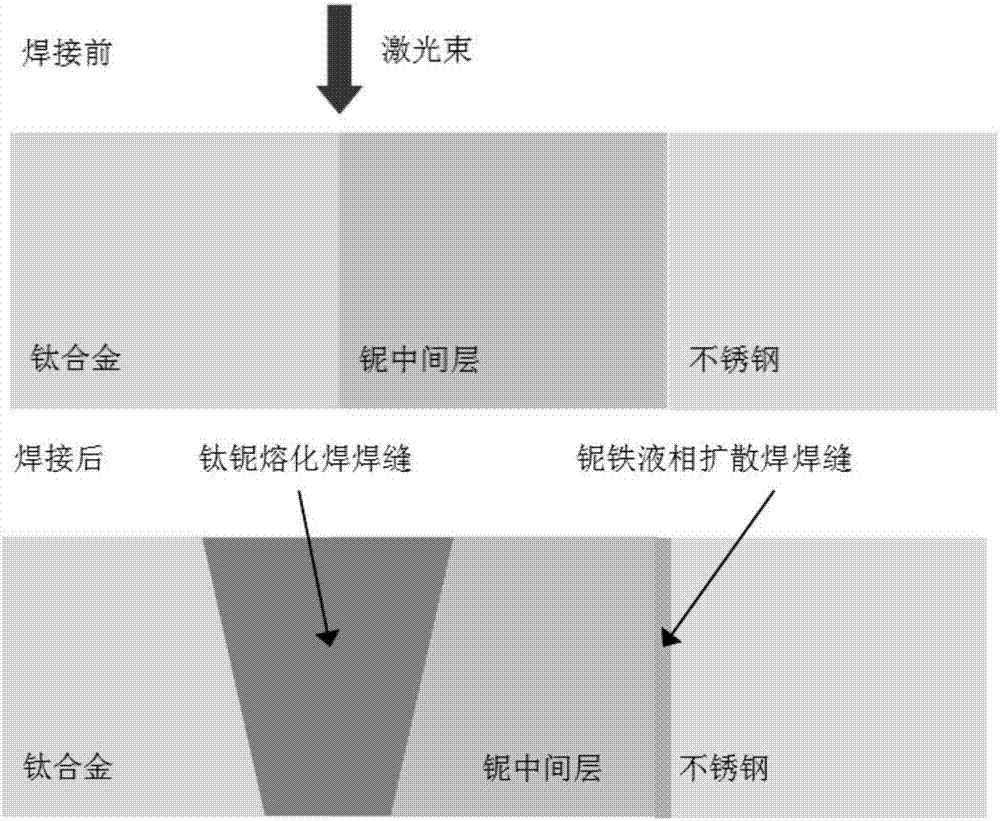

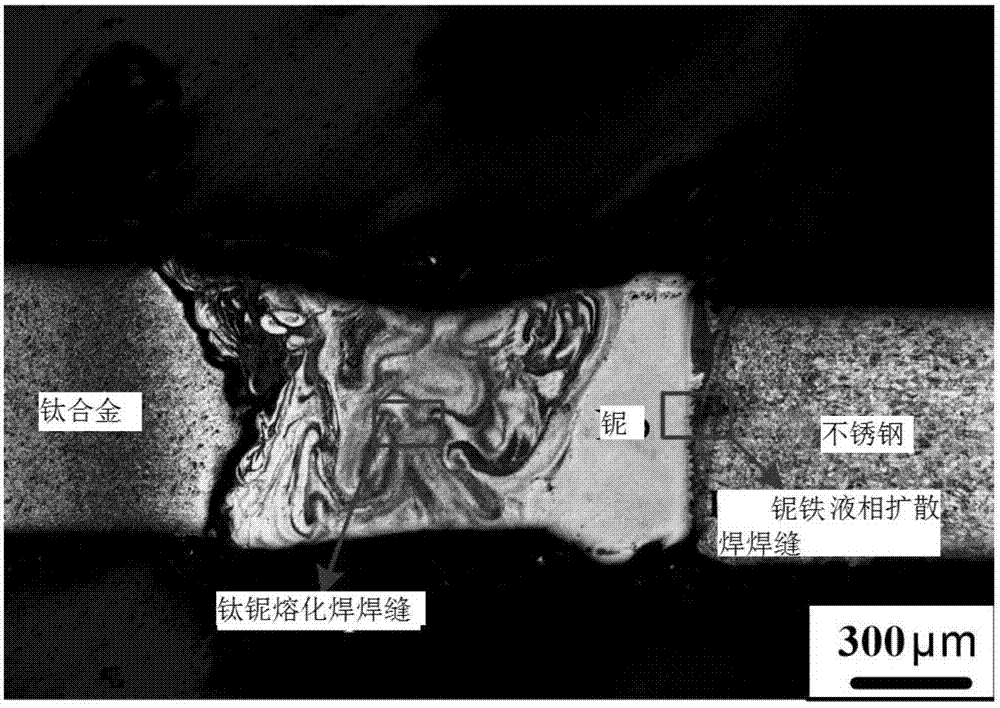

[0033] like figure 2 When welding, the focus of the laser spot is set on the titanium alloy, at a distance of 0-2 mm from the titanium-niobium contact surface, so that the titanium and niobium metals are melted to form a titanium-niobium fusion welding seam; under the heat conduction of the niobium intermediate layer, the niobium -The temperature near the stainless steel contact surface reaches the eutectic temperature of niobium and iron at 1373°C, and a liquid phase is formed; du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com