Welding material composition for flux adhesive fiberglass backing (FAB)

A submerged arc automatic welding and welding material technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of untimely after-sales service, low impact toughness, long procurement cycle, etc., and achieve cost reduction, Stable welding arc and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

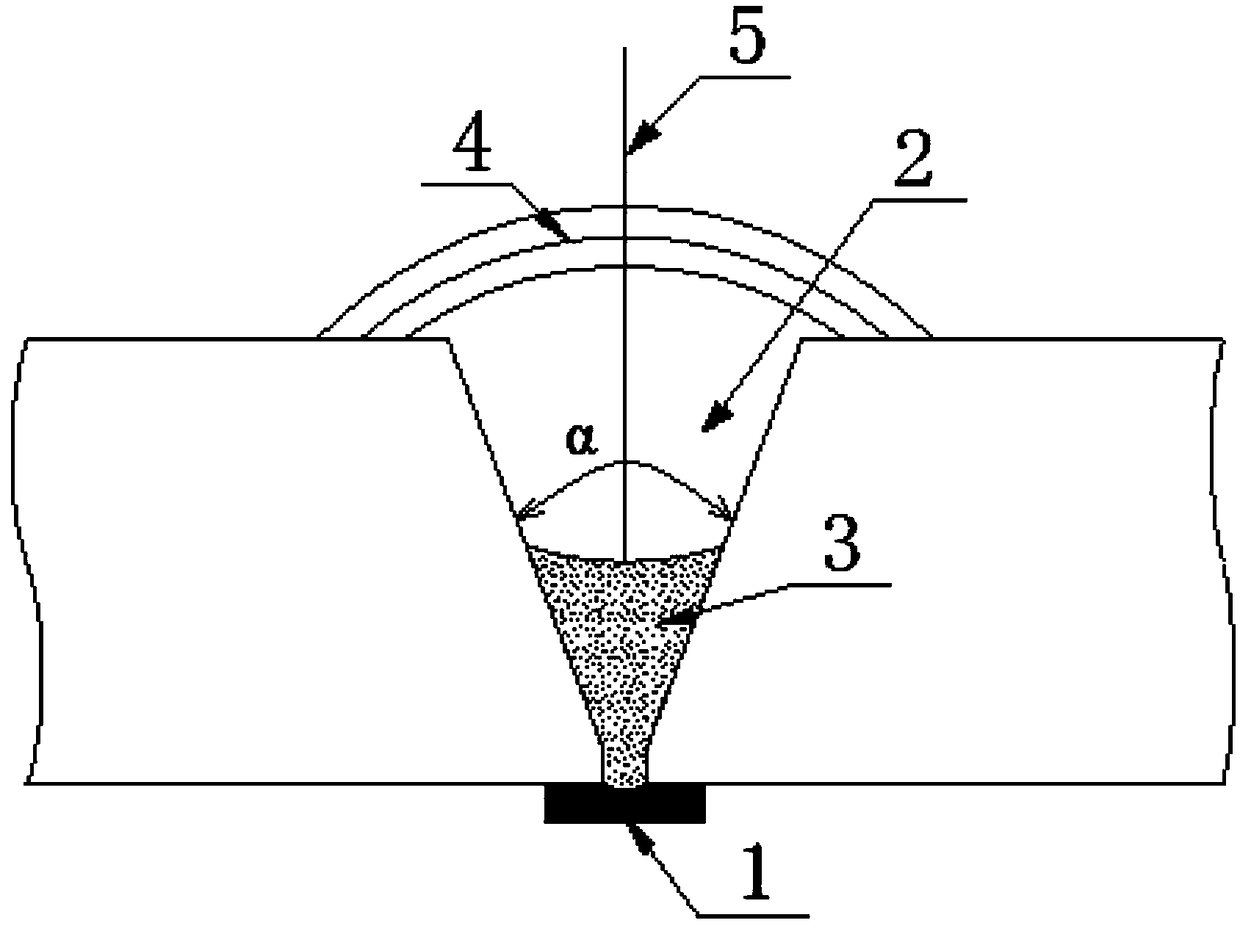

[0034] Such as figure 1 As shown, this embodiment is used for the welding material composition of soft cushion single-sided submerged arc automatic welding, and the composition includes the following components: welding wire, surface flux and filler powder, and the gap between the welding wire, surface flux and filler powder The mass ratio is: 1:1.5:1.5,

[0035] The mass percentages of each component in the welding wire are: C is 0.15%, Si is 0.03%, Mn is 2.2%, Cr+Ni is 0.1%, S is 0.012%, P is 0.012%, and the balance is Fe powder ;

[0036] The mass percentages of each component in the surface flux are: SiO 2 18%, MgO 30%, TiO 2 10%, Al 2 o 3 19%, CaO 18%, S 0.018%, P 0.018%, H 2 O is 0.03%, impurity is 0.15%, and the balance is Fe powder;

[0037] The mass percentages of each component in the filling powder are respectively: 0.008% for C, 0.05% for Si, 1.3% for Mn, 2.6% for Ni, 0.3% for Mo, 0.021% for S, 0.021% for P, and 0.021% for P. The amount is Fe powder.

[0038...

Embodiment 2

[0047] Such as figure 1 As shown, this embodiment is used for the welding material composition of soft cushion single-sided submerged arc automatic welding, and the composition includes the following components: welding wire, surface flux and filler powder, and the gap between the welding wire, surface flux and filler powder The mass ratio is: 1.1:1.5:1.6,

[0048] The mass percentages of the components in the welding wire are: 0.12% for C, 0.01% for Si, 1.98% for Mn, 0.3% for Cr+Ni, 0.018% for S, 0.018% for P, and the balance is Fe powder ;

[0049] The mass percentages of each component in the surface flux are: SiO 2 14%, MgO 22%, TiO 2 12%, Al 2 o 3 16%, CaO 12%, S 0.012%, P 0.012%, H 2 O is 0.02%, impurities are 0.2%, and the balance is Fe powder;

[0050] The mass percentages of each component in the filling powder are respectively: C is 0.004%, Si is 0.05%, Mn is 1.5%, Ni is 2.5%, Mo is 0.9%, S is 0.023%, P is 0.023%, and the remaining The amount is Fe powder.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com