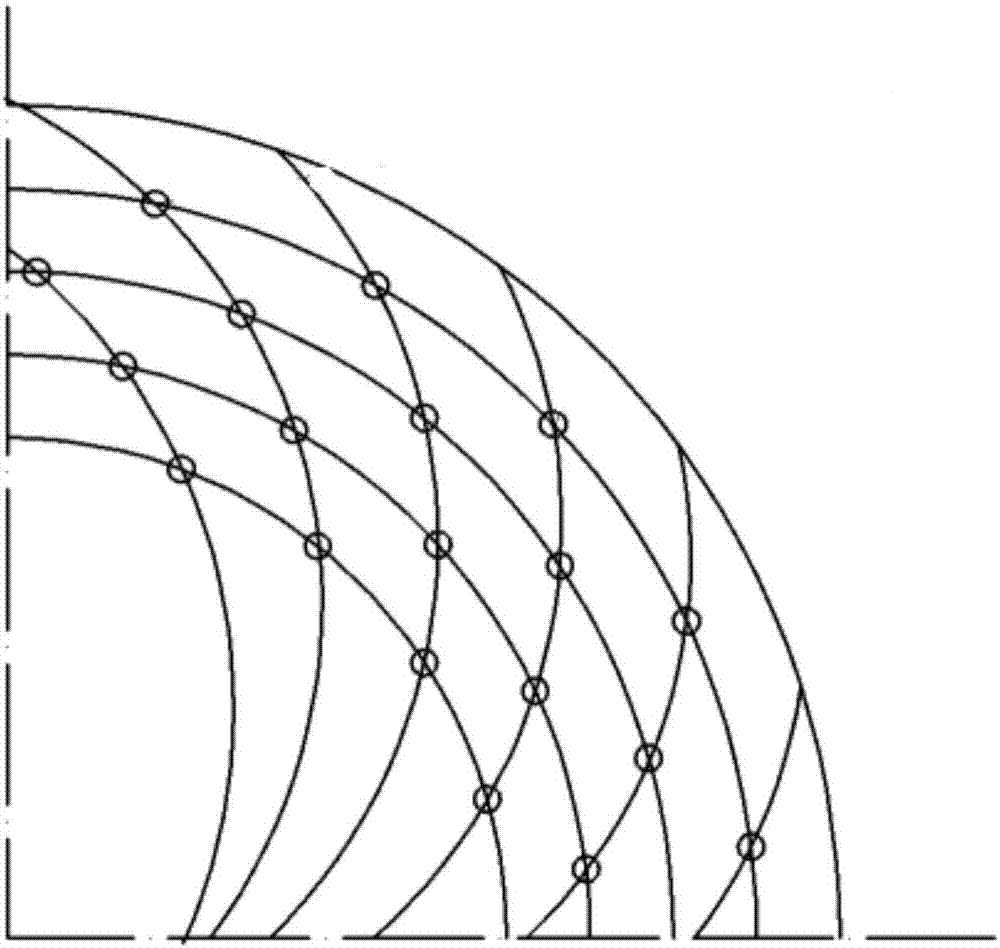

Diamond spiral locating and distribution ultrathin layer composite saw blade and manufacturing technology thereof

A helical and diamond technology, which is applied in the field of diamond helical positioning and distribution of ultra-thin layer composite saw blades and its manufacturing process, can solve the problems of high cutting resistance, hindering the development of cutting processing technology, and limiting the use range of diamond saw blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Diamond helically positioned and distributed ultra-thin layer composite saw blade, the saw blade diameter is Φ500mm, the ultra-thin slice size of the working layer in the node block: length × height × thickness = 40mm × 10mm × 0.3mm; the ultra-thin slice size of the isolation layer: length × Height × thickness = 40mm × 10mm × 0.2mm, each block contains 7 layers of working layer ultra-thin slices and 6 layers of isolation layer ultra-thin slices, the size of the saw blade segment is length × height × thickness = 40mm × 10mm × 3.3mm .

[0033] Working layer ultra-thin sheet carcass formula mass ratio: cobalt powder-55%, nickel powder-10%, iron powder-5%, titanium powder-2%, chromium powder-3%, copper powder-20%, tin powder- 5%, the particle size of the powder is 325 mesh (45 microns) or finer; the diamond volume concentration is 8%, and the particle size is 80 / 100 mesh (150-178 microns).

[0034] The mass ratio of the ultra-thin sheet formulation of the isolation layer: ...

Embodiment 2

[0044]Diamond helically positioned and distributed ultra-thin layer composite saw blade, the diameter of the saw blade is Φ1600mm, the size of the ultra-thin slice of the working layer in the block: length × height × thickness = 24mm × 12mm × 0.4mm; the size of the ultra-thin slice of the isolation layer: length × Height × thickness = 24mm × 10mm × 0.2mm, each block contains 17 layers of working layer ultra-thin slices and 16 layers of isolation layer ultra-thin slices, the size of the saw blade segment is length × height × thickness = 24mm × 12mm × 10mm.

[0045] Working layer ultra-thin sheet carcass formula mass ratio: cobalt powder-45%, nickel powder-15%, iron powder-10%, titanium powder-2%, chromium powder-3%, copper powder-20%, tin powder- 5%, the particle size of the powder is 325 mesh (45 microns) or finer; the diamond volume concentration is 8%, and the particle size is 40 / 60 mesh (380-250 microns).

[0046] The mass ratio of the ultra-thin sheet formulation of the is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com