Tower-type wind power station structure

A tower-type, wind-powered engine technology, applied in wind turbine components, wind power generation, wind engines, etc., can solve the problems of insufficient installation density of wind engines, inability to be fully developed and utilized, unsatisfactory site utilization efficiency, etc., to shorten the power consumption The effect of exporting wires, reducing maintenance and management costs, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

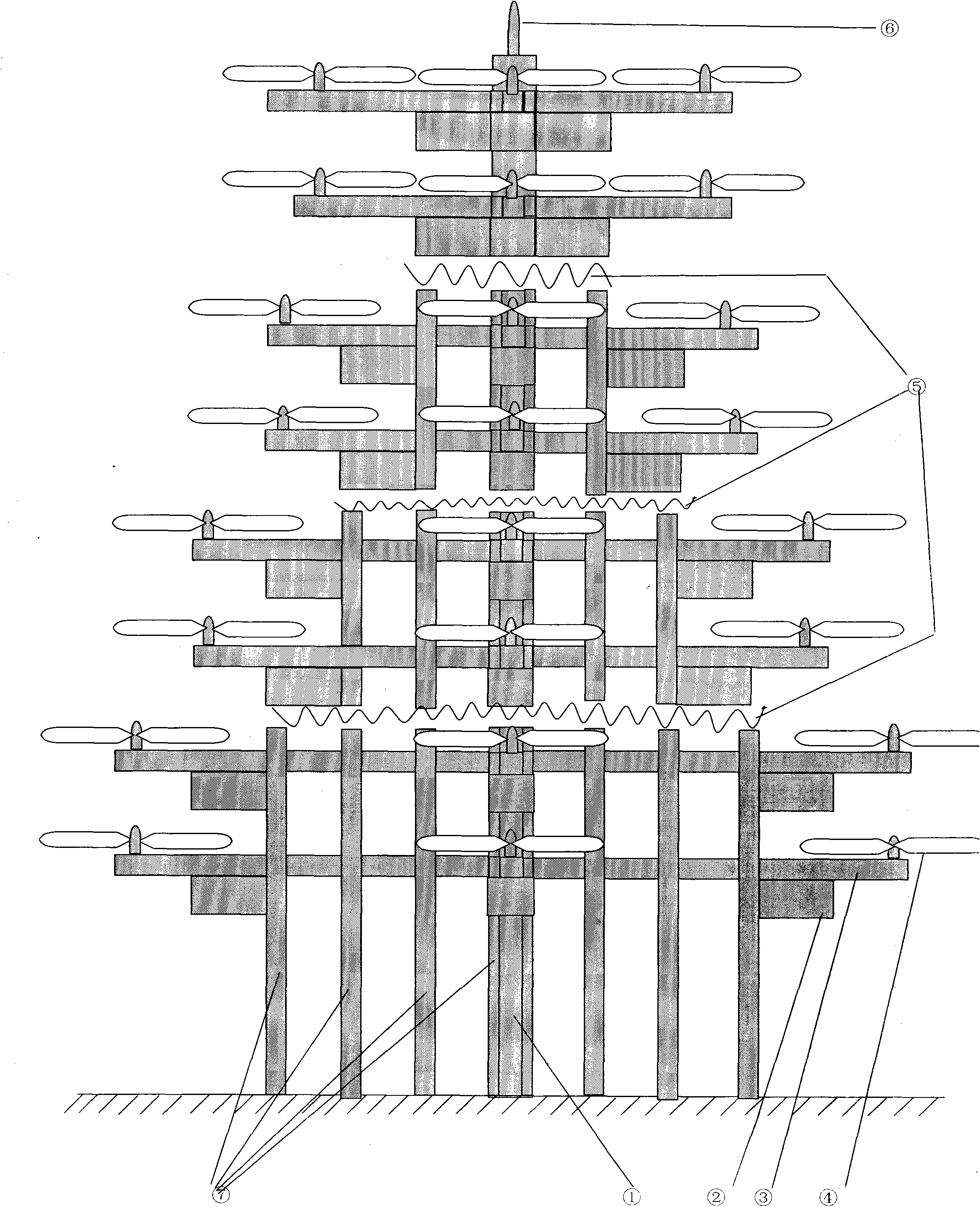

[0054] Embodiment 1 is based on the premise of better geographical, geological and wind energy conditions

[0055] For wind turbine selection, products with large models, large specifications, and mature technologies are preferred.

[0056] The height of the tower is designed according to the ideal height that can be achieved by the existing technology.

[0057] Tower pillars Construct 6 vertical cylindrical load-bearing columns whose diameters gradually shrink from bottom to top, distributed to form a regular hexagon, forming the innermost layer of the tower pillars, whose height is the total elevation of the main body of the tower. Then take the two load-bearing columns on the same side as the starting point, and with the same spacing width, radially outward, and build a certain amount of load-bearing columns in pairs from the inside to the outside at a certain distance, and the height is determined by the inner layer It is lowered outward in stages, and the innermost load-...

Embodiment 2

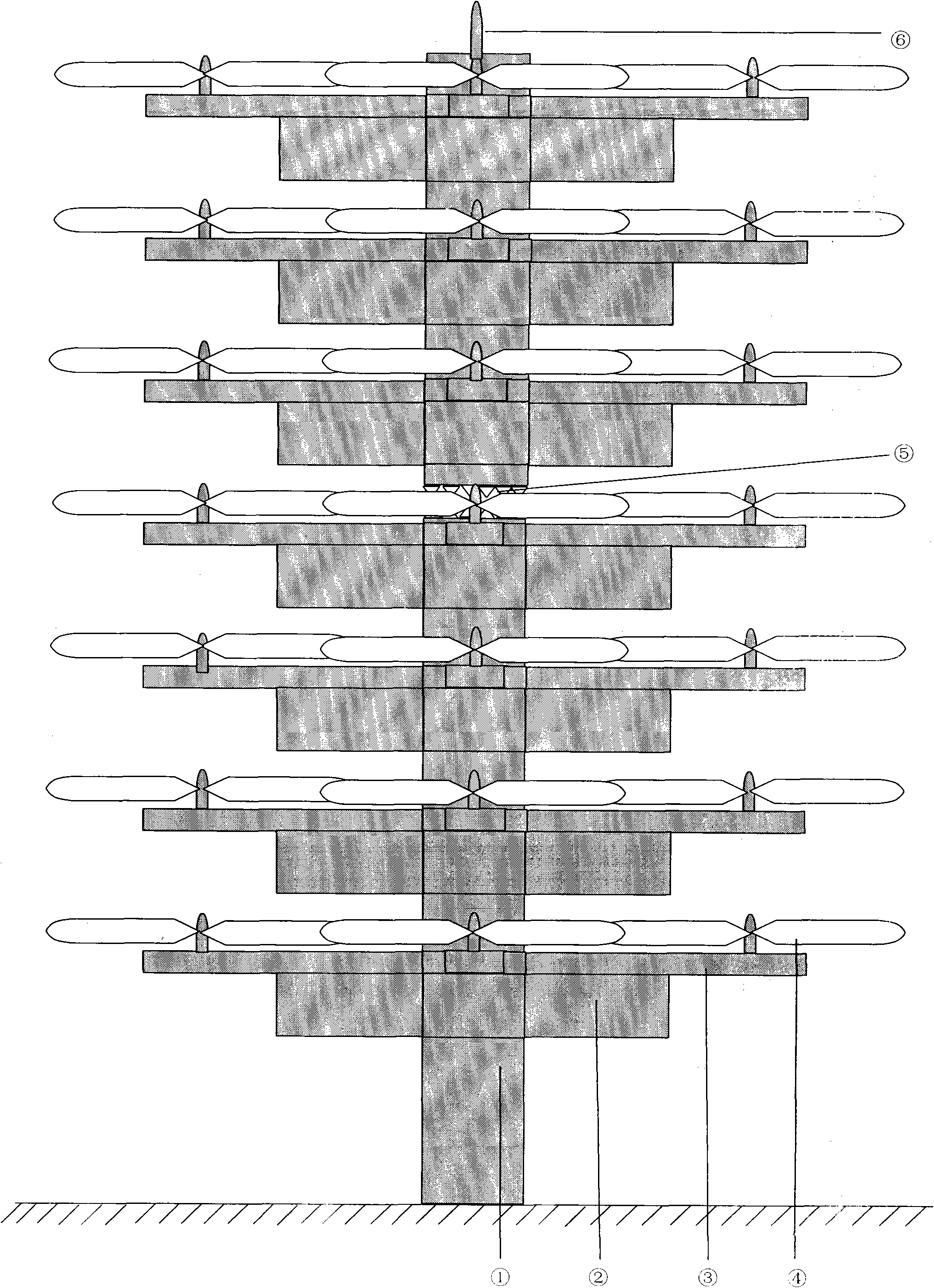

[0064] Embodiment 2 is based on the usual geographical, geological and wind energy conditions

[0065] Selection of wind turbines Choose medium-sized or large-scale products with mature technology.

[0066] The height of the tower is designed according to the height of more than 300 meters.

[0067] The pillar body of the tower is quadrangular: the cross-sectional area is consistent from bottom to top; it is closed from bottom to top, and the joint with the tower hanging building and the tower beam is the passage space, and each floor has a pedestrian door opening, and the top is closed as a platform structure. Install lightning protection devices.

[0068] The load-bearing columns are 4 to the top; cylinders are preferred; the diameter specification is gradually reduced from bottom to top; structural beams and auxiliary beams are constructed between adjacent load-bearing columns. Auxiliary beams and electric energy output wires are arranged on auxiliary beams, and the distr...

Embodiment 3

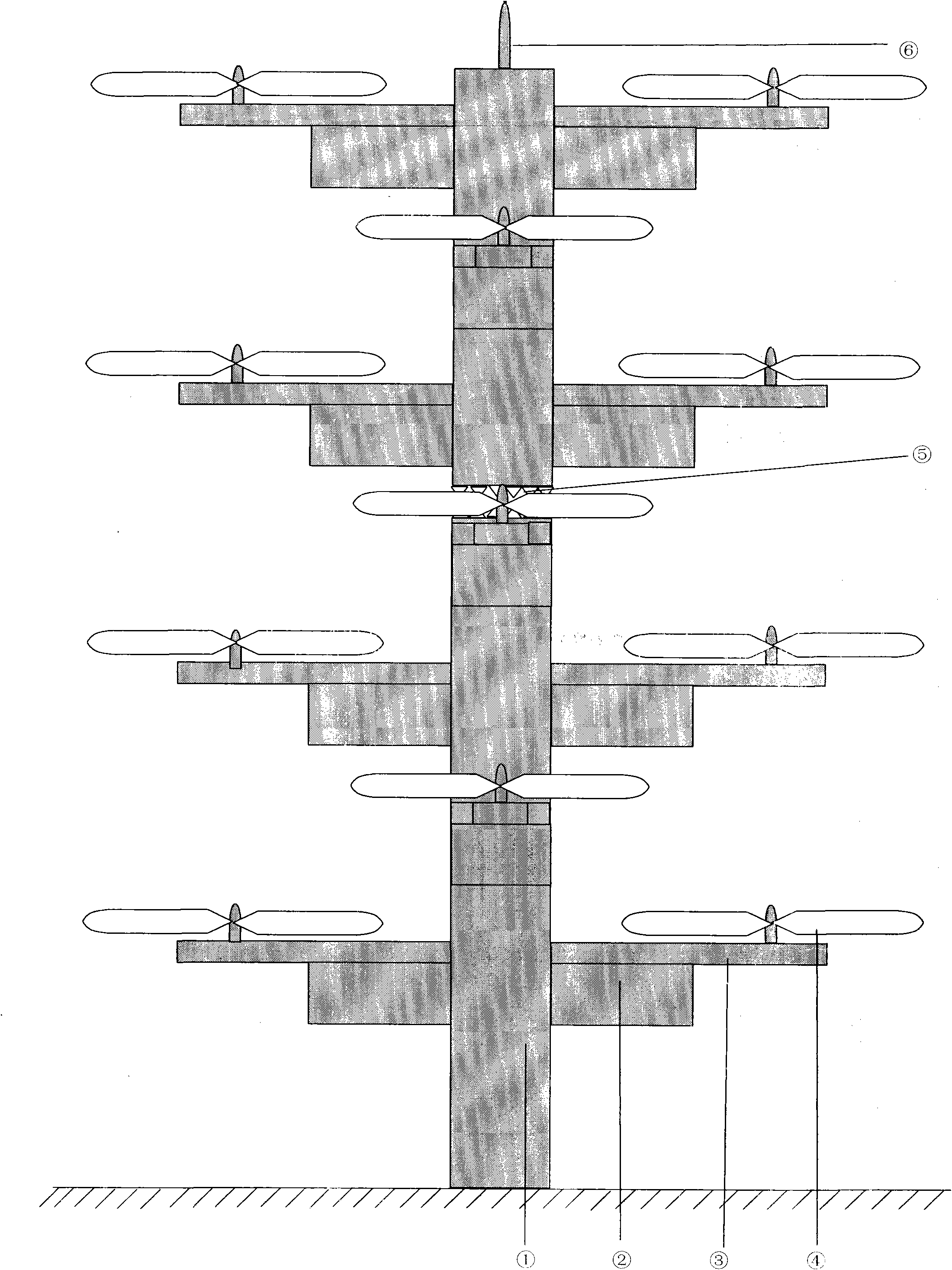

[0074] Take the tower pillar body composed of 3 load-bearing columns as an example

[0075] The main features of the implementation plan are: in order to ensure the stability and safety of the tower structure, when constructing the tower hanging building and the tower beam, first of all, at each corner of the triangle, that is, the point where the three load-bearing columns are located, and this point is the center of the construction. Three beams parallel to the corresponding side, each of which is four times the length of the corresponding side, form a group of scissor-shaped cantilever beams on the outside of each side of the triangle, and then use the scissor-fork cantilever beams as load-bearing cantilever beams And on the basis of it, build a tower hanging building and a tower hanging beam ( Figure 8 ).

[0076] Other embodiments are similar or similar to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com