Manufacturing method of printed circuit conductive circuit

A conductive circuit and printed circuit technology, which is applied in the field of printed circuit board manufacturing, can solve the problems of inability to meet the requirements of high-frequency and high-speed signal transmission, uneven and rough erosion of circuit graphics, and inability to realize mass production, etc., to avoid The production cost is too high, avoid rough and uneven, and avoid the effect of poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

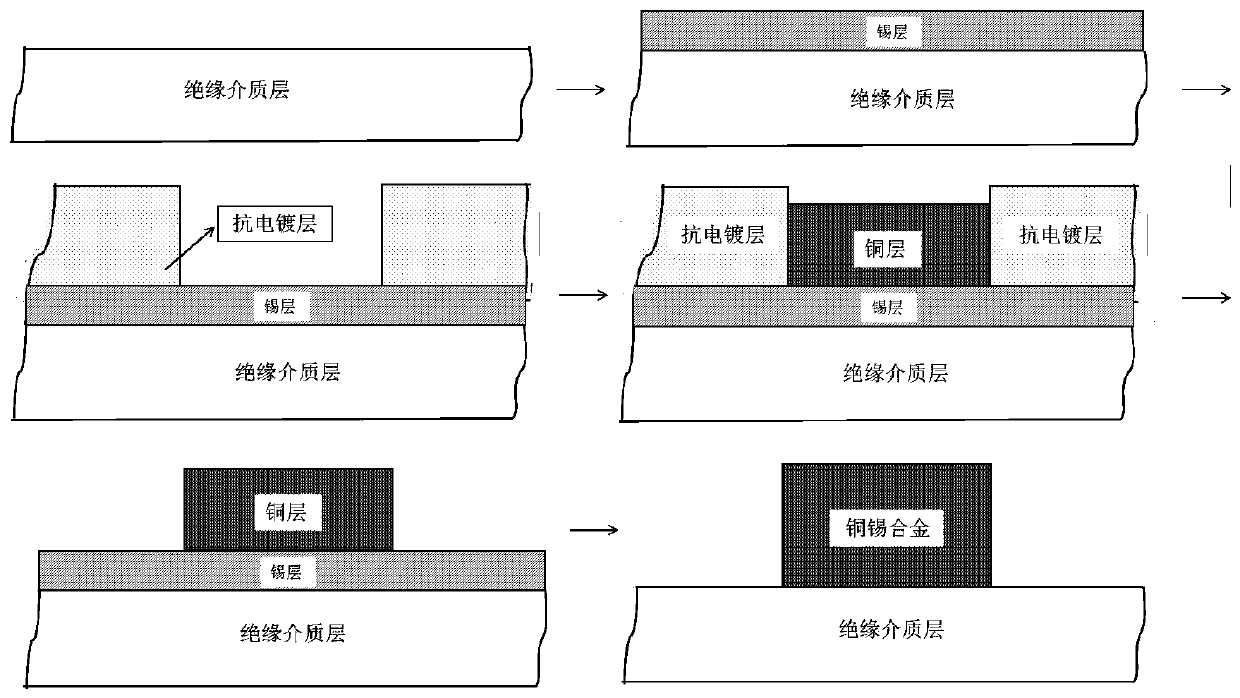

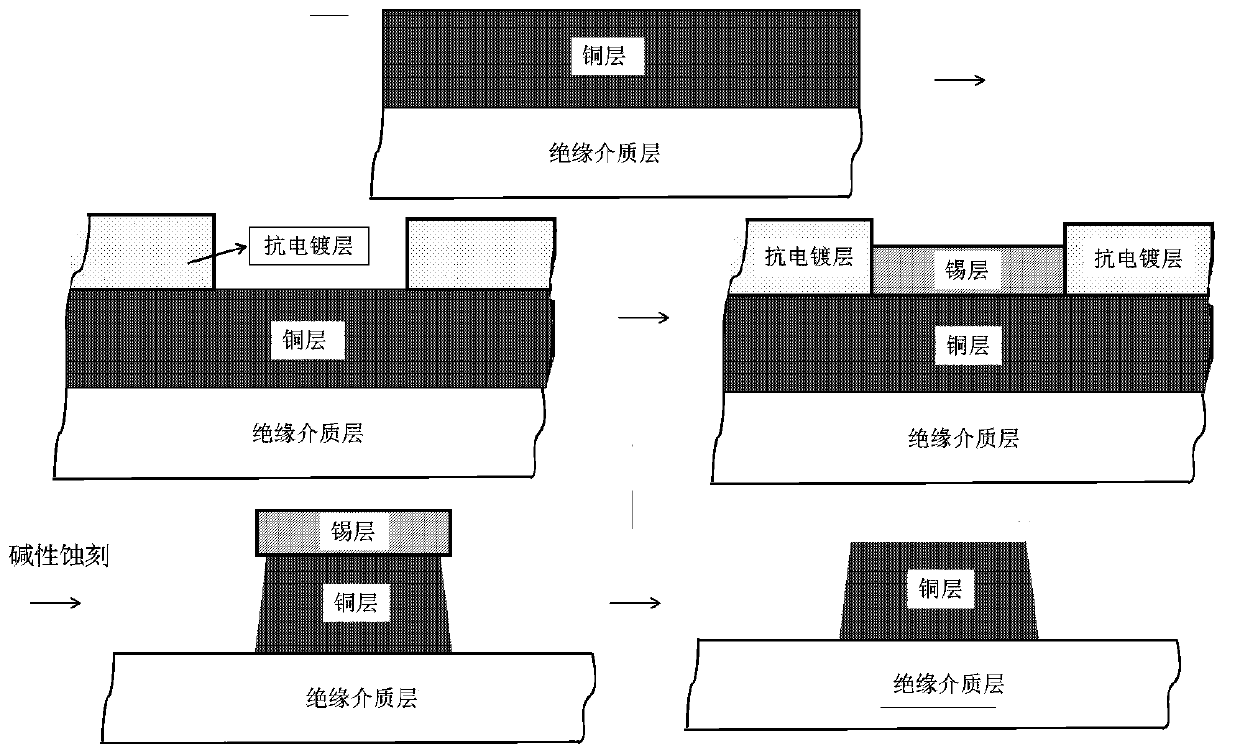

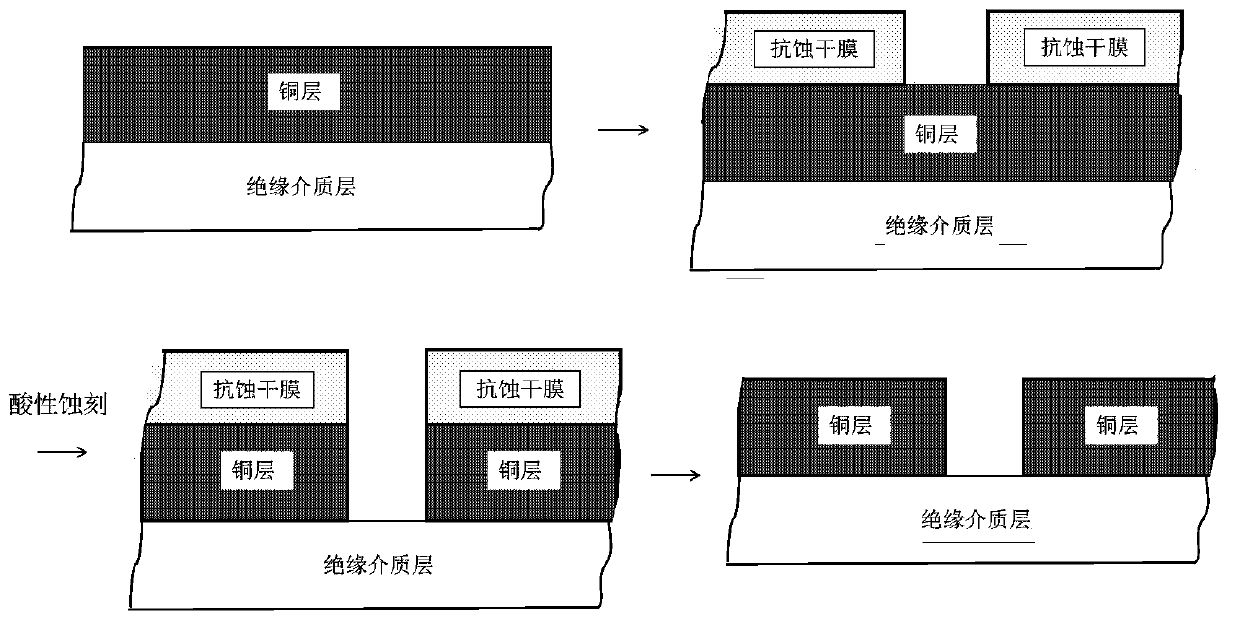

[0039] Cut the epoxy resin substrate of 20mm*100mm, after the plasma surface treatment, according to the plating solution formula shown in Table 1, the tin seed layer with a thickness of 2 μm is grown on the surface of the substrate by electroless tin plating by immersion plating; after the growth is completed, Cover the patterned dry film; then carry out electroplating copper according to the plating solution formula shown in Table 2, form copper conductive lines on the tin seed layer area not covered by the dry film on the substrate surface, and 5wt% hydrogen at 60 ° C Remove the dry film in the sodium oxide solution; then heat-treat at 180°C for 30s, take it out and cool it to room temperature naturally after heat treatment; finally, etch the tin seed layer area not covered by the electroplated copper layer to obtain the printed circuit conductive circuit.

[0040] The plating bath formula of table 1 growth tin seed layer

[0041] Bath composition concentration ...

Embodiment 2

[0047] Compared with Example 1, the present embodiment differs in that: the PI (Polyimide, polyimide) of 15mm*100mm is used as the substrate, and the surface treatment method is soaked in the KOH solution of 1mol / L for 10 minutes, and the remaining steps are the same as Example 1 is the same.

Embodiment 3

[0049] Compared with Example 1, this embodiment differs in that: use 15mm*100mm PET (PolyethyleneTerephthalate, polyethylene terephthalate) as the substrate, and soak in 1mol / L KOH solution for 10 minutes as surface treatment mode, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com