A double tungsten electrode tig narrow gap welding method with high deposition efficiency and high welding speed

A technology of welding speed and deposition efficiency, which is applied in the field of TIG welding, can solve the problems of low deposition efficiency and slow welding speed, and achieve the effects of good forming, increased welding speed and reduced number of welding passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

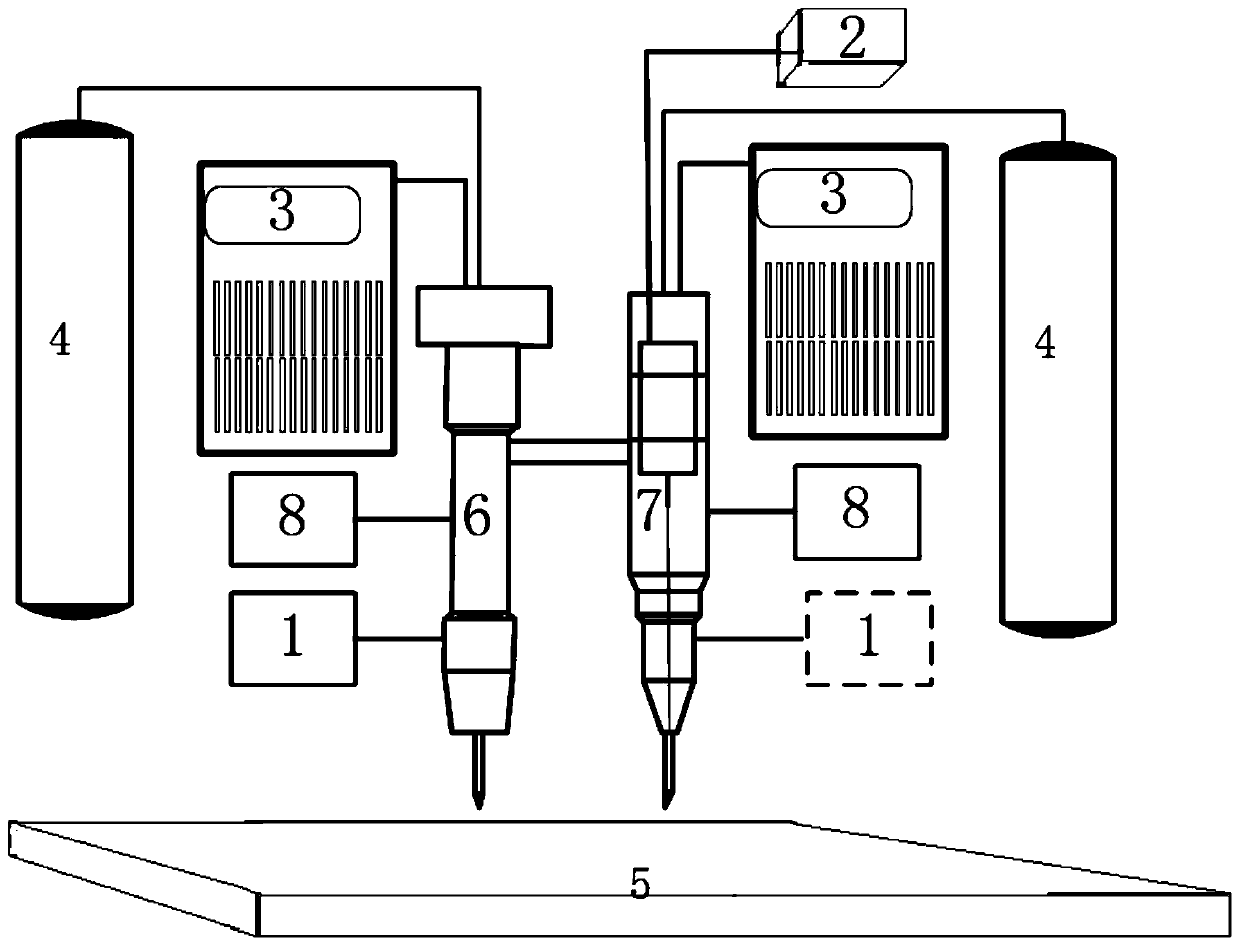

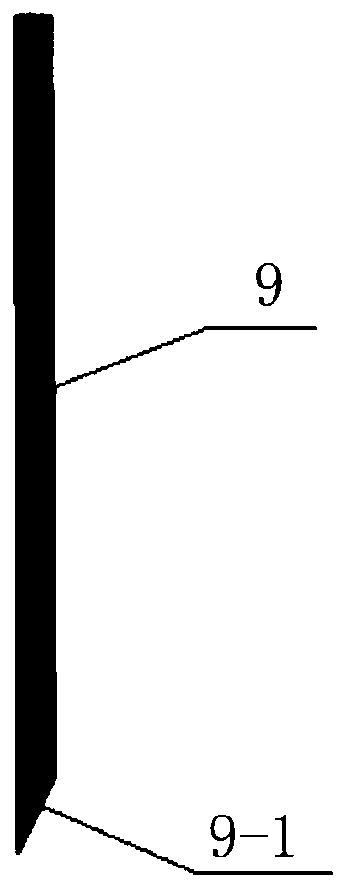

[0035]A double tungsten electrode TIG narrow gap welding method with high deposition efficiency and high welding speed. The narrow gap welding of 9% Ni steel with a thickness of 26 mm and U-shaped groove in this embodiment is welded. The distance between the two tungsten electrodes and the workpiece is the same. The welding system includes two welding machines, two welding torches, welding power supply, and wire feeding device. The two welding machines are respectively connected with a rotating tungsten electrode welding torch and a stationary tungsten electrode welding torch. The two welding machines independently control welding parameters, and the two welding torches are respectively Both are connected with an attitude adjustment device, which is used to adjust the distance between the welding torches in the horizontal direction, the distance between the welding torch and the workpiece in the vertical direction, and the angle between the welding torch and the vertical directi...

Embodiment 2

[0043] A double tungsten electrode TIG narrow gap welding method with high deposition efficiency and high welding speed, its equipment and steps are as described in Embodiment 1, the difference is that in step (4), two welding torches are connected with two wire feeding devices, Implement double welding torches and double wire feeding; DC welding is adopted, and the tungsten pole of the second welding torch is rotated through the switch of the motor control box of the second welding torch before the arc is struck; when welding, the two welding torches strike the arc at the same time, and the welding current of the first welding torch is 320A, the flow rate of the shielding gas is 30L / min, the current of the second welding torch is 250A, the flow rate of the shielding gas is 30L / min, the welding speed is 400mm / min, the wire feeding speed of the first wire feeding device is 800mm / min, the second The wire feeding speed of the wire feeding device is 600mm / min.

[0044] In this emb...

Embodiment 3

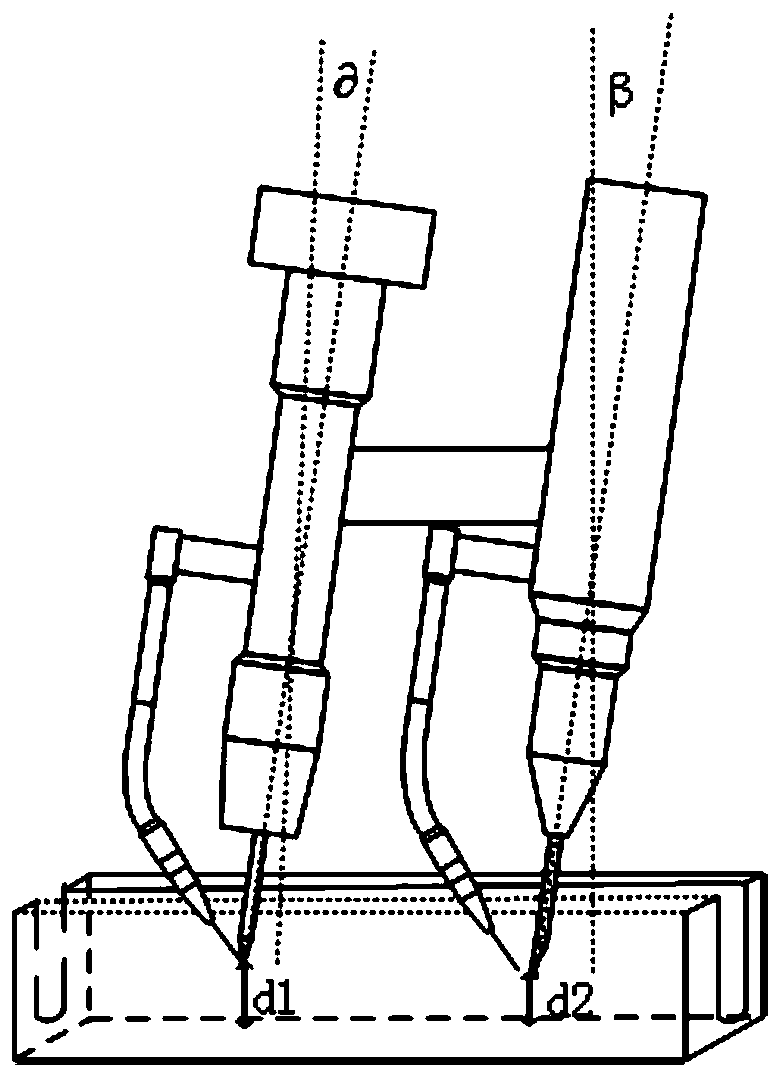

[0046] A double tungsten electrode TIG narrow gap welding method with high deposition efficiency and high welding speed, the equipment and steps are as described in Embodiment 2, the difference is that in step (2), the attitude of the two welding torches is adjusted by the attitude adjustment equipment, The distance between the first welding torch and the bottom edge of the workpiece is d1, and d1 is 5mm; the distance between the second welding torch and the bottom edge of the workpiece is d2, and d2 is 5mm; the horizontal distance between the tungsten electrodes of the two welding torches is 50mm; angle is is 0°, the angle between the second welding torch and the vertical direction is β, and β is 15°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com